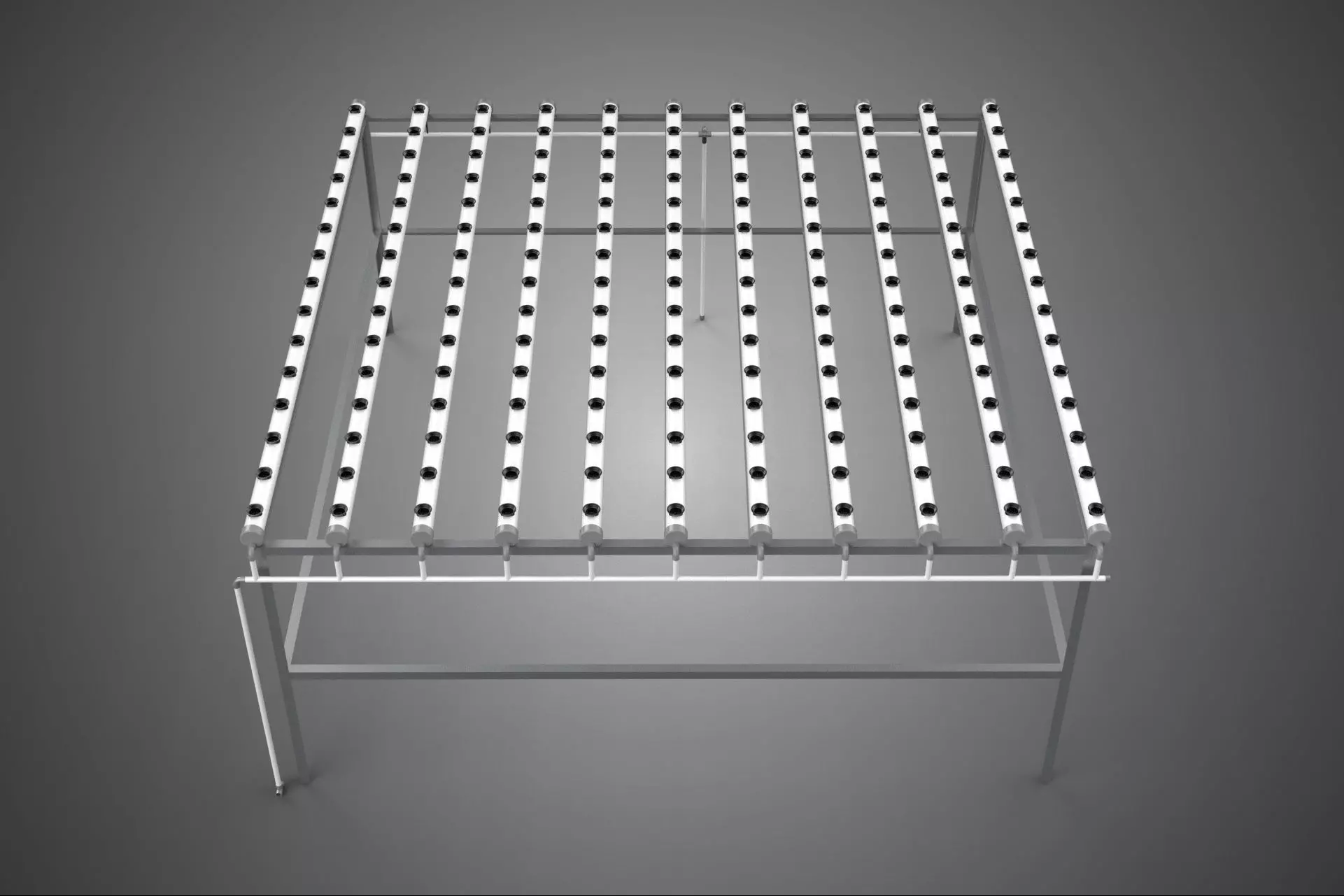

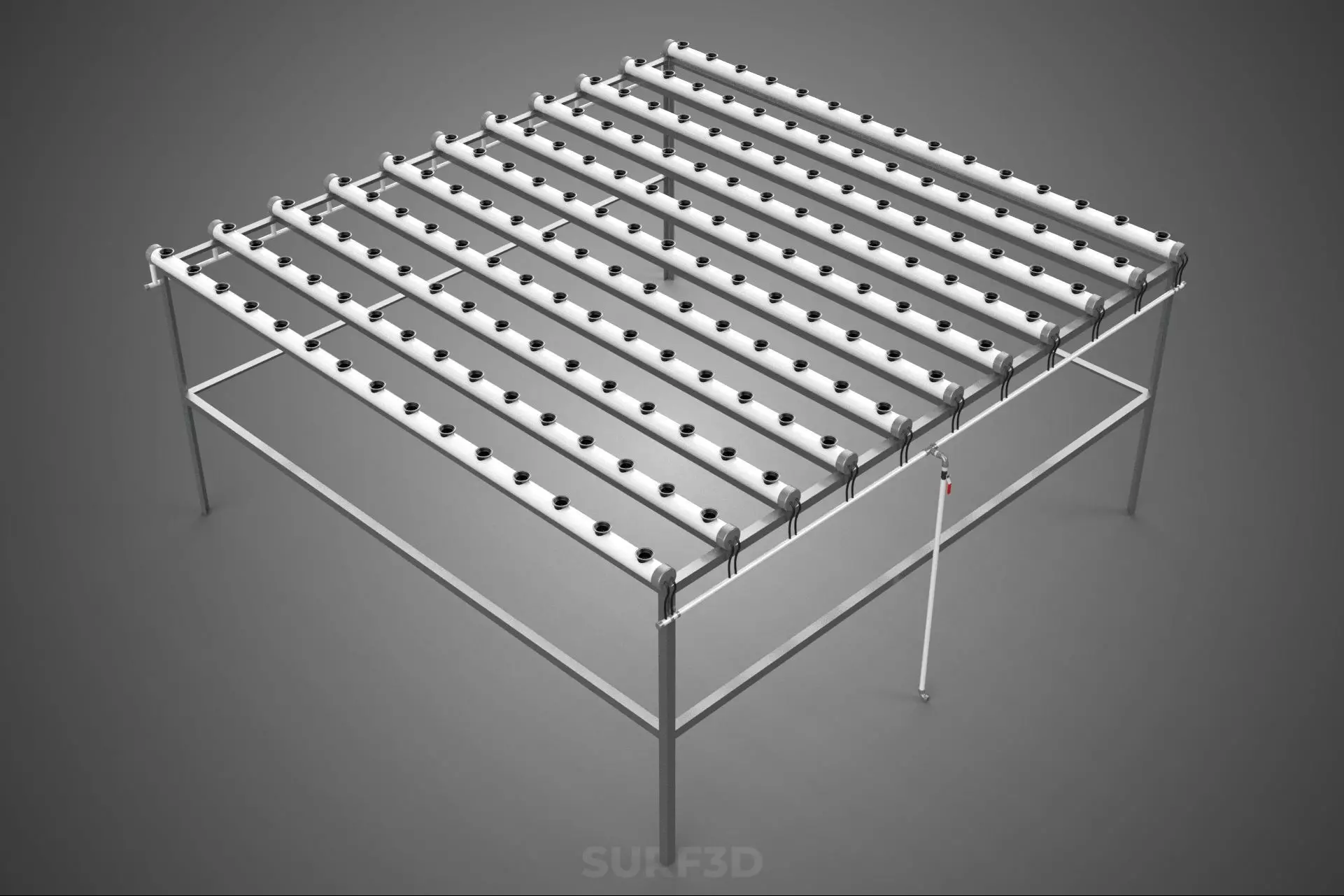

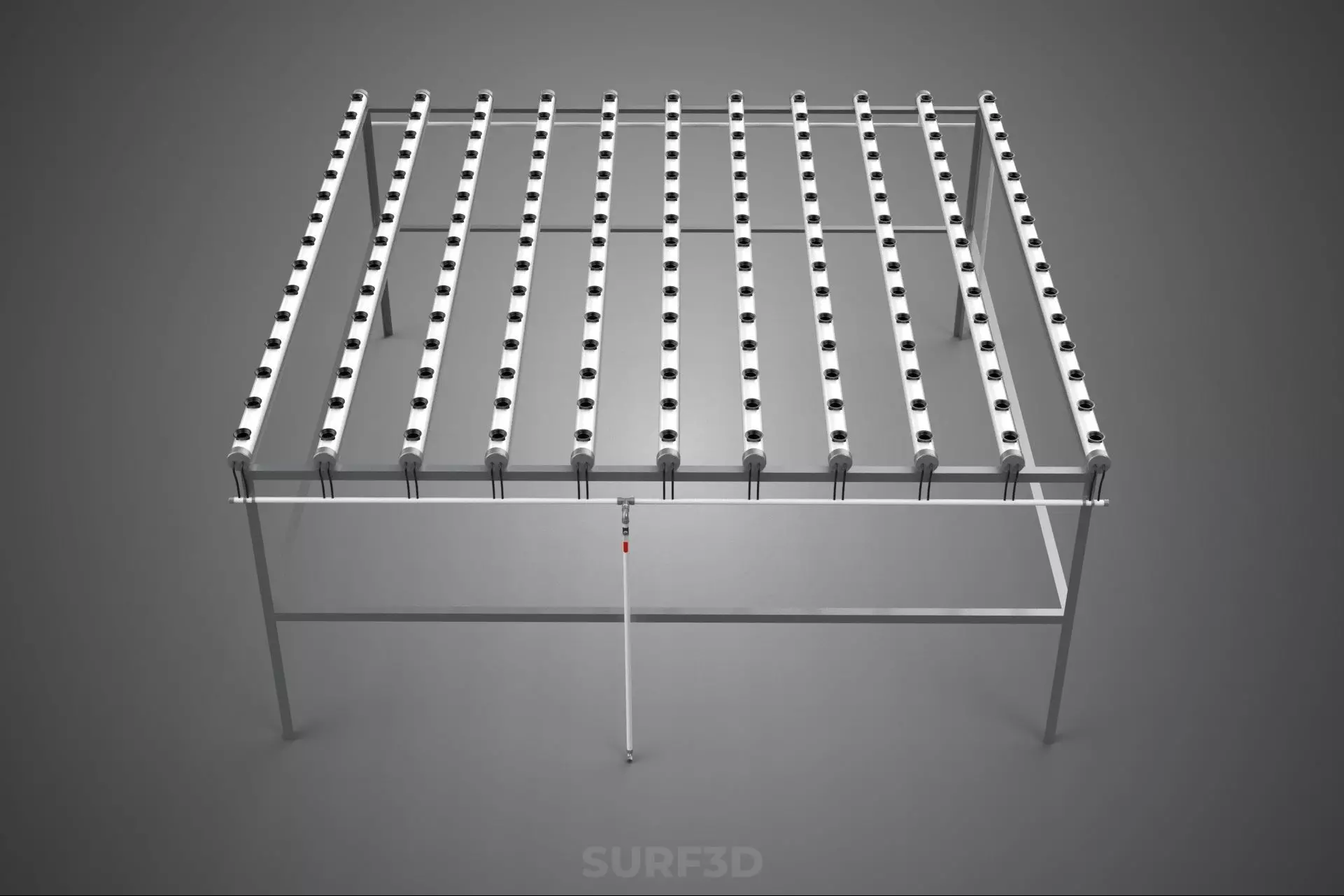

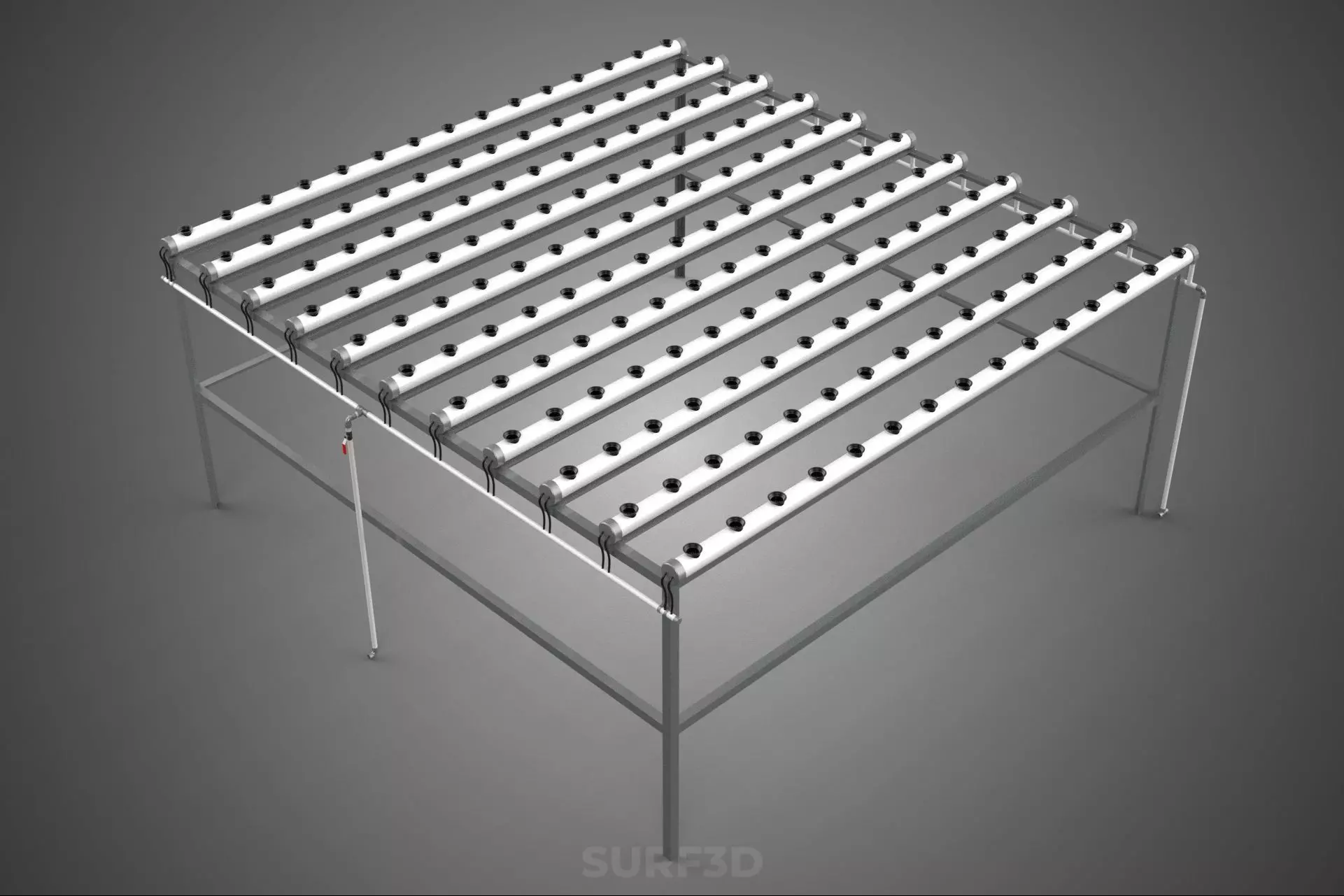

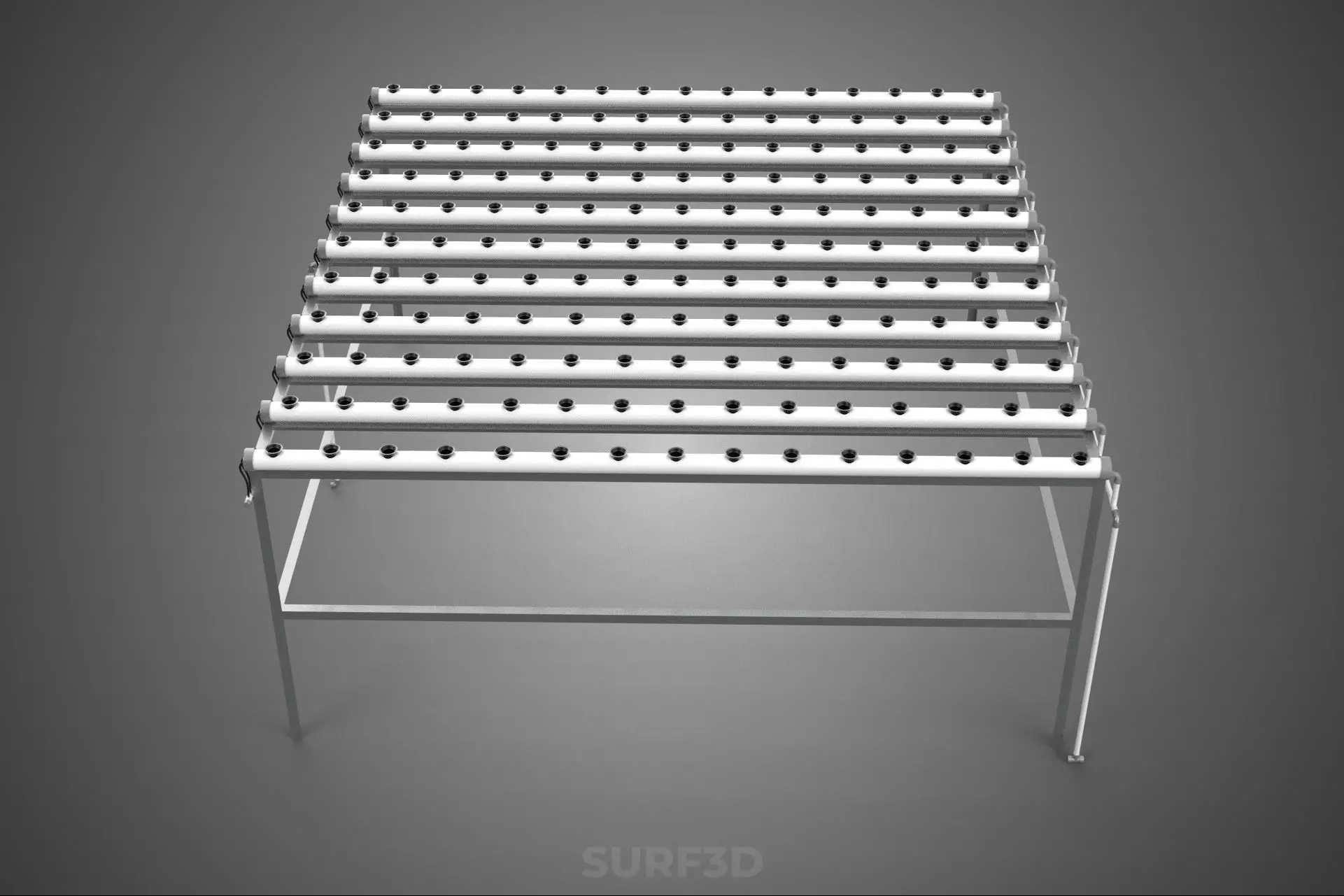

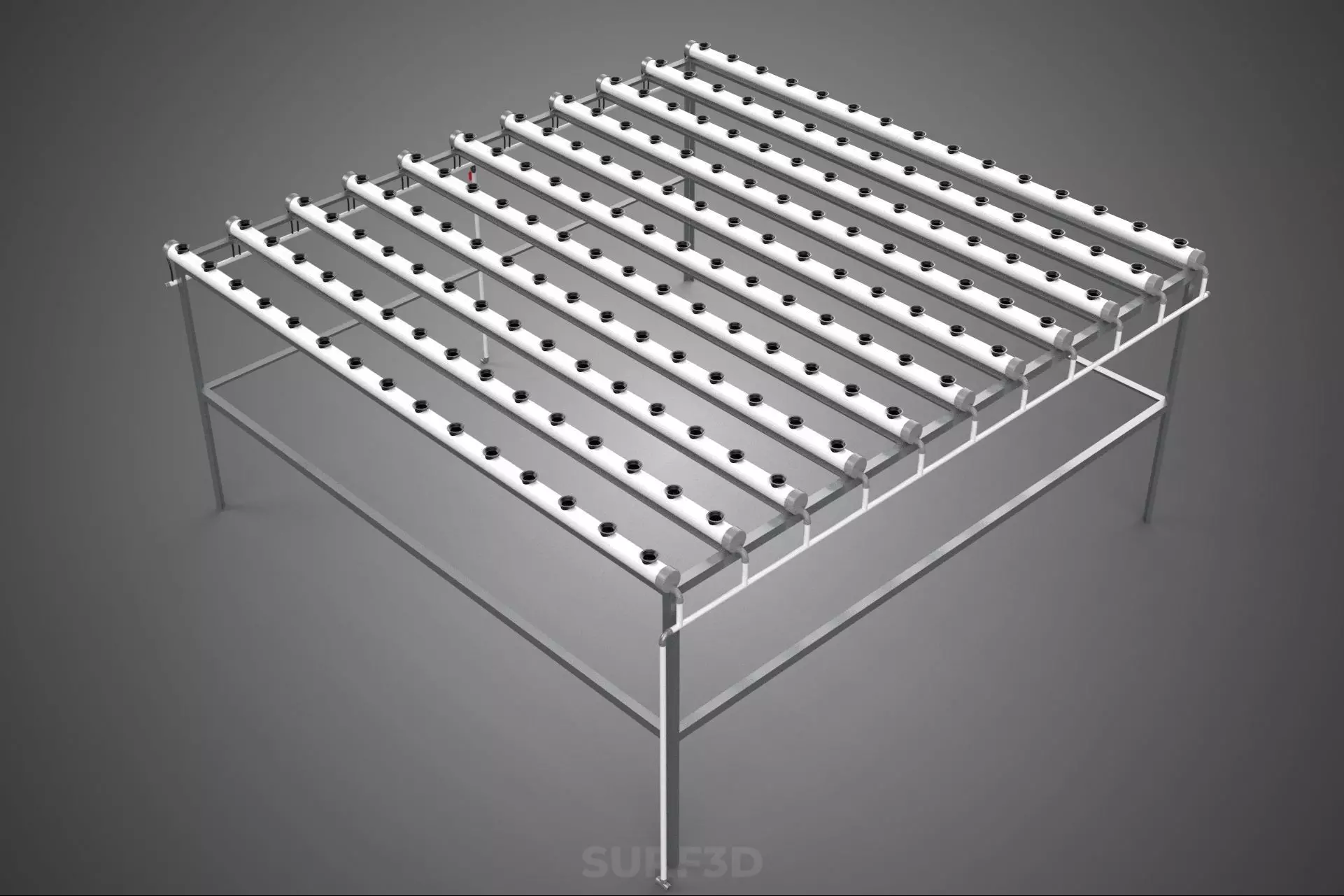

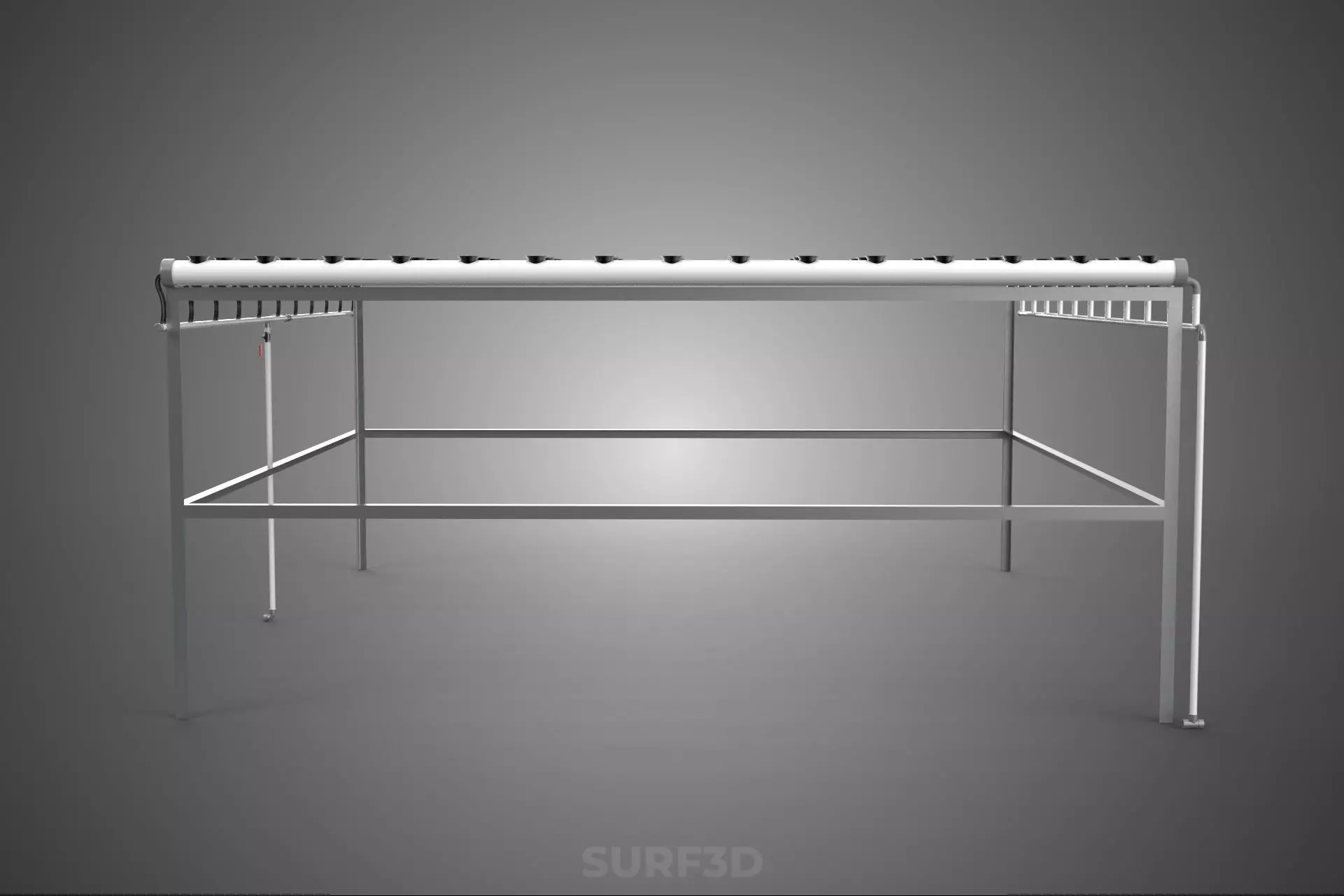

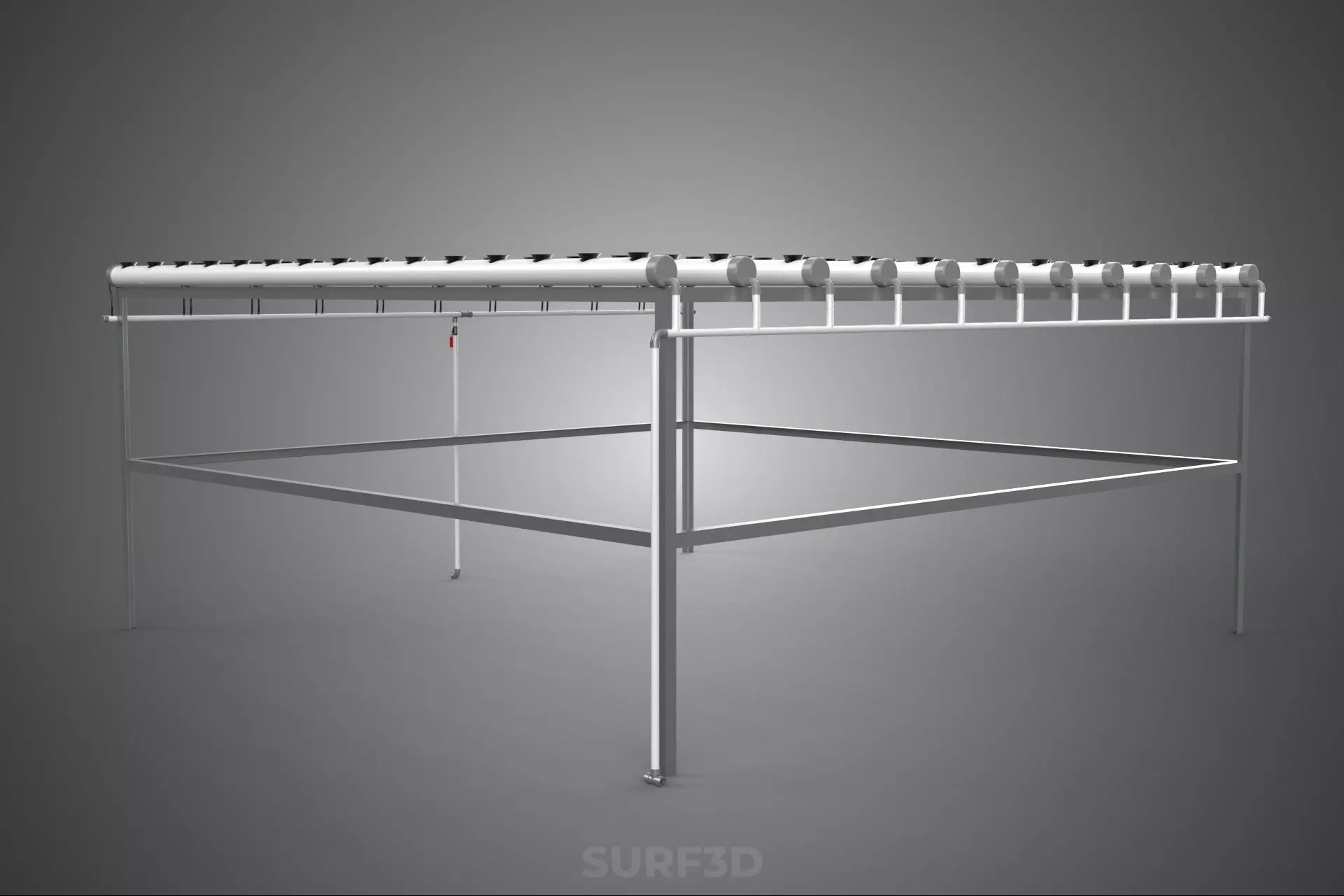

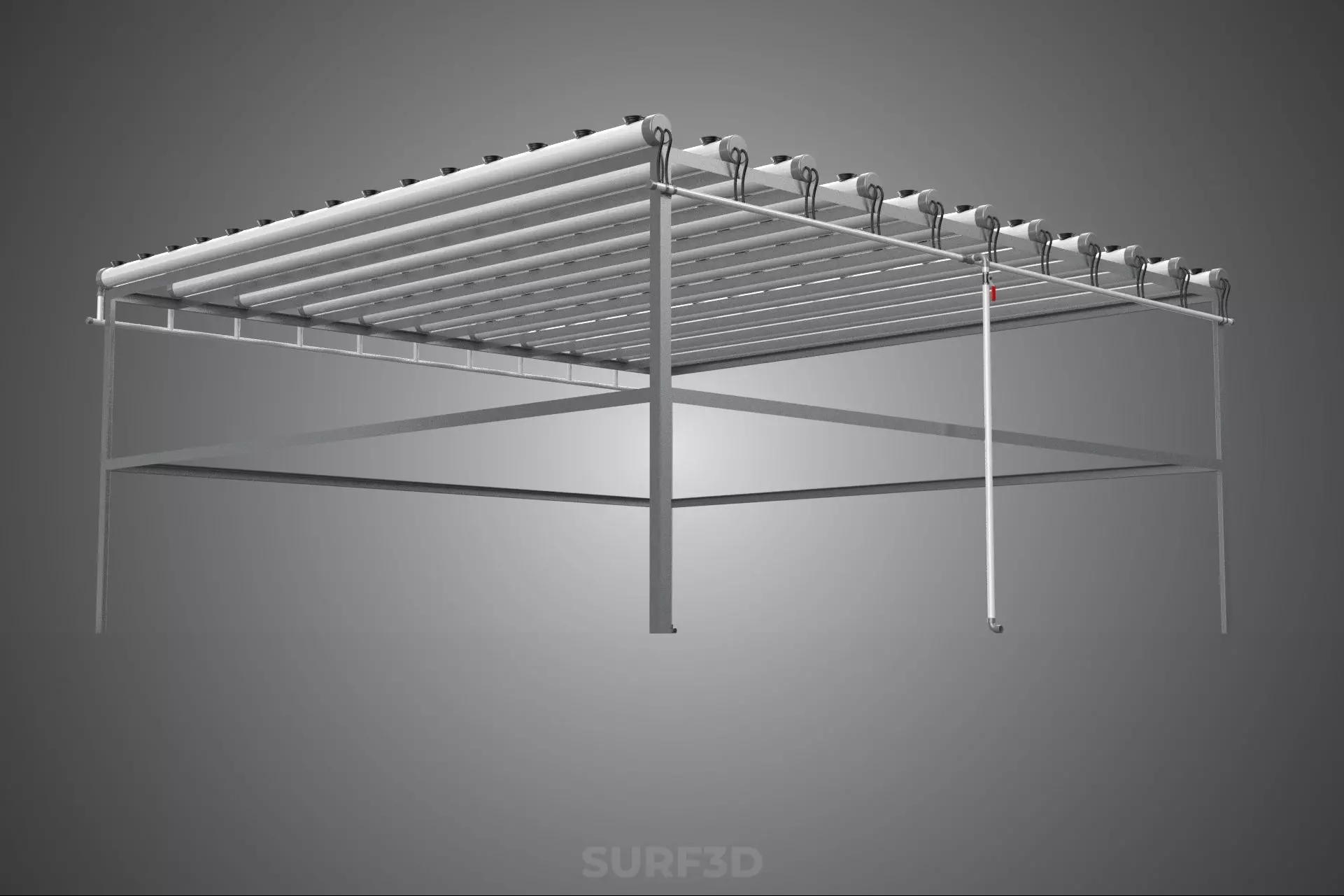

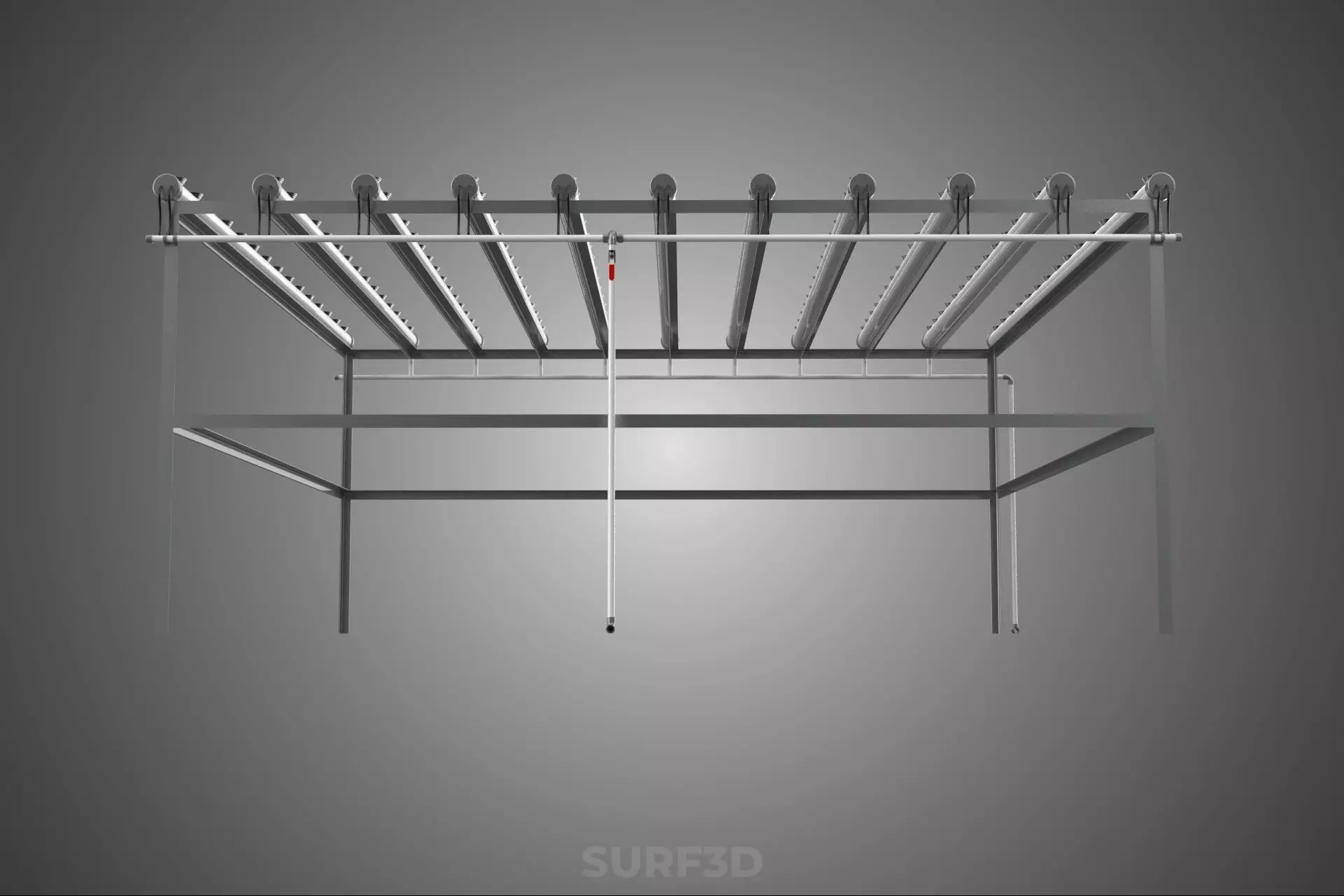

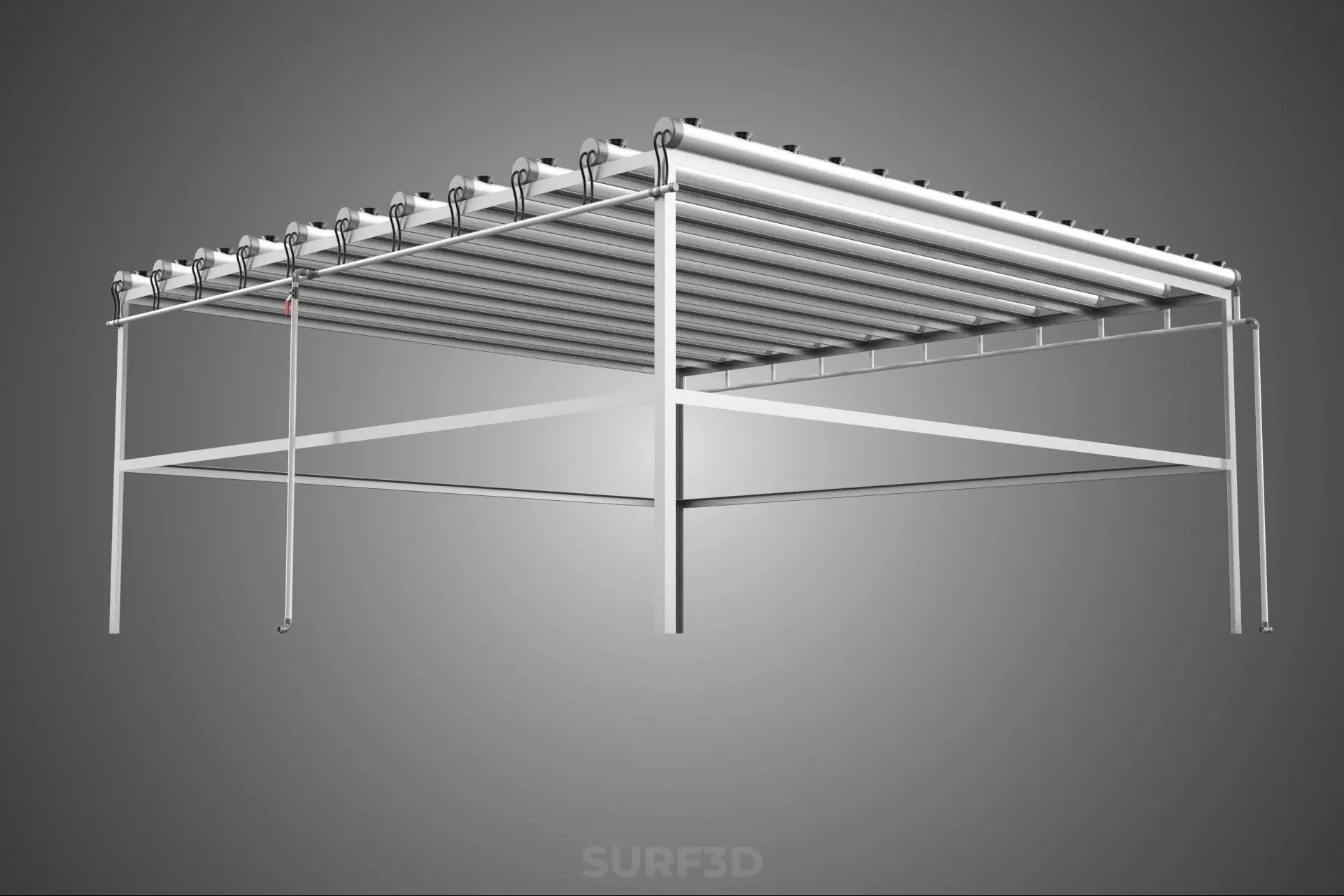

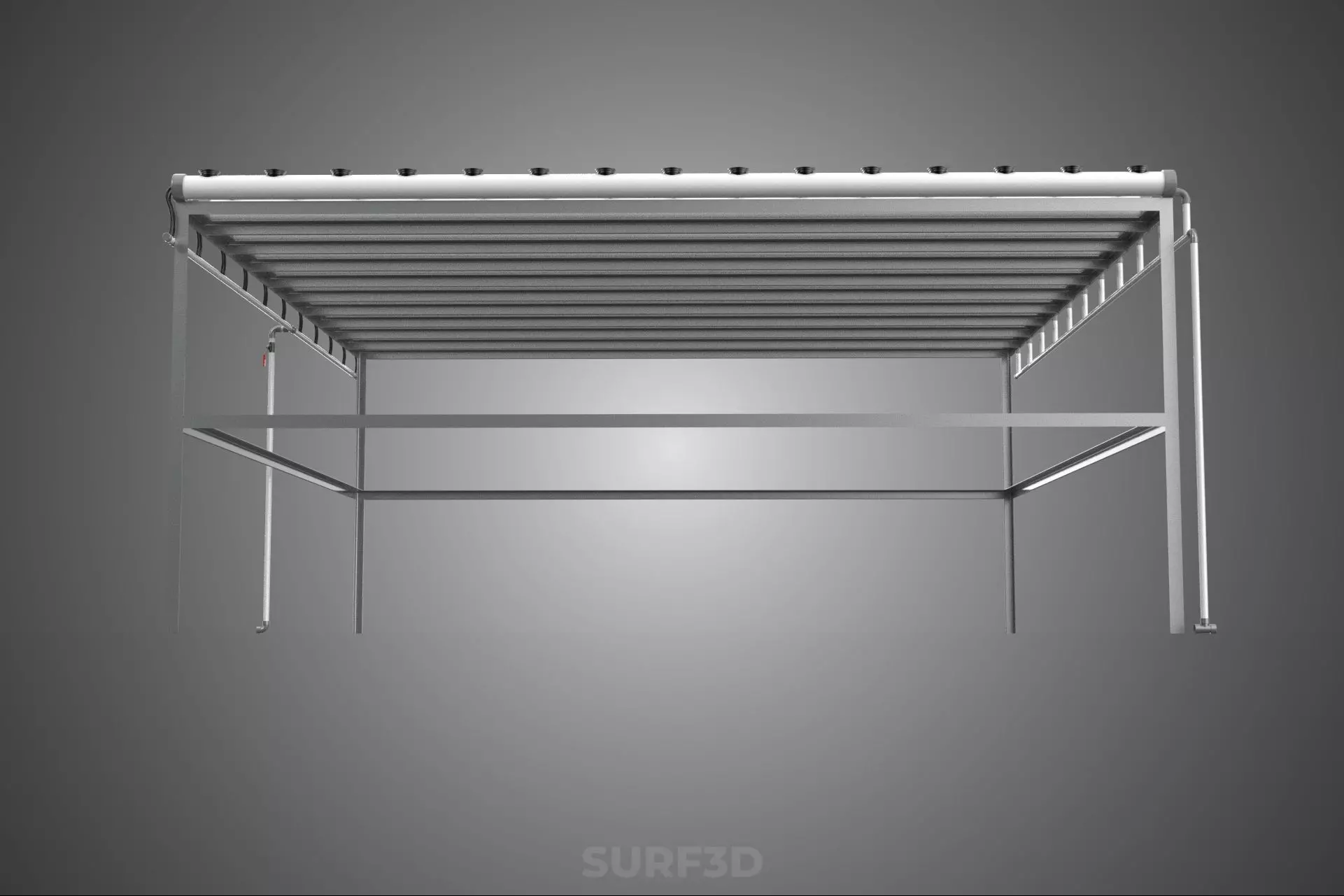

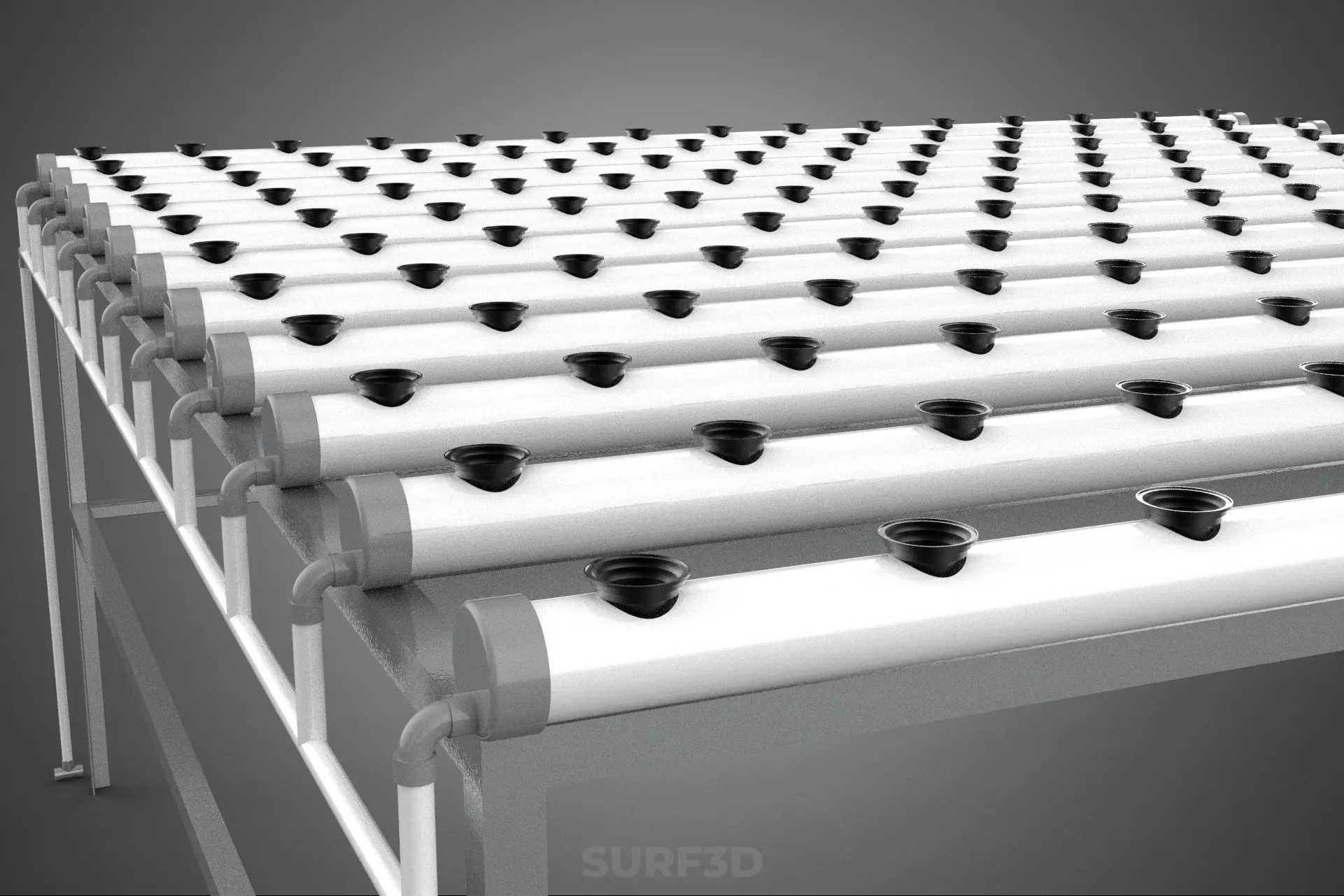

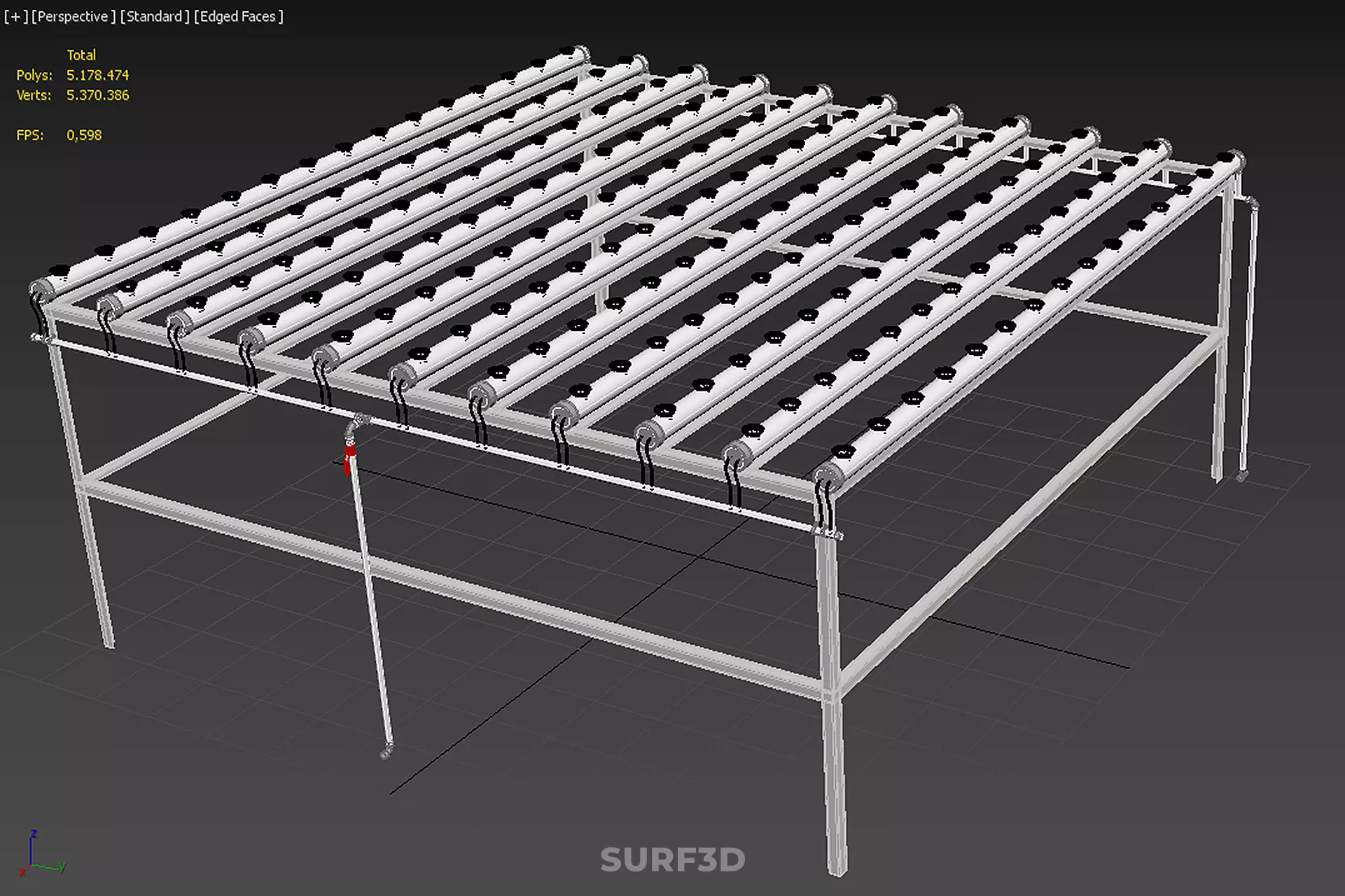

NFT GROW RACK PVC NETPOT SETUP SOIL-LESS HYDROPONIC FARM PLANT 3D model

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

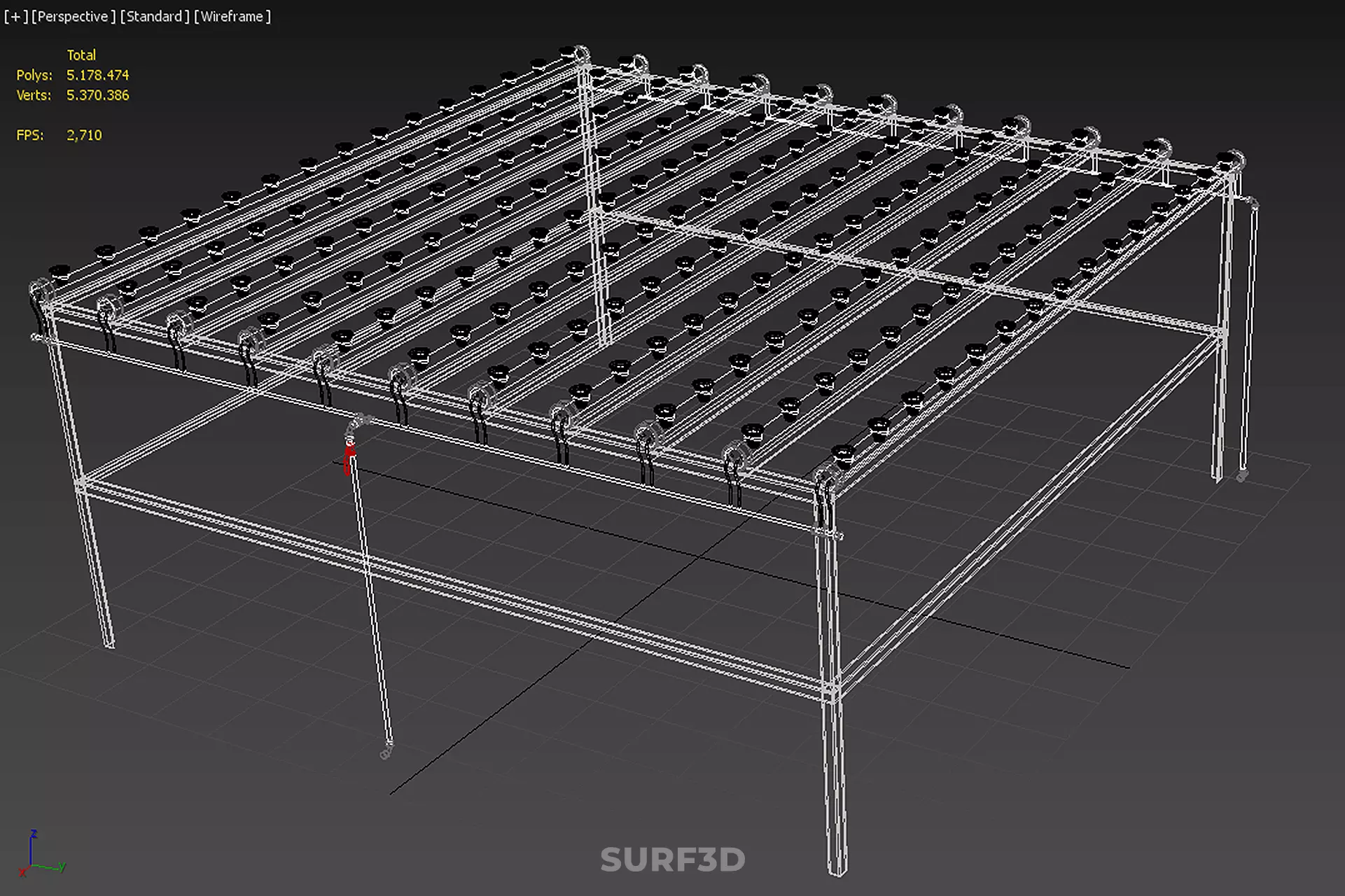

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

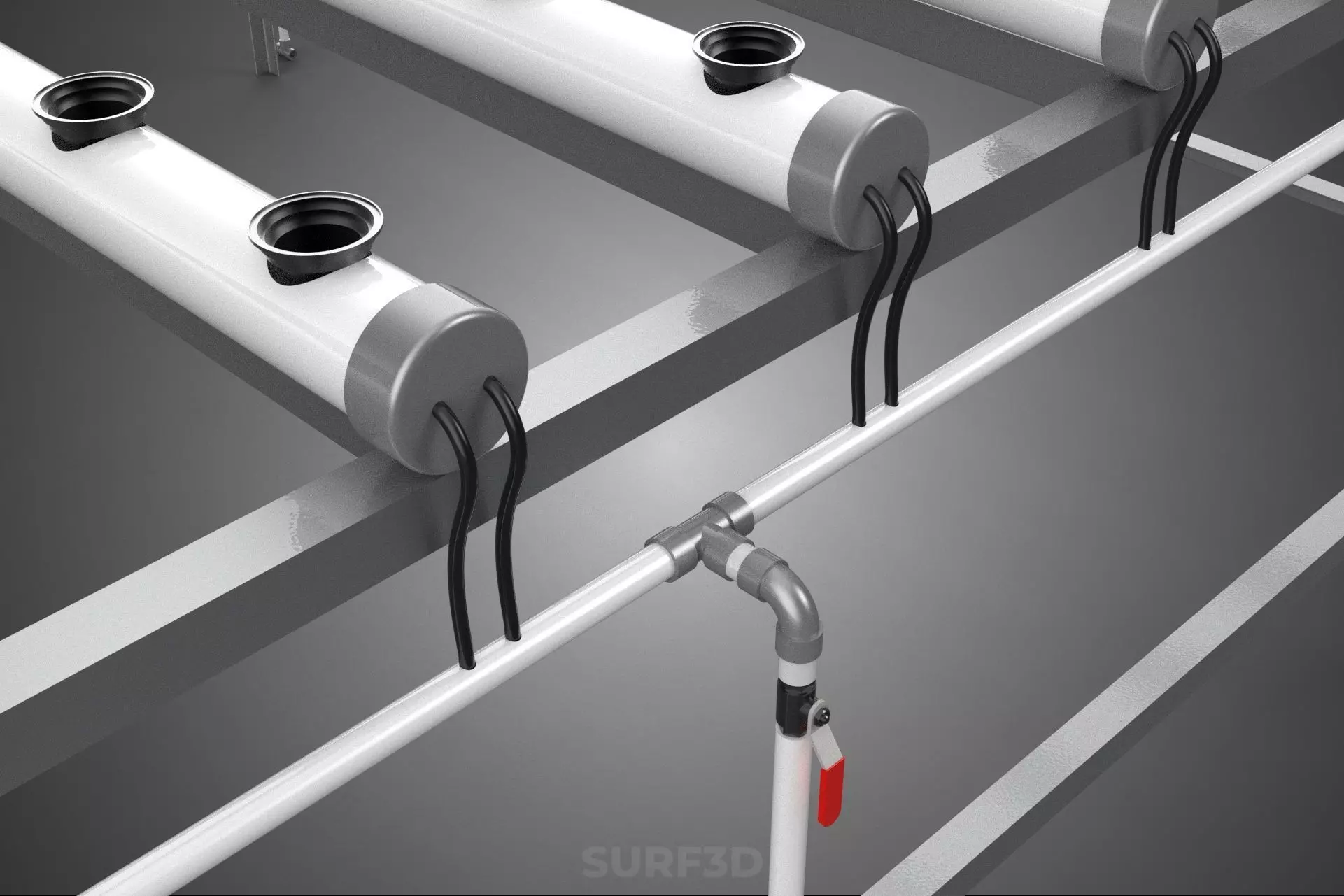

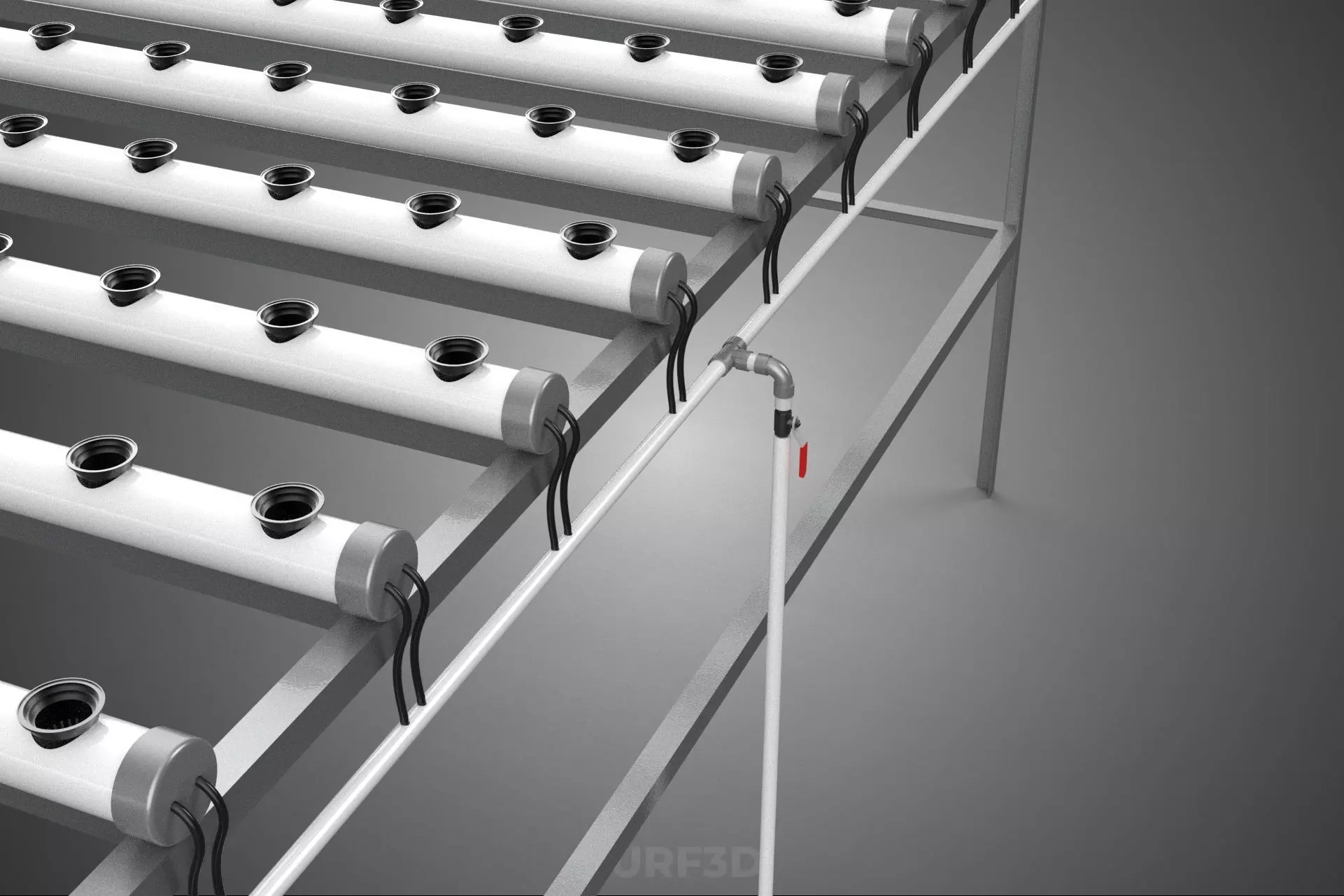

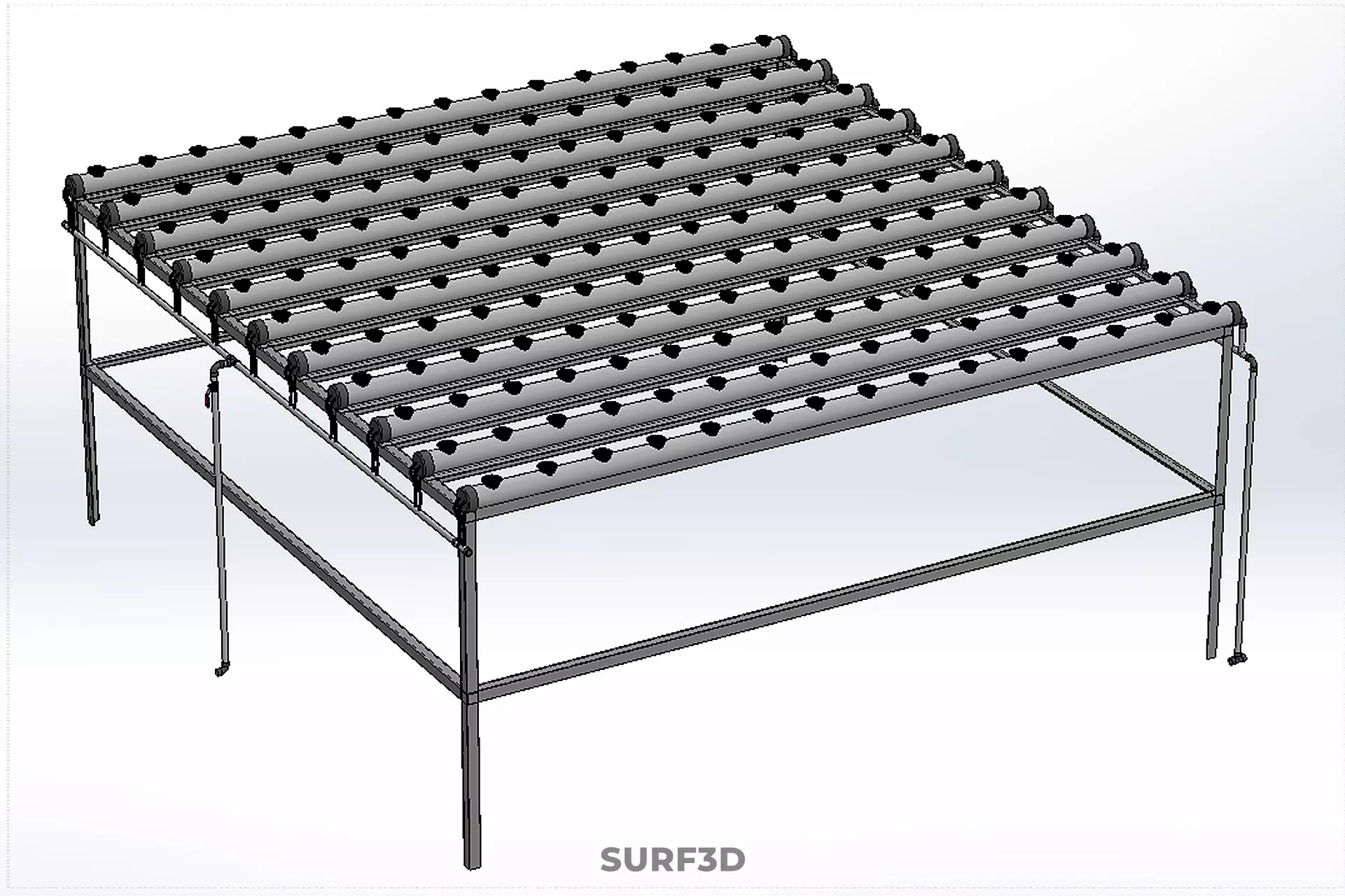

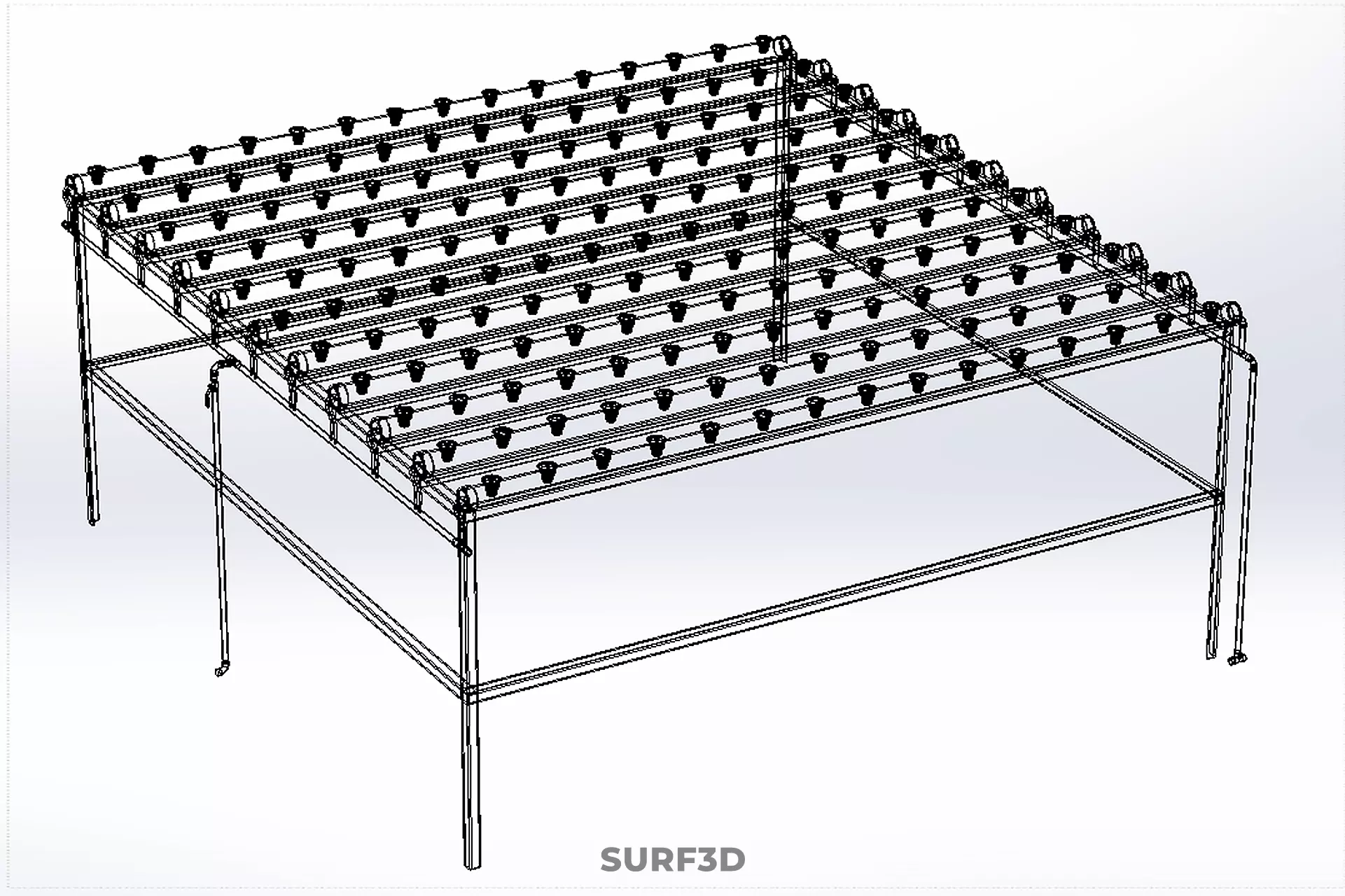

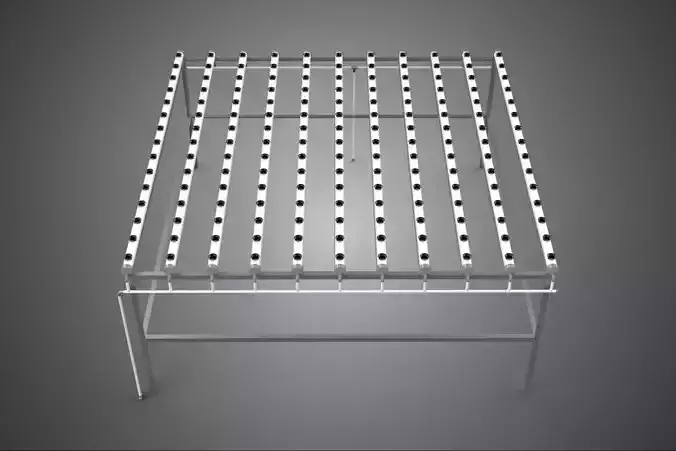

The NFT Grow Rack PVC Netpot Setup for Soil-less Hydroponic Farm Plant describes a specific implementation of Nutrient Film Technique (NFT) hydroponics optimized for controlled environment agriculture (CEA) and small to medium-scale farming operations. This system configuration leverages standardized materials, particularly polyvinyl chloride (PVC) components, to create a modular, efficient, and reproducible method for cultivating crops without the use of traditional soil media.

NFT is a widely adopted hydroponic method characterized by the continuous circulation of a shallow stream of nutrient-rich water (the film) across the bare roots of plants. Unlike deep water culture (DWC) or drip systems, NFT utilizes gravity and precise slope angles to ensure the thin film—typically only a few millimeters deep—flows through channels, providing the roots with simultaneous access to moisture, essential mineral nutrients, and crucial atmospheric oxygen. Maintaining adequate oxygenation is paramount, as the shallow depth prevents root saturation and subsequent asphyxiation.

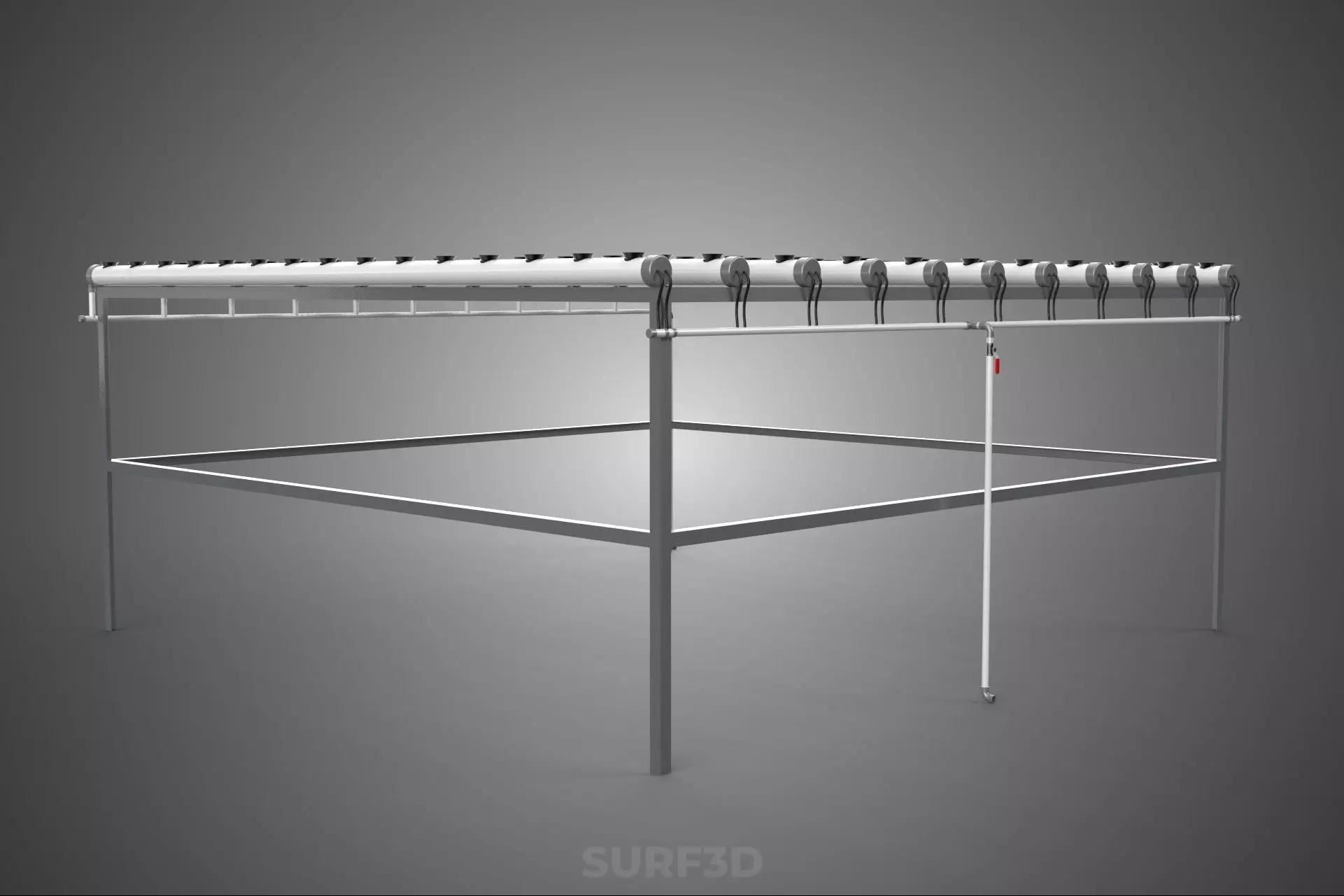

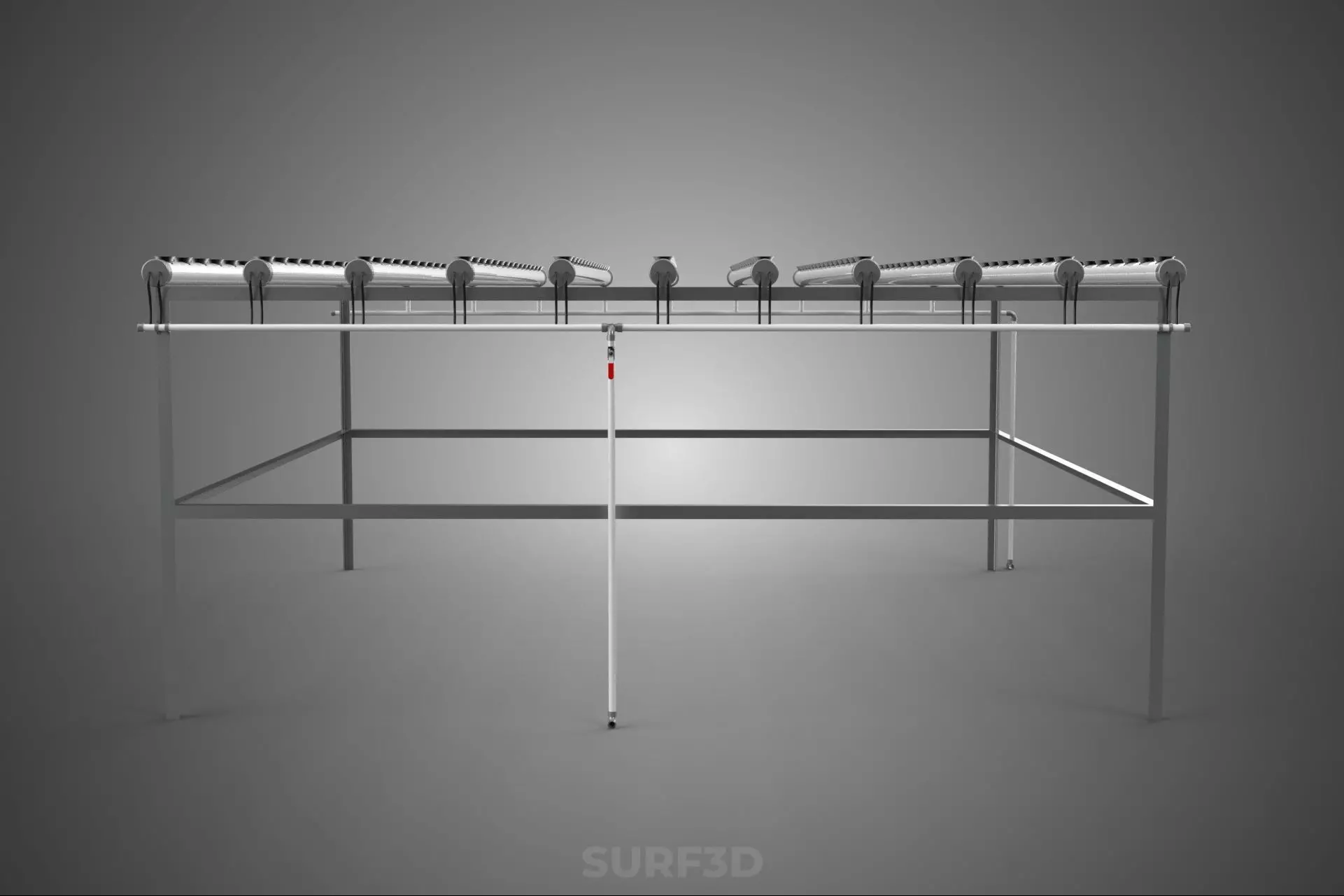

The specific setup detailed involves three primary structural and functional elements: the Grow Rack, PVC Channels, and Netpots.

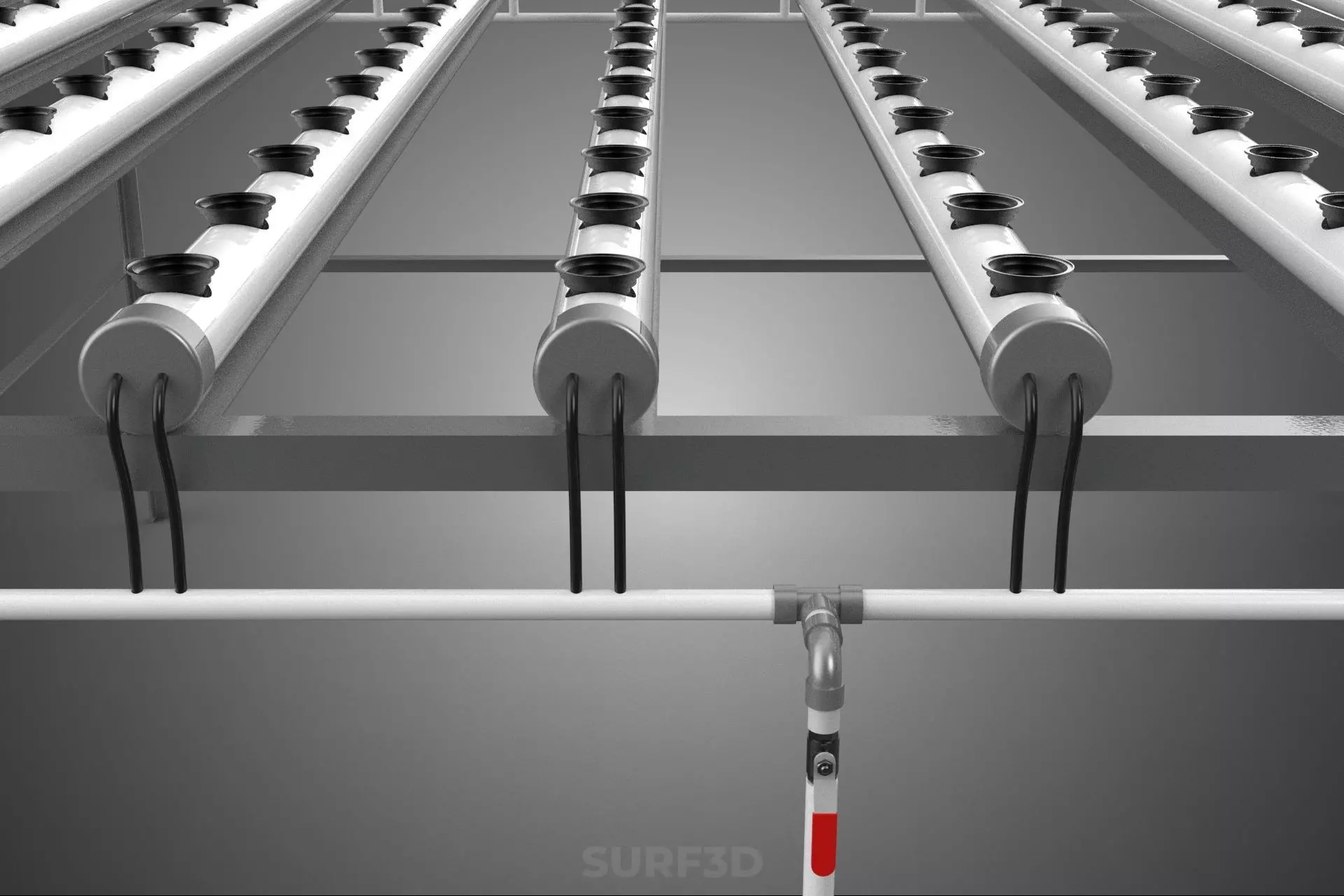

The grow rack is the physical framework, often constructed from galvanized steel, aluminum, or robust PVC piping, designed to hold the NFT channels at the necessary incline. These racks are typically tiered (vertical farming configuration) or arranged in parallel horizontal rows to maximize plant density within a limited footprint. Stability, load-bearing capacity, and resistance to high-humidity environments are essential design considerations.

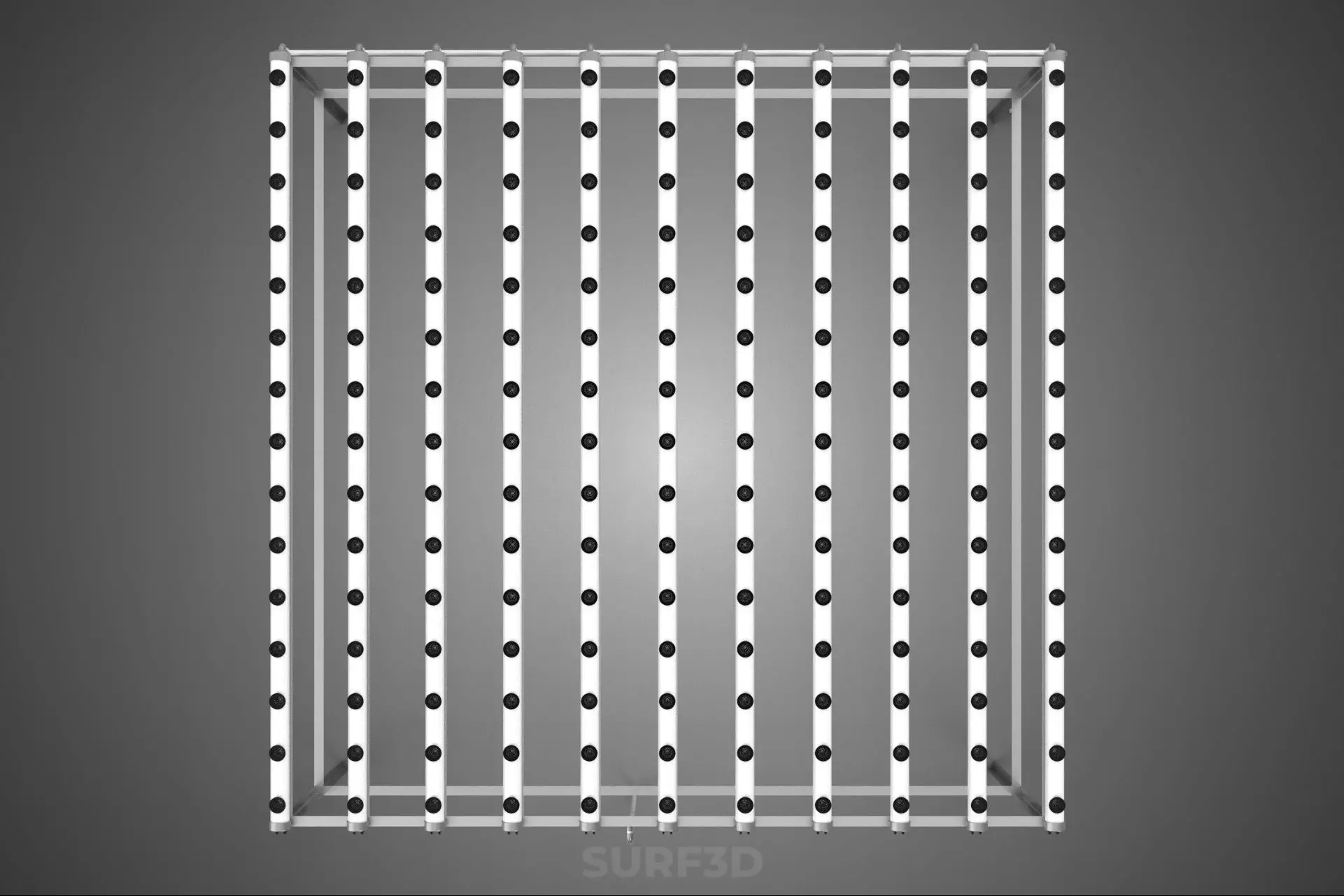

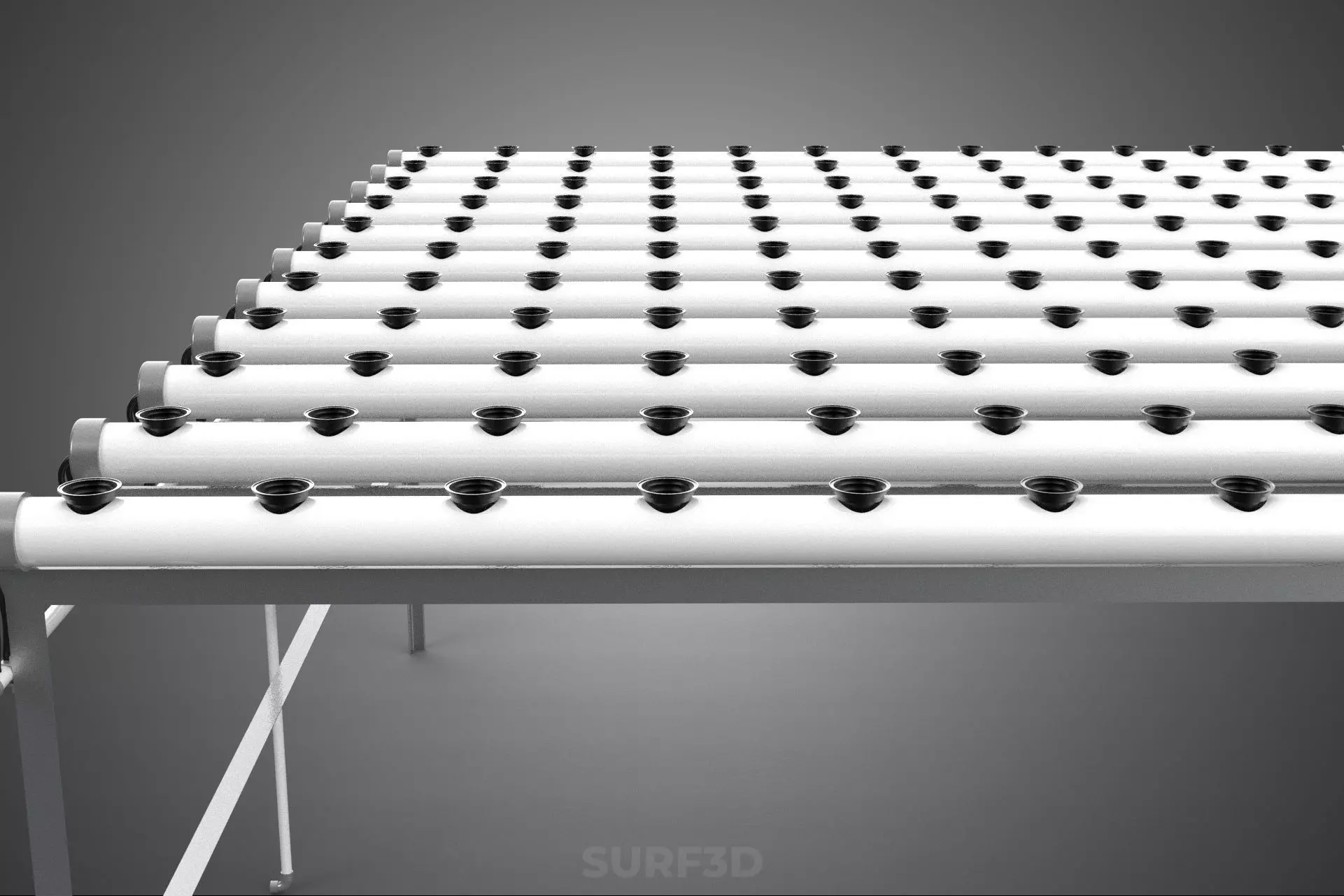

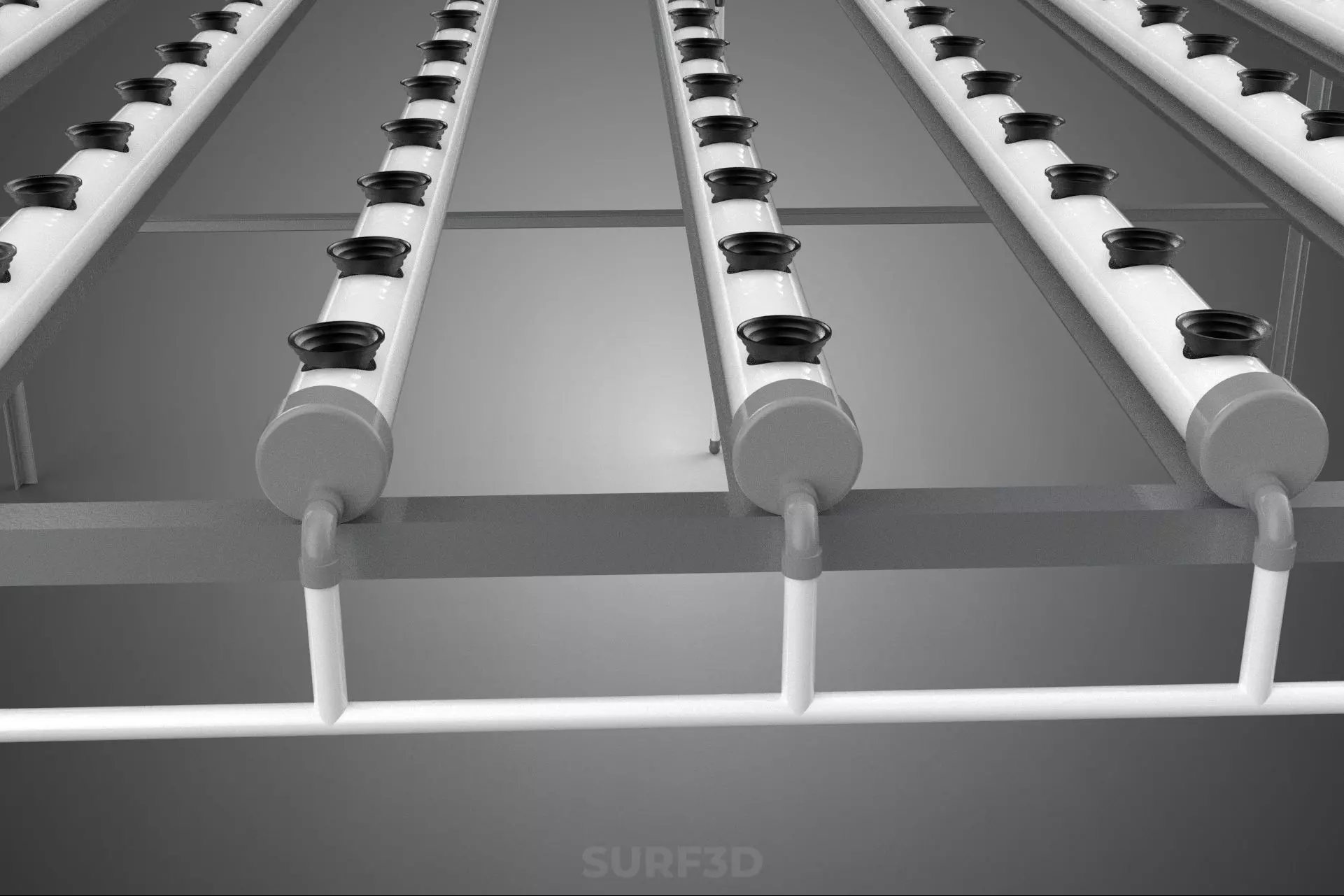

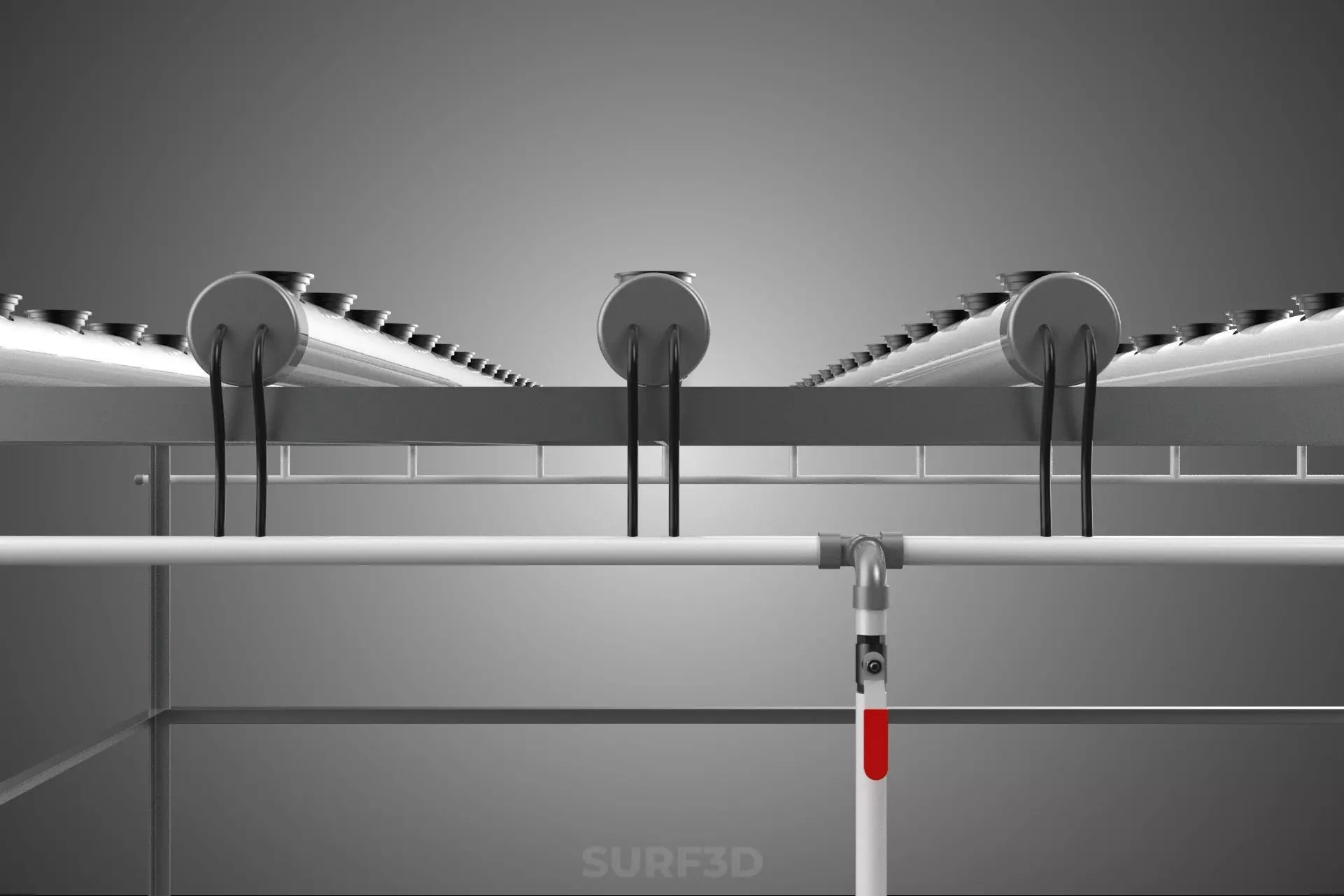

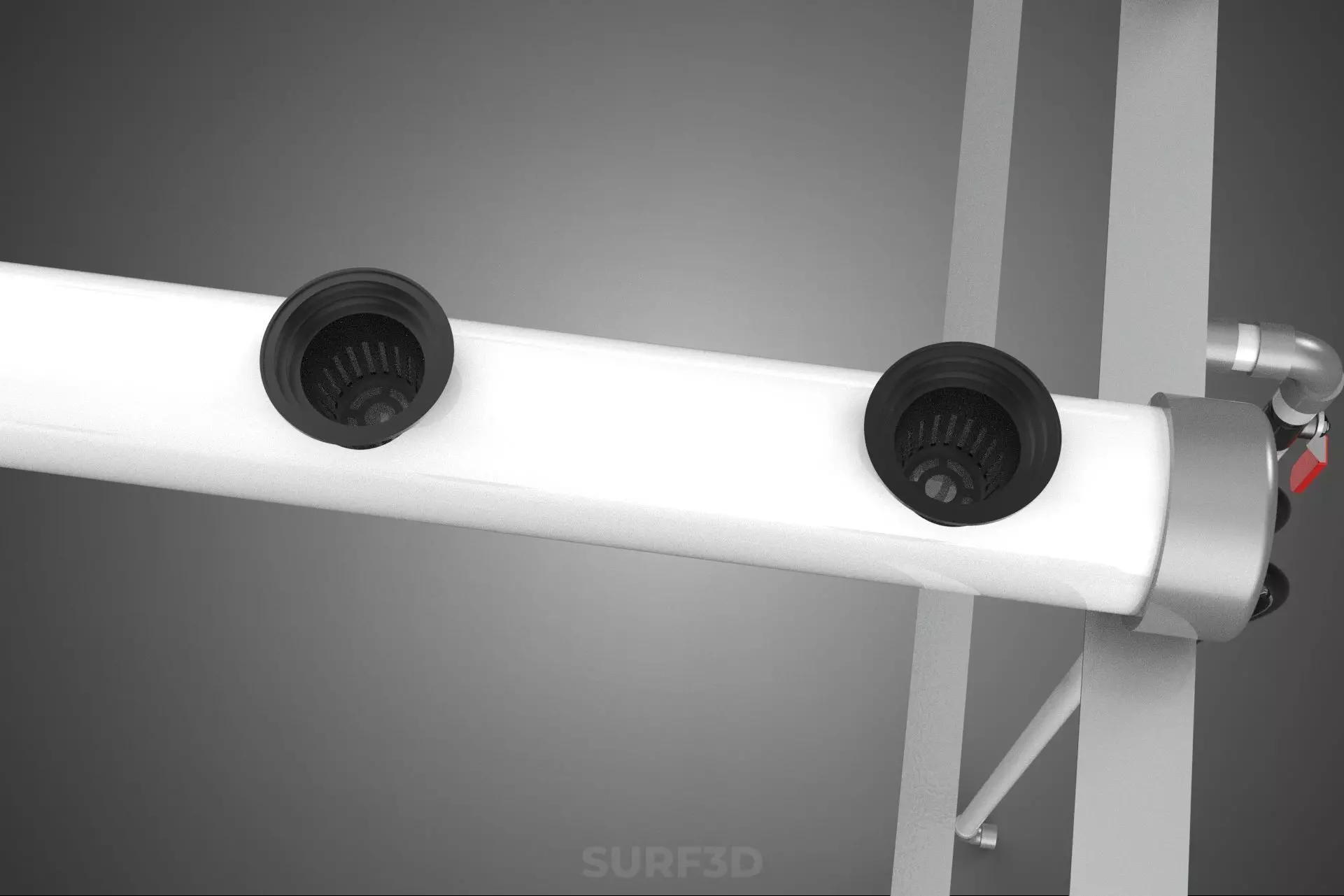

The primary conduits for nutrient delivery are specialized channels, or gullies, constructed from inert, food-grade PVC. These channels are engineered with specific dimensions (width and depth) appropriate for the crop type (e.g., shallow channels for leafy greens like lettuce, deeper ones for strawberries). The channels are mounted on the grow rack at a gentle gradient, typically between 1:30 to 1:100 (1 cm drop per 30 to 100 cm length), to ensure continuous, slow flow without pooling or flooding. Plant sites—pre-drilled holes in the channel lids—are spaced according to the crop's mature size.

PVC netpots serve as the primary containers for supporting young plants and holding the initial rooting media (e.g., rockwool, coco coir, or peat pellets). These pots are designed with open mesh sides and bottoms, allowing the roots to grow freely out of the pot and into the flowing nutrient film within the PVC channel below. The use of PVC ensures material compatibility and durability in constant contact with the nutrient solution.

The system requires a reservoir tank to hold the nutrient solution (a balanced mixture of mineral salts dissolved in water), a submersible pump to lift the solution to the highest point of the channels, and plumbing (PVC tubing) to distribute the solution evenly across all channels. A return line collects the effluent from the lowest end of the channels, filters it, and directs it back to the reservoir, creating a closed-loop, recirculating system. Monitoring and automated adjustments for pH and electrical conductivity (EC) are often incorporated to maintain optimal nutrient levels.

This specific PVC-based NFT setup offers several operational advantages:

-

Water Efficiency: The recirculating nature of NFT significantly reduces water consumption compared to traditional agriculture.

-

Nutrient Control: Precise control over the nutrient formula optimizes plant health and accelerates growth rates.

-

Modularity and Scalability: PVC components are readily available, inexpensive, and allow for easy expansion, reconfiguration, or repair.

-

Disease Reduction: Eliminating soil mitigates many soil-borne pathogens and pests.

-

Cleanliness: The sterile environment facilitates the production of high-quality, clean produce, making it popular for cultivating quick-turnaround crops such as leafy greens, herbs, and certain fruiting plants (e.g., strawberries).

The NFT Grow Rack PVC Netpot Setup is a fundamental infrastructure model used globally in commercial hydroponic farms, research facilities, and hobbyist CEA endeavors, bridging accessible technology with high-efficiency agricultural production.

KEYWORDS: Hydroponics, NFT, Nutrient Film Technique, PVC, Grow Rack, Soil-less, CEA, Controlled Environment Agriculture, Netpot, Recirculating System, Modular Farming, Plant Cultivation, Rockwool, Leafy Greens, Vertical Farming, Nutrient Solution, Agriculture Technology, Water Efficiency, pH Control, EC Monitoring, Hydroponic System, PVC Gutter, Crop Yield, Plant Support, Closed Loop, Commercial Hydroponics, Root Zone Oxygenation, Soilless Culture, Hydroponic Setup.