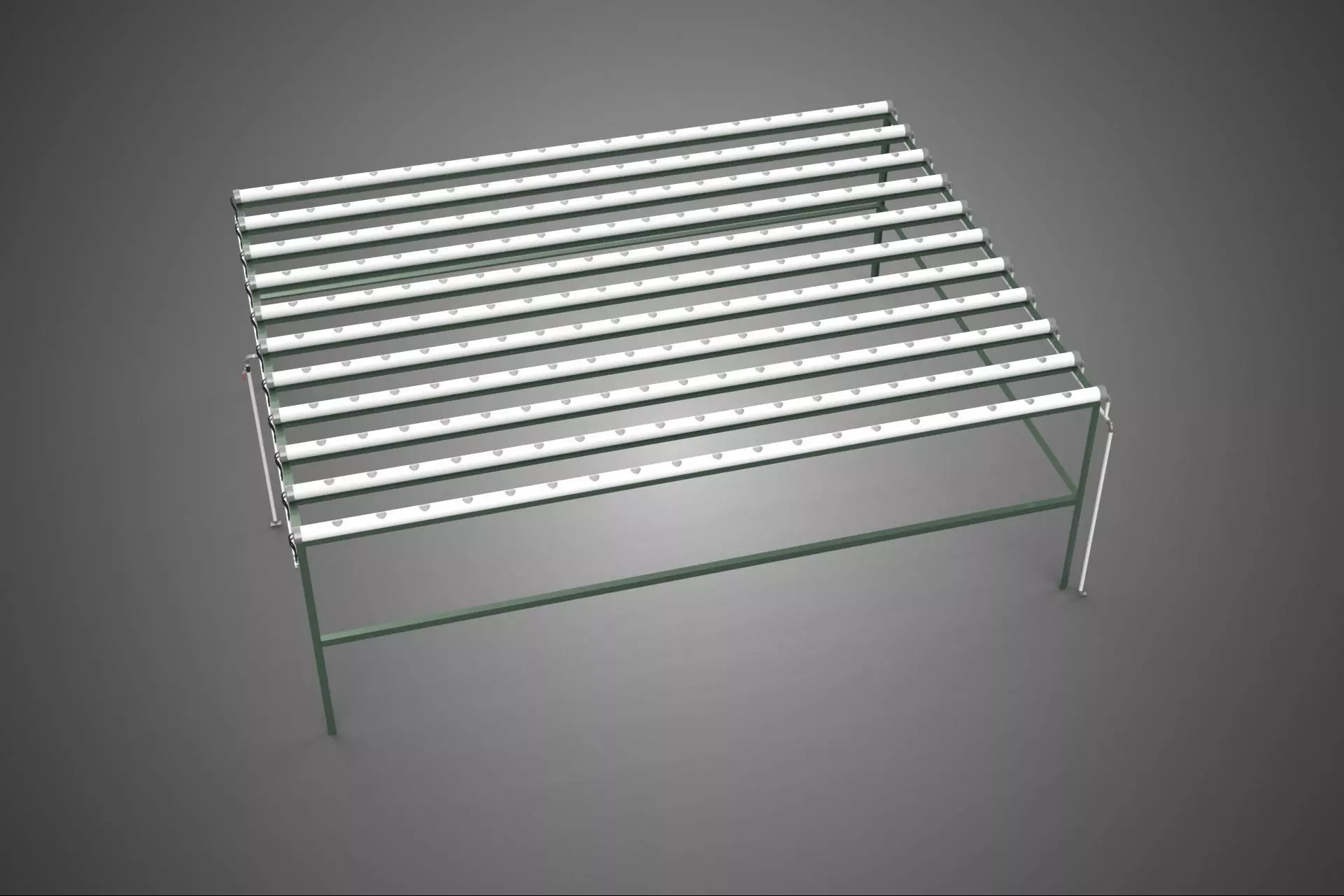

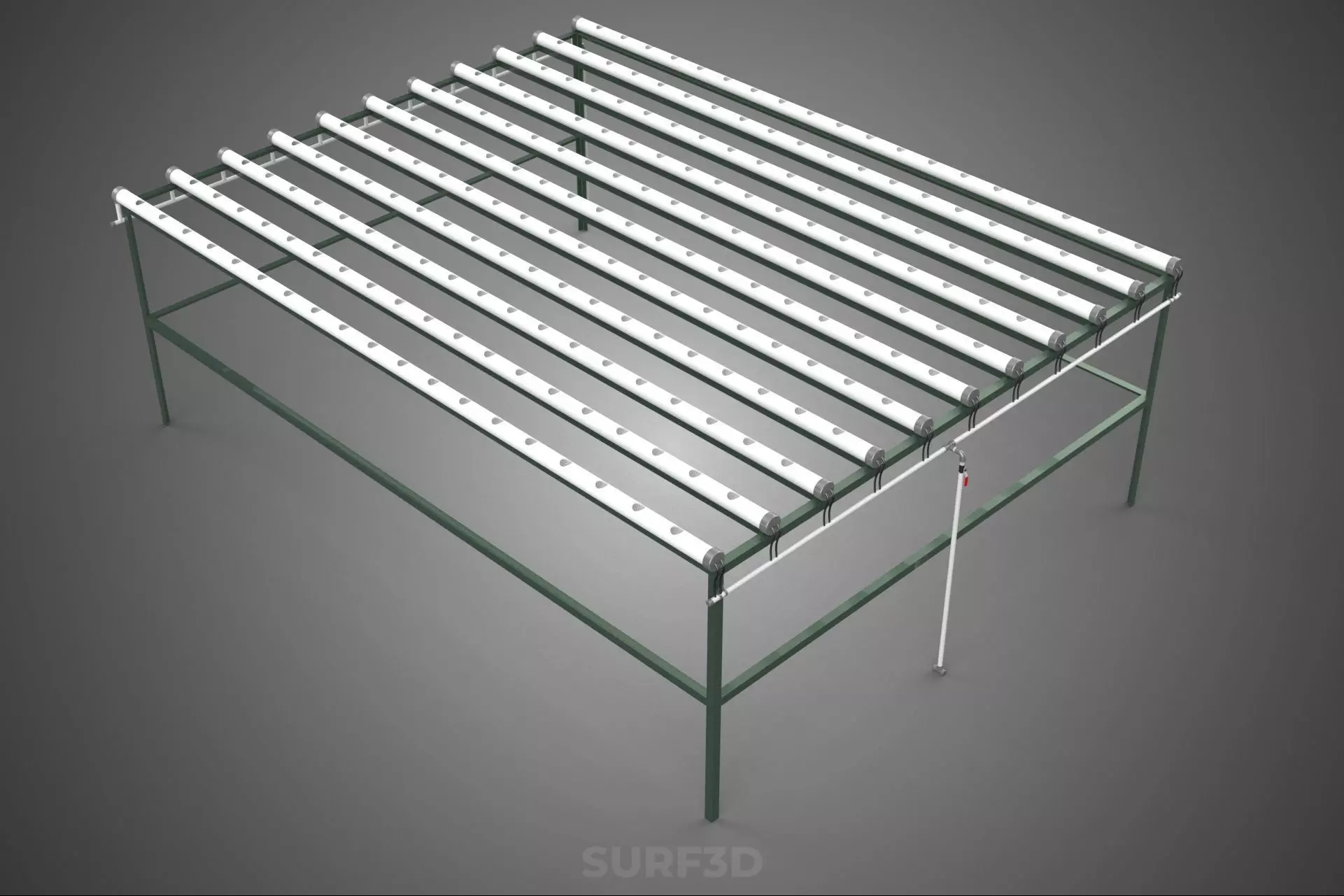

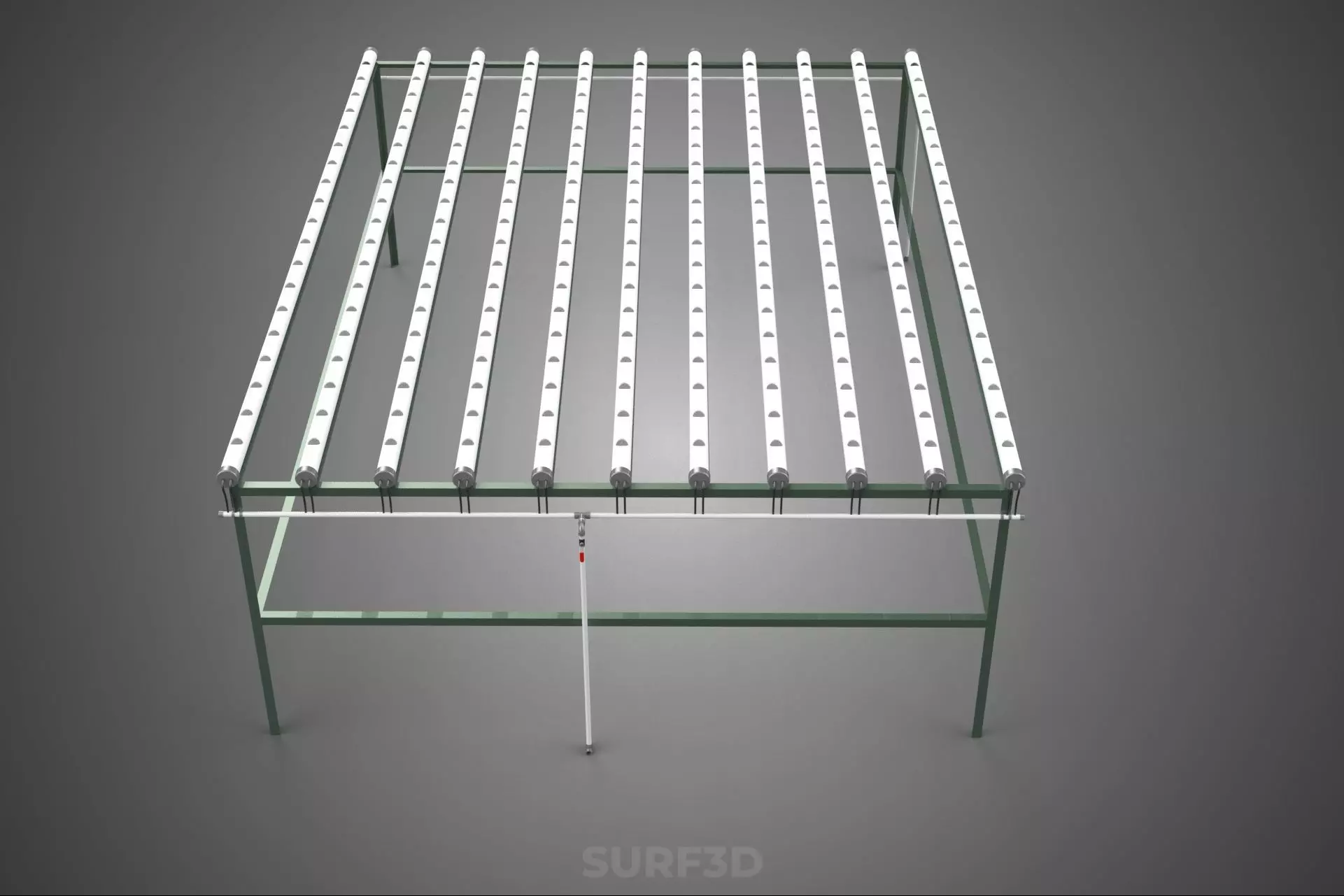

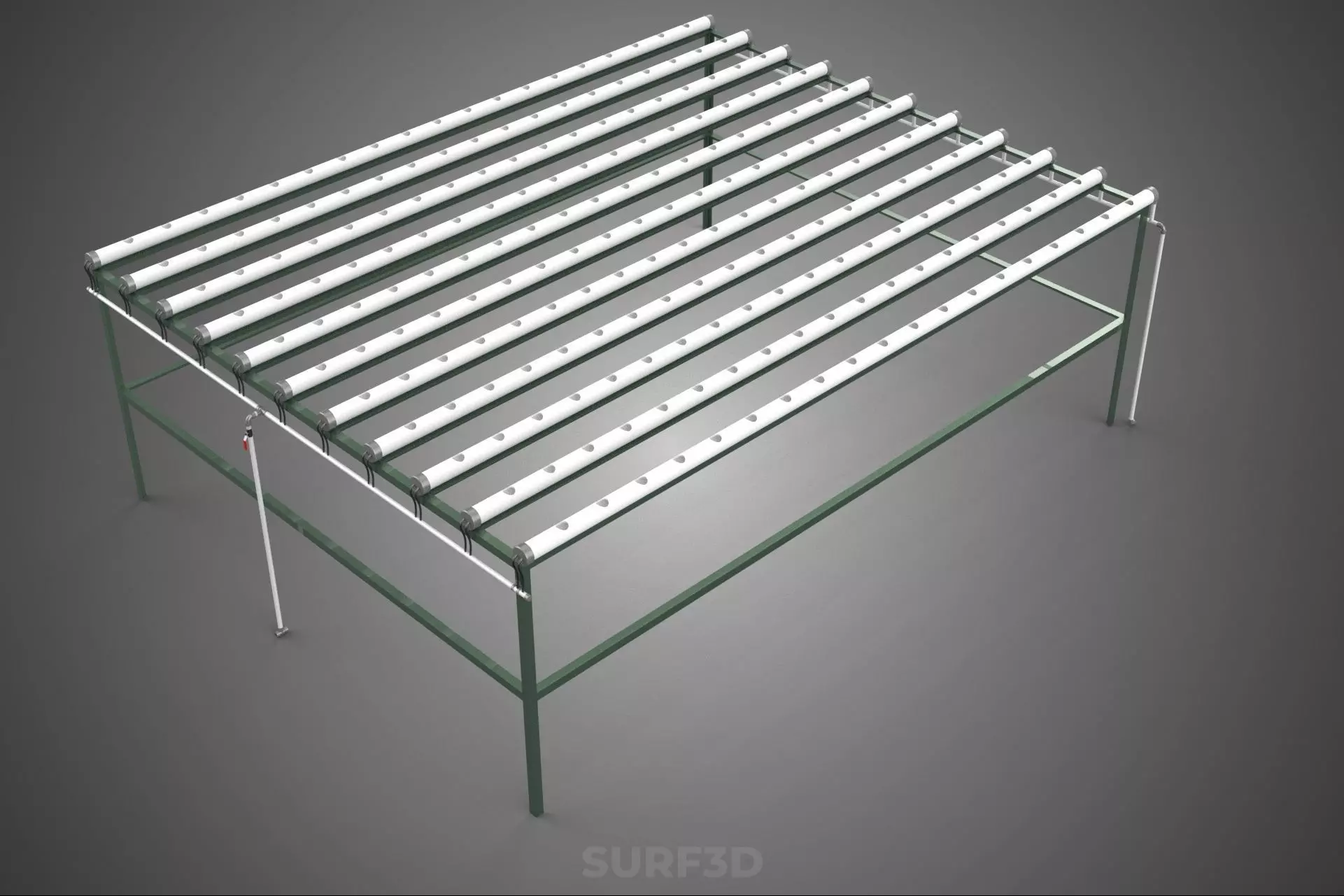

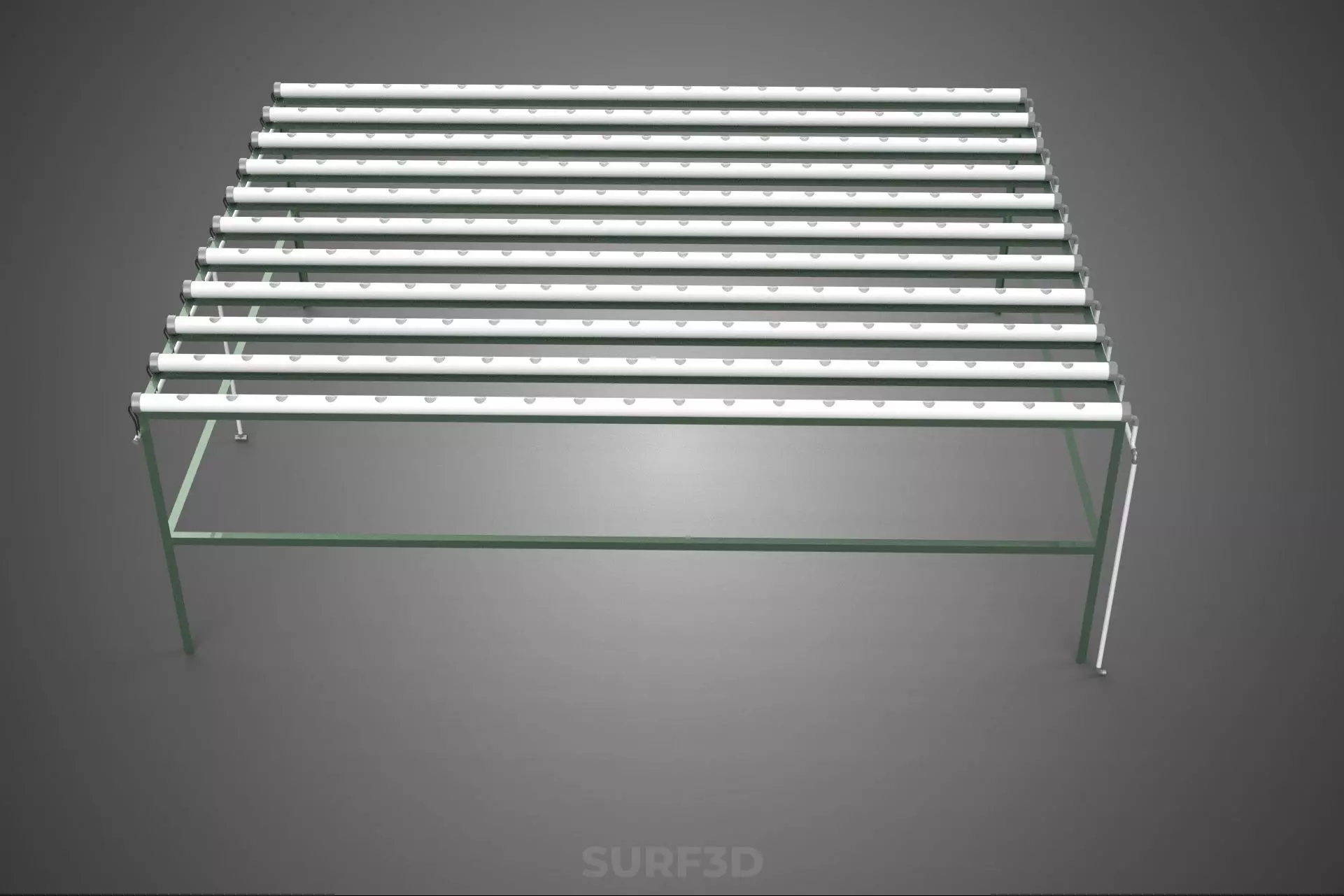

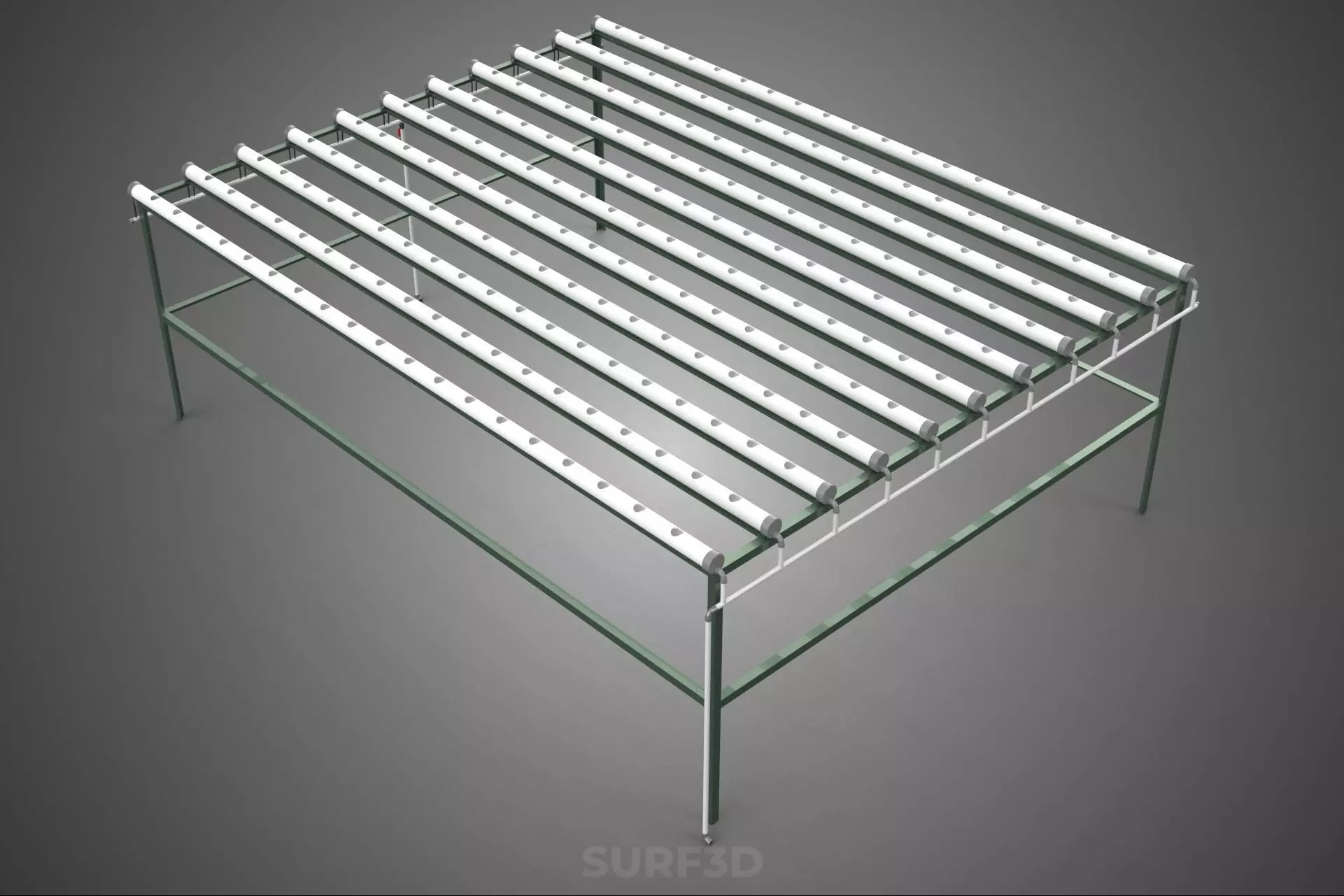

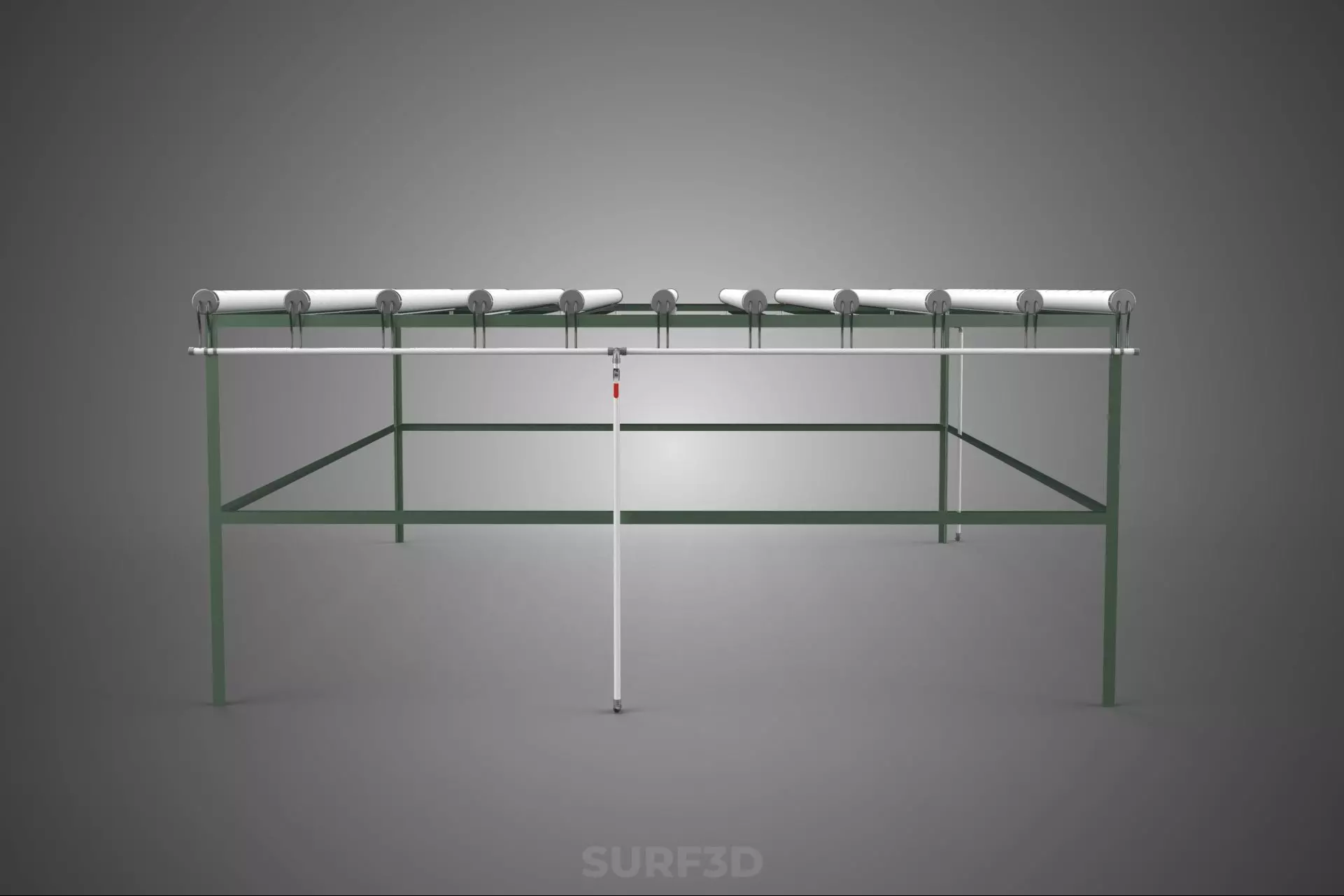

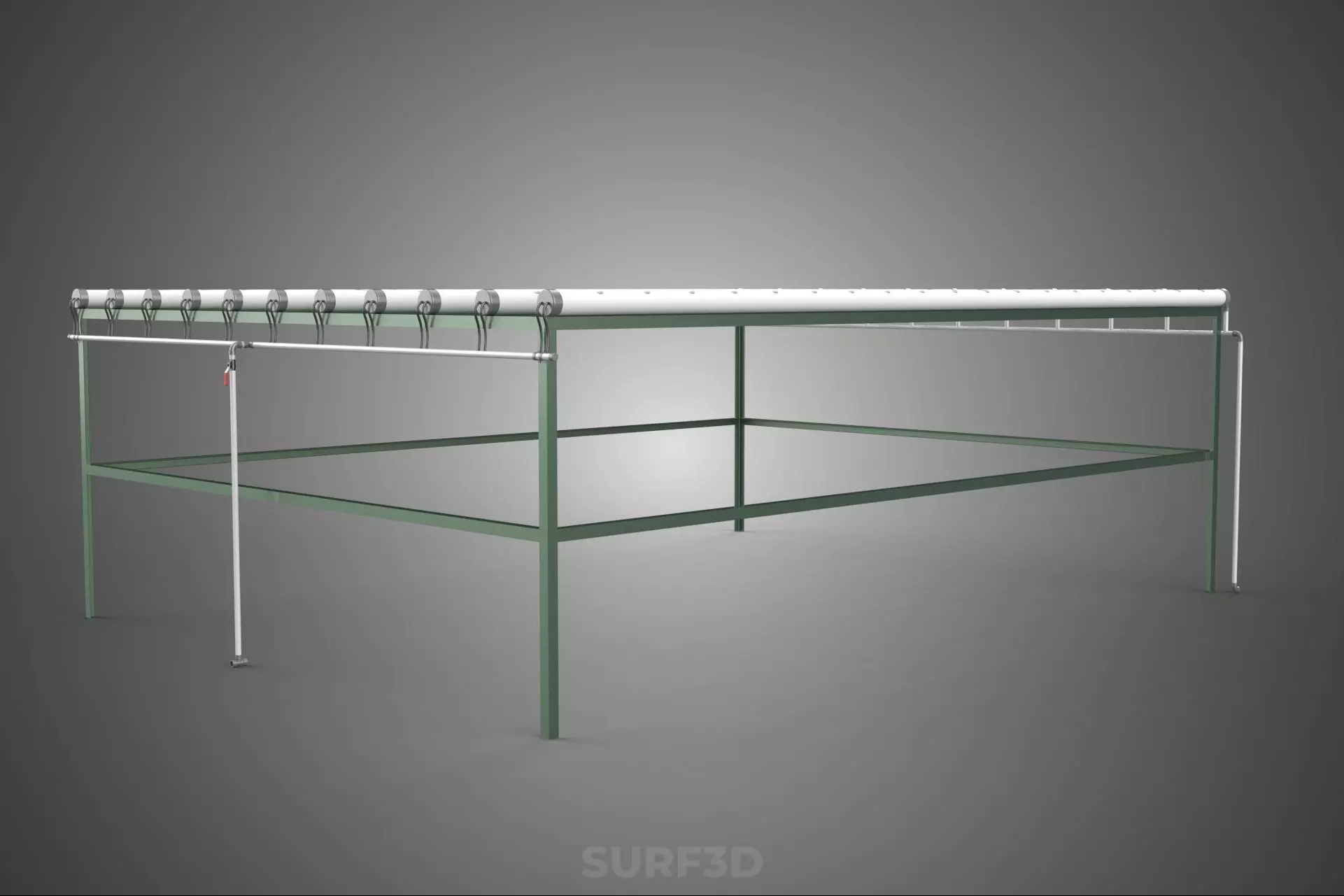

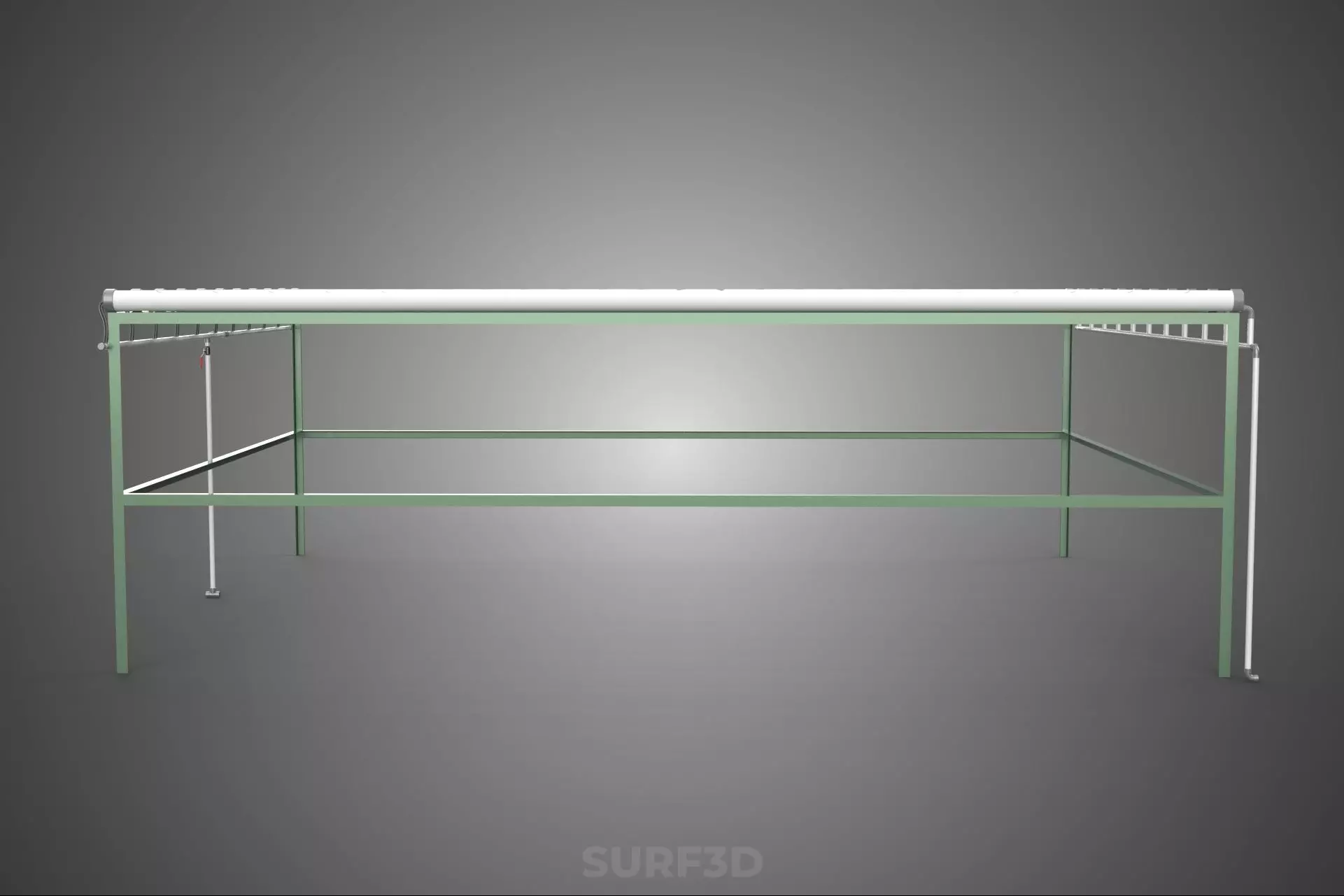

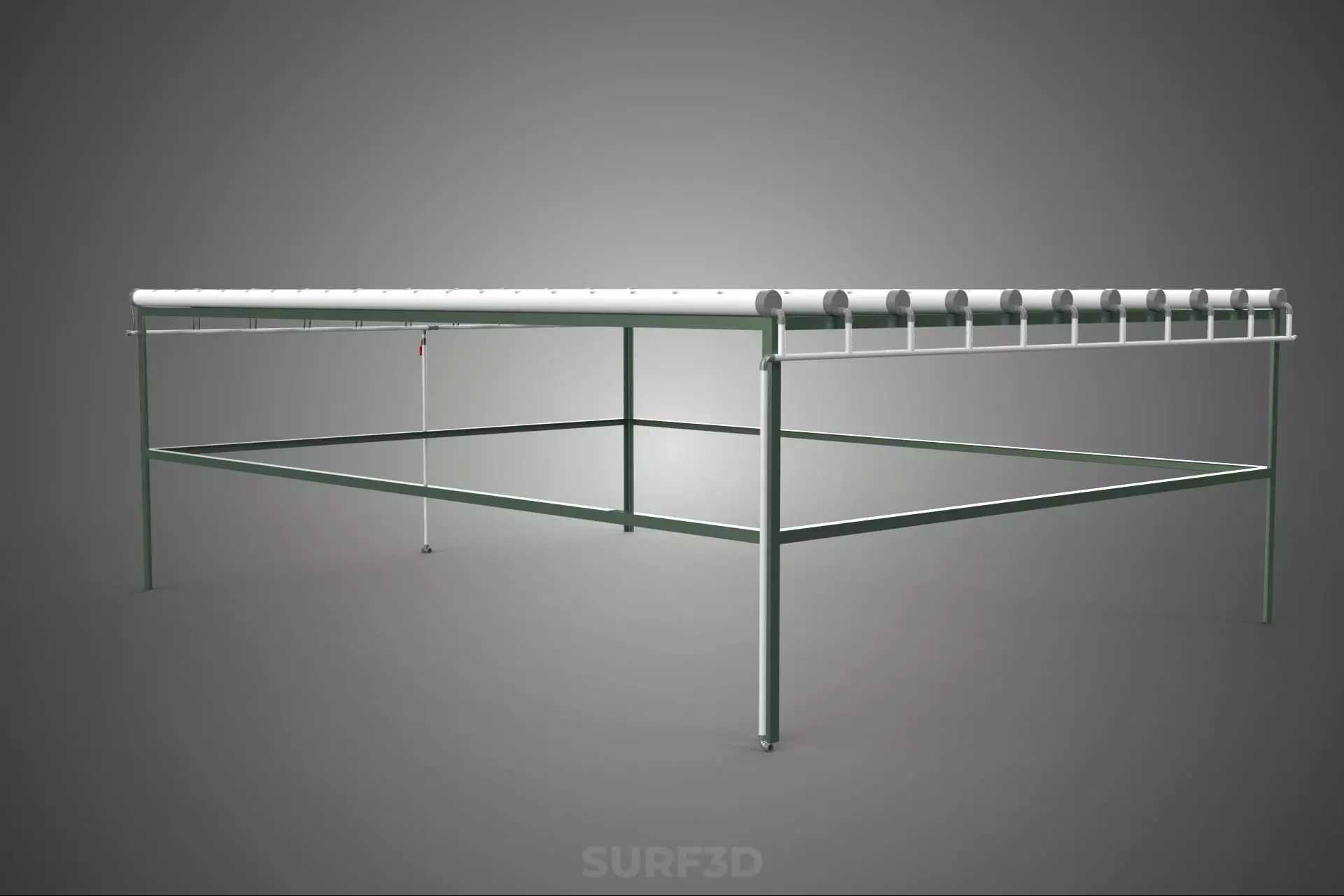

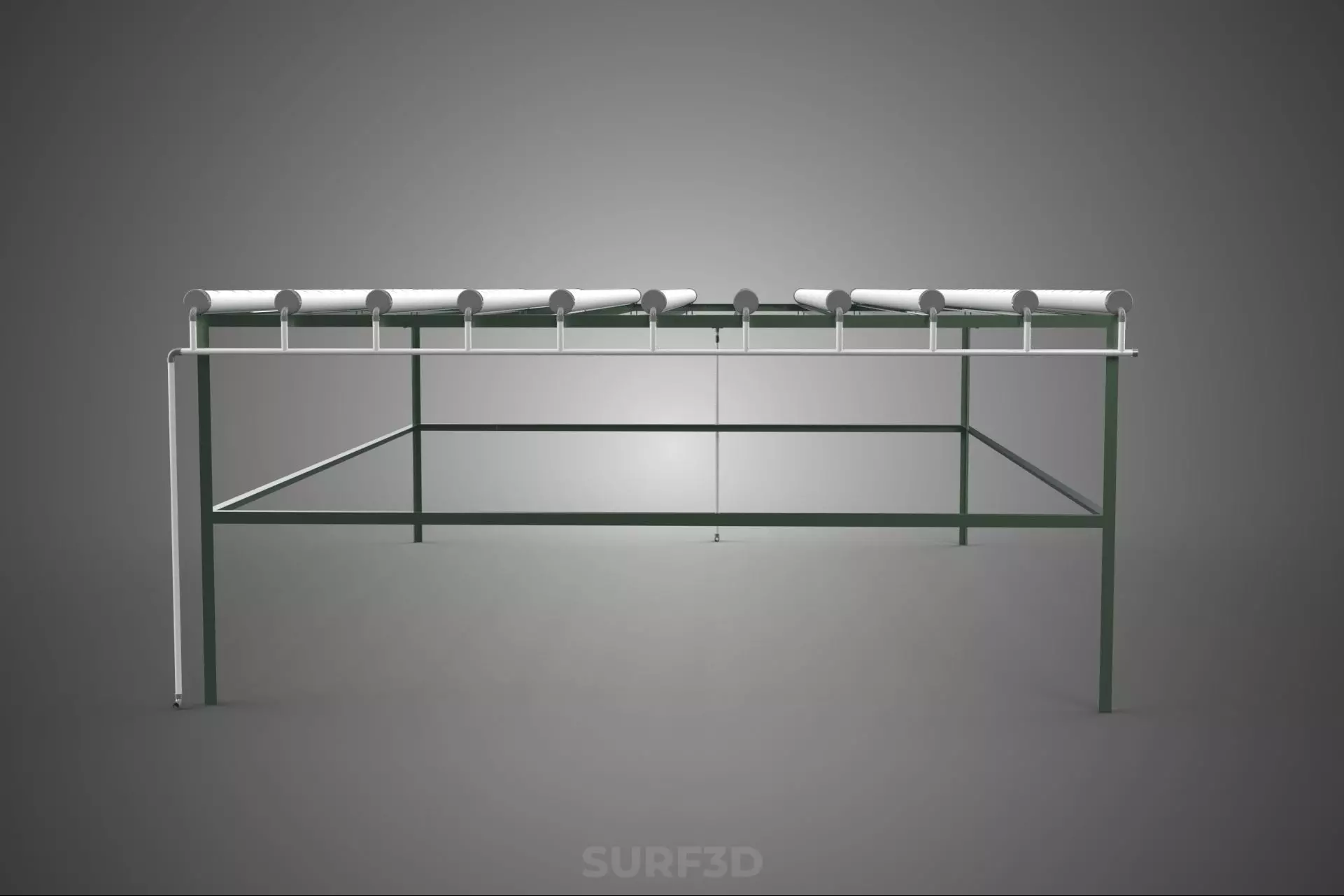

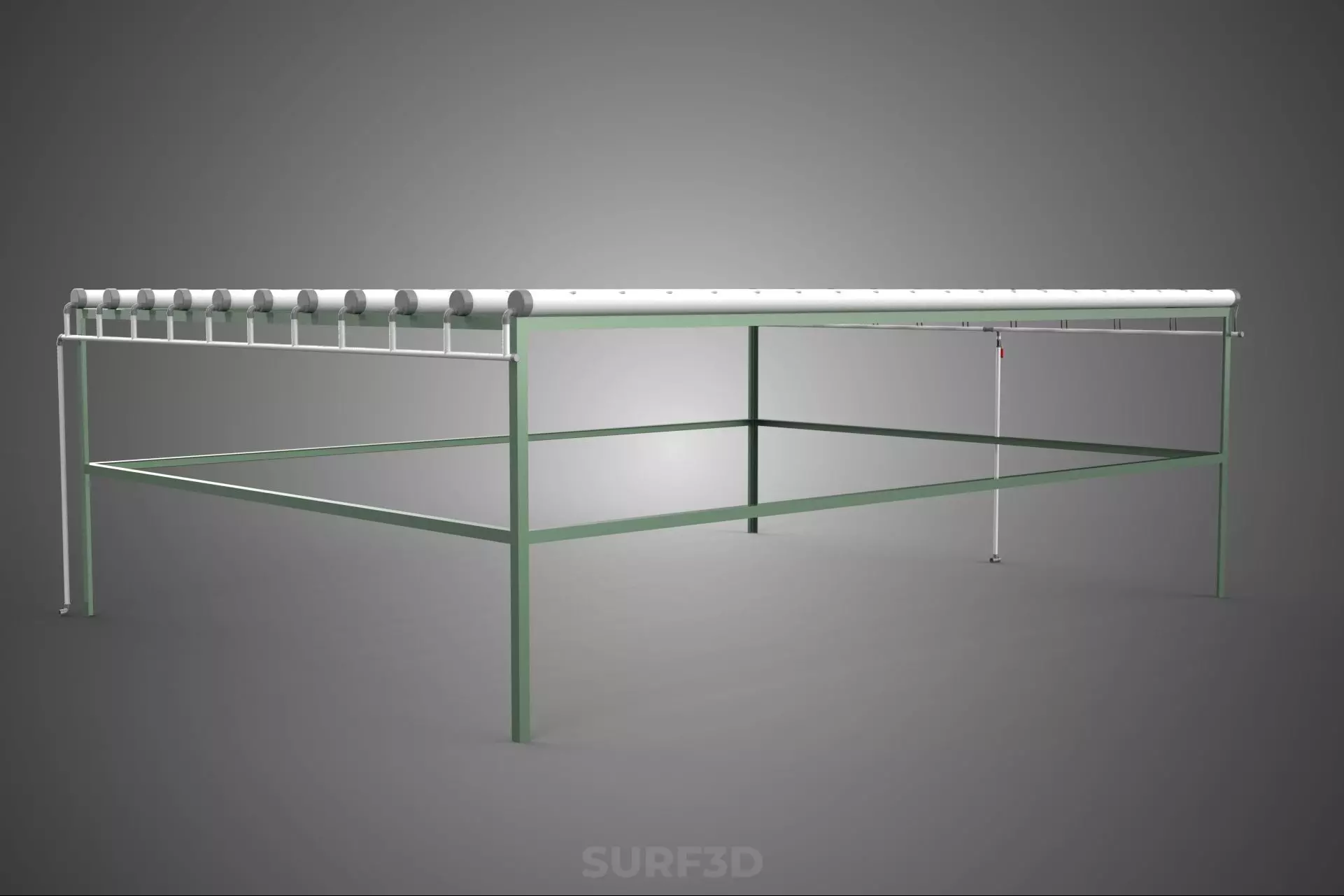

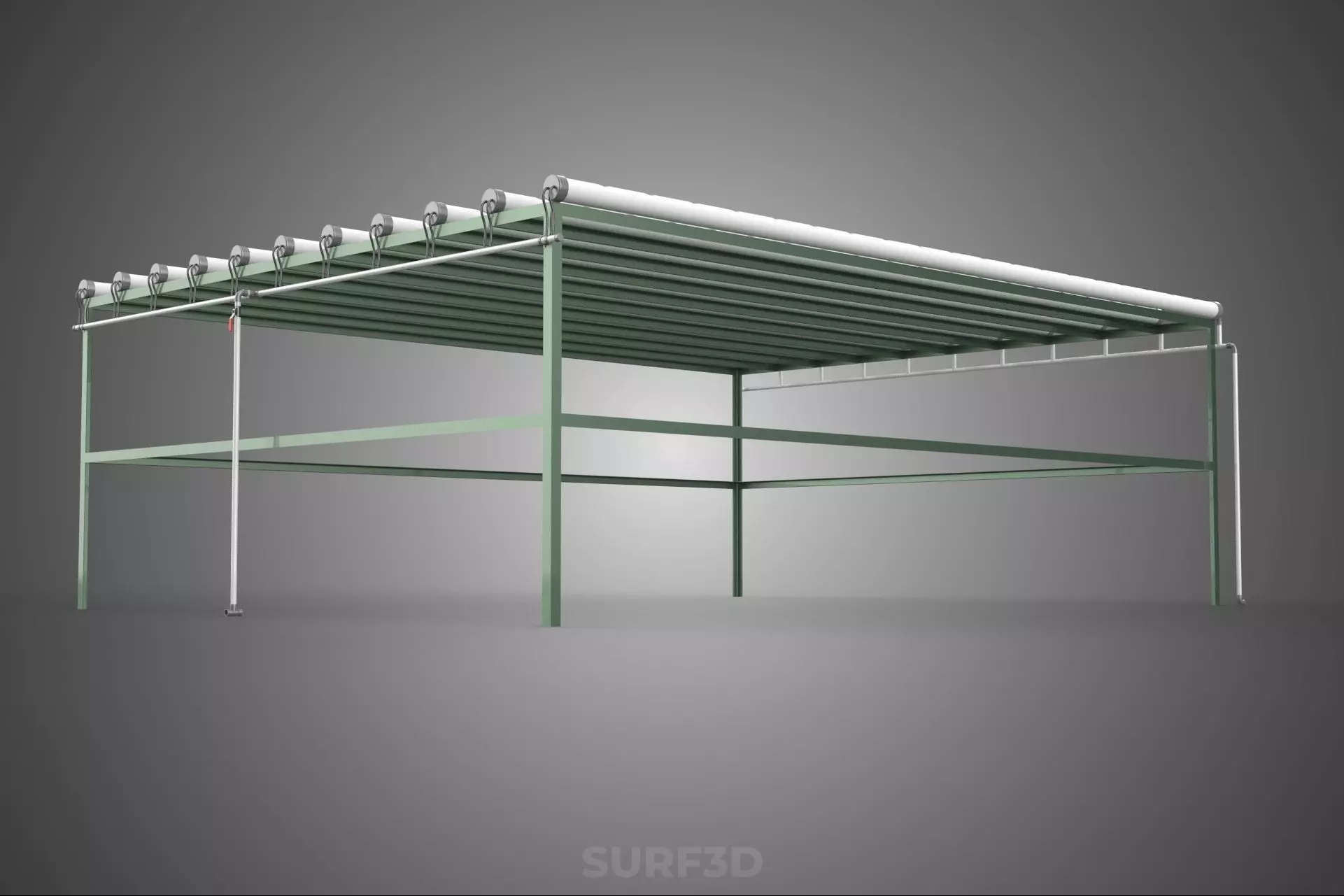

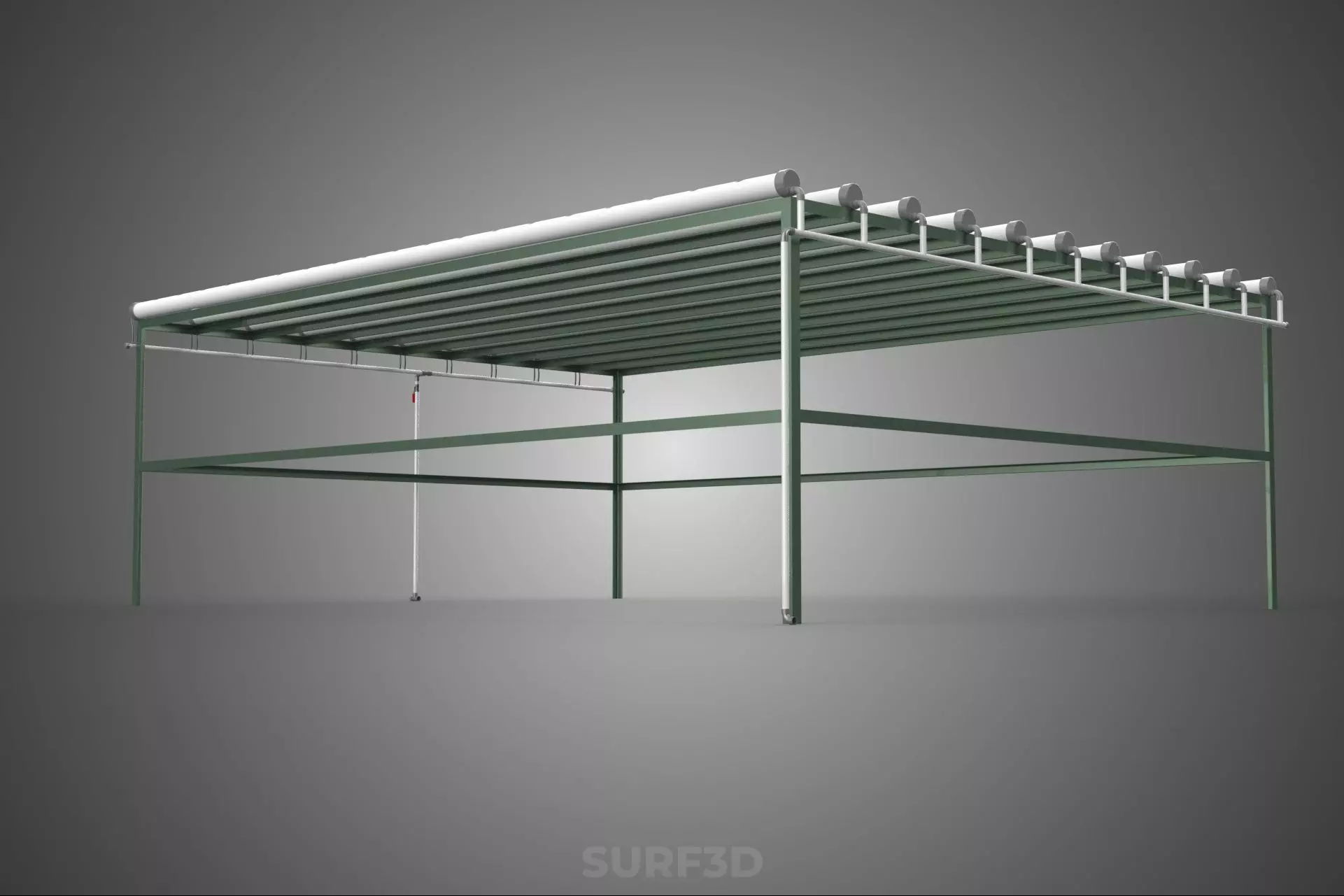

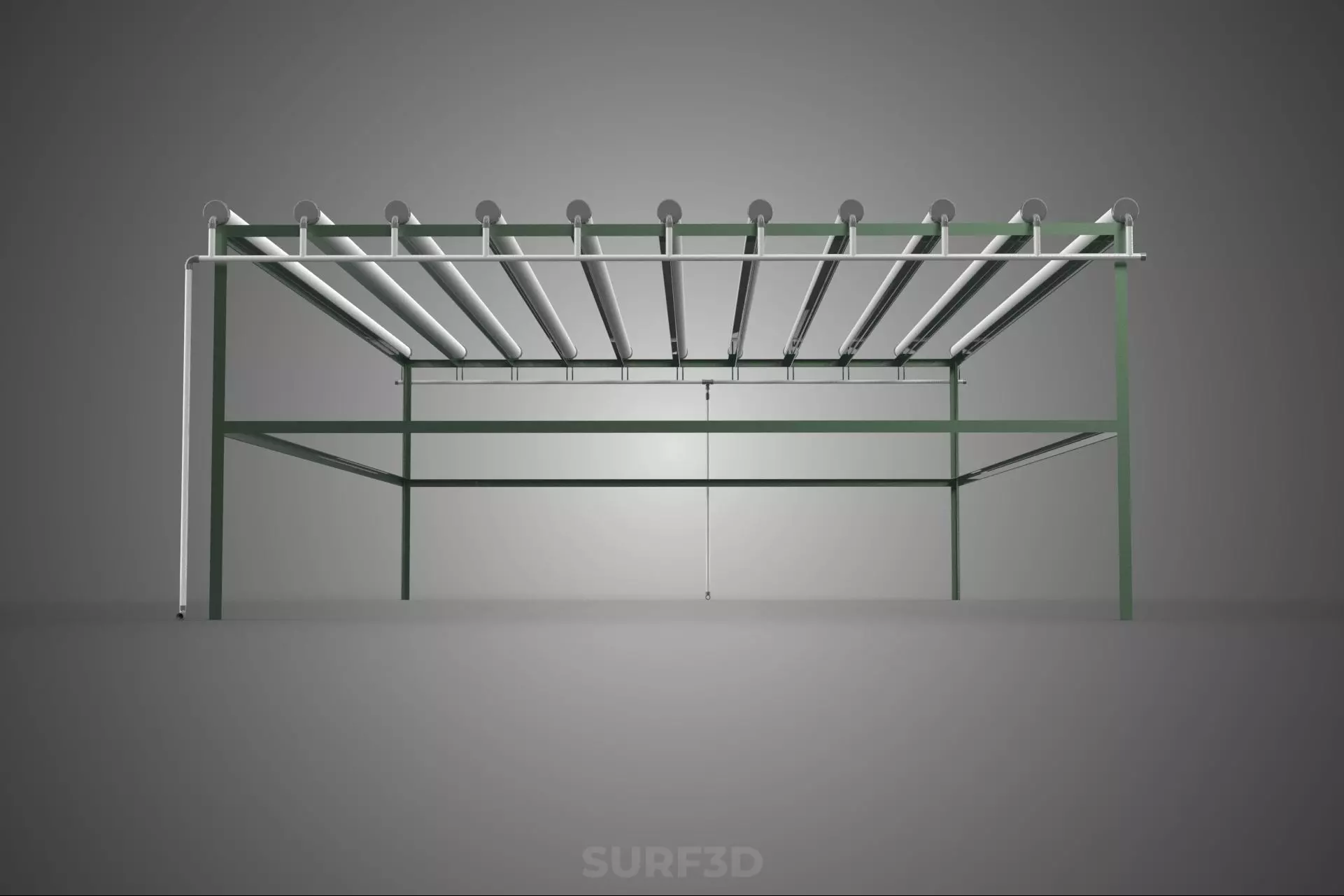

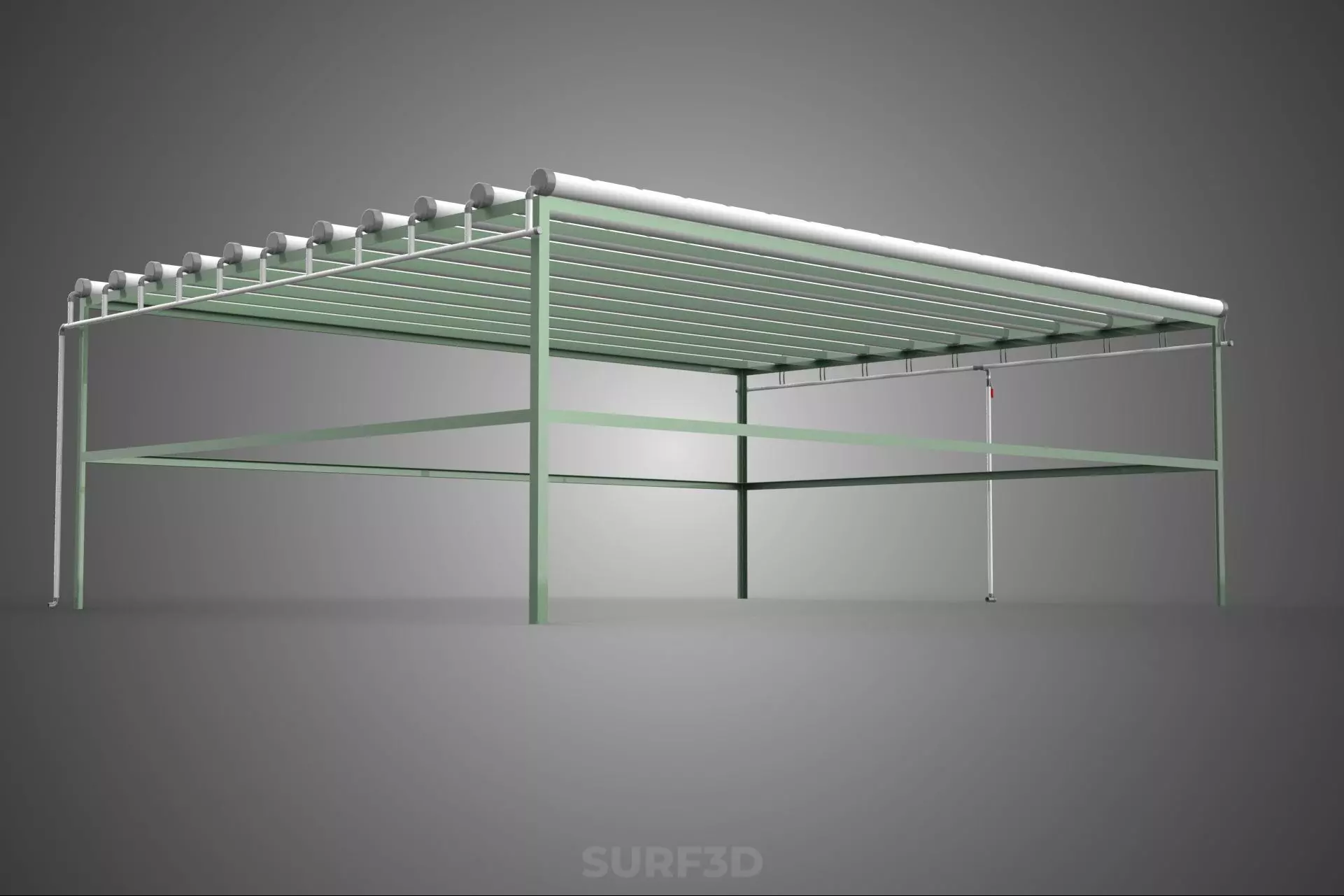

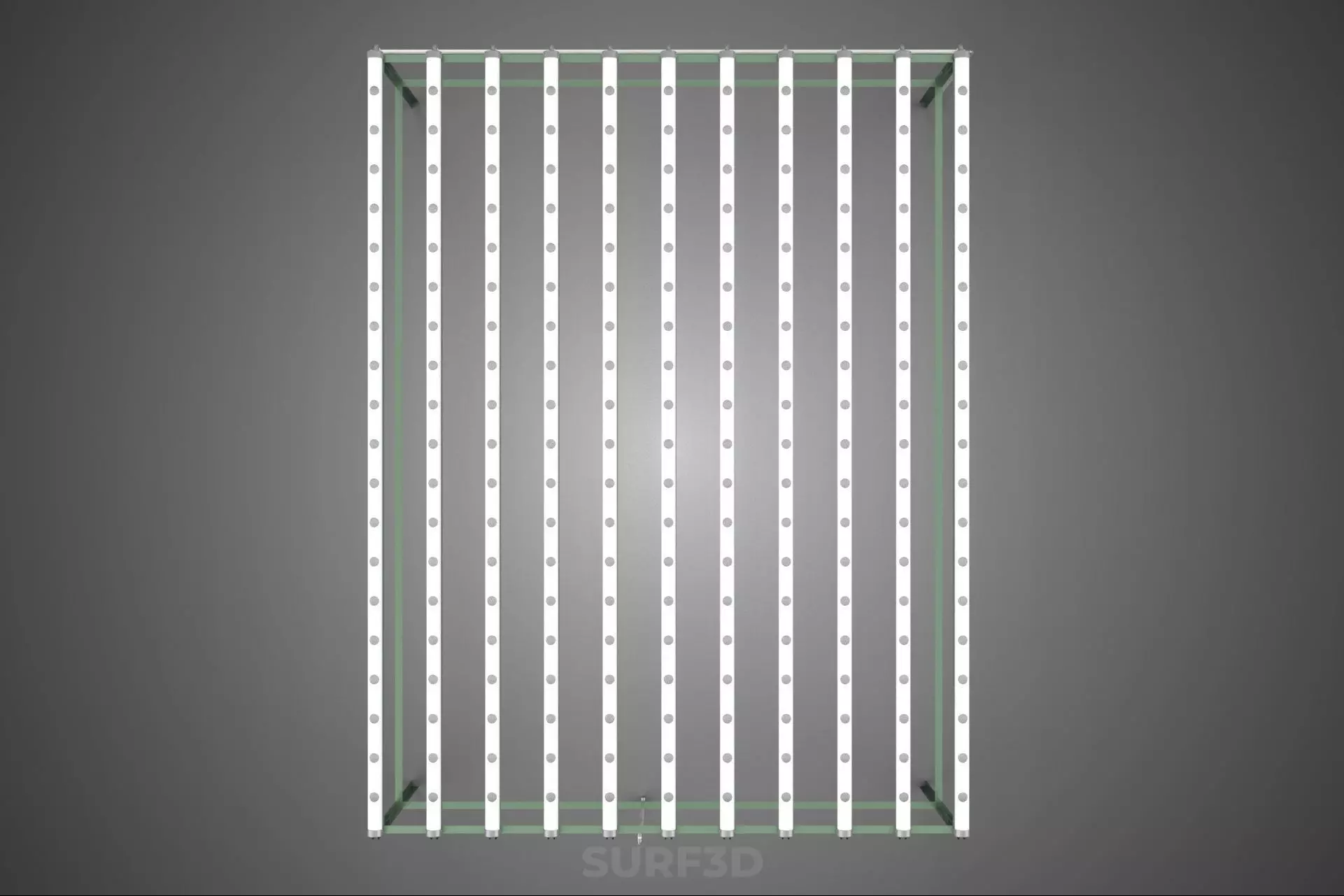

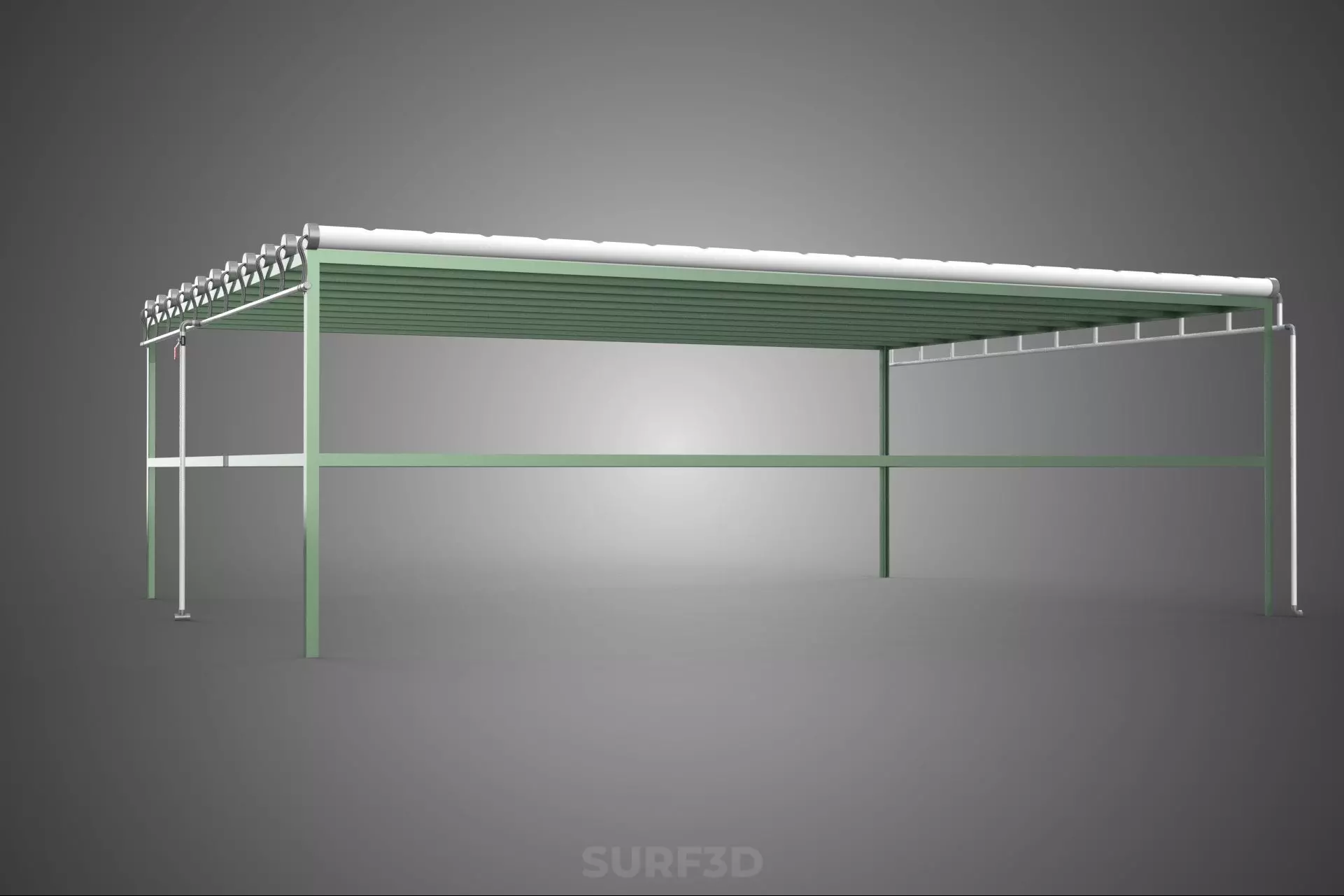

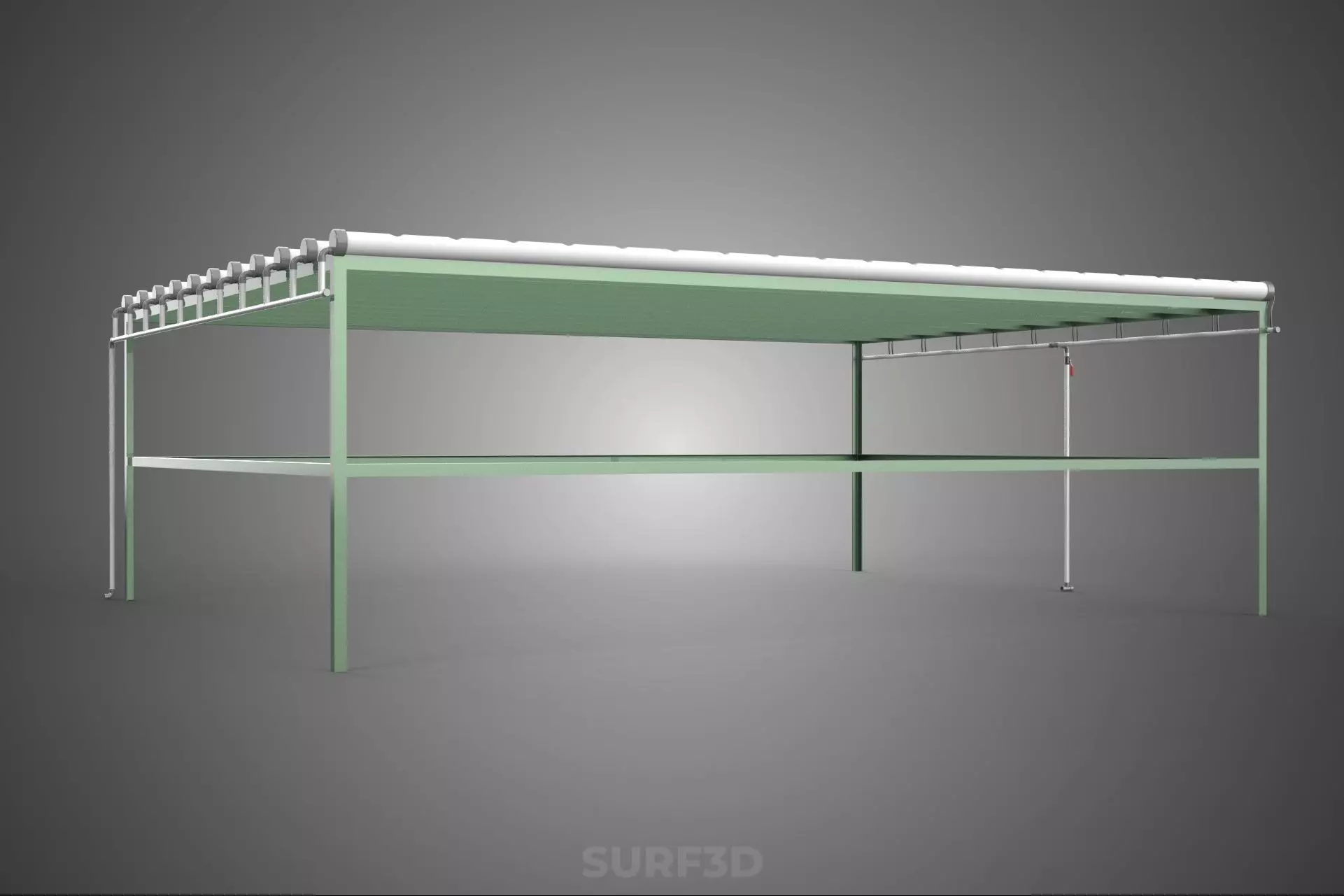

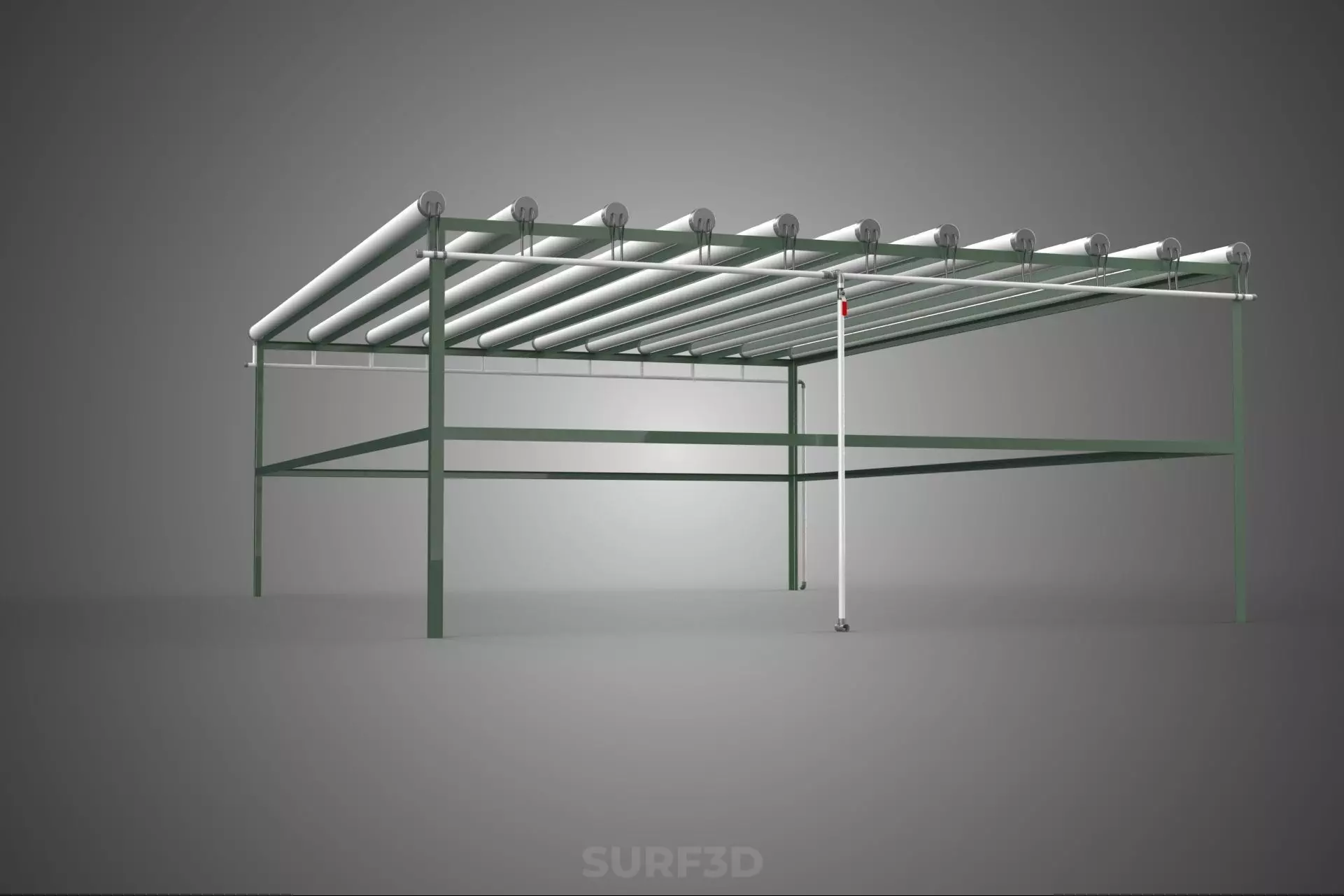

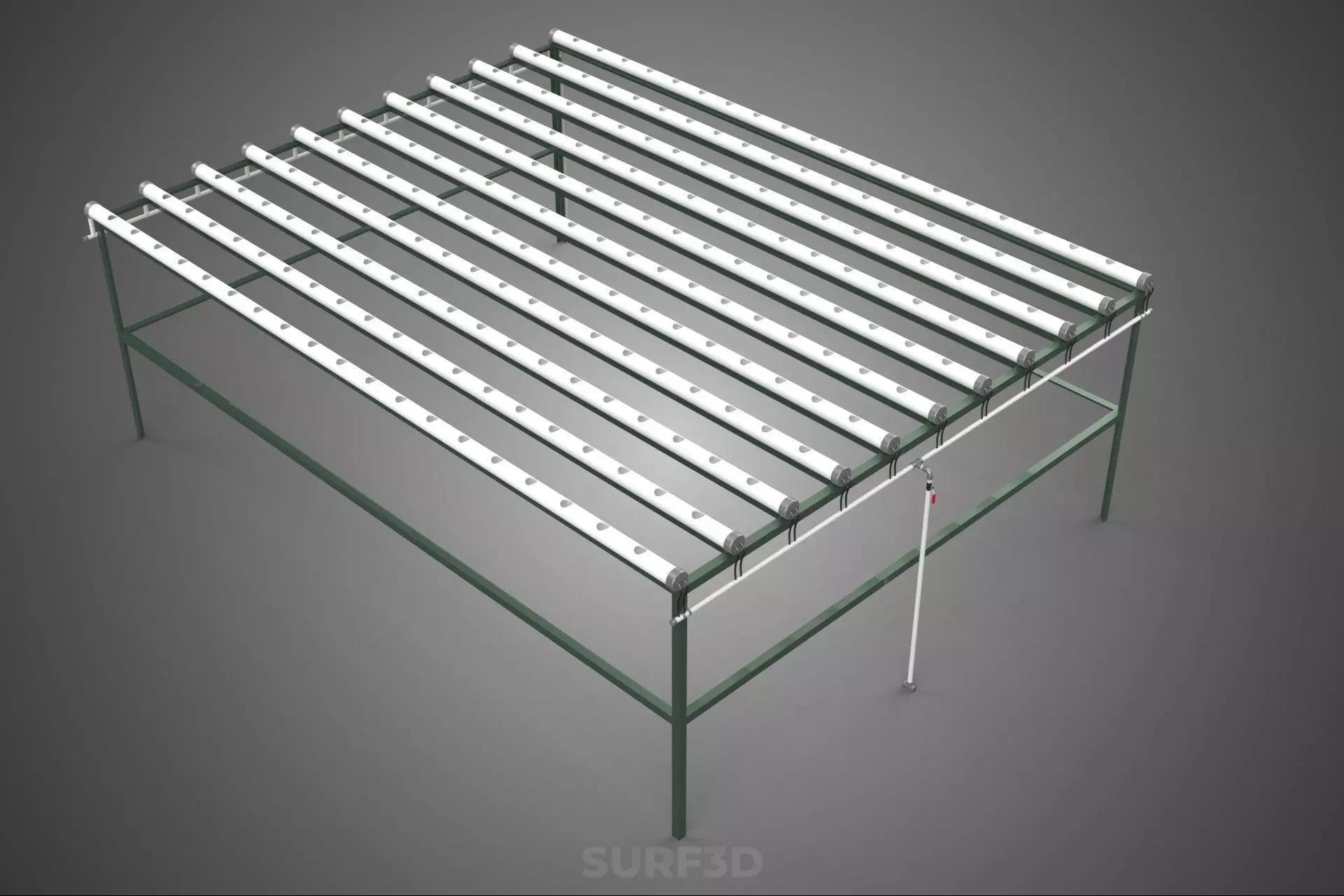

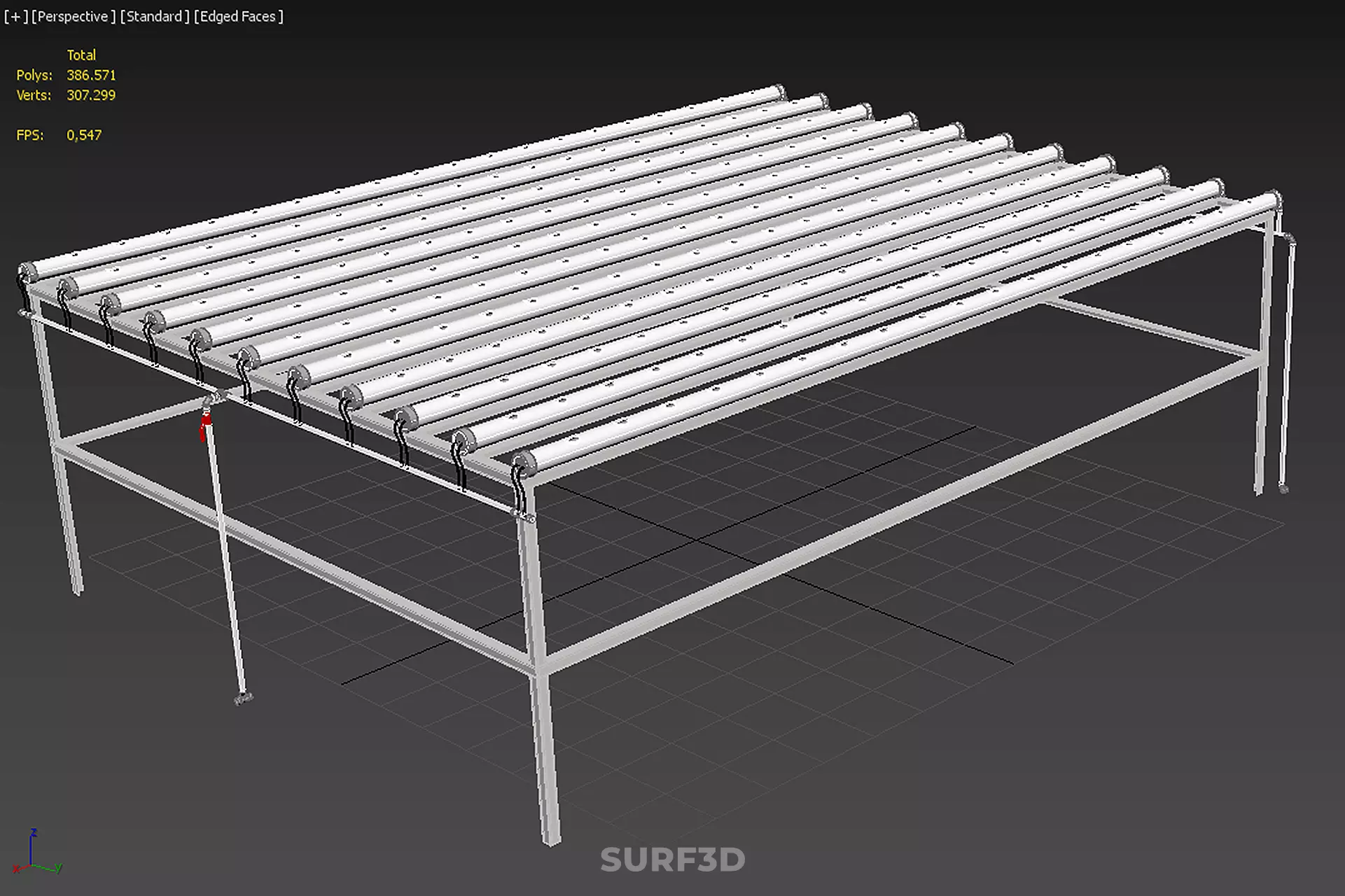

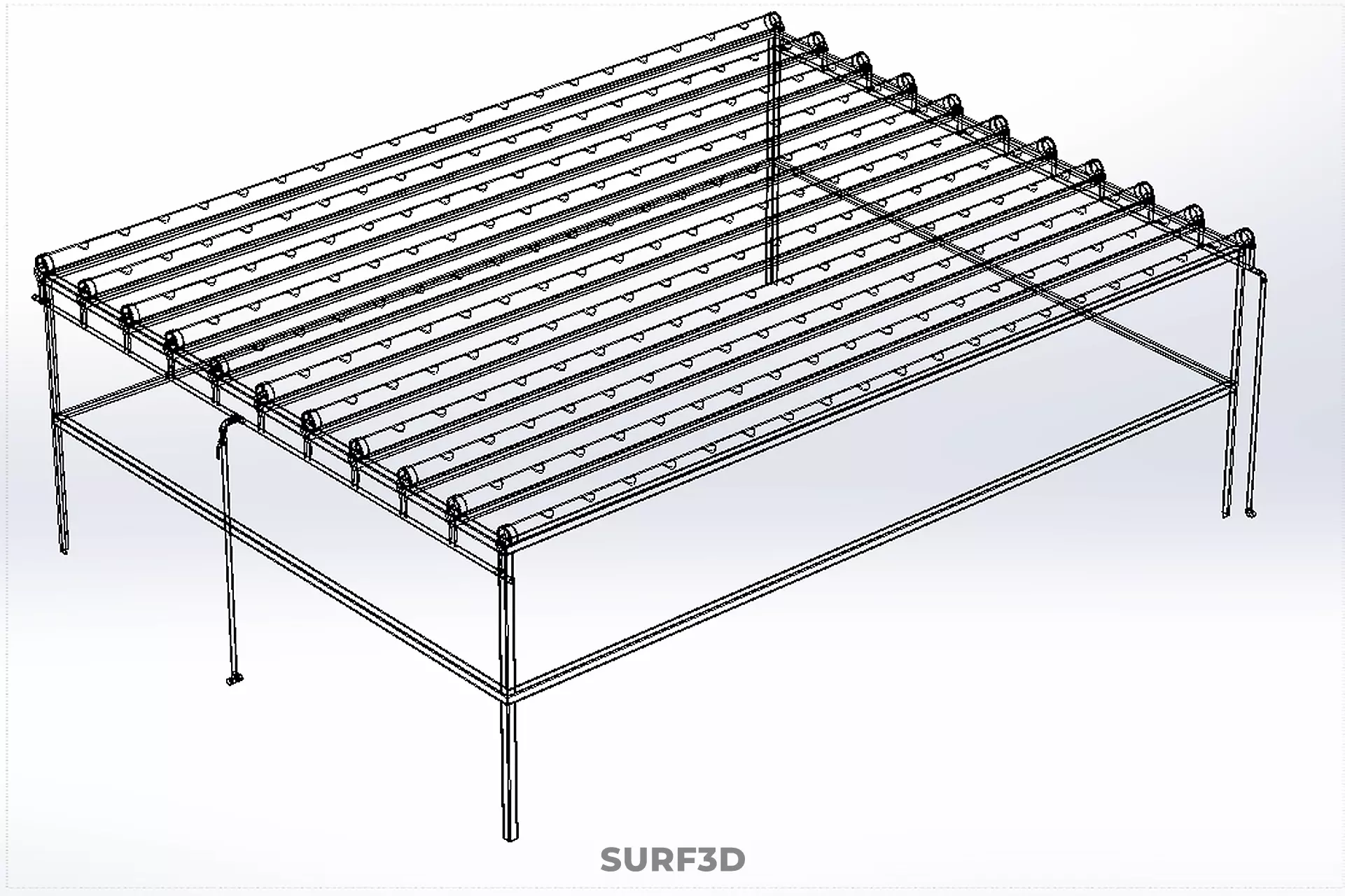

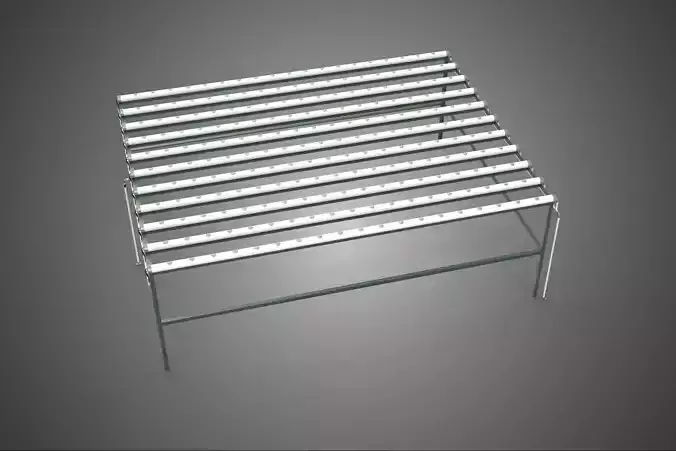

MODULAR HYDROPONIC RACK PARALLEL PVC PIPE DIY GARDEN FARM PLANT 3D model

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

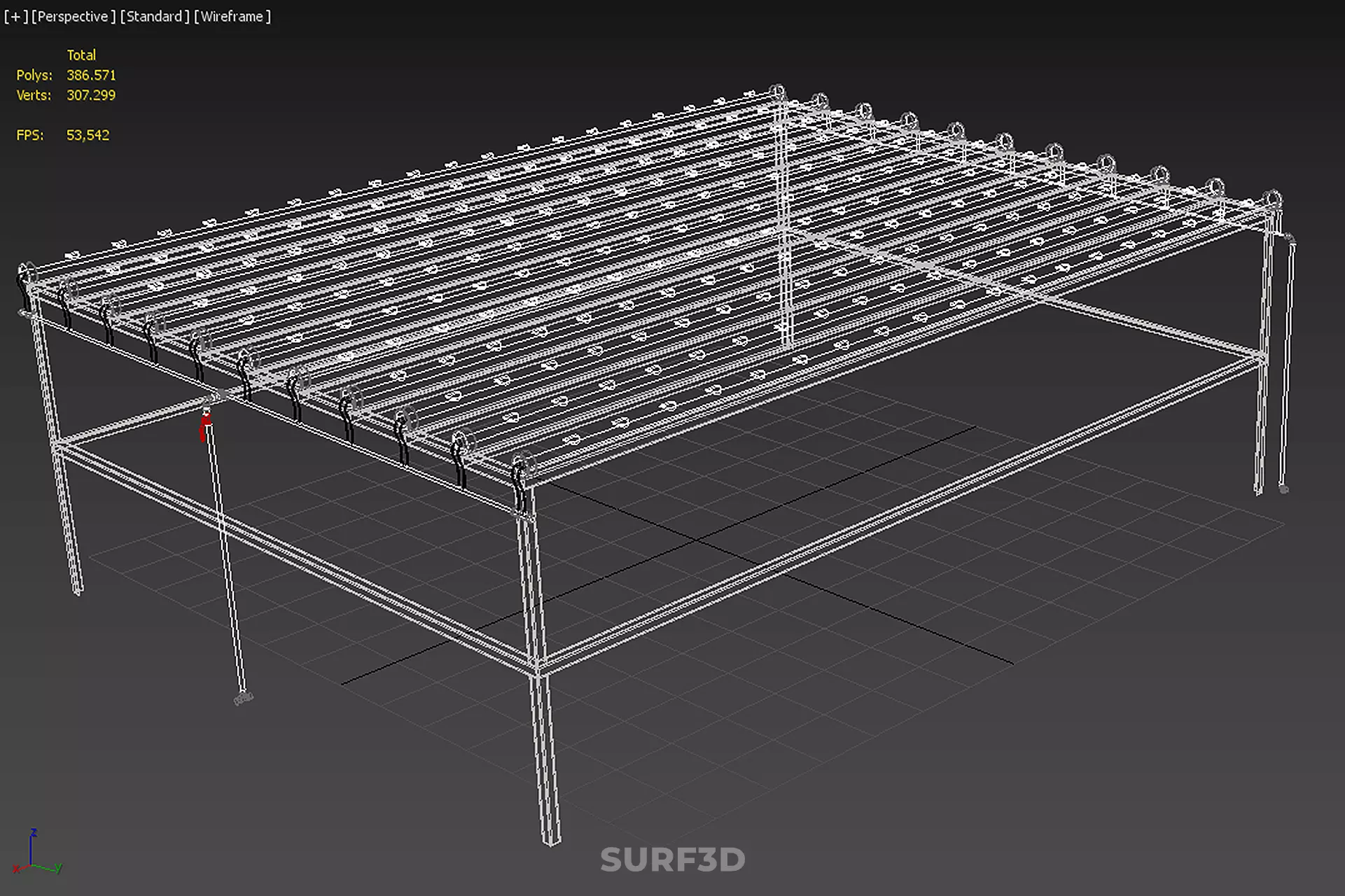

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

A Modular Hydroponic Rack utilizing Parallel PVC Piping is a defined system within Controlled Environment Agriculture (CEA), characterized by its standardized, scalable design and Do-It-Yourself (DIY) construction methodology. This apparatus facilitates the soilless cultivation of various crops, primarily leafy green vegetables, herbs, and small fruits, by circulating a nutrient-rich aqueous solution directly to the plant roots. It represents a common and cost-effective approach to both urban agriculture and small-to-medium scale farming operations.

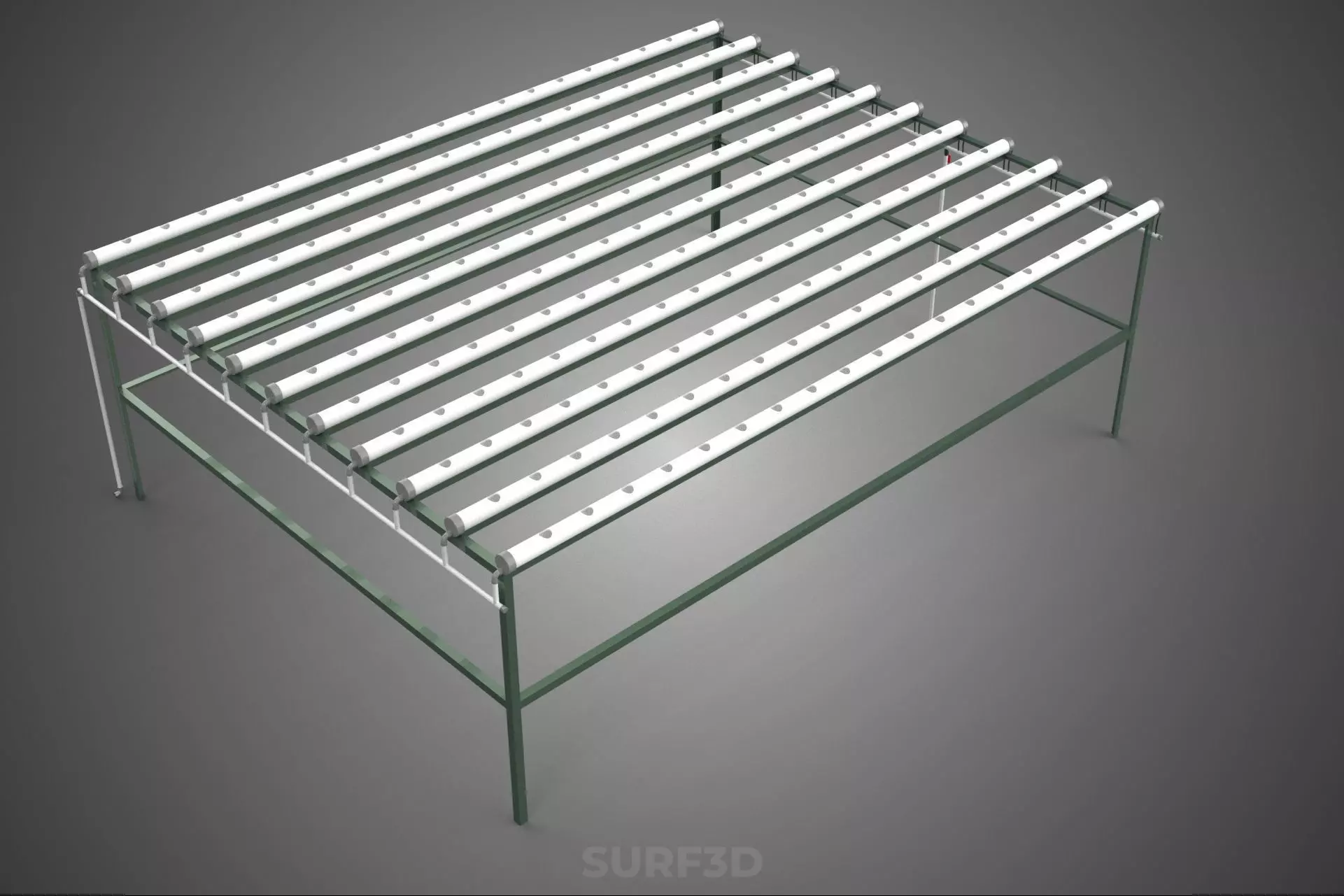

The fundamental structure is a rigid rack, often constructed from lightweight, corrosion-resistant materials, predominantly Polyvinyl Chloride (PVC) piping and fittings (typically Schedule 40 or thinner drainage variants). PVC is selected for its chemical inertness, durability, low cost, and ease of cutting and assembly, allowing non-specialized users to fabricate the system using standard tools.

The rack geometry typically involves an inclined or vertical framework designed to maximize space efficiency, often adopting A-Frame, vertical stack, or tiered horizontal configurations. The critical functional elements are the parallel PVC pipes, which are positioned horizontally or at a slight incline (1:40 to 1:60 slope) to utilize gravitational flow. These parallel channels serve as the primary cultivation conduits.

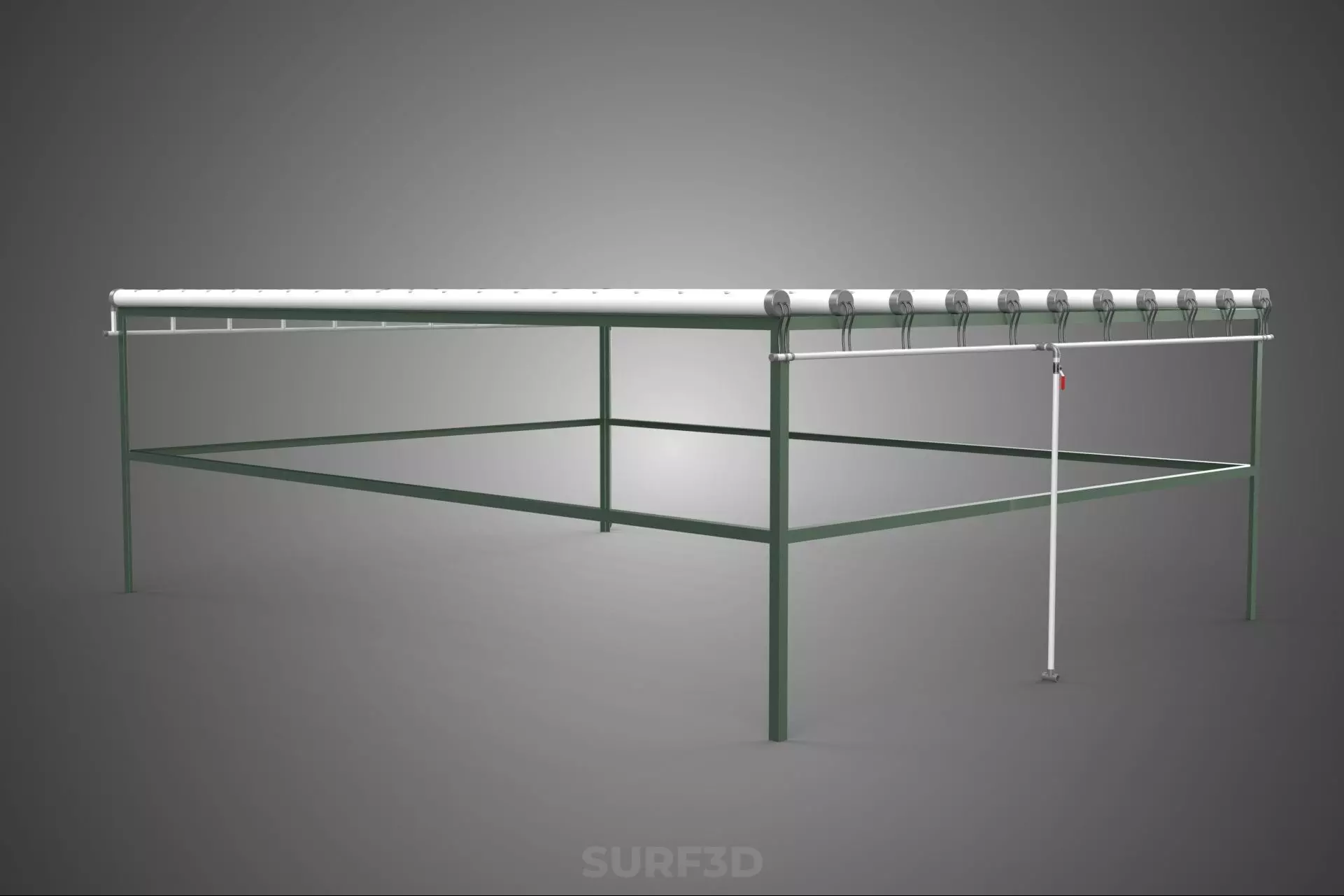

Plant stations are created by drilling evenly spaced apertures along the upper surface of the pipes. These holes are sized to accommodate net pots, rockwool cubes, or other media supports, ensuring the roots are suspended within the internal pipe volume. The parallel arrangement ensures that all growing channels receive uniform flow from a central distribution manifold, which is supplied by a submersible pump located in a primary nutrient reservoir.

The parallel PVC pipe rack is versatile but is most commonly implemented using recirculating hydroponic techniques:

- Nutrient Film Technique (NFT): This is the most frequent application. A thin layer (or film) of the nutrient solution flows continuously along the base of the parallel channels. This shallow flow ensures that the roots are adequately saturated with water and dissolved minerals while maintaining sufficient access to atmospheric oxygen, crucial for preventing hypoxia and root rot.

- Deep Flow Technique (DFT) / Raft Culture (Modified): Less common in small-diameter PVC systems, this method involves maintaining a deeper level of solution within the pipe channels. While less dependent on precise pipe slope, it requires greater attention to aeration within the reservoir or the channels themselves.

The system operates as a closed loop. The nutrient solution is cycled from the reservoir, pumped to the highest point of the rack, travels through the parallel cultivation channels via gravity, and is collected by a return manifold, draining back into the reservoir for re-use and replenishment. This methodology significantly enhances water use efficiency compared to conventional soil-based agriculture.

### Modularity and Scalability

The defining characteristic of this system is its modularity. Individual rack sections or bays are designed as standardized, interchangeable units. This allows the user to easily expand the system horizontally or vertically by adding pre-fabricated units without requiring a complete system overhaul. Furthermore, individual parallel pipes can be isolated or removed for maintenance, crop harvesting, or disease management, contributing to overall system resilience and operational flexibility. The DIY construction model fosters customization to fit unique architectural constraints, such as small greenhouse footprints, basements, or urban rooftops.

KEYWORDS: Hydroponics, Modular, PVC, DIY, NFT, DFT, Soilless culture, Parallel channels, Recirculating system, Urban agriculture, Vertical farming, CEA, Pipe rack, Scalability, Water efficiency, Crop production, Home gardening, Greenhouse technology, Nutrient solution, Cost-effective, PVC piping, Closed-loop, A-Frame, Net pots, Horticulture, Plant cultivation, Drainage, Reservoir, Aeration, Standardization