1/5

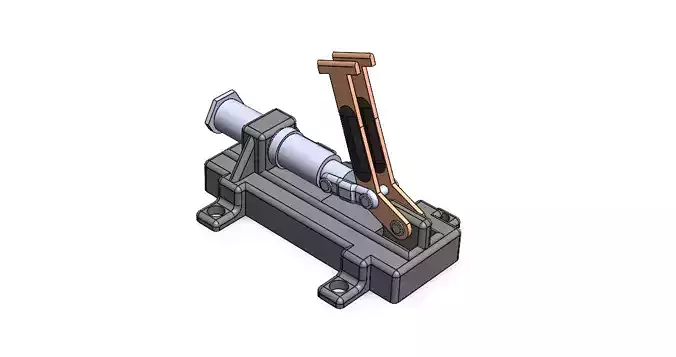

Manual Mechanical Press | SolidWorks 3D ModelThis is a functional manual mechanical press, fully designed in SolidWorks, based on an academic mechanical engineering study.

The press uses a lever mechanism to multiply force applied by hand, reaching a maximum piston stroke of 100mm and input force of 300N applied at 50mm from the handle end.

All individual parts are accurately modeled and assembled in 3D, making it suitable for 3D printing, technical demonstrations, educational purposes, or even light-duty workshop applications.

Technical Features:

Max input force: 300N

Stroke: 0–100mm

Mechanism: Hand lever-actuated piston

Materials used in design: Carbon Steel (St37-2), Alloy Steel (for pins & piston)

Includes simplified stress analysis results

Included Files:

All components in .STL and .STEP formats

Preview images (rendered from SolidWorks)

Bill of materials & design notes (on request)

File is for non-commercial use unless otherwise agreed.The design is protected — this is a functional object, not a decorative model.

Settings and manufacturing instructionsManufacturing & Assembly Instructions:

- This model is composed of multiple mechanical parts. Each component is provided as a separate STL and/or STEP file.

- Parts should be printed or machined separately, then assembled manually.

Recommended 3D Printing Settings (if using FDM):

- Layer Height: 0.2 mm

- Infill: 40–60% (higher for structural parts)

- Supports: Required for overhangs (especially under the piston and arm)

- Material: PLA+ or PETG for prototypes; Nylon or Polycarbonate for functional use

Assembly Notes:

- All pins and shafts are press-fit or can be secured with screws

- You may replace printed pins with metal rods or bolts for higher strength

- Lubrication (e.g., PTFE or silicone grease) is suggested for sliding partsNoteThe pins included in the design are modeled for theoretical purposes only and are not intended for actual assembly use, as both ends are closed with a head.For improved strength and durability, it is recommended to replace these with your own bolts, screws, or threaded fasteners depending on your specific application and material.

Tolerances:

- Designed with ~0.3 mm clearance between moving parts for typical FDM printer accuracy

- You may need to lightly sand or ream holes for smoother assembly

Material Suggestions (if machined):

- Frame/Base: Carbon Steel (St37-2 or S235JR)

- Piston: Alloy Steel

- Handle: Stainless or Carbon Steel

- Pins: Hardened Steel or AISI 304

This model is meant for educational and light-duty demonstration purposes. It is not certified for industrial force loads.

REVIEWS & COMMENTS

accuracy, and usability.