1/6

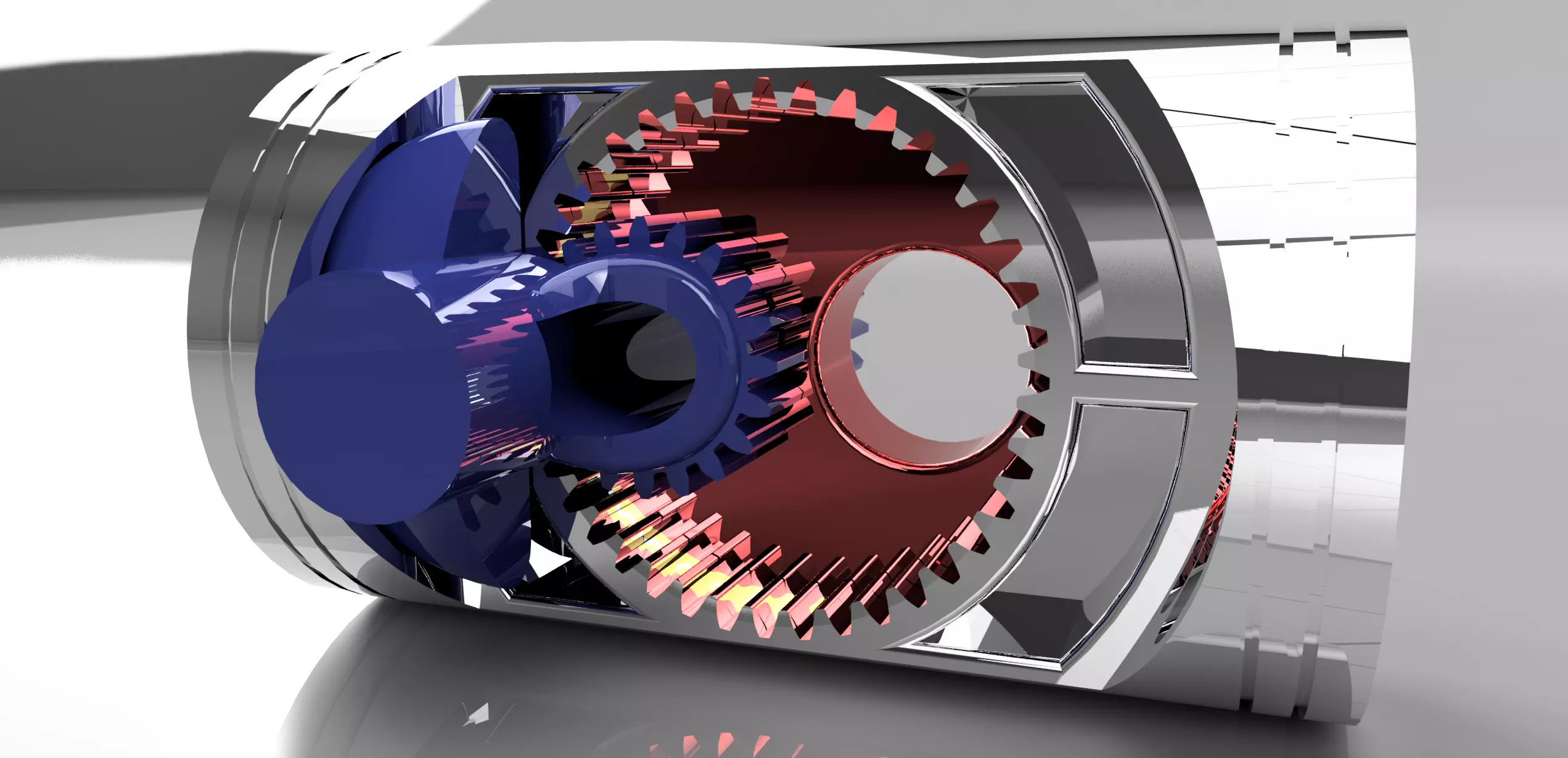

My design for a new type of internal combustion engine, Using a crankshaft and a counter rotating eccentric lobe, which are kept in sync with a simple gear system. This is simply a different way of building the short block of an engine...with many advantages..such as reduced friction..smaller size..far less moving parts, higher revs, more power, and so on. This concept could be used in engines of any size or cylinder number..even a one cylinder configuration is possible. I left out the main crankshafts counter weights in my animation so that the concept could be shown clearer, also an engine built in a 4 cylinder or configuration would be much easier to balance. And here are the technical specs....... There would be one or two ring gears (with teeth numbering 2x) attached to or part of the pistons surrounding the crankshafts with their diameter equal to the throw of both crankshafts combined or (2y). One or two gears (with teeth numbering x and diameter equal to y) attached to the primary crankshaft affixed to the rod journal so that they ride inside of the ring gear(s). The main crankshaft and secondary (or eccentric lobe) will have the same offset, therefor if each crankshaft has a throw of two inches the pistons would then travel a total of four inches. The engine would have a minimum of two pistons, each set of opposing pistons are bolted together, making one solid unit. This engine would have opposing pistons similar to a Boxer engine configuration, with the exception that the pistons are directly across from one another. The cylinders and heads will work the same as they do in a conventional engine. The benefits of this design; There are no connecting rods. So the engine should be able to withstand much higher RPMs than a conventional engine. This design also insures that the pistons will stay in-line with the cylinders, and therefor reducing friction. There are also less moving parts, a 4-cylinder engine built using this design would have only 5 moving parts in the short block, as opposed to the 9 moving parts found in conventional 4-cylinder engines. Components; A. The crankshaft, a standard looking engine crankshaft, with the exception of the gear(s) permanently affixed to the rod journal, with teeth numbering x. The diameter of the gear(s) is equal to the throw of the main crankshaft or y. B. The secondary crankshaft, or eccentric lobe is round with an offset hole that the main crankshafts (A) rod journal rides in. C. The pistons, which when bolted together form one solid unit from piston to piston. . They have a hole in the middle where the main (A) and secondary (B) crankshaft ride. D. Ring gear(s), with teeth numbering 2x. The gear(s) that are affixed to the main crankshaft (A) ride inside this ring gear(s). The diameter or the ring gear(s) is equal to the throw of both crankshaft and eccentric lobe combined or (2y).

REVIEWS & COMMENTS

accuracy, and usability.