1/3

Designing pistons and connecting rods involves several considerations to ensure optimal performance and reliability in an internal combustion engine. Here are some key aspects to consider:

Piston Design:Material Selection: Pistons are commonly made from aluminum alloys due to their lightweight and thermal conductivity properties. The material must withstand high temperatures and pressures without deforming.

Shape and Dimensions: The piston's shape and dimensions are critical for maintaining efficient combustion, minimizing friction, and ensuring proper clearance within the cylinder bore.

Skirt Design: The skirt provides stability and guides the piston within the cylinder. It needs to be designed to minimize friction and wear while ensuring adequate strength.

Crown and Combustion Chamber: The crown shape and design affect compression ratio, turbulence in the combustion chamber, and heat dissipation. Design considerations include valve reliefs, piston rings, and cooling galleries.

Piston Rings: Piston rings seal the combustion chamber and regulate oil consumption. The number, type (compression rings, oil control rings), and placement are crucial for efficiency and emissions.

Cooling Features: Some pistons include cooling galleries or oil squirters to manage temperature and improve durability under high thermal loads.

Connecting Rod Design:Material and Construction: Connecting rods are commonly made from steel or aluminum alloy, balancing strength, weight, and durability. High-performance engines may use titanium or other exotic materials.

Length and Shape: Connecting rod length affects engine geometry and piston dwell time at top dead center. The rod's profile (I-beam, H-beam) balances weight and strength.

Big End and Small End Design: The big end connects to the crankshaft journal and must withstand high forces. The small end connects to the piston pin and influences piston motion and stability.

Balance and Weight: Balancing the connecting rods ensures smooth engine operation at high RPMs. Weight distribution and precise machining are crucial for performance and longevity.

Bearings and Lubrication: Bearings at both ends of the connecting rod reduce friction and wear. Proper lubrication through oil passages or pressure-fed systems is essential for longevity.

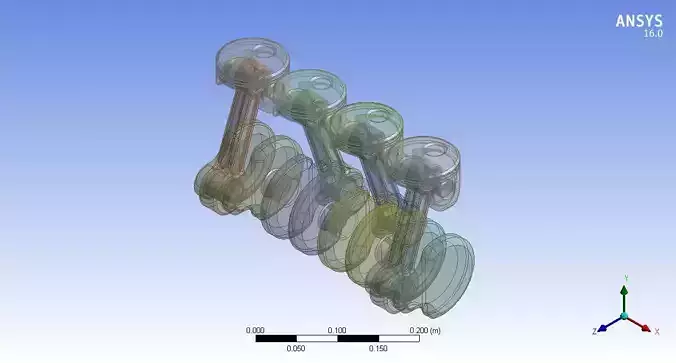

Finite Element Analysis (FEA): Advanced design tools like FEA simulate stress, strain, and fatigue to optimize rod design for strength and weight.

Integration with Engine Design:Clearance and Tolerance: Ensure proper clearances between the piston and cylinder walls, as well as between the connecting rod and crankshaft journal.

Dynamic Balancing: Engine balance is crucial for smooth operation and longevity. Balancing involves matching piston and connecting rod weights and ensuring even distribution of forces.

Performance Optimization: Designs should consider power output, efficiency, emissions, and reliability under varying conditions.

Manufacturability: Designs must be manufacturable within cost constraints while meeting performance targets.

In summary, piston and connecting rod design is a complex interplay of material science, mechanical engineering principles, and performance optimization to achieve a balance between strength, weight, durability, and efficiency in internal combustion engines.

REVIEWS & COMMENTS

accuracy, and usability.