1/11

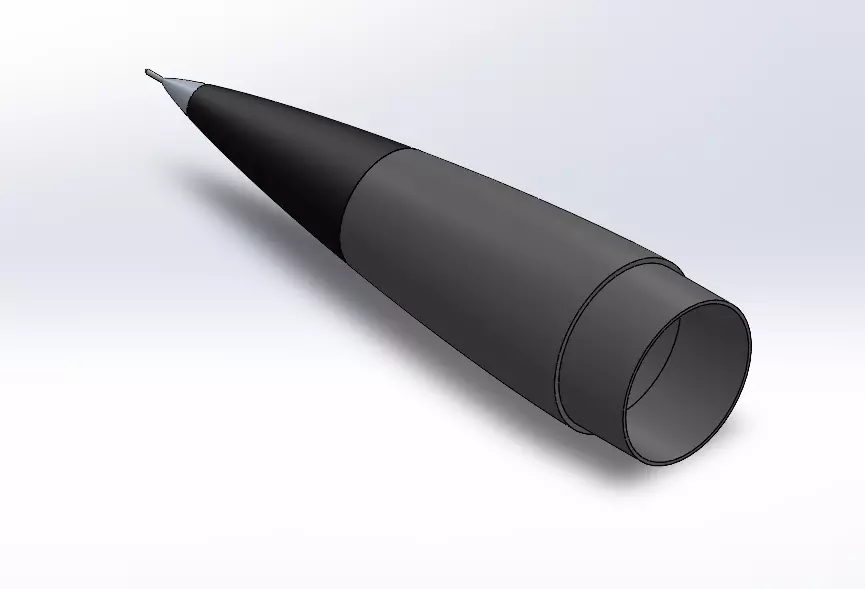

This is a precisely modeled LD-Haack (Von Kármán) style nosecone, based on the Haack series (C = 0) equations, designed to minimize aerodynamic drag for model rocketry applications.

The geometry was generated via MATLAB and modeled in SolidWorks for high-fidelity export and production. The shape ensures smooth airflow and optimal aerodynamic performance for subsonic and supersonic regimes.

Model Structure:

Aluminium Tip (ideal for machining or metal printing – optional)

Body Part 1

Body Part 2

These 3 parts form the full aerodynamic shell of the nosecone. Internal mounts (e.g., for Pitot or sensors) are not included, but the geometry allows room for custom integration.

Features:

Von Kármán profile (C = 0) for lowest drag per given length & diameter

Modular 3-part design for easier printing or machining

Printable in FDM,SLA,PLA,NYLON....

Can be adapted for Pitot tube installation if desired

Suggested Materials:

Tip: Aluminum (machined or metal-printed)

Body Parts: Nylon 6, PETG, or PLA+ (reinforced if needed)

Printing Guidelines:

Layer Height: 0.2 mm

Infill: 30–60%

Supports: Recommended for the tip interface

Tolerances: Designed for ±0.1 mm fit

Included Files:

aluminium_tip.stl

nosecone_part1.stl

nosecone_part2.stl

Note: The aluminium tip is included without a Pitot tube hole, allowing users to assemble a fully enclosed and aerodynamic nosecone without instrumentation.This makes the model suitable for use in non-sensor rocket configurations or as a general aerodynamic prototype.

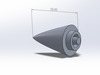

Note: This model includes only the aerodynamic shell. Sensor mounts, Pitot adapters, or recovery features are not included, but can be custom added by the user if needed.Settings and manufacturing instructionsAssembly: 565.78 mm

The model consists of 3 main parts:

Aluminium Tip 49.57 mm

Body Part 1 229 mm

Body Part 2 324.21 mm

The parts are designed to fit together with friction or light sanding. Bonding using epoxy or cyanoacrylate (super glue) is recommended for permanent assembly.

The nosecone can be mounted onto a rocket body using your own adapter or coupler system (not included).

3D Printing Guidelines:

Recommended printing orientation: Vertical, tip facing up

Layer Height: 0.2 mm

Infill: 30–60% (depending on flight/stress expectations)

Wall/Perimeter Shells: 3–5

Supports: Required only at the bottom connection faces

Material Suggestions:

PLA+ (for prototypes)

PETG or ABS (for functional use)

Nylon 6 (for durability and heat resistance)

The aluminium tip can be metal 3D printed or machined for best results, especially in high-speed applications.

Tolerances:

Designed with a tolerance of ±0.1 mm for 3D printing compatibility

You may need to lightly sand or post-process mating surfaces for a tight fit

Customization:

The internal volume of the nosecone allows for user-defined modifications (e.g., sensor housing, recovery hardware)

Tip and internal walls can be drilled or adapted as needed

REVIEWS & COMMENTS

accuracy, and usability.