All studies were made with Polyester as it pretty nicely resembles Young’s module for 3D printed PLA as some of my research concluded. I highly recommend all models to be printed on the side, so that the printing layers won’t interfere with the structural rigidity of the support. All simulations have a minimum safety factor of 3. In the end please do note that these simulations don’t have the best accuracy and I am not to be held responsible for any structural failures, thus I present the computer generated MK1 and MK2, alongside MK3, a more classical approach:

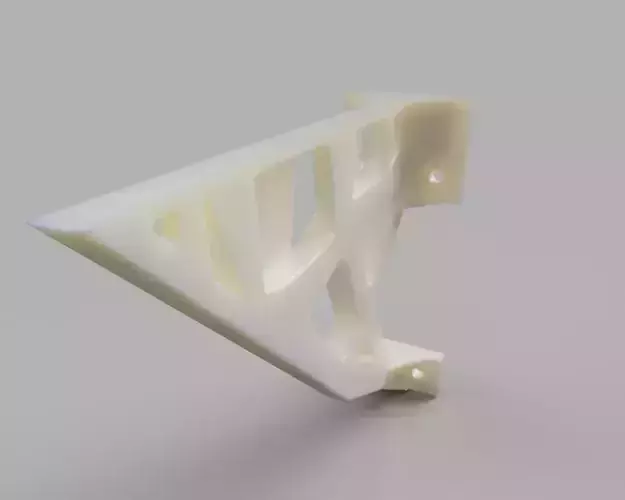

Support MK1:

- -Maximum load 100KG/per support. (apparently way more but I wouldn’t recommend)

- -Uses four M8 (8mm diameter) screws, and 24mm washers.

- -Has a additional hole for a M6 (6mm diameter) screw on the top, to secure the rack.

Suport MK2:

- -Maximum load of 15KG/per support.

- -Uses two M8 screws, washers might help distribute the load but are not necessary.

Suport MK3:

- -Maximum load of 50KG/per support.

- -Uses two M8 screws, washers might help distribute the load but are not necessary.