1/34

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

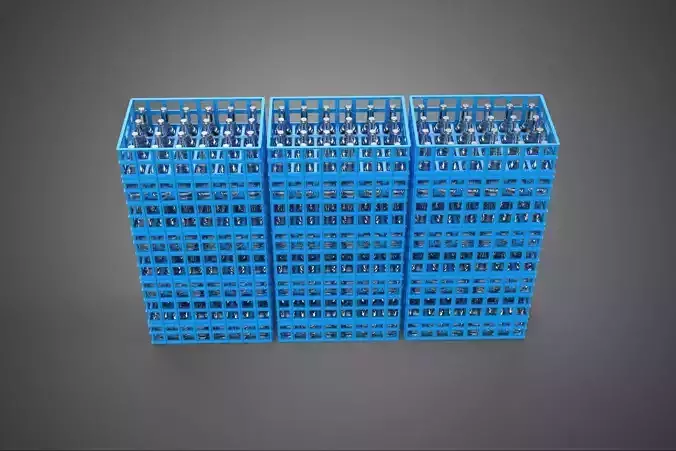

The described configuration, commonly employed within beverage logistics and industrial warehousing, represents a highly formalized system for high-density vertical storage and management of liquid consumables. The arrangement integrates standardized modular plastic containers, contents, and specialized structural support mechanisms to maximize volumetric efficiency and ensure product integrity during static storage or staged distribution.

The Crate: The primary container unit is a blue plastic crate, typically manufactured from High-Density Polyethylene (HDPE) or Polypropylene (PP). This material choice provides necessary durability, impact resistance, and hygienic properties essential for food-grade packaging, while the color (blue) often serves as a visual identifier for the owning corporation or specific content classification within the supply chain. These crates are designed as Returnable Transit Packaging (RTP), featuring a reinforced structural perimeter, ergonomic handling apertures, and standardized stacking lugs or interlocking geometry to maintain lateral stability when subjected to vertical compression. Each crate is packed, indicating that the container is fully loaded with uniform plastic or glass bottles of a specified volume (e.g., 24 units per crate).

The Contents: The packed contents are liquid-filled bottles, usually relating to non-alcoholic beverages such as water, soft drinks, or dairy products. The stability of the overall stack relies on the consistency of the bottle size and their secure placement within the compartmentalized sections often featured inside the crate structure.

The Racking System (Vertical Rack/Tray Box): The support infrastructure is a specialized storage framework referred to variously as a vertical rack, modular stacking frame, or, less formally, a tray box. This structure is generally constructed from coated steel (e.g., powder-coated or galvanized) to ensure high load-bearing capacity and resistance to corrosion and environmental factors within the warehouse environment. The rack’s fundamental function is to define and maintain the precise vertical column, transferring the cumulative weight of the stacked crates directly to the floor. This mitigates the risk of crush failure associated with relying solely on the structural integrity of the lowest plastic crate. The racking system dictates the maximum allowable height of the stack, optimizing overhead warehouse space utilization (cubing).

The methodology employed is one of vertical stacking, where multiple identical, loaded crates are sequentially placed one above the other within the defined bays of the vertical rack. This system allows for exceptionally dense storage—often exceeding four meters in height—while simultaneously facilitating controlled inventory management.

In logistical applications, this stacked configuration is often designed to fit the standardized footprint of logistics pallets (ee.g., EUR-pallet or ISO pallet), allowing the entire vertical unit, defined by the rack structure, to be moved efficiently via forklift or pallet jack, streamlining staging and transportation processes from the manufacturing facility to the distribution center or retail outlet. This integrated system ensures product safety, minimizes product loss through handling damage, and standardizes inventory counting procedures.

KEYWORDS: Beverage logistics, Blue plastic crate, HDPE, Returnable Transit Packaging, Vertical stacking, Warehouse storage, High-density storage, Industrial racking, Bottle crate, Distribution system, Modular storage, Supply chain management, Stacking lugs, Plastic handling box, Palletization, Inventory control, Load-bearing structure, Storage efficiency, Polypropylene, Formalized system, Vertical rack, Tray box, Packed goods, Standardized footprint, Container geometry, Material handling, Racking structure, Closed-loop logistics, Staging area, Beverage industry.

REVIEWS & COMMENTS

accuracy, and usability.