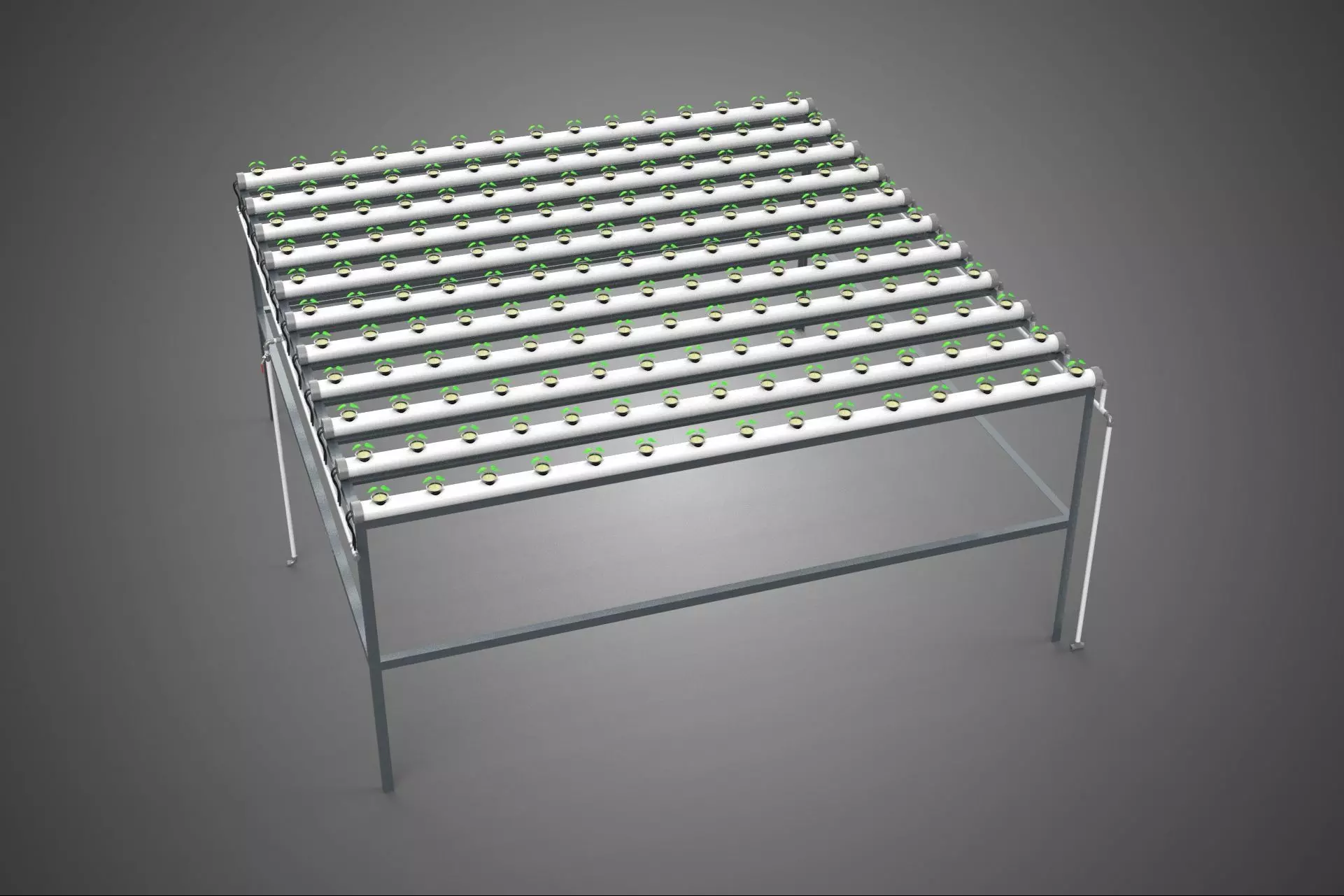

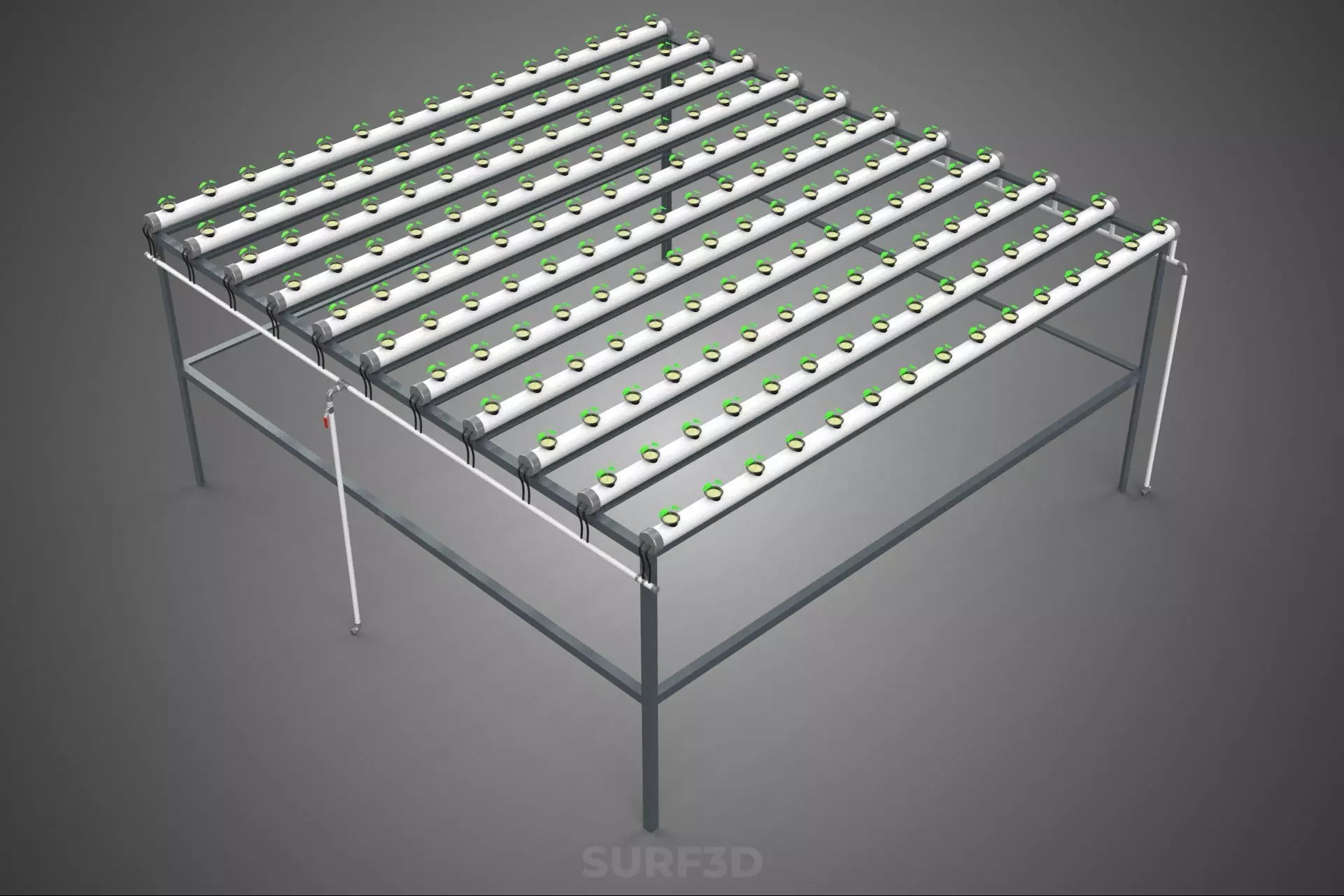

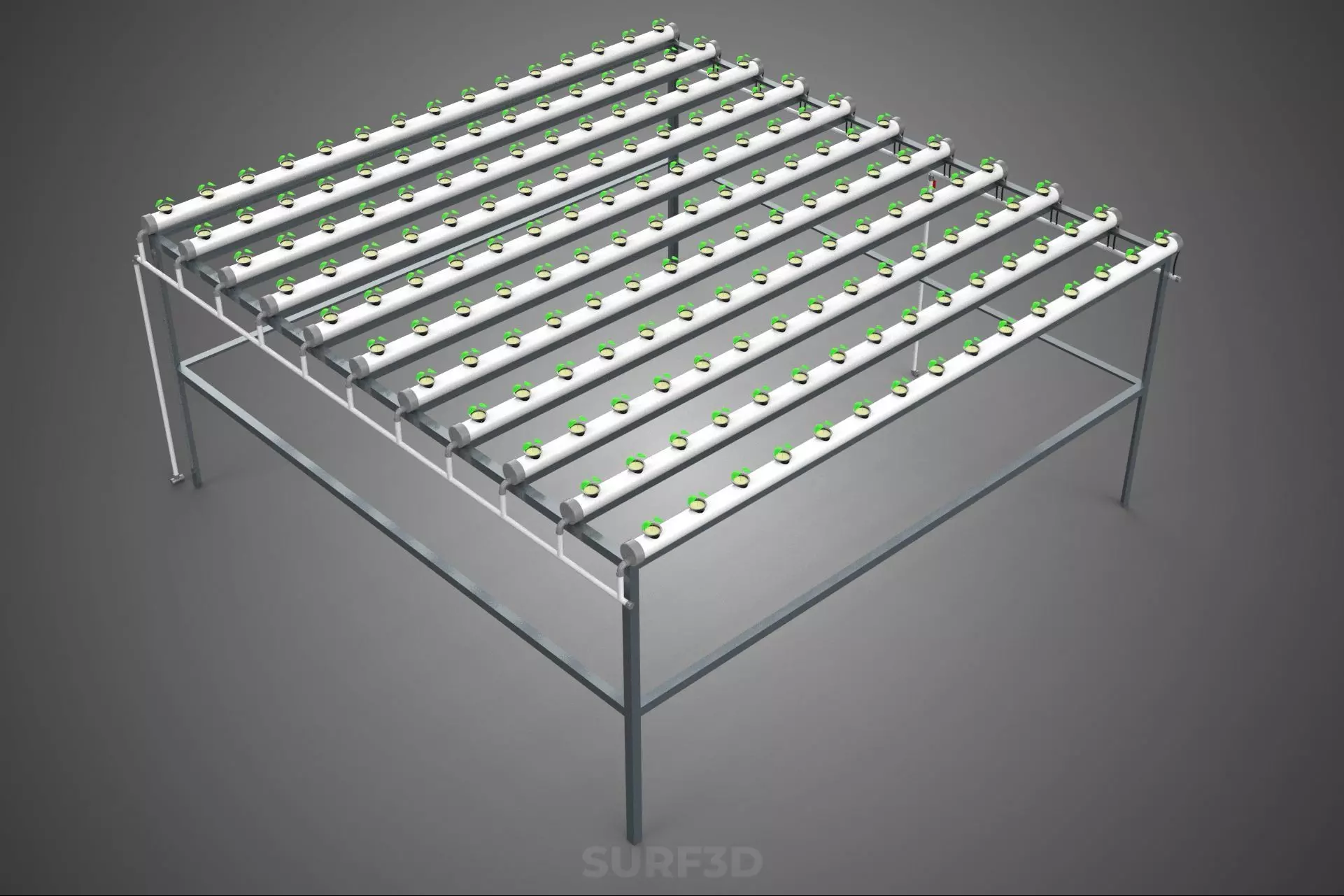

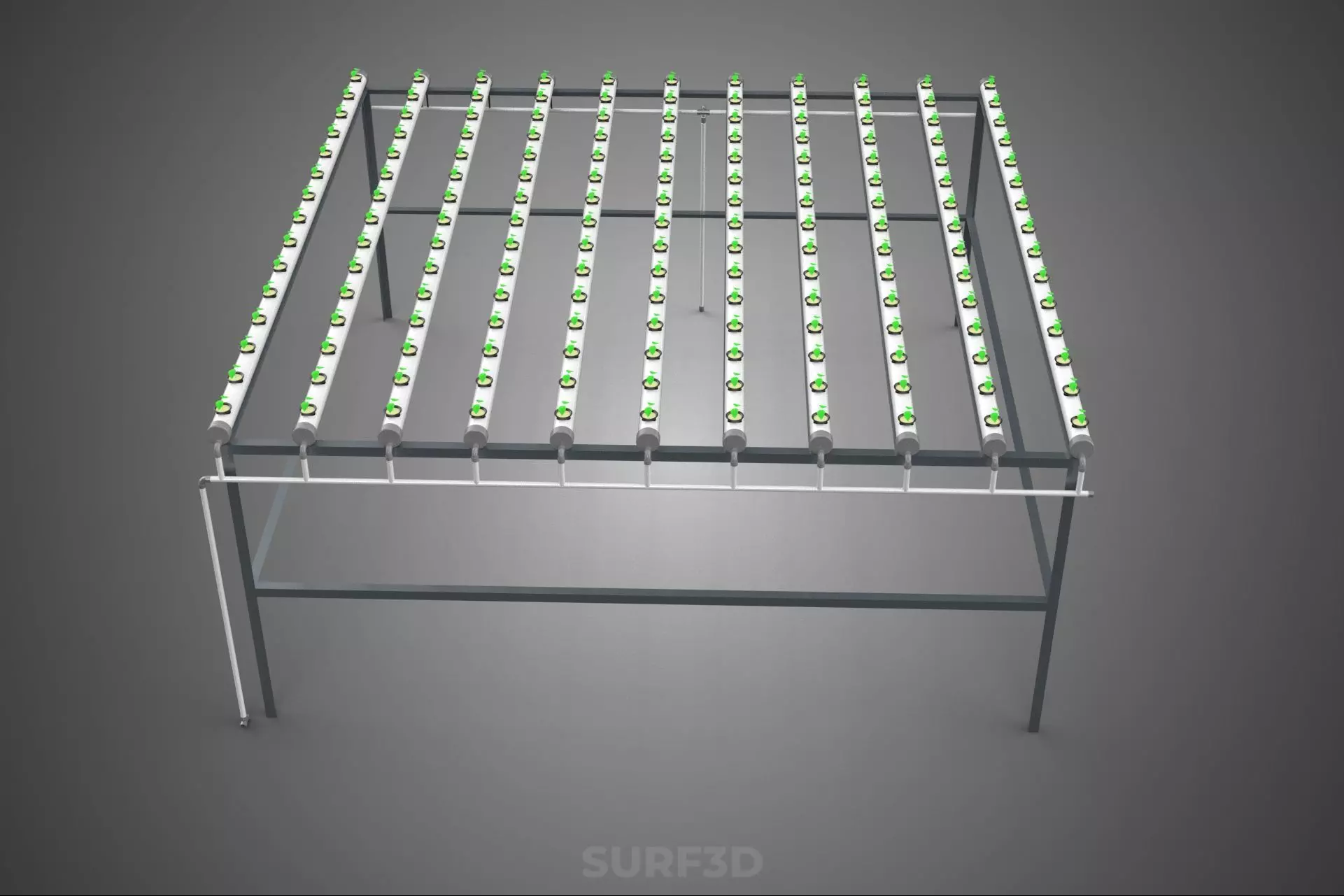

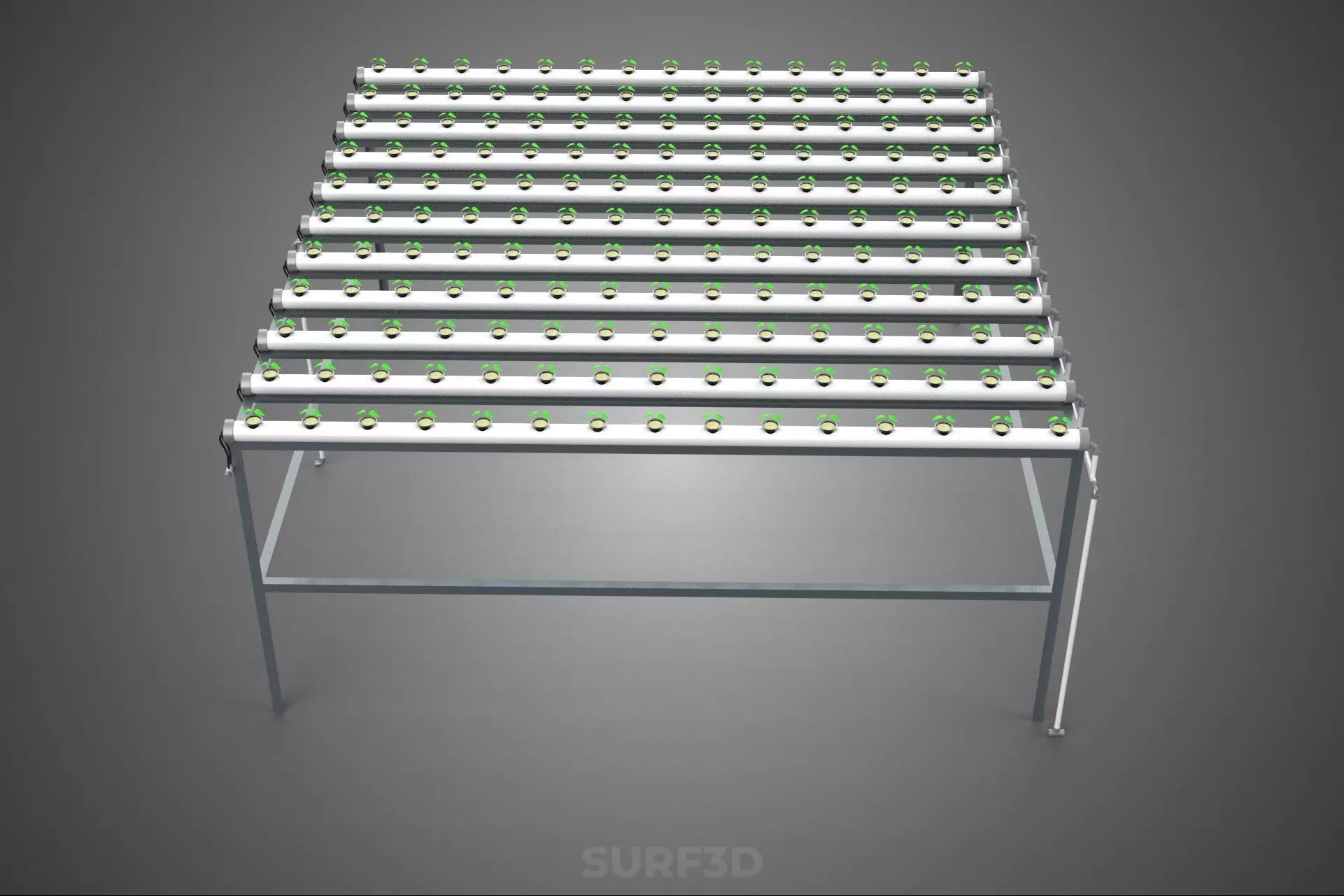

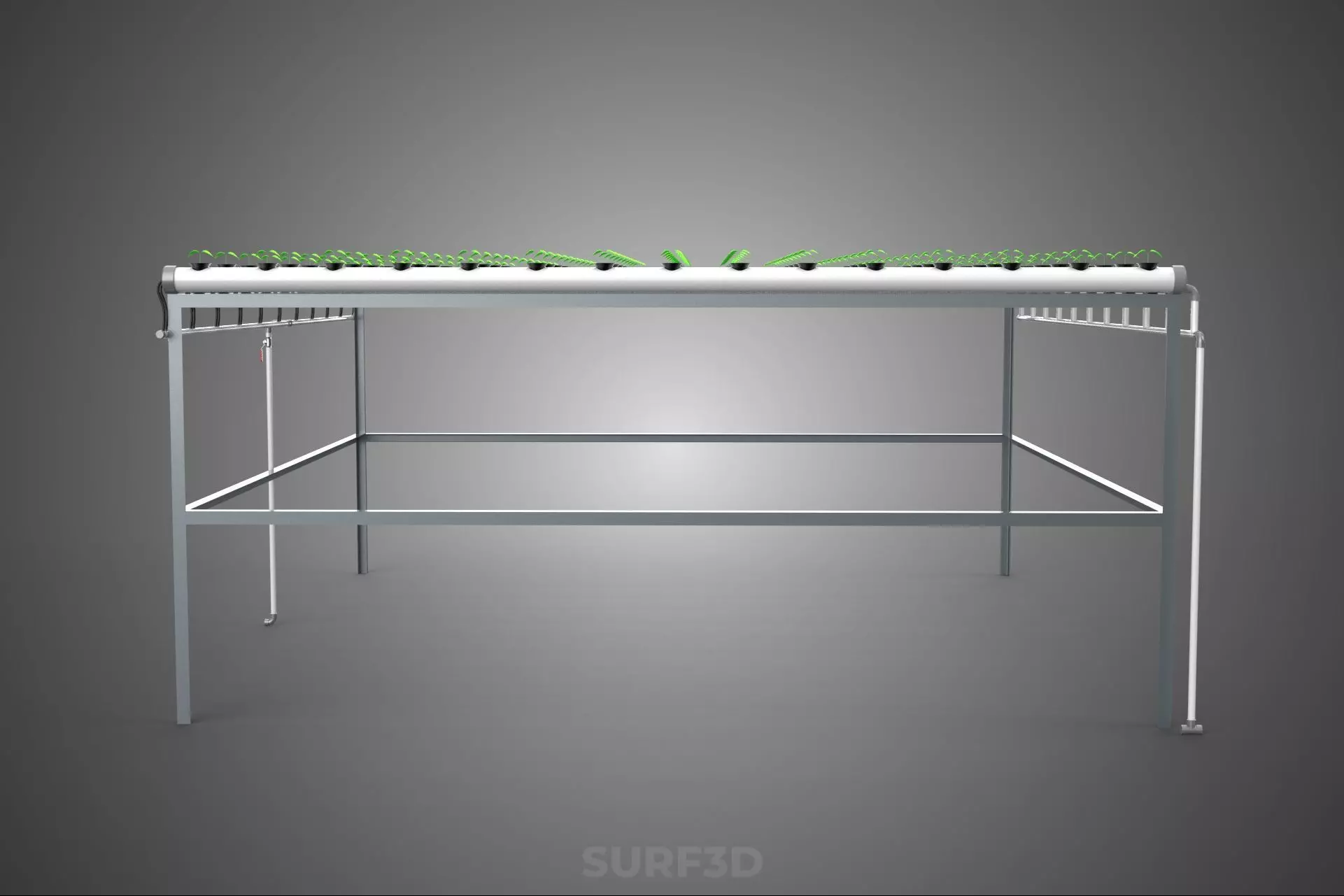

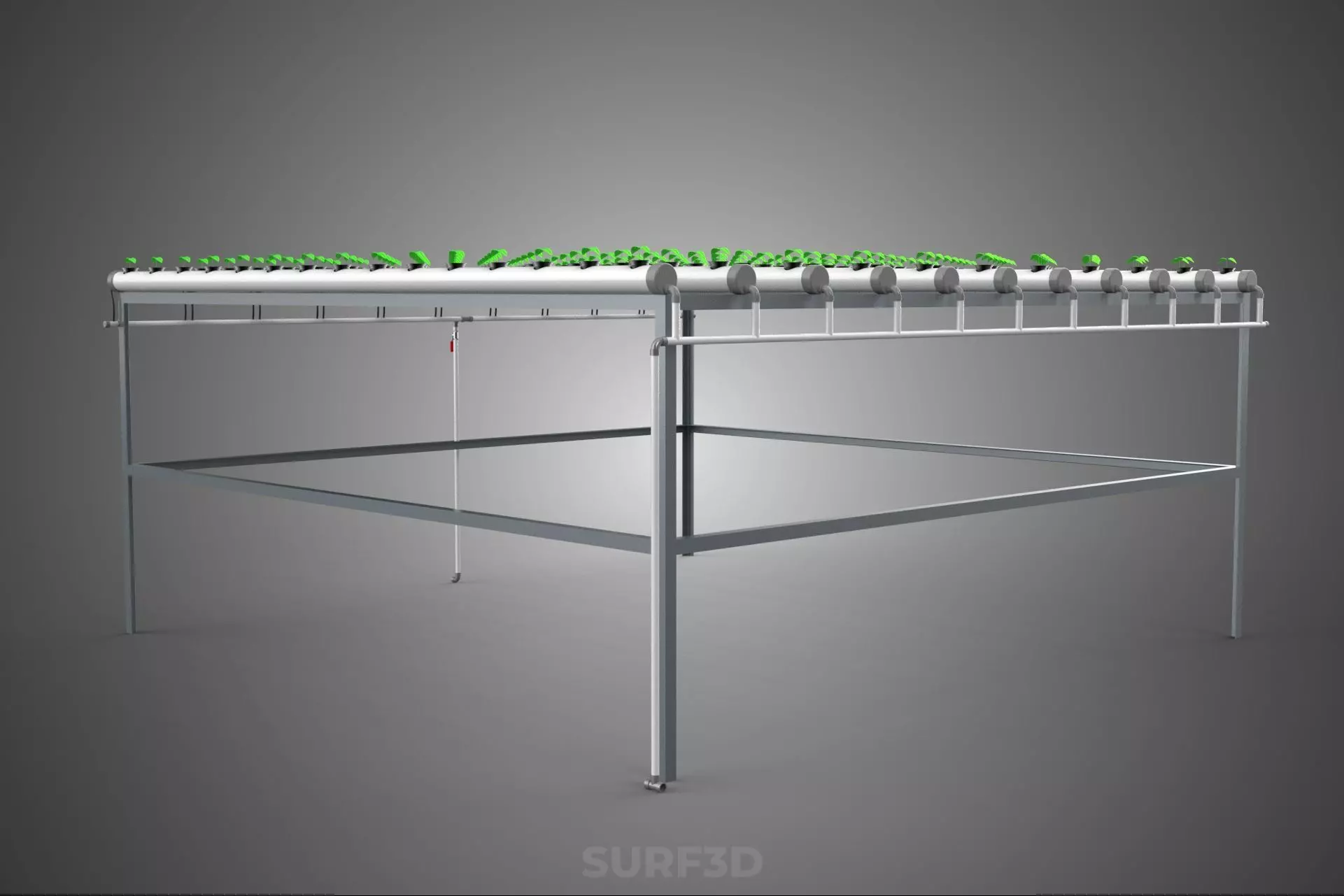

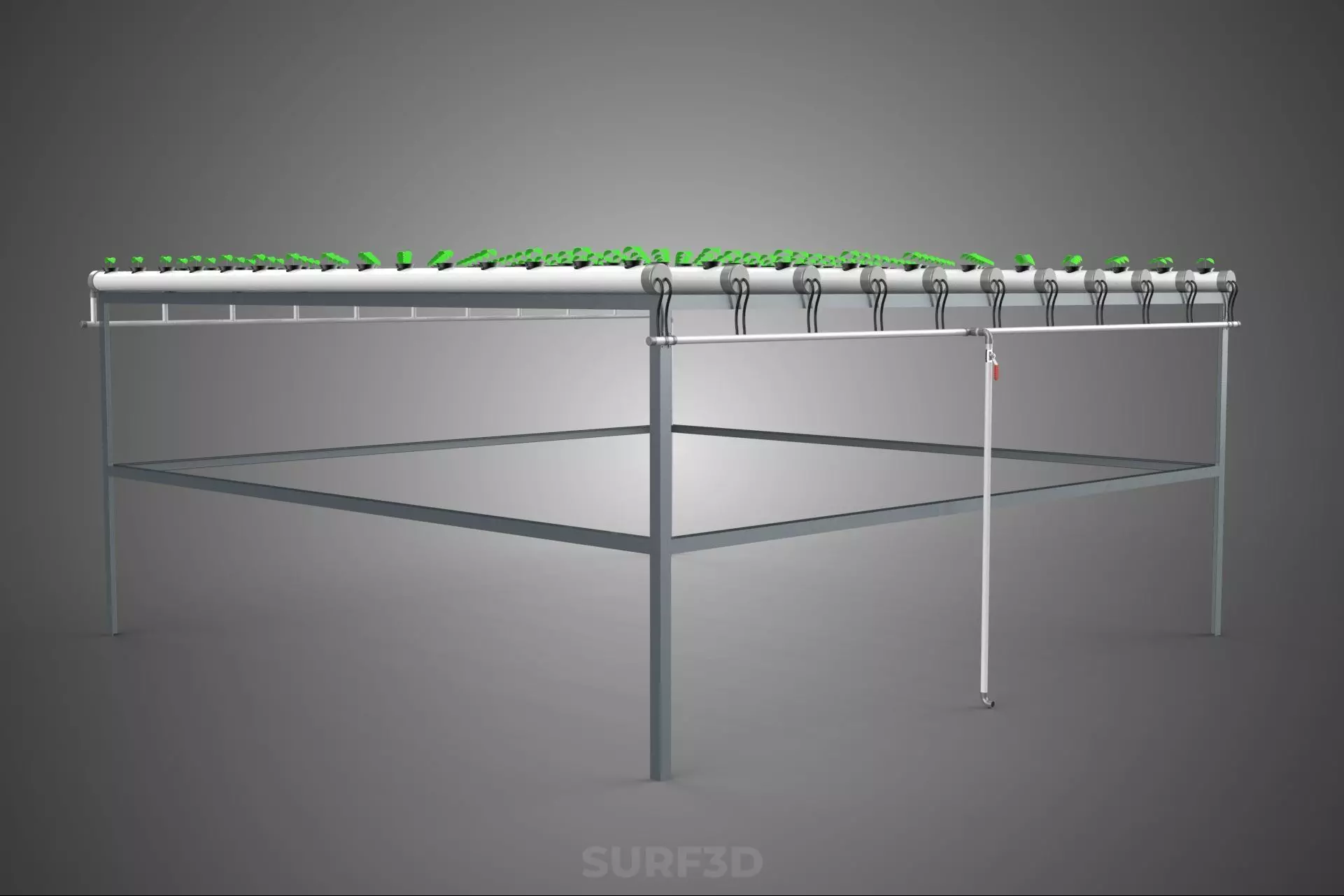

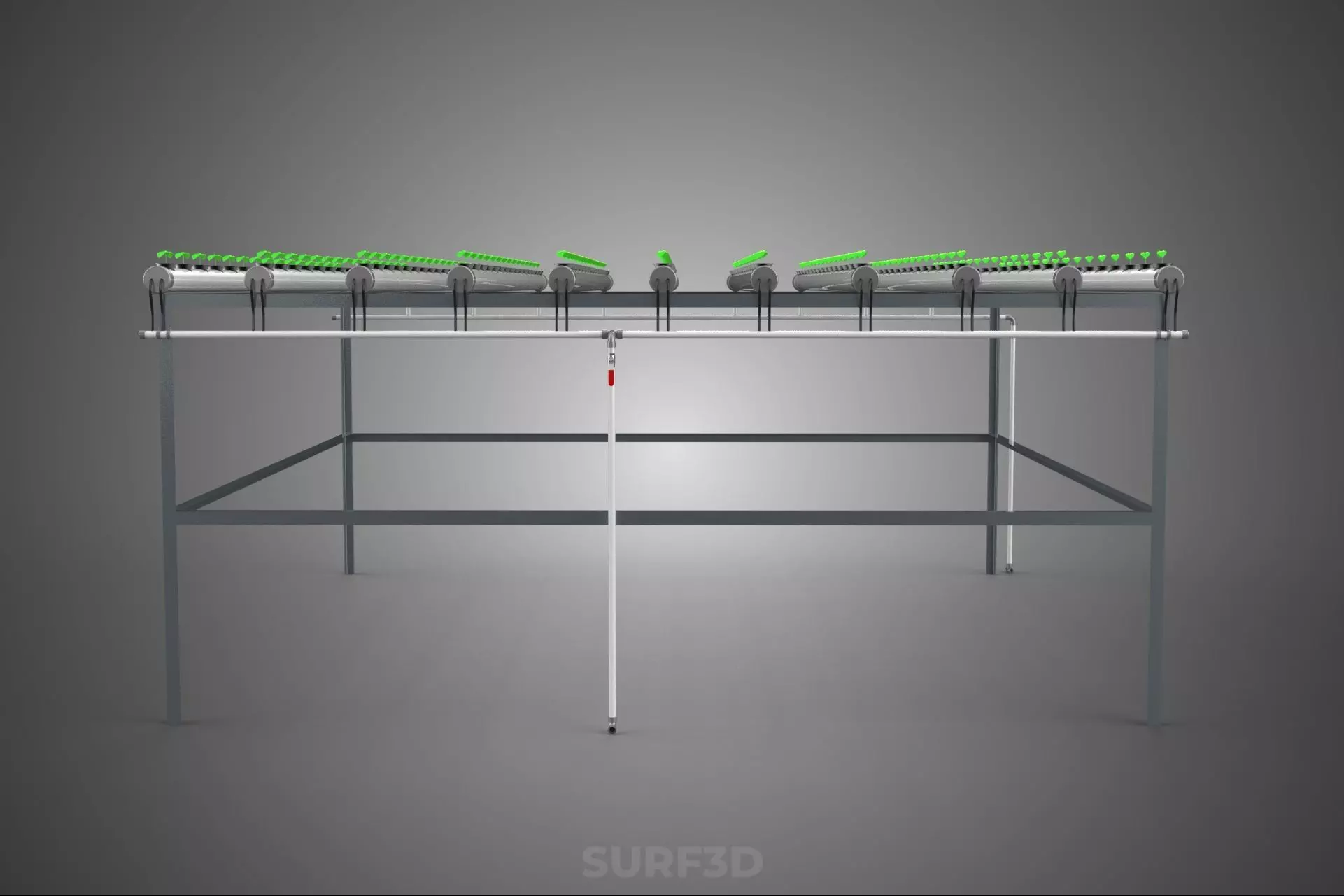

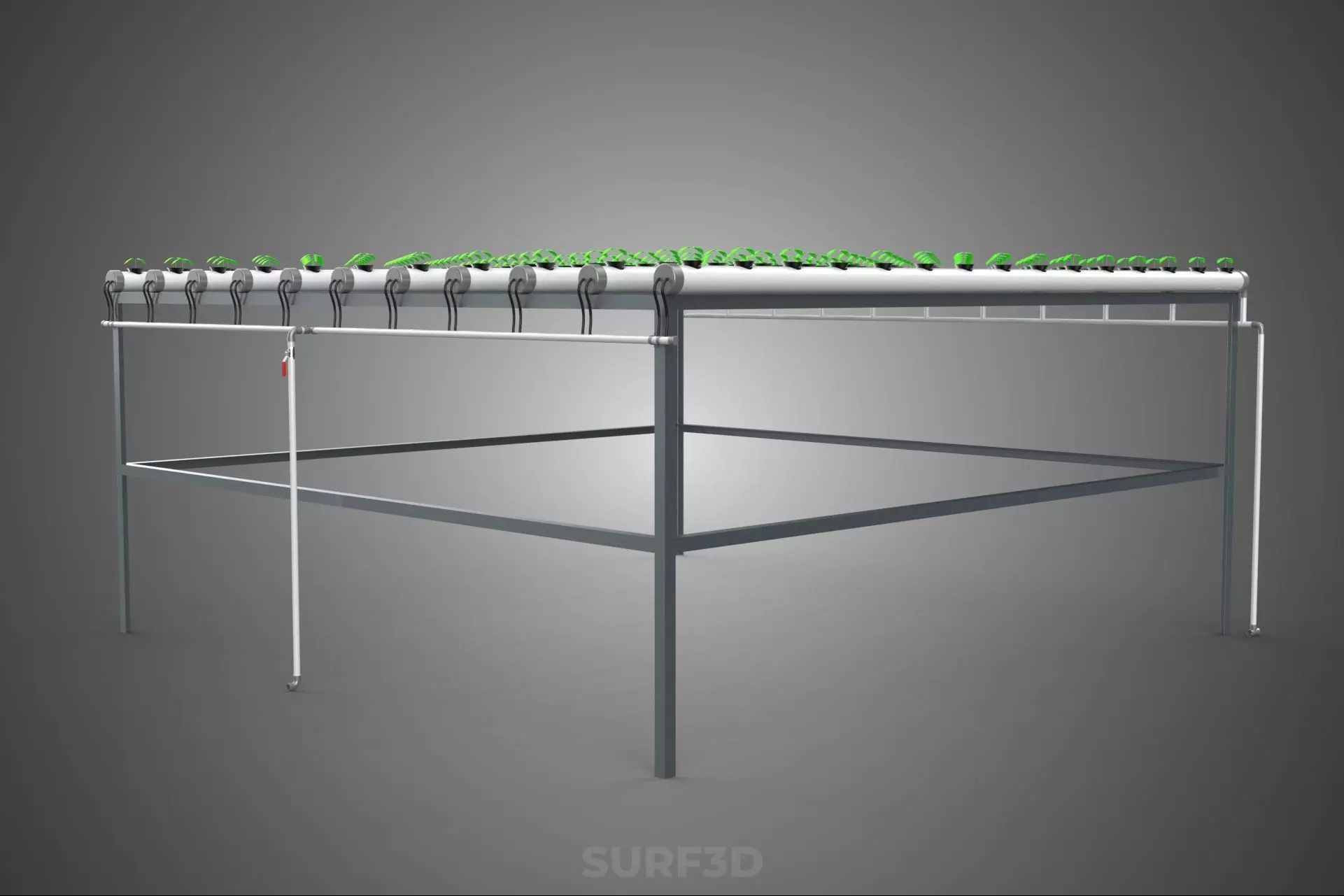

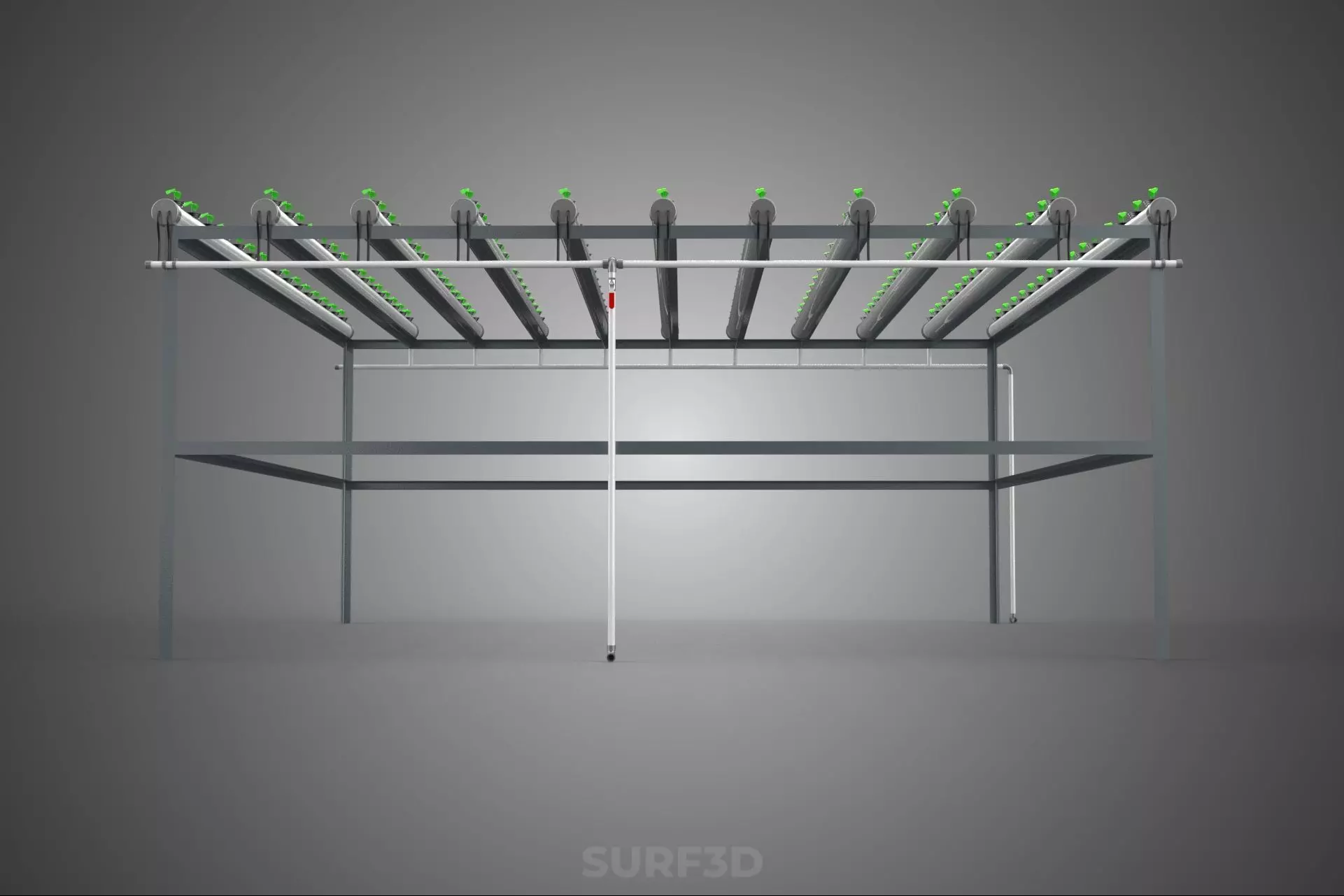

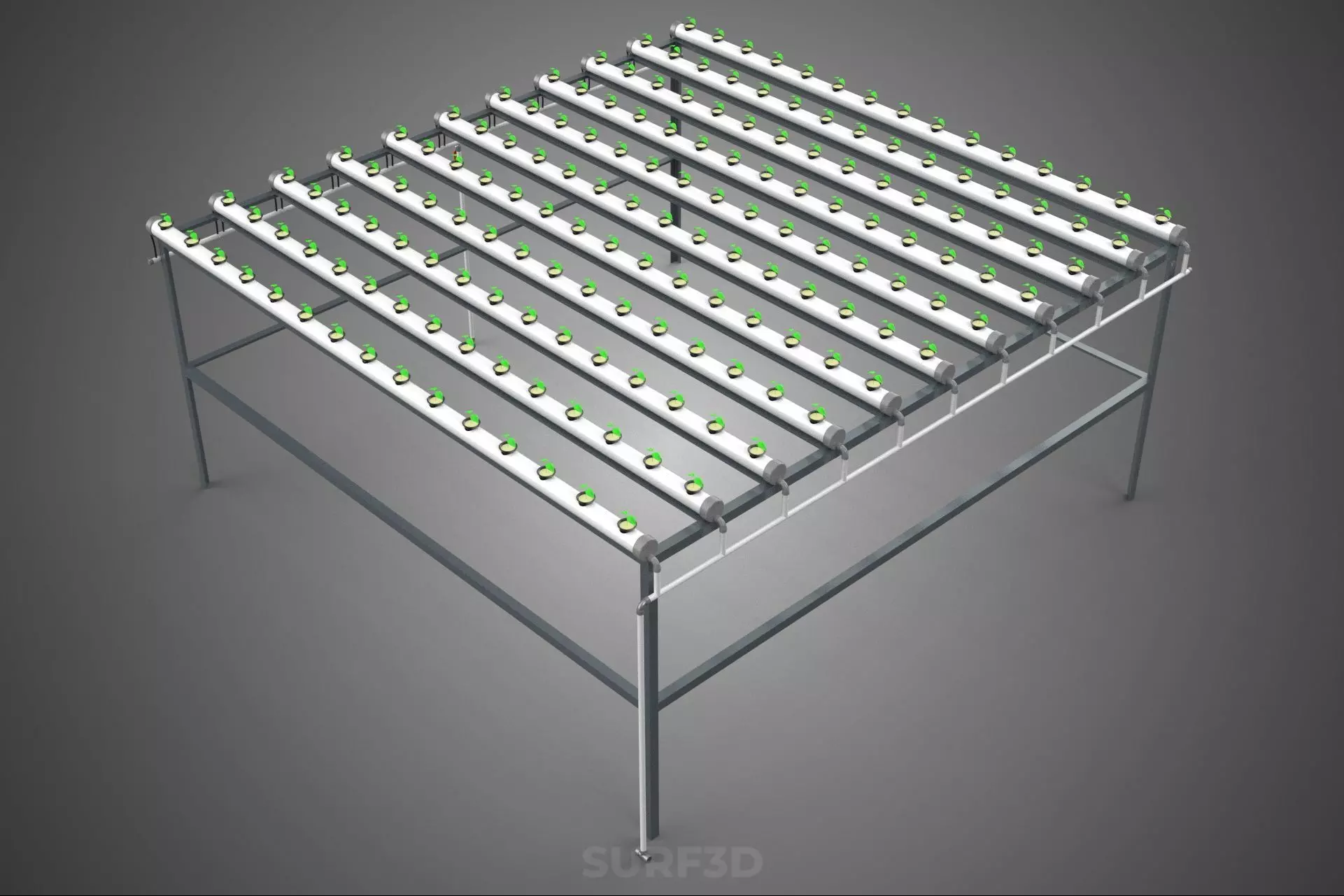

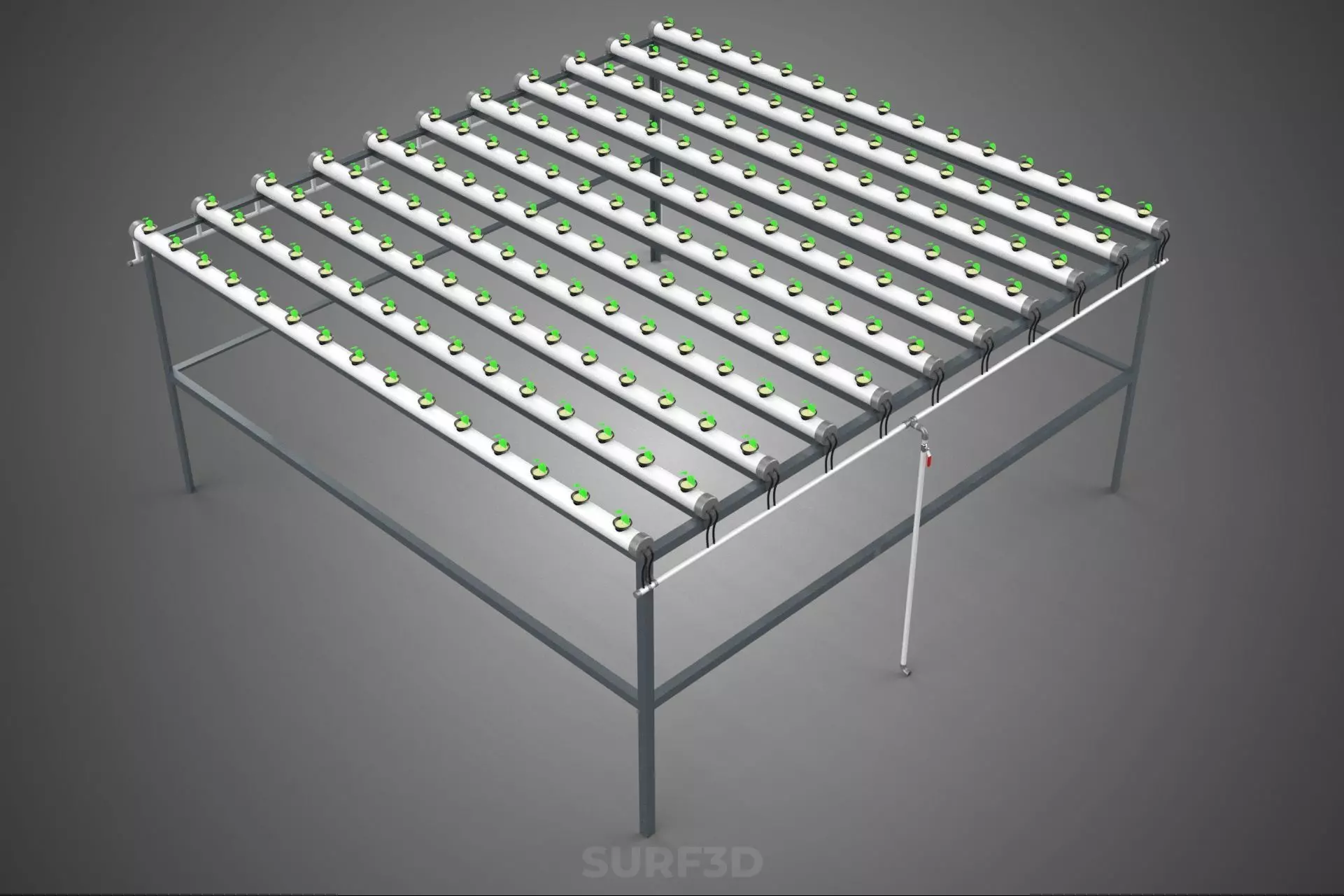

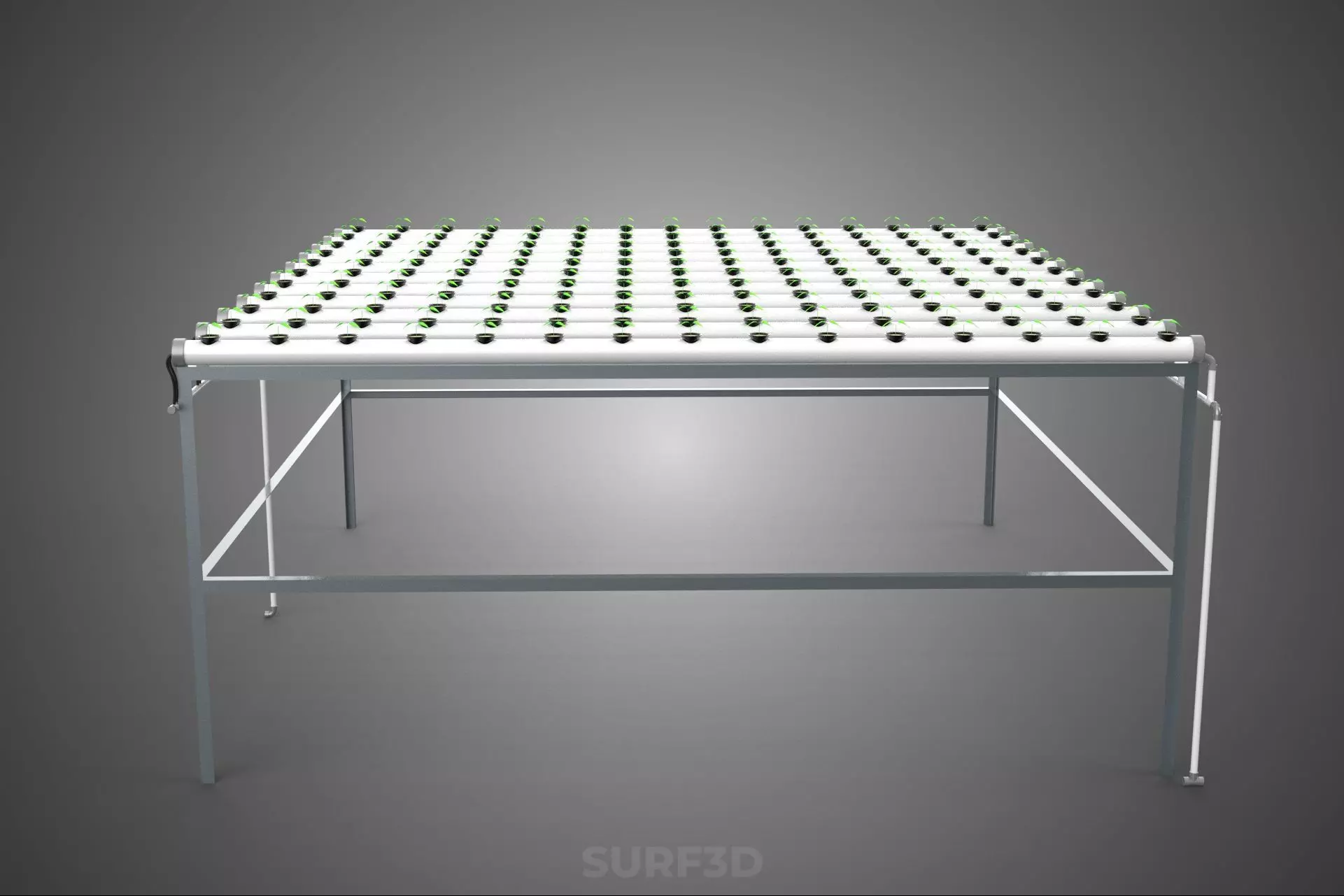

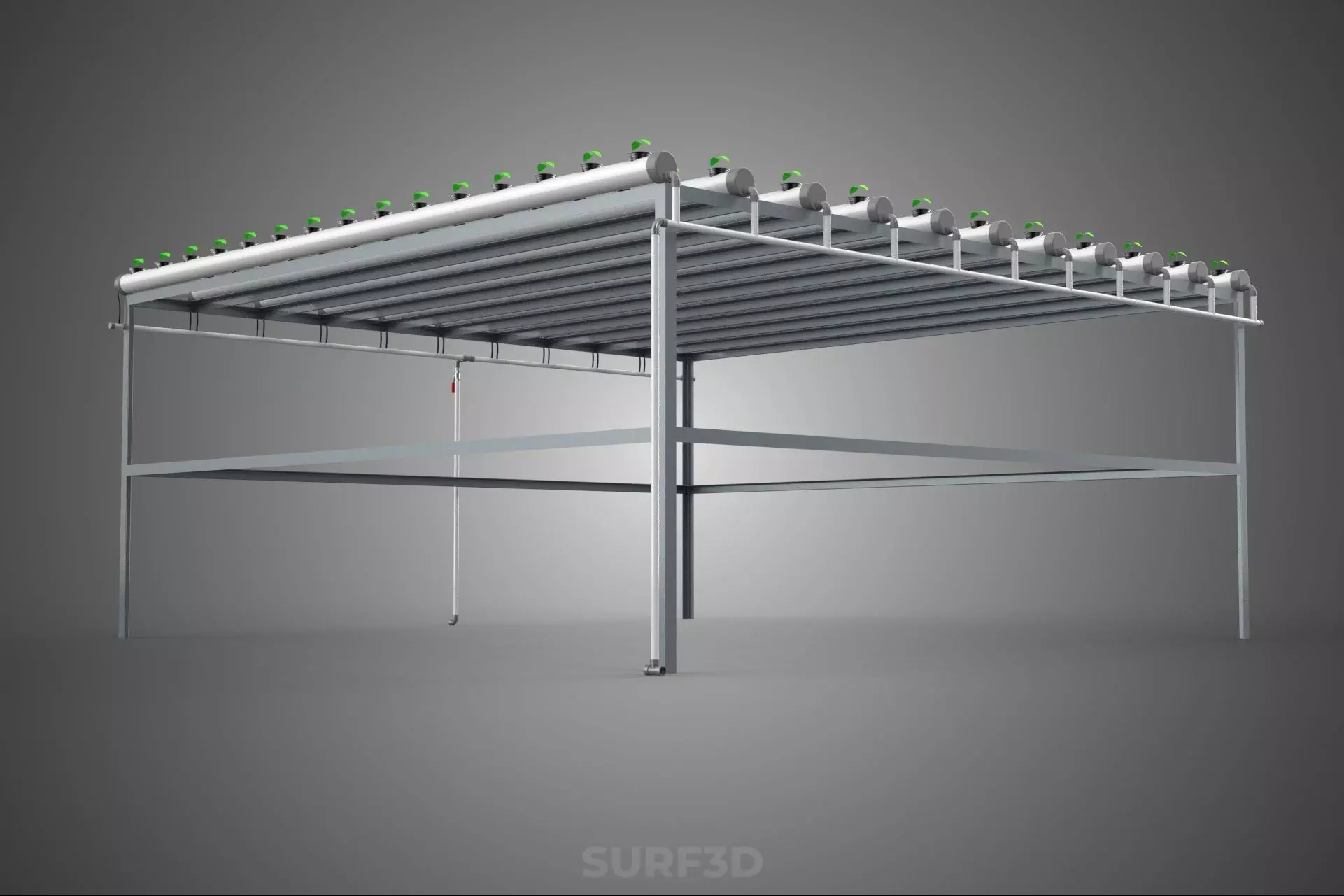

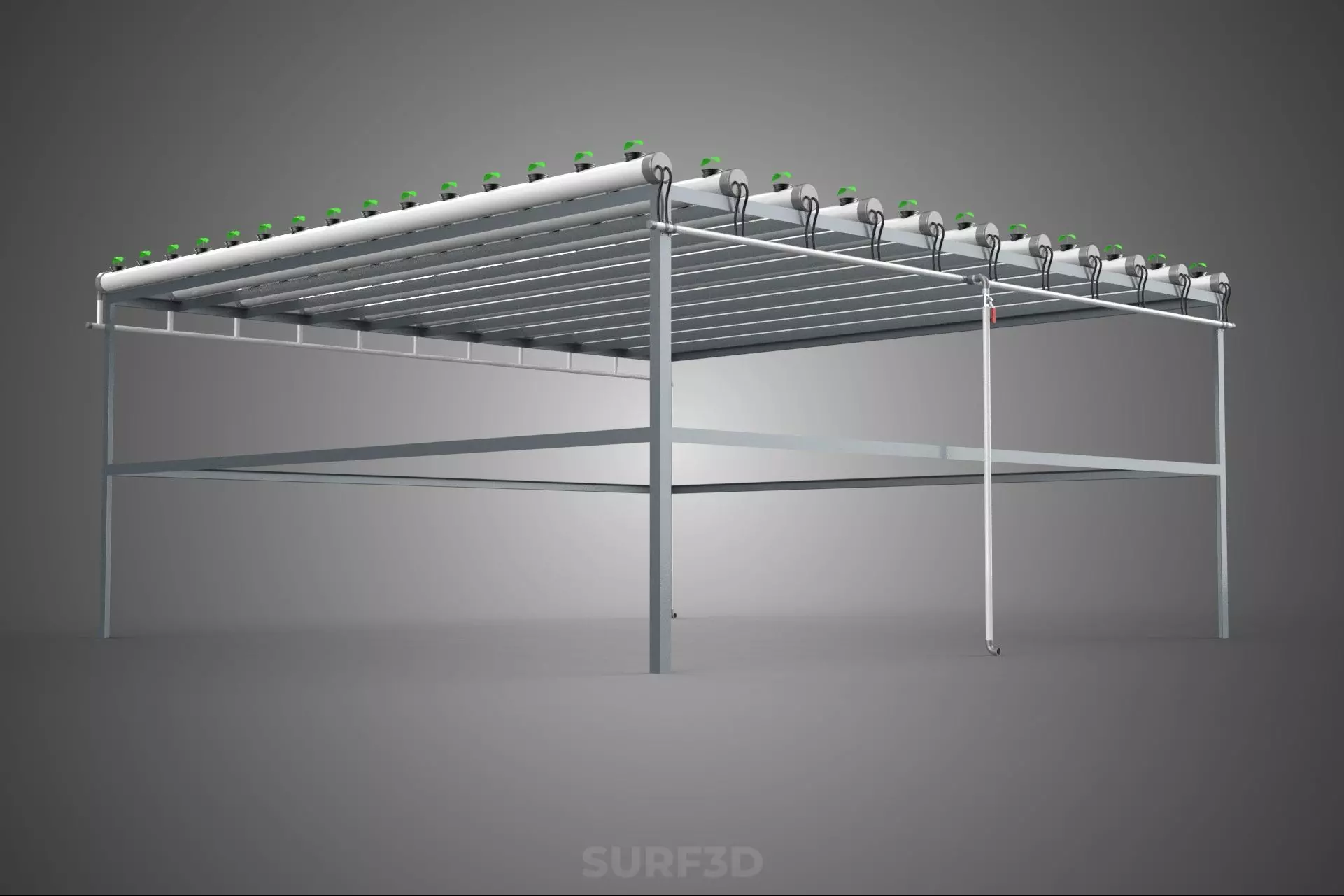

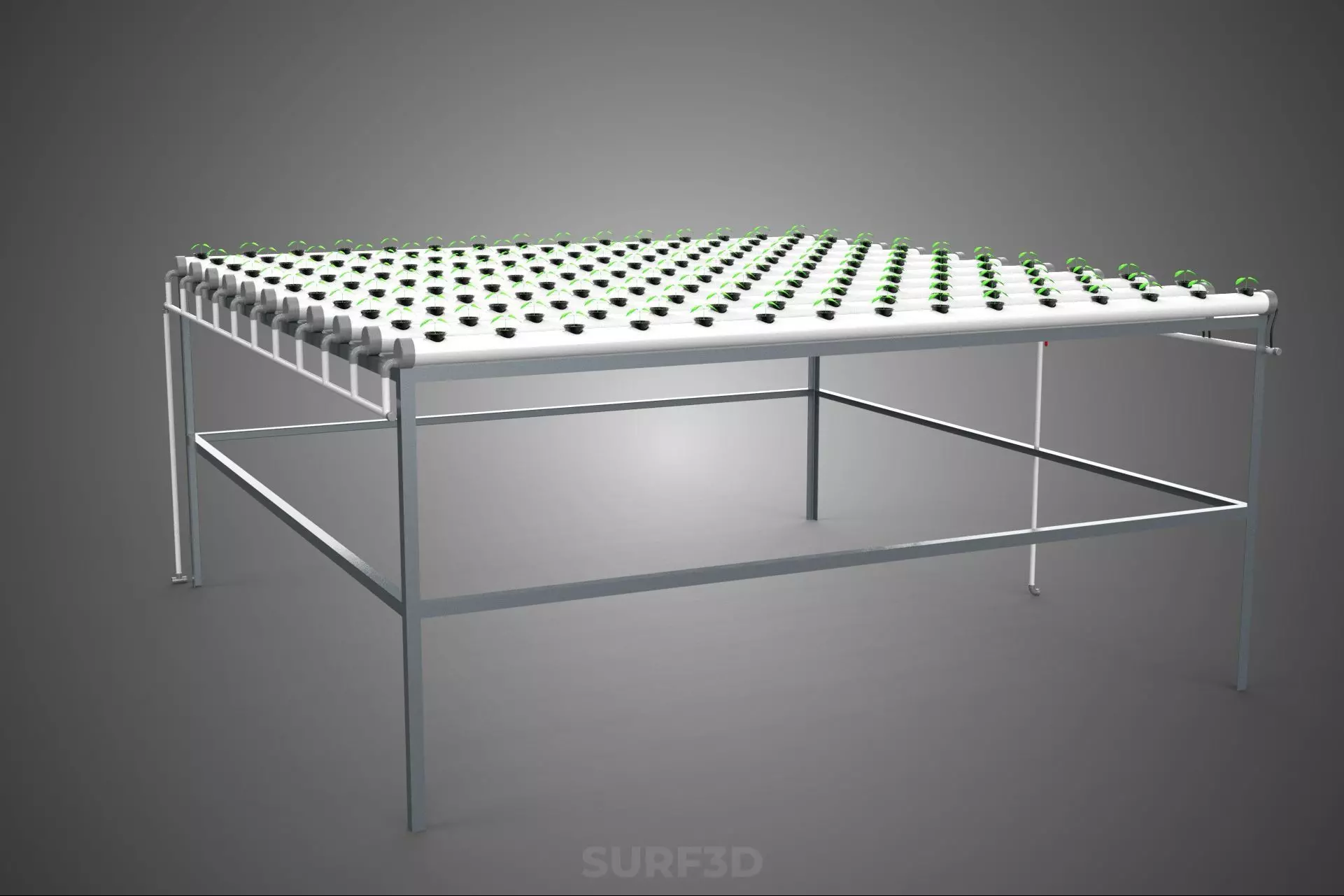

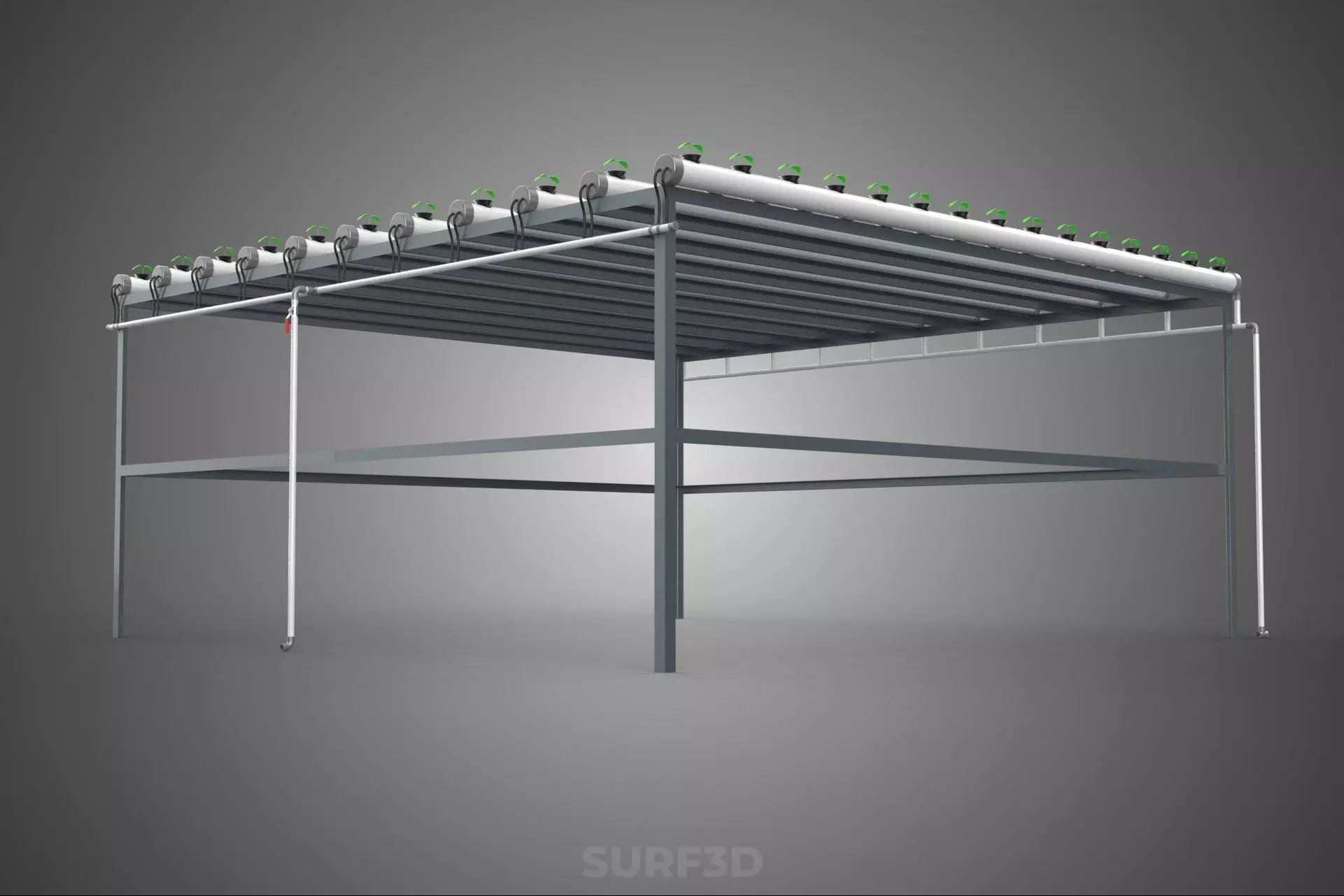

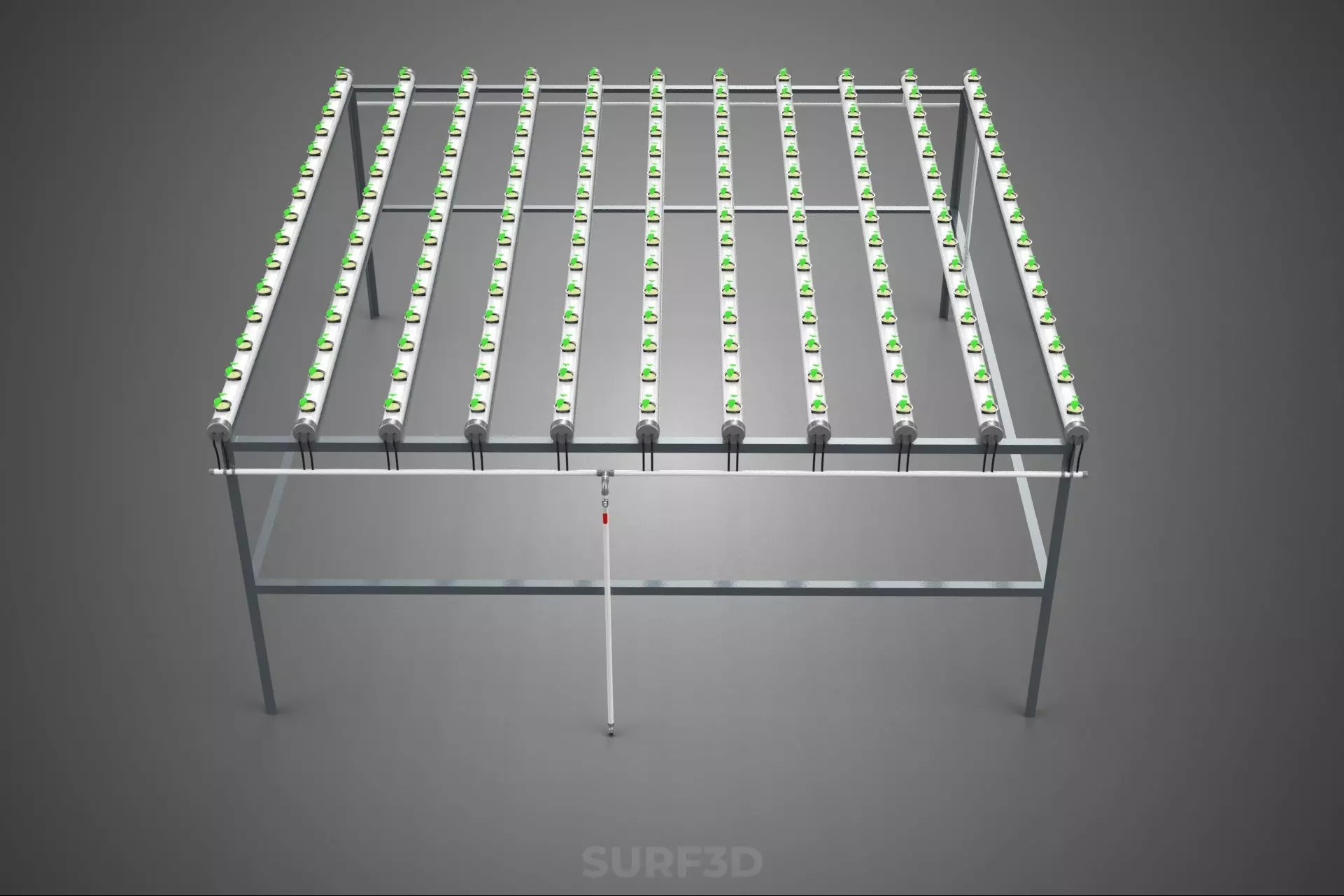

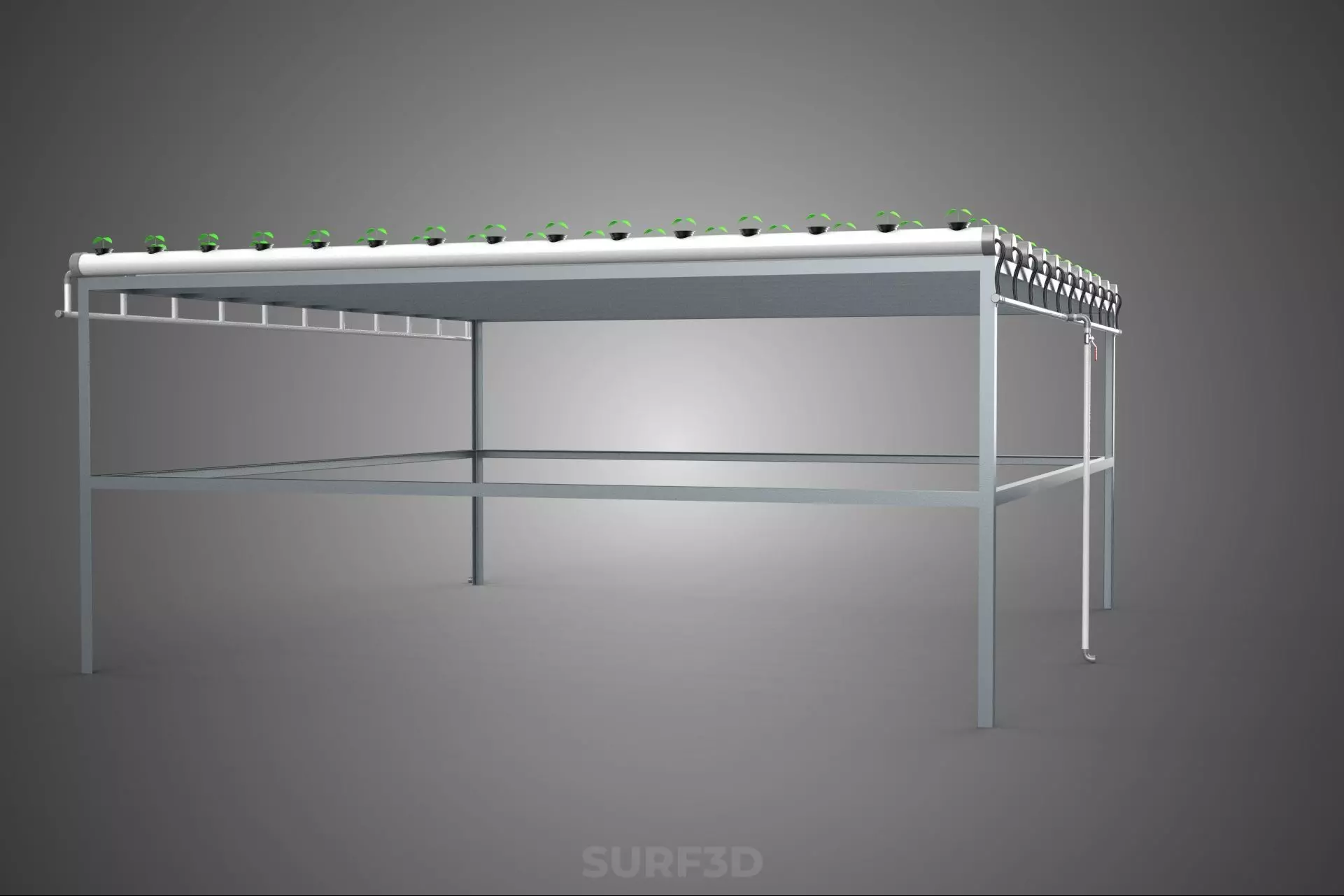

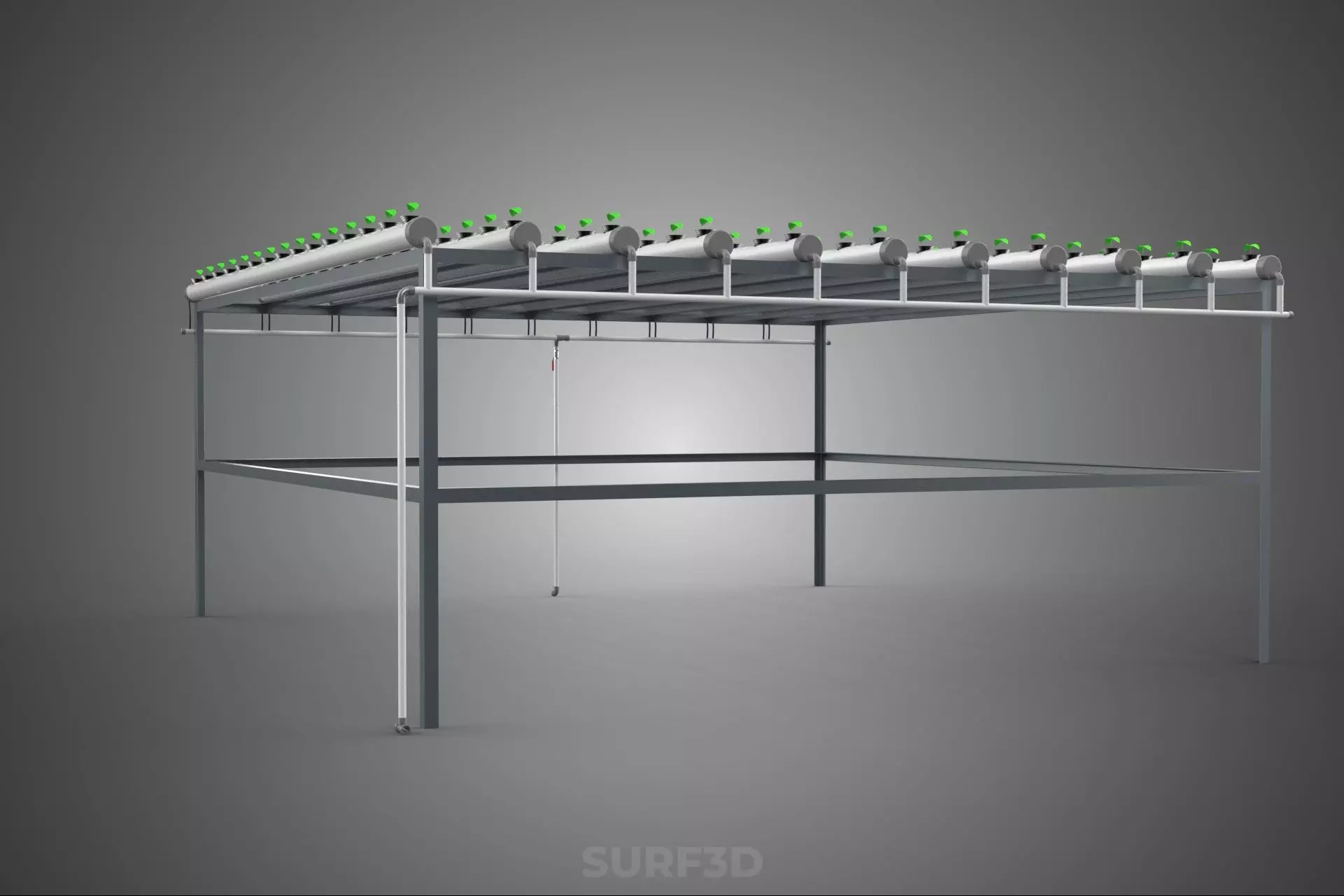

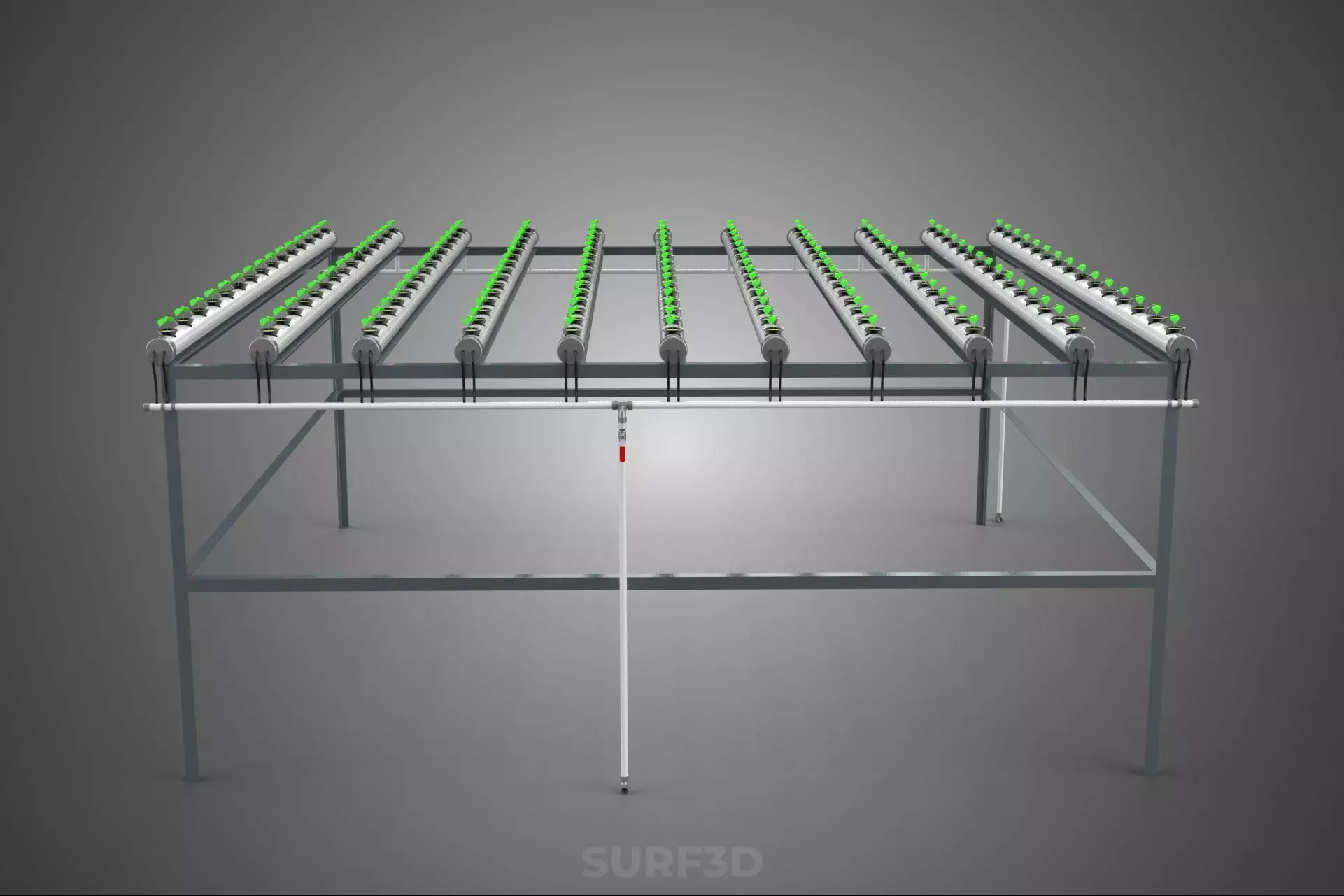

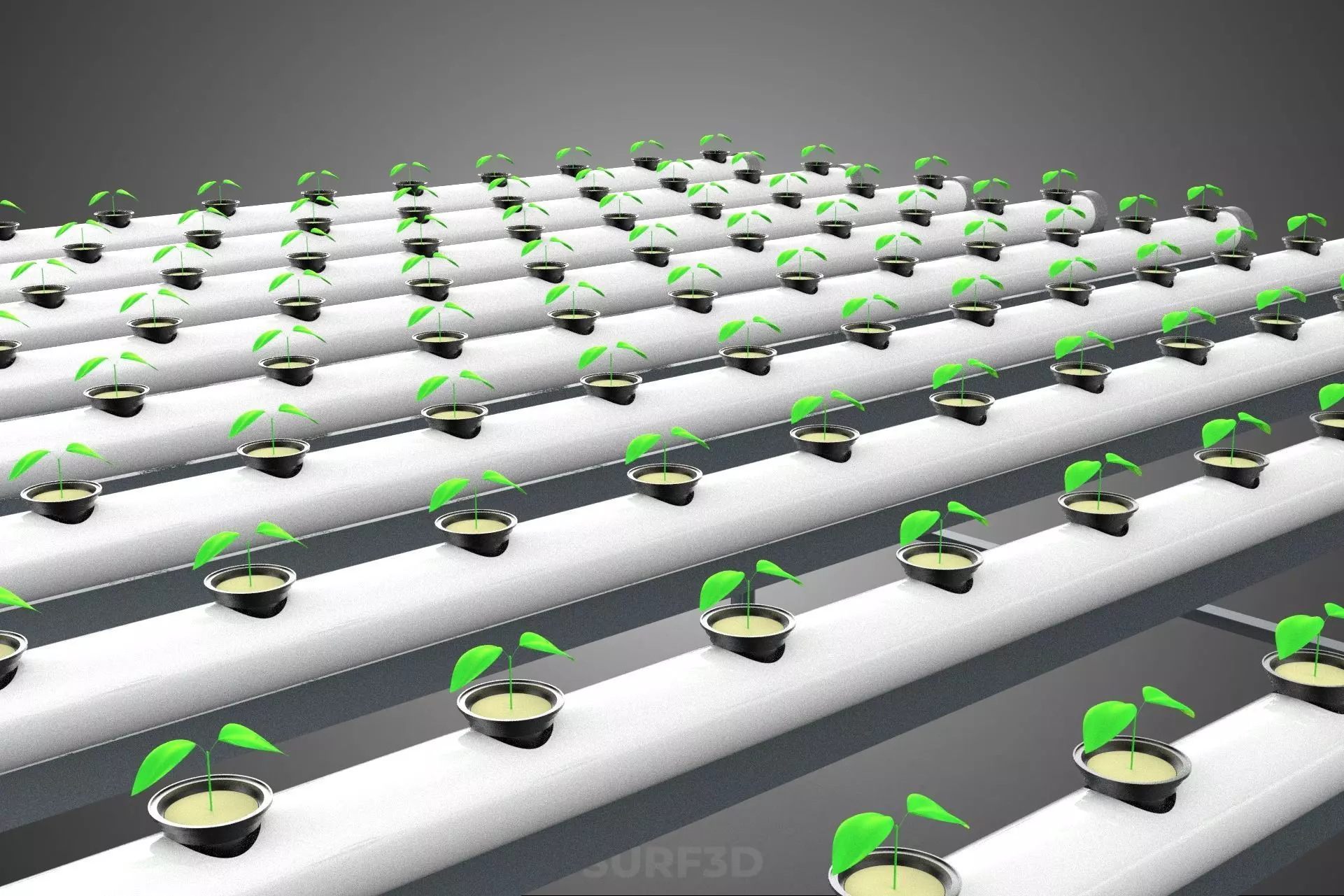

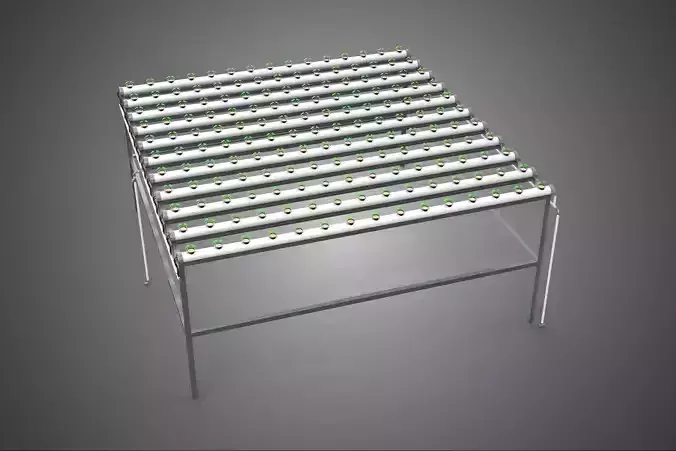

HYDROPONIC FARM SETUP SEEDLINGS GROW NET POTS PARALLEL NFT PIPES 3D model

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

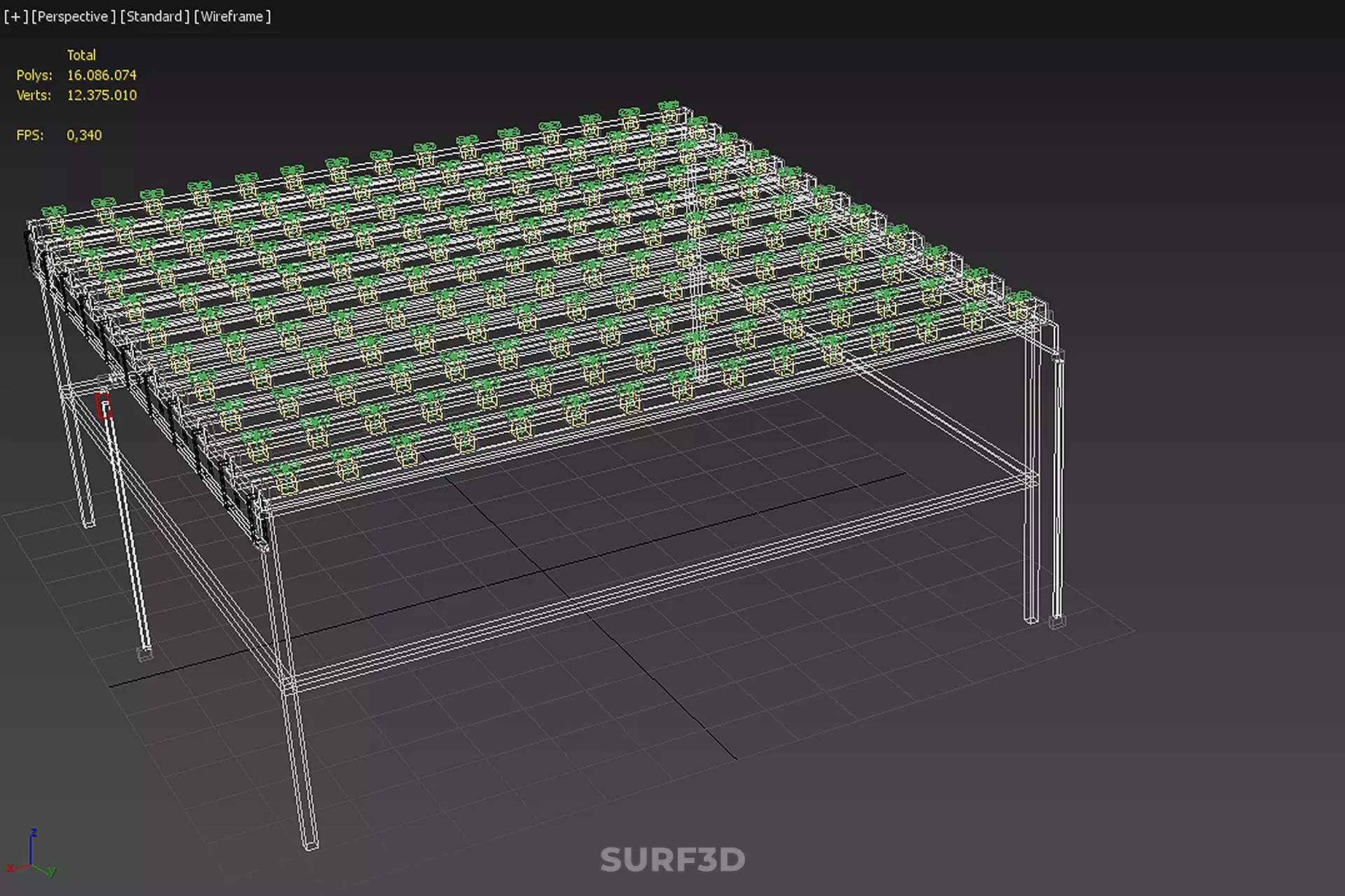

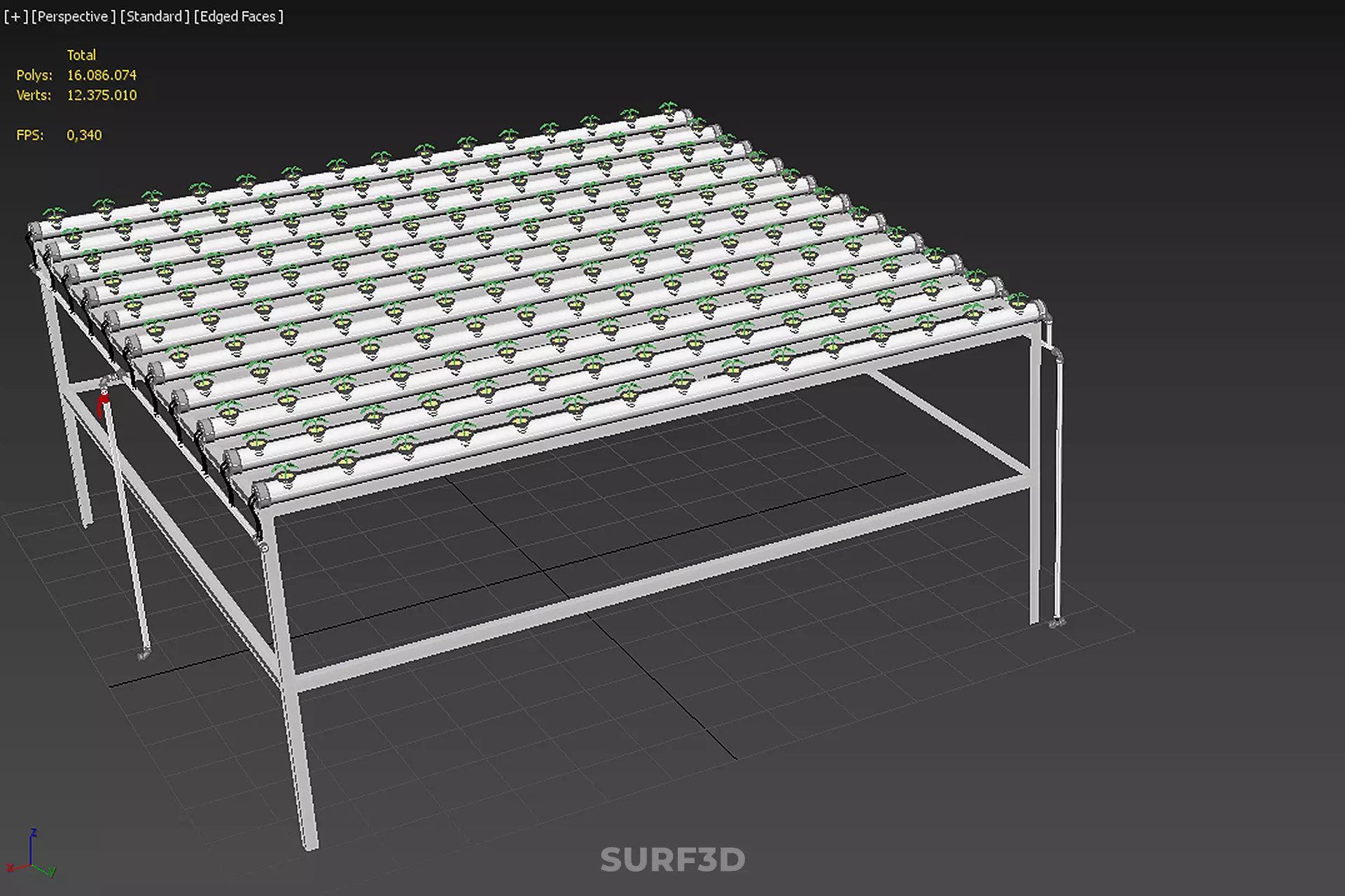

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

HYDROPONIC FARM SETUP SEEDLINGS GROW NET POTS PARALLEL NFT PIPES

This title describes a specific, controlled-environment horticultural system predicated upon the Nutrient Film Technique (NFT), a highly efficient method of soilless cultivation. The setup integrates several key components—specialized structural piping, dedicated seedling establishment protocols, and inert root containment vessels—to maximize nutrient delivery and volumetric crop density. This configuration is widely utilized in commercial agriculture for the high-density production of quick-turnaround crops, such as leafy greens and herbs.

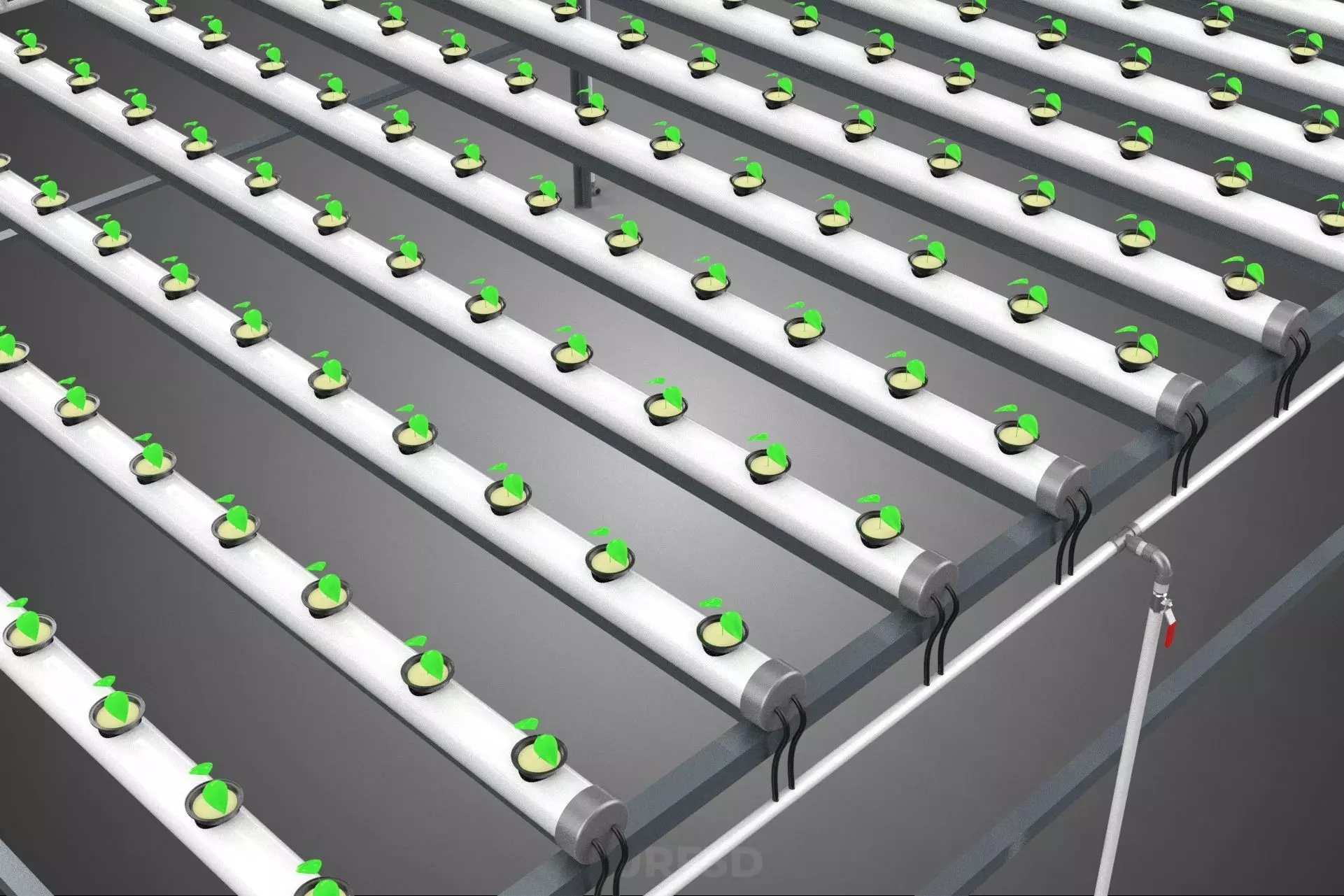

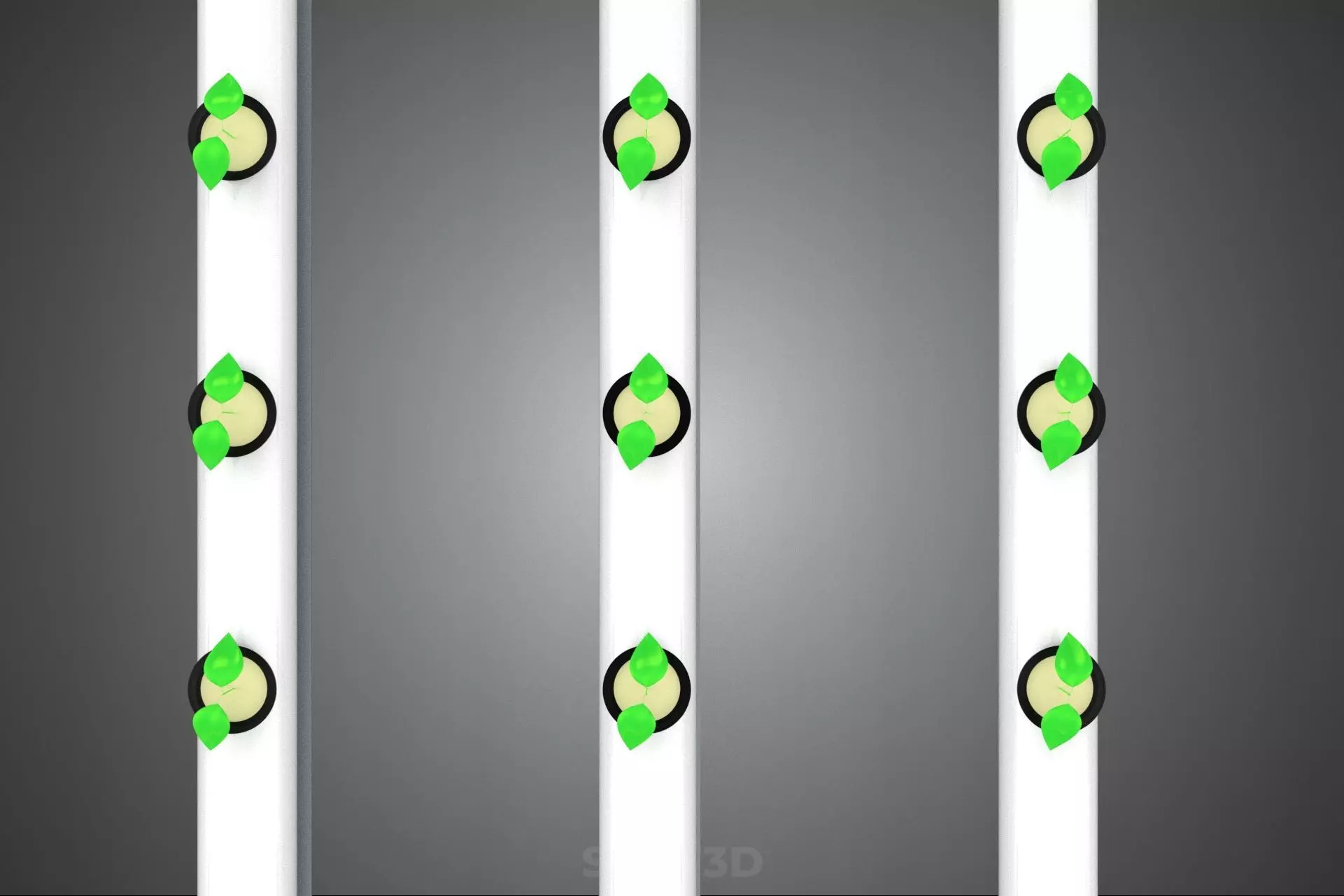

The NFT system operates by allowing a very shallow stream, or ‘film,’ of balanced nutrient solution (1–3 mm deep) to flow continuously or intermittently over the roots of the plants. Unlike deep water culture (DWC) or media-based systems, NFT channels are designed to limit the amount of water contact, ensuring that the upper portion of the root mass remains exposed to air, facilitating crucial oxygen uptake (aeration).

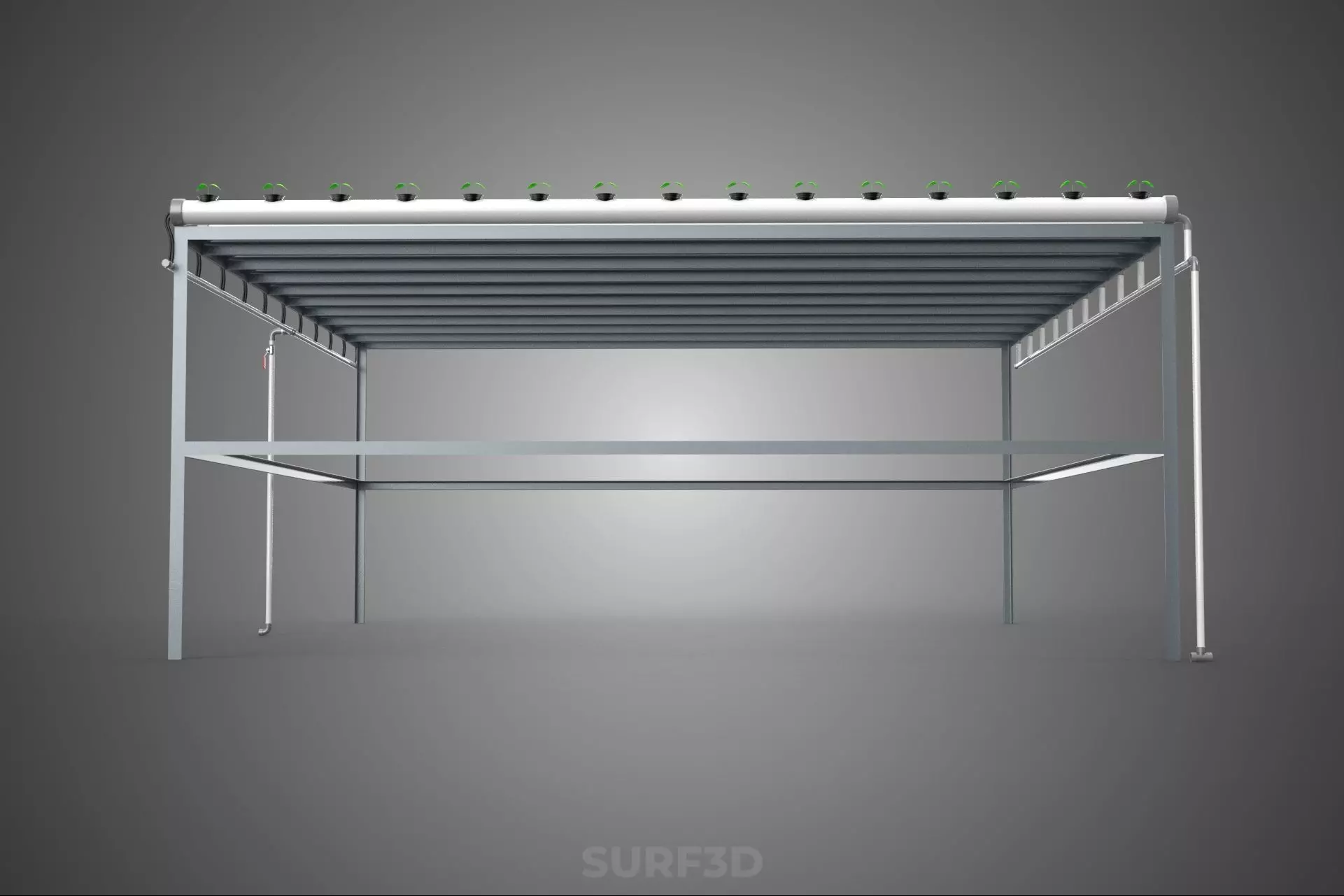

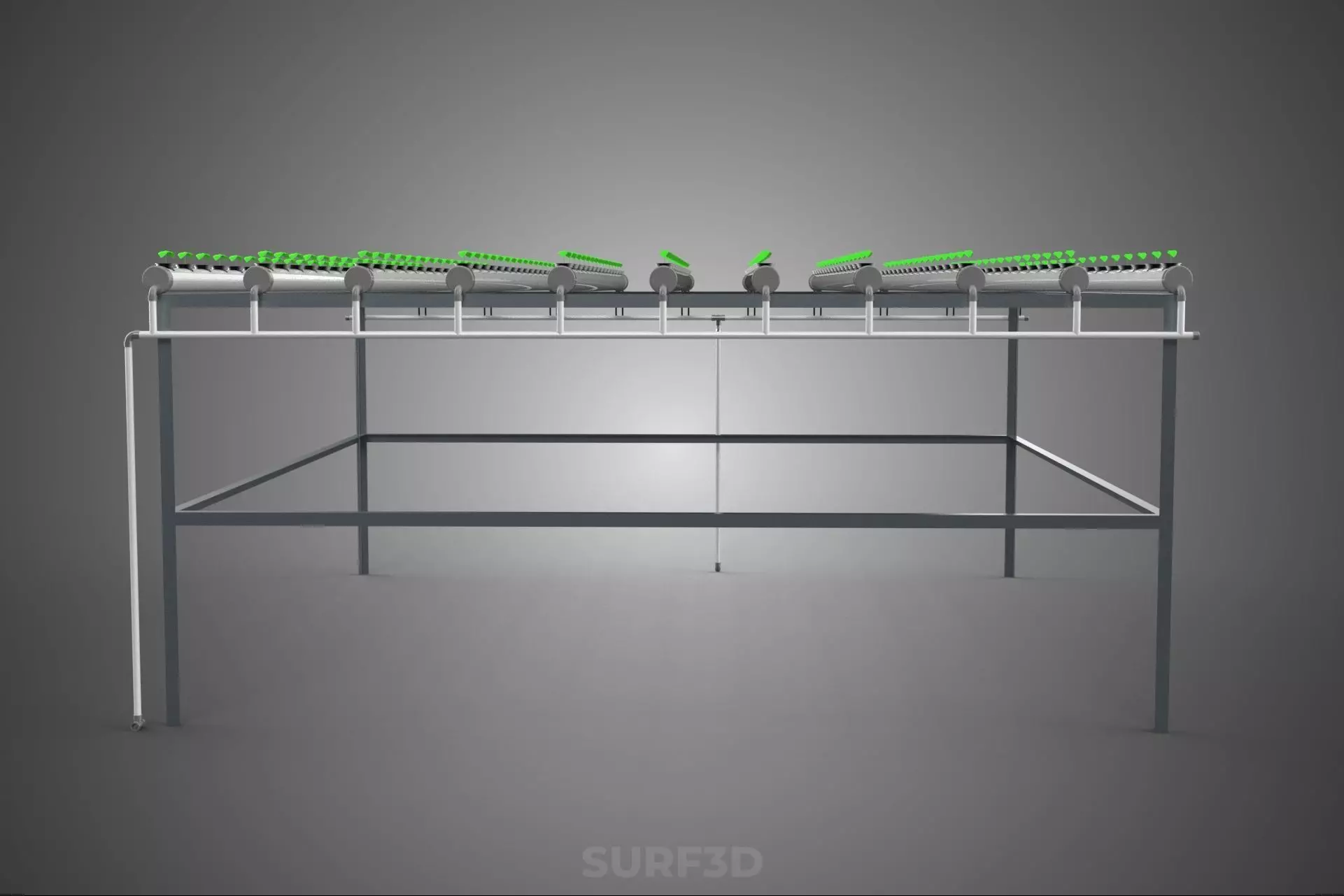

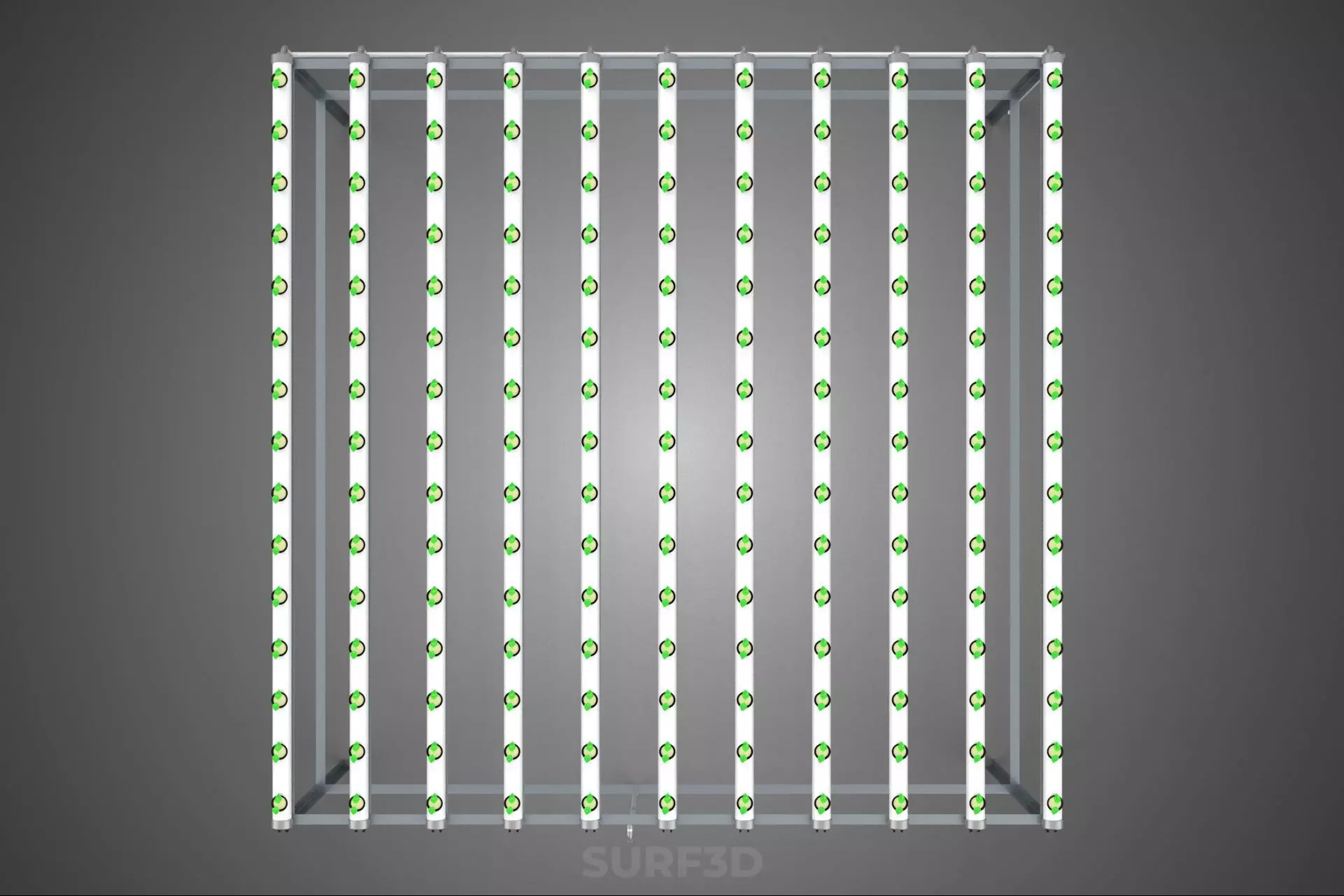

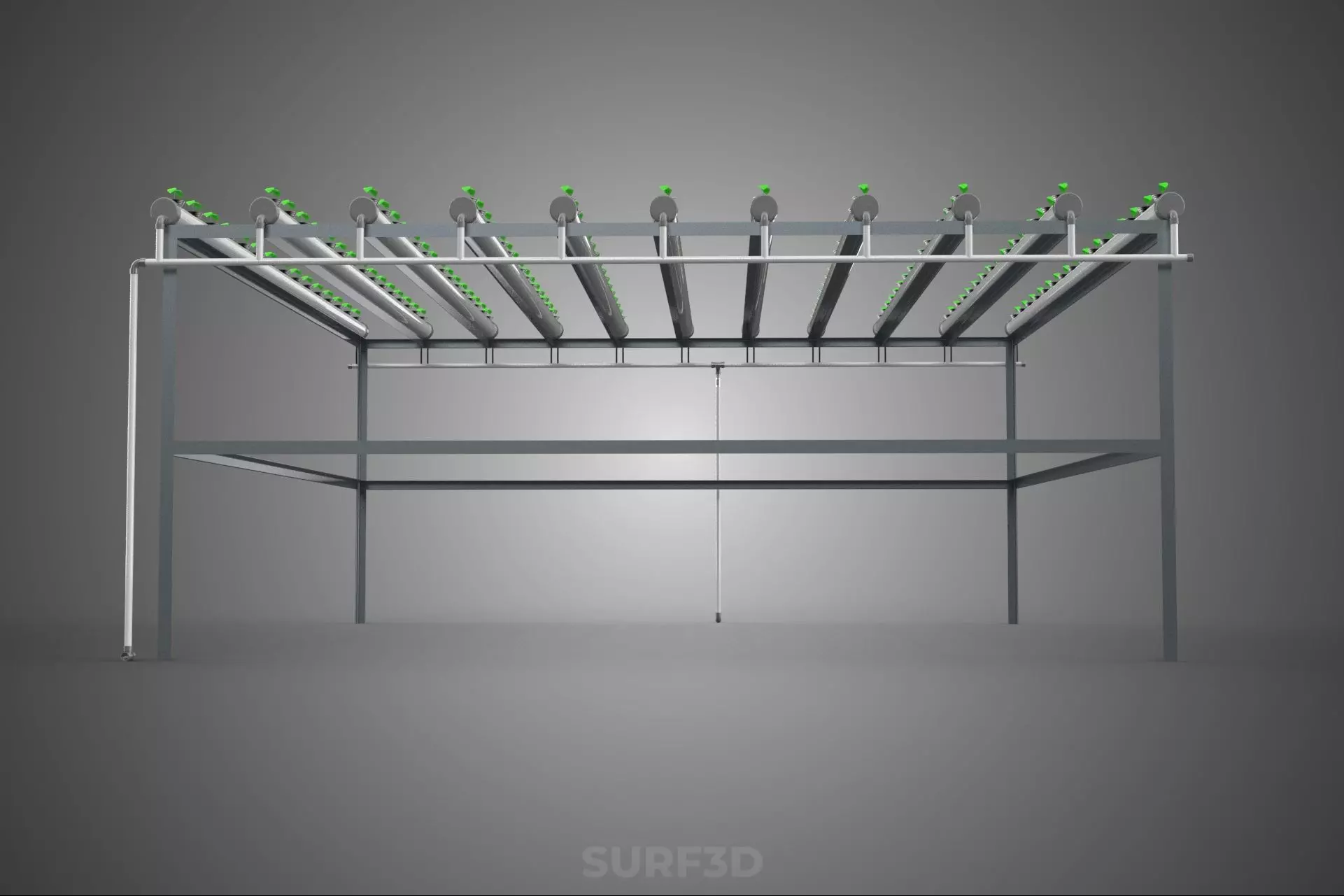

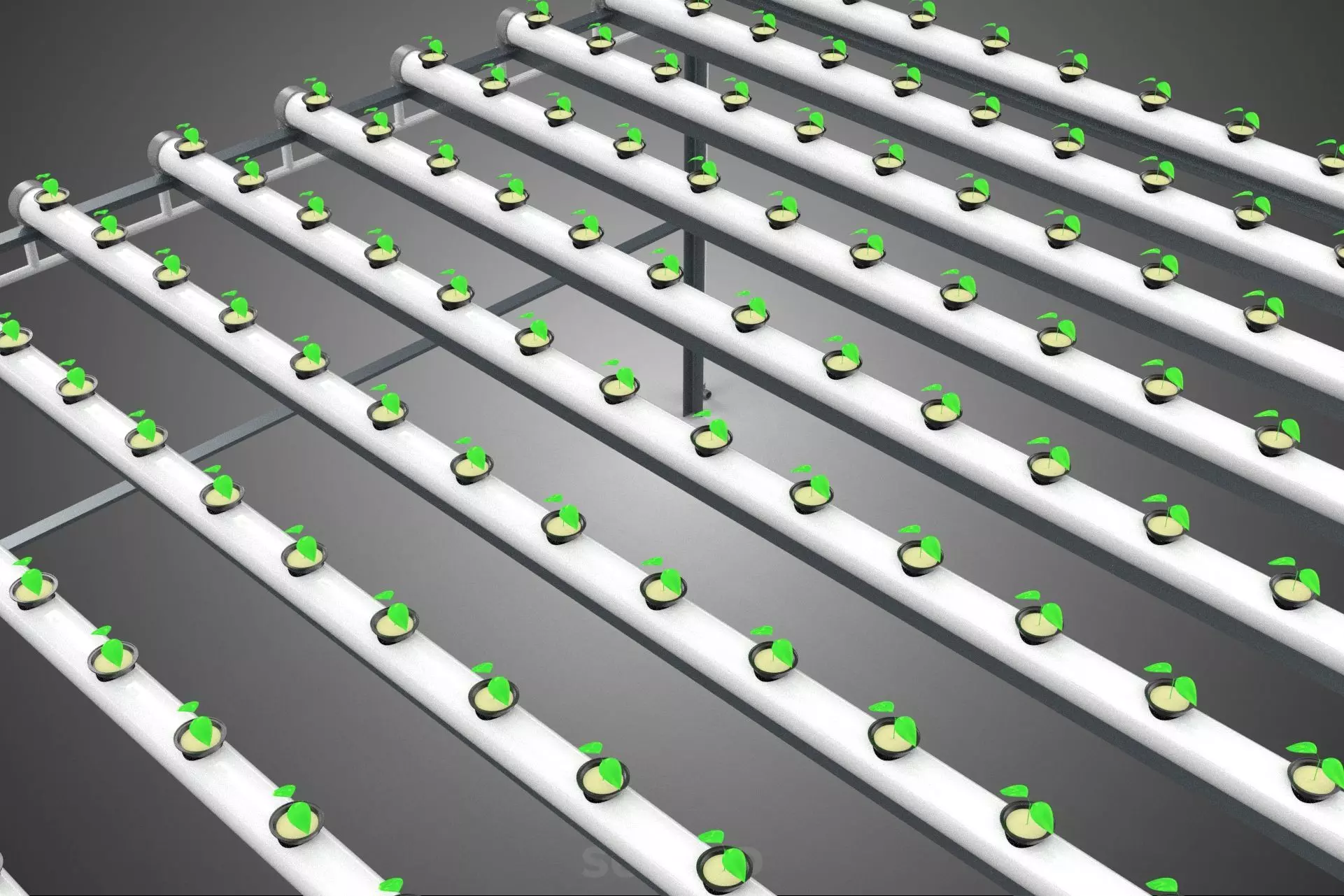

The defining structural element of this setup is the arrangement of parallel growth channels.

A. Pipe Construction and Alignment: The growth channels, or ‘pipes,’ are typically constructed from food-grade, UV-stabilized, and opaque PVC (polyvinyl chloride) or polypropylene. Opacity is mandatory to prevent light penetration, which would foster detrimental algal growth within the nutrient solution channels. The pipes are arranged in arrays, often stacked vertically (multi-tier farming) to optimize the utilization of vertical space within greenhouses or controlled environment agriculture (CEA) facilities.

B. Inclination and Flow: The pipes are positioned with a precise, slight gradient (generally 1:100 to 1:30, or 1% to 3% slope) to allow the nutrient solution to flow purely by gravity from the high point (inlet) to the low point (outlet). This gravitational flow eliminates the need for auxiliary pumps within the channels themselves. The parallel layout facilitates the even distribution of the pumped nutrient solution across multiple rows simultaneously, draining back into a shared catchment manifold and central reservoir.

The initiation and integration of the plant into the NFT pipeline is a staged process designed to minimize stress and maximize system cleanliness.

A. Seedling Stage: Plants are initiated in a dedicated nursery environment. Seeds are typically sown into sterile, inert starting media, commonly rockwool cubes, peat pellets, or coco coir plugs. This stage ensures reliable germination and the establishment of a preliminary, robust root ball before transfer to the main production system. Pre-germination outside the main channels prevents particulate contamination of the NFT solution.

B. Grow Net Pots: The mature seedlings are transplanted into plastic Grow Net Pots. These containers feature an open mesh structure, allowing the roots to easily penetrate and extend into the NFT channel. The net pots act as structural anchors, supporting the plant’s stem and holding the starting medium plug in place. They are sized to fit snugly into pre-drilled holes in the top surface of the NFT pipes, ensuring that the base of the pot and the root cluster are suspended just above the lowest point of the channel, permitting contact with the flowing nutrient film while maintaining necessary root exposure to air.

The combination of parallel piping and net pot deployment in NFT results in high resource efficiency:

- Water and Nutrient Efficiency: The system is typically closed-loop and recirculating. Unused solution is collected and returned to the reservoir, minimizing water wastage and maximizing nutrient uptake control.

- Density and Automation: The parallel, linear arrangement supports high planting density and is highly conducive to automation in monitoring, harvesting, and sanitization processes.

- Disease Management: The separation of plants within individual pots and the flow dynamics reduce the risk of soil-borne pathogens and limit the rapid transmission of water-borne diseases between plants compared to large communal reservoirs.

KEYWORDS: Hydroponics, Nutrient Film Technique, NFT, Net Pots, Parallel Pipes, Seedlings, CEA, Controlled Environment Agriculture, Recirculating System, PVC Piping, Soilless Culture, Root Zone Aeration, Rockwool, Grow Channels, Commercial Hydroponics, Water Efficiency, High Density Farming, Gravity Flow, Nutrient Solution, Reservoirs, Transplanting, Opaque Channels, Leafy Greens, Vertical Farming, Slope Gradient, Mesh Containers, Closed-Loop System, Horticultural Technology, Automation, Crop Yield.