1/3

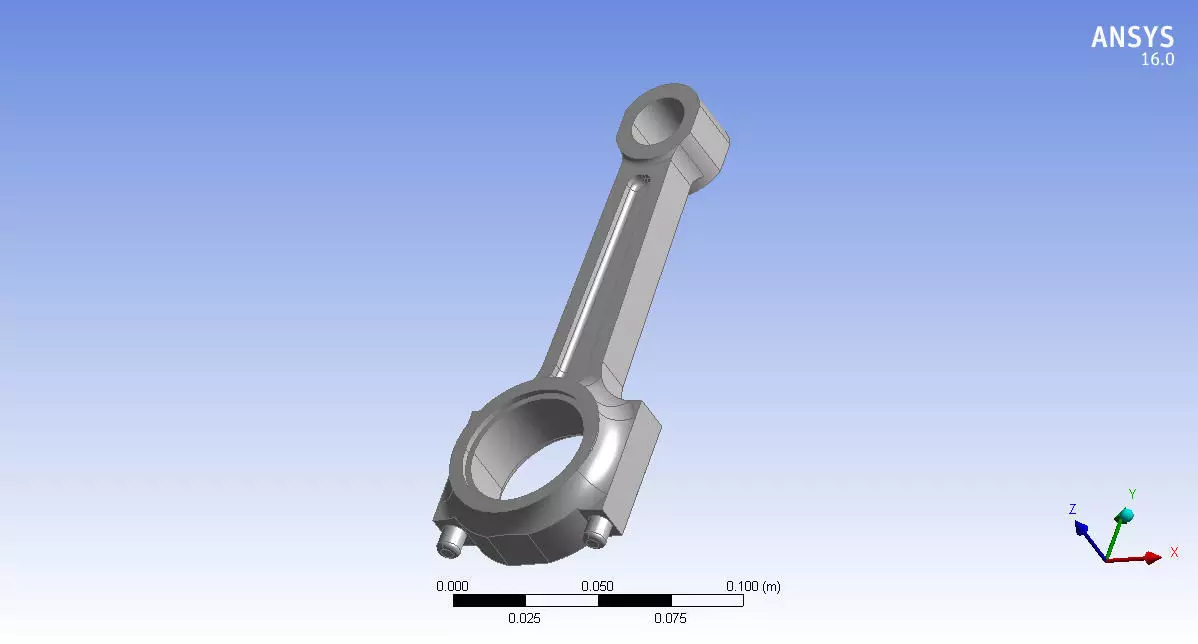

The connecting rod is a crucial component in an internal combustion engine (IC engine) that plays a vital role in converting the reciprocating motion of the piston into rotational motion of the crankshaft. Here are some key design details and considerations for connecting rods in IC engines:

Materials:Connecting rods are typically made from strong and lightweight materials such as:

Steel: Most common due to its strength and durability.Aluminum: Used in some high-performance engines for its lighter weight.Titanium: Used in racing engines for its high strength-to-weight ratio.Design Features:Shape and Dimensions:

Connecting rods are typically I-shaped or H-shaped, depending on the engine design.Length and thickness are critical to ensure strength and rigidity while keeping weight minimal.Big End and Small End:

The big end connects to the crankshaft journal and usually has a bearing for smooth rotation.The small end connects to the piston pin (wrist pin) and also has a bearing for reduced friction.Bearings:

Bearings at both ends of the connecting rod reduce friction and wear.Material and design of bearings are critical for durability and efficient operation.Manufacturing Techniques:

Connecting rods are often forged for strength or machined from billets for precision.High-performance engines may use advanced techniques like titanium forging for weight savings.Heat Treatment:

Heat treatment processes like quenching and tempering are used to strengthen the connecting rod material.Performance Considerations:Strength and Durability:

Must withstand high forces and stresses generated by combustion and engine RPM.Fatigue resistance is crucial due to cyclic loading.Weight Optimization:

Lighter connecting rods reduce inertia and allow higher engine RPM and efficiency.However, strength must not be compromised.Balancing:

Connecting rods must be balanced to minimize vibrations and ensure smooth engine operation.Assembly and Lubrication:

Proper assembly torque and lubrication are crucial for longevity and performance.Lubrication ensures minimal wear between bearings and journals.Special Applications:High-Performance Engines:

Racing engines often use exotic materials like titanium for connecting rods to reduce weight without sacrificing strength.Longevity and Maintenance:

Some engines may require connecting rods with special coatings or treatments for longevity in harsh operating conditions.Design Innovations:

Advancements in materials science and manufacturing techniques continue to drive improvements in connecting rod design for efficiency and performance.In summary, the connecting rod is a meticulously engineered component in IC engines, balancing strength, weight, and durability to ensure smooth and efficient engine operation across various applications.

REVIEWS & COMMENTS

accuracy, and usability.