1/10

If you are in need of product design services for your business, or just need a custom personal model created, feel free to reach out. I offer CAD services for 3D printing product design.

unreal3ddesign.com

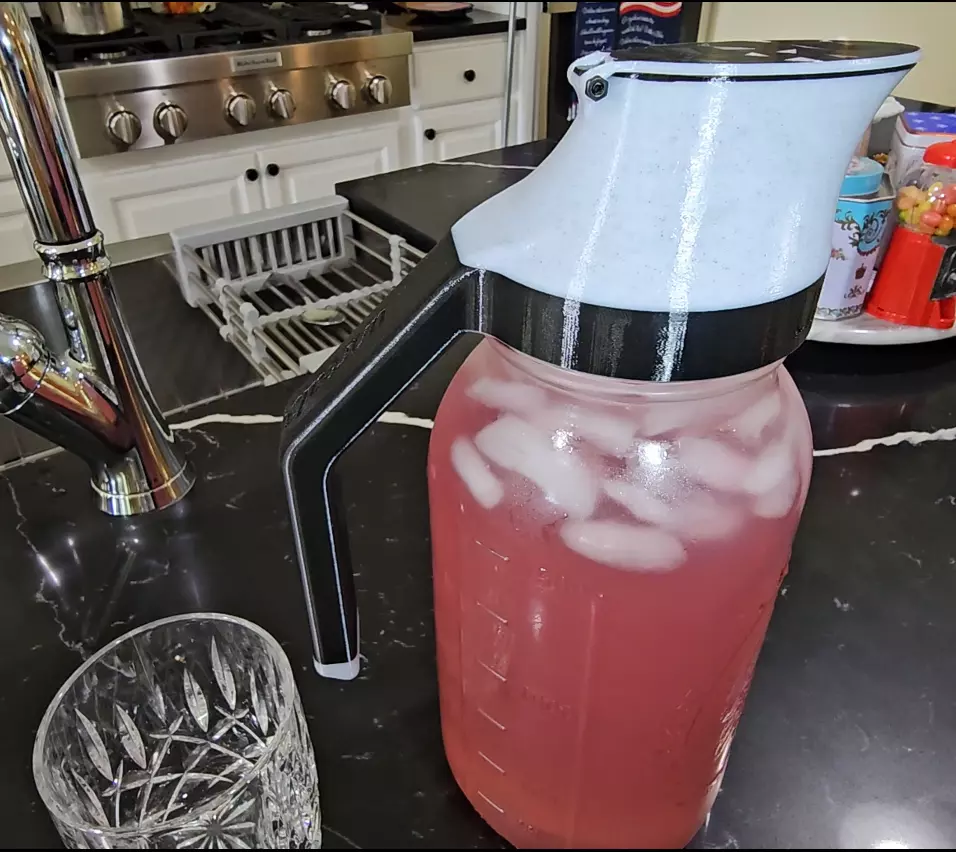

This model fits a half gallon size mason or ball jar, and turns it into a convenient and stylish beverage pitcher. It also can expand the capacity of the jar by a little bit since it can be filled up past the TPU seal, as long as it is printed correctly and creates a good seal.

Available in 2 versions, one for a bolt hinge, and one for a filament hinge.

If using the bolt hinge model, you will need a single m2.5x20mm hex head bolt, and a M2.5 nut. You may also want to add a small dab of super glue on the end of the bolt once the nut is in place, to keep it from coming loose.

If using the filament hinge model, just connect the lid to the main body using a short piece of 1.75mm diameter 3D printing filament, keep about 1mm or so sticking out both sides of the hinge, and melt the ends flat with a lighter to keep it in place.

See included technical drawings for references.

https://youtu.be/ApPpKIrfWfw

3D printing settings:

The seal must be printed in TPU. I used Overture 95A TPU and it works great as long as it is dry and calibrated. The main body and lid, could be done in PLA or PETG. Personally I don't like PLA for, reasons, so I used PETG. Whatever material you use, make sure it is safe for food contact.

The main body prints upside down, no supports, but you will want inner & outer brims because you won't have much touching the plate and you want to make sure it sticks. As long as it sticks to the plate, the main body is very easy to print and requires no supports at all. For the main body I used a 0.16mm layer hight, 4 wall lines, and 15% cubic infill and it was more than strong enough for what it needs to do.

The lid, only needs supports under the hinge part, and they are easy to remove.

For the TPU seal, I recommend 2 wall lines, 4 top and bottom layers, and 20% gyroid infill. And make sure to use concentric pattern on the top and bottom surfaces; This makes sure the extrusion lines of the top and bottom surfaces are working with the seal and not against it.

REVIEWS & COMMENTS

accuracy, and usability.