1/11

If you are in need of product design services for your business, or just need a custom personal model created, feel free to reach out. I offer CAD services for 3D printing product design.

unreal3ddesign.com

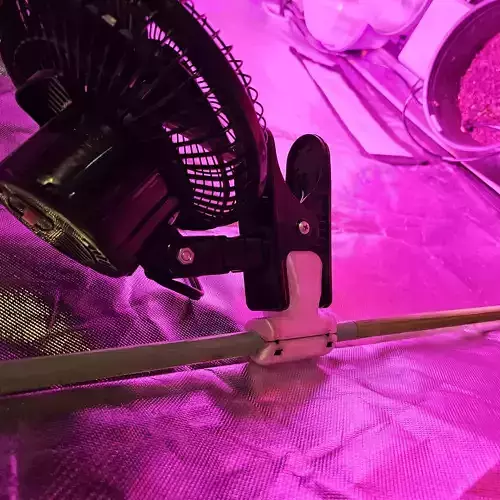

Needed a way to mount my clip-on fan inside my 2x4x5 grow tent.

This mount uses 4 M3x12mm hex screws, 4 washers, and 4 M3 brass thread inserts.

Mounts onto the tent poles which are 16mm diameter on my tent.

Some of the pictures are difficult to see because of my grow light and because the part is printed in clear PETG. My apologies. Will update them later if I get time.

3D printing settingsBoth models should import with the optimal print orientation, and should include support painting for all the necessary supports, if you use the .3mf files.

Use manual supports if you want to use the support painting I applied, of course. Normal or Tree supports, should work fine either way. Personally I used tree supports and they were easy to remove. Leaves a bit of support scaring but, meh, it's a functional part. You could probably do it with possibly no supports with a different print orientation if you like but I saved them with what I felt was the optimal orientation for strength.Using brims could be useful as well, if you think you need it, but I was able to print it fine without them with a textured build plate.

I printed this in PETG. First test, I did get breakage around one of the screws due to overtightening, but I am sure if this was printed in something like nylon it would be far stronger and that would not be an issue. But it works fine with PETG so long as you do not overtighten the screws. Plus it broke around the screw head first, not the brass threads. So at least the bulk of it was not wasted, I only had to reprint the smaller part, and didn't have to reset all new threads. Still plenty strong, I was just kind of stress testing it on the first go.

4 wall lines recommended for strength.

REVIEWS & COMMENTS

accuracy, and usability.