1/4

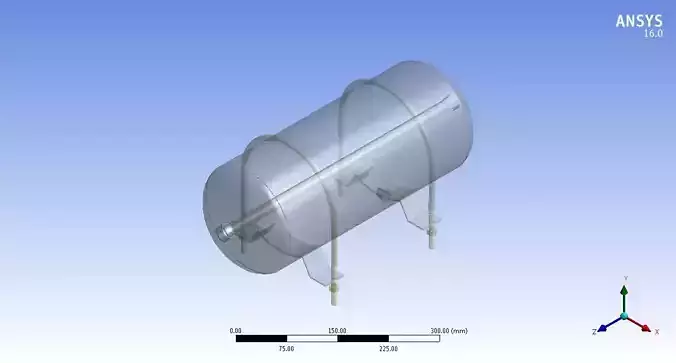

Model Overview: The air brake tank CAD model in SolidWorks is meticulously designed to adhere to industry standards, ensuring optimal functionality and integration within pneumatic brake systems.

Design Features: It incorporates a cylindrical tank body with precision-engineered end caps, designed for efficient air compression and storage. The inlet and outlet ports are strategically positioned to facilitate seamless air flow regulation.

Material Specifications: Crafted from high-grade stainless steel/aluminum alloy to withstand high-pressure environments, ensuring durability and safety in operational conditions.

Internal Structure: The interior includes baffles and partitions to prevent sloshing and ensure uniform air pressure distribution, enhancing stability and performance during braking maneuvers.

Mounting and Integration: The model features mounting brackets with standardized hole patterns, facilitating straightforward installation and compatibility with various vehicle chassis configurations.

CAD Detailing: Each component, from weld seams to bolt connections, is meticulously detailed in the CAD model, ensuring precise manufacturing guidelines and assembly procedures.

Simulation and Testing: Prior to production, the CAD model undergoes rigorous simulation tests within SolidWorks to validate structural integrity, pressure tolerance, and performance under varying operational conditions.

Compliance and Standards: Designed in accordance with DOT (Department of Transportation) regulations or equivalent standards, ensuring regulatory compliance and reliability in commercial vehicle applications.

Assembly Documentation: Detailed assembly drawings and exploded views accompany the CAD model, providing comprehensive guidance for assembly line technicians and maintenance personnel.

Future Development: Continuous improvement and feedback integration ensure that the CAD model evolves to meet emerging industry requirements and technological advancements in pneumatic braking systems.

REVIEWS & COMMENTS

accuracy, and usability.