1/2

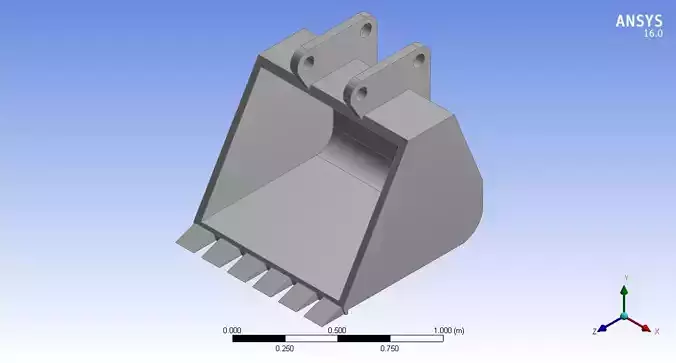

The design of JCB buckets, used in construction and excavation equipment, typically follows a few key principles to ensure efficiency, durability, and ease of use:

Material: JCB buckets are usually made from high-strength steel to withstand the stresses of digging, lifting, and loading materials. The material choice ensures longevity and resistance to wear and tear.

Shape and Size: The buckets come in various shapes and sizes depending on the specific application. Common types include general-purpose buckets, trenching buckets, grading buckets, and rock buckets. Each type is designed with specific features to optimize performance for different tasks.

Cutting Edge: The cutting edge of the bucket is crucial for efficient digging. It's typically made from hardened steel or equipped with replaceable teeth for better penetration into the ground or material being excavated.

Capacity and Volume: The capacity of the bucket (measured in cubic yards or meters) dictates how much material it can handle per scoop. Larger buckets are used for moving loose materials like soil or gravel, while smaller buckets are suited for precision work or tighter spaces.

Attachment Mechanism: JCB buckets are designed to be compatible with quick couplers or hitch systems on JCB machines. This allows for quick attachment and detachment of buckets, enhancing the versatility of the equipment.

Reinforcements and Ribbing: To enhance durability and structural integrity, buckets often feature reinforcements and ribbing in key stress areas. This prevents deformation and extends the bucket's lifespan under heavy use.

Dump Angle: The angle at which the bucket releases its load (dump angle) is designed to facilitate efficient material handling and reduce spillage.

Optional Features: Depending on the model and intended use, JCB buckets may include additional features such as bolt-on cutting edges, wear plates, drainage holes, and integrated lifting eyes for improved functionality and maintenance.

Overall, JCB bucket designs are engineered to optimize productivity, durability, and ease of operation in various construction and excavation applications. Each design aspect is carefully considered to meet the demands of the job and ensure efficient performance over the equipment's lifecycle.

REVIEWS & COMMENTS

accuracy, and usability.