1/9

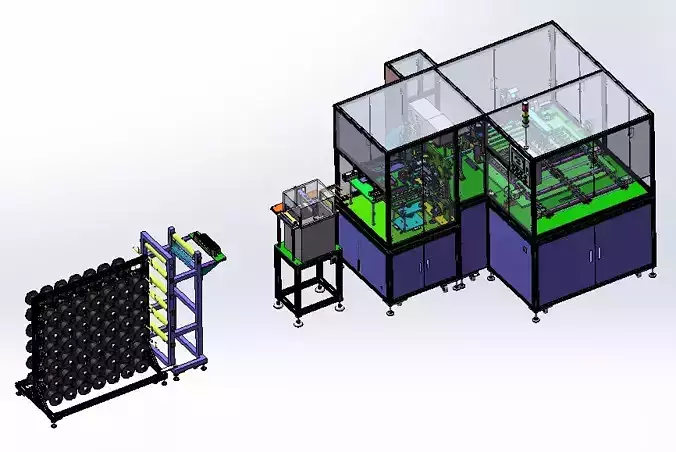

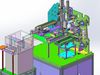

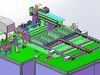

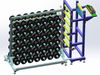

The applicable products of this equipment are: industrial wire, FPC, FFX flexible cable, 0.3-1MM wire diameter, various products glued laser cutting, etc. The equipment is mainly a copper wire cutting and processing equipment, the equipment is mainly used for copper wire FPC soft wire cutting glue, the main highlight of the equipment is the wire material feeding rack part is also a complex glue structure, this feeding rack can be dozens of coils of wire at a time, The main functions of the equipment are: 1. wire feeding and feeding, 2. ultrasonic cleaning of wire, 3. line body adhesive paper mechanism, 4. soft wire laser cutting and peeling, 5. line cutting, 6. soft wire automatic receiving manipulator, 7. automatic feeding tray circulating conveyor belt, equipment bus for integrated automatic operation, manual assistance in loading and unloading, feeding rack structure The feeding rack can be applied to various sizes of barrel incoming wires copper wire FPC soft row, simple loading and unloading operation only need to sleeve the wire to the rotating shaft of the feeding rack, the copper wire in the material rack is ultrasonic cleaning after sorting the structure of the drum and harness, and the cleaned wire enters the glue machine, the incoming material of the wire body can be arranged up to more than 30 wires, the number of wires can be automatically selected and arranged, the size of the adhesive tape can also be selected, when the wire enters the glue station, the glue pulling mechanism pulls out the adhesive paper and then pastes it to the wire, the upper and lower sides are pasted together to tie the wire sticker together, the battery cell glue pulling structure is a stepper motor moving structure complex, the switchboard uses 2 servo motors and a stepper motor and more than ten cylinders composition, which is a complex structure of sticker paper mechanism, Pasting head and suction label for vacuum adsorption, the position length of the glue can be adjusted according to the requirements, the adjustable range is relatively large, the wire feeding structure is also designed more ingeniously, the glue position of the line is segmented, and then the laser cutting of the surface is also cut at the back end of the glue, after laser cutting, the cutting machine for line cutting, the cutting length is set manually, the cutting is completed by the reclaiming manipulator directly grabbed into the receiving box, the receiving box is recycled by the discharge conveyor belt for conveying the material tray, the conveyor belt has a total of 6 small motors driven, Respectively, a section of conveyor belt 2, two sections of conveyor belt 2 jacking transfer machine each, conveyor belt is divided into one in and one out, feeding conveying for the left discharge conveyor belt is right, left feeding conveyor belt in the carrier is the shape of the product, when the product is used up, by the jacking conveyor empty carrier tray or blister plate, jacking weigh loaded into the right empty conveyor belt Then, empty material tray for recovery, the motor power of this conveyor belt is relatively small, the conveyed product is relatively light, so the use of circular belt design, It is very convenient in terms of installation and debugging, and the round belt is more wear-resistant, if you want to replace it is also very convenient, because the action in the equipment is more complicated, the cylinder structure is more, there is a need and interested friends can download and learn the drawing content is very good, the above is the whole structure and working principle of this equipment.

REVIEWS & COMMENTS

accuracy, and usability.