Mason Jar Mug Mod v2 3D print model

Reach out anytime for CAD services.

unreal3ddesign.com

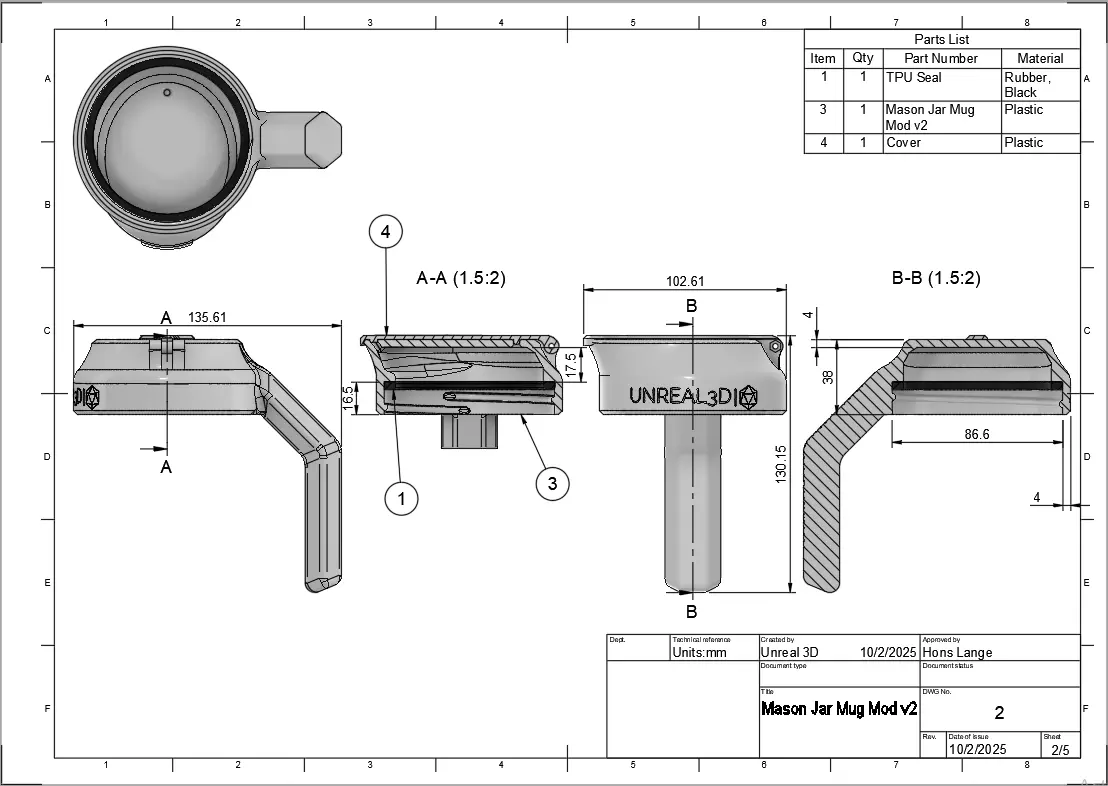

This is version 2 of my Mug Mod design. I still like the first one so I am keeping it up for download, but this one has some really nice improvements.Left and Right handed models included.

Click the link below if you want to check out version 1.https://www.cgtrader.com/3d-print-models/house/kitchen-dining/wide-mouth-jar-coffee-mug-adapter

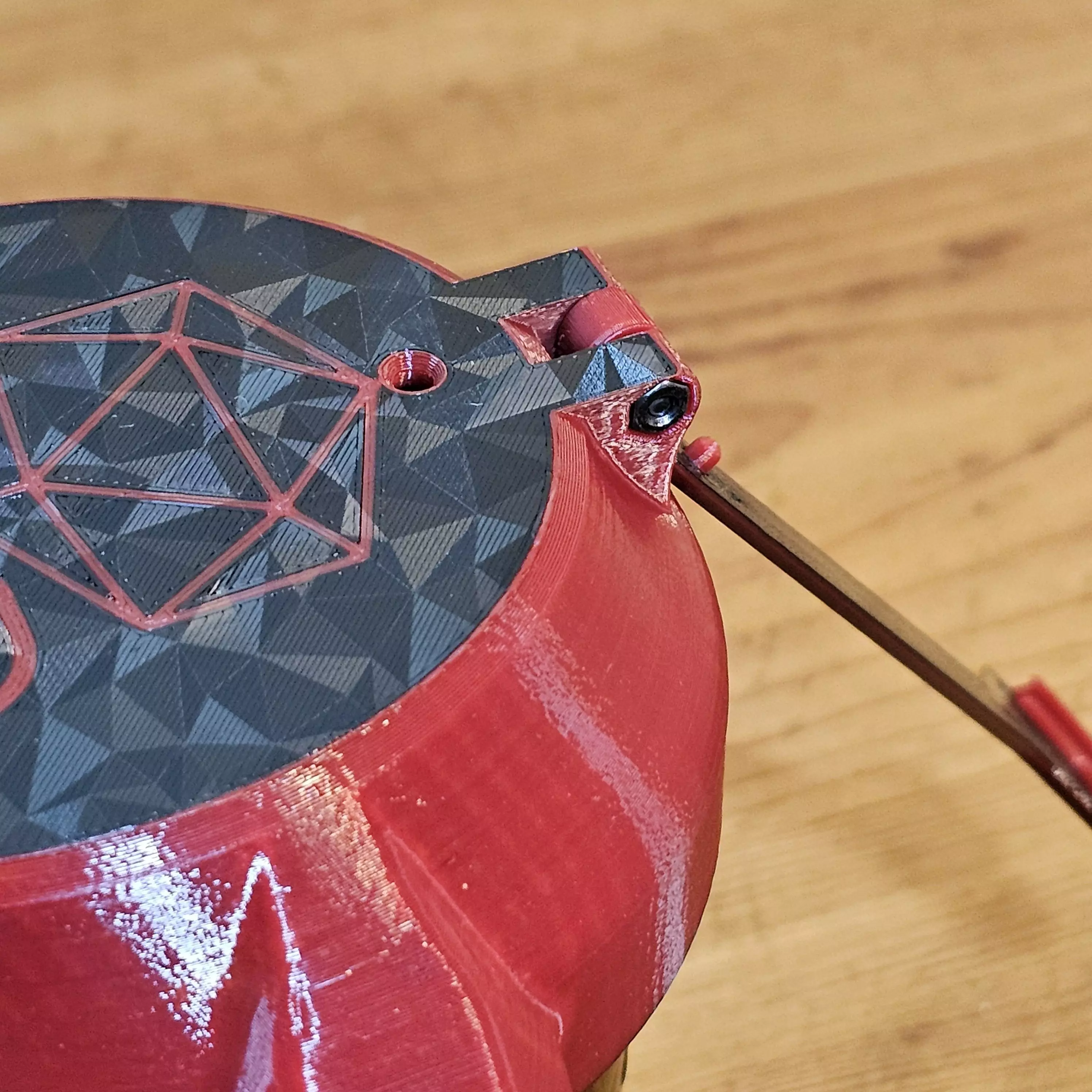

Includes a hinged cover that snaps open and closed in a very satisfying way. Helps to trap more of the heat and keeps dust out of your coffee when you are on the run.

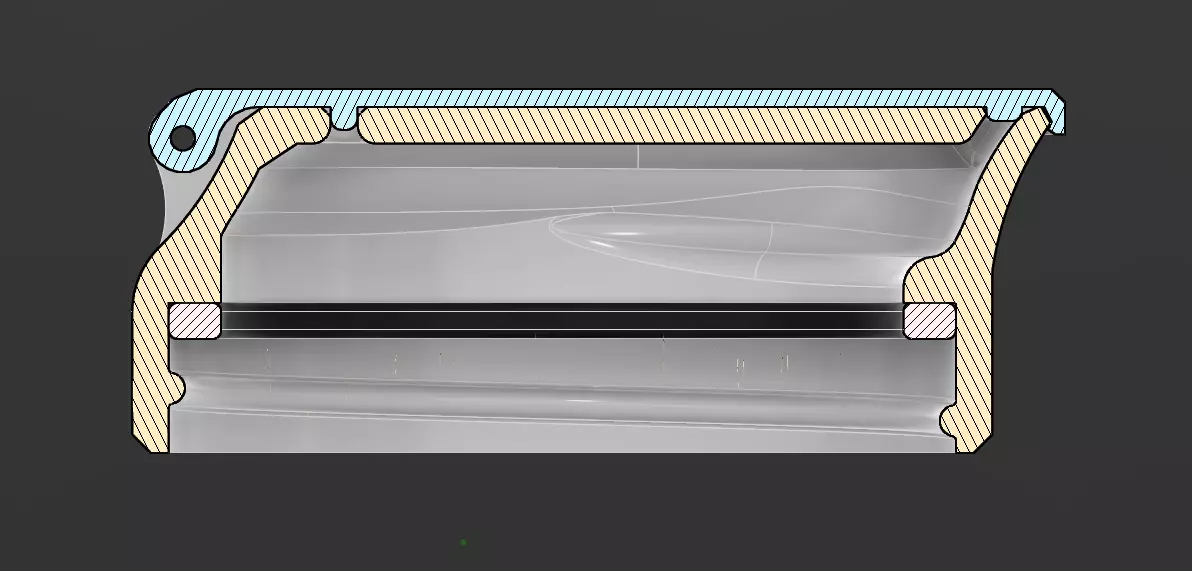

This model also has much more body around the rim where it seals against the glass, and the top is elevated another 17.5mm above the rim. This should completely eliminate any possibility of the creep issue I had dealt with on early prototypes of version 1.

Also the mouthpiece where you actually sip from is much more ergonomic. Less drip, way more comfortable, and the cover that snaps over it is a major improvement.

The handle could be slightly longer in my opinion, but I did not change it because, I just have really big hands, it should be fine for most people.

3D printing settingsThe logo on the top, as with version 1, is totally optional. If you simply make the whole top surface one color, no logo will show, it will just print a normal first layer. The logo is only embossed -0.01mm depth, the printer will not even recognize the logo unless you paint it to make it stand out.

This design also requires x1 M2.5x18mm hex head bolt, and x1 M2.5 nut, for the cover hinge. Very easy to install, the nut is inset to make it very easy and make sure it does not come loose on it's own.

Print upside down with the top flat on the build plate. Same with the cover. No supports necessary anywhere. Very clean print.I just recommend fine tuning your filament calibrations and keep your flow rate slightly on the higher side, to make sure all the walls are sealed water tight. If you don't, liquid will get through the walls and into the infill and leak out the bottom of the handle and it is basically useless. So do make sure you are fine tuned for this print. Do lots of tests printing small cups or something and fill them with water, set them on a paper towel overnight and see if they leak, labeling each one with the flow rate it was printed with. Slowing down on the outer walls helps too.Also, it is important that the main body is printed with concentric fill pattern on the top surfaces(the model is printed upside down remember, to this makes all the bottom surfaces of the model concentric fill pattern, including the rim where it must seal against the TPU, which is where it is important to have concentric top surfaces for a proper seal.)

Print in a material of your choice that is both heat tolerant enough for hot coffee, and is safe for food contact. I use PETG and it works just fine.

The TPU seal obviously must be printed in TPU, I recommend 95a, but also make sure to use concentric fill pattern on the top and bottom for a proper seal. 2 wall lines and 20% gyroid infill should do just fine.