1/2

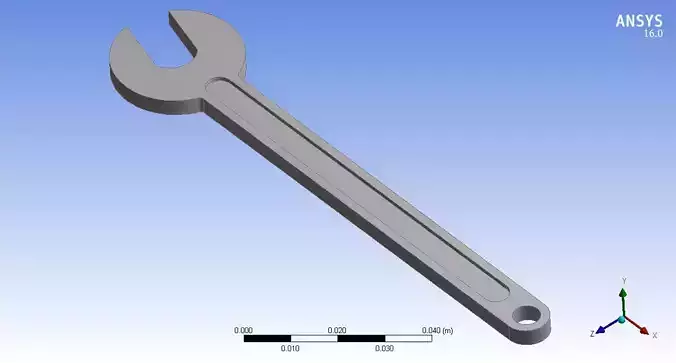

Designing a steel spanner involves considering various factors to ensure it meets functional requirements and ergonomic considerations. Here are key aspects to keep in mind:

Material Selection:

Steel Type: Choose a steel alloy suitable for the spanner's intended use. Common choices include carbon steel (such as SAE 1045), alloy steels (e.g., chromium-vanadium), or tool steels for higher strength and durability.Surface Treatment: Consider options like heat treatment (hardening and tempering) to enhance hardness and toughness, and coatings (e.g., chrome plating) for corrosion resistance.Design Specifications:

Size and Dimensions: Determine the spanner's size based on the intended application (e.g., small wrench for precision work or large wrench for heavy-duty tasks).Head and Handle Design: Design the head to fit various types of fasteners (e.g., hexagonal, square, or specialized shapes). The handle should be ergonomic for comfortable grip and leverage.Mechanical Properties: Ensure the spanner can withstand the required torque without deformation or failure. This involves calculating stress and strain under typical operating conditions.Manufacturing Considerations:

Forging or Machining: Decide whether to forge the spanner from a steel blank (for greater strength) or machine it from a solid bar (for precision).Tolerances: Specify machining tolerances to ensure parts fit together correctly and function smoothly.Assembly: Consider how components (head, handle) will be assembled (e.g., welding, riveting) to ensure durability and reliability.Ergonomics and User Experience:

Handle Shape and Grip: Design the handle for comfort and anti-slip properties, considering factors like grip texture and shape.Weight Distribution: Distribute weight evenly to reduce user fatigue during prolonged use.Accessibility: Ensure the spanner design allows for easy access to fasteners in various positions and orientations.Safety and Durability:

Rounded Edges: Avoid sharp edges that could cause injury or damage to surrounding materials.Durability Testing: Conduct tests (e.g., torque testing, fatigue testing) to validate the spanner's durability and ensure it meets safety standards.Cost and Manufacturing Feasibility:

Material Cost: Balance performance requirements with material costs to achieve a cost-effective design.Manufacturability: Design for ease of manufacturing, considering processes like forging, machining, and assembly.Quality Control and Testing:

Inspection: Implement quality control measures to ensure each spanner meets design specifications and performance requirements.Testing: Perform functional testing to validate torque capacity, durability, and ergonomics under realistic conditions.By carefully considering these factors during the design process, you can create a steel spanner that is not only functional and durable but also ergonomic and safe for users. Iterative improvements and feedback from testing will help refine the design to optimize performance and usability.

REVIEWS & COMMENTS

accuracy, and usability.