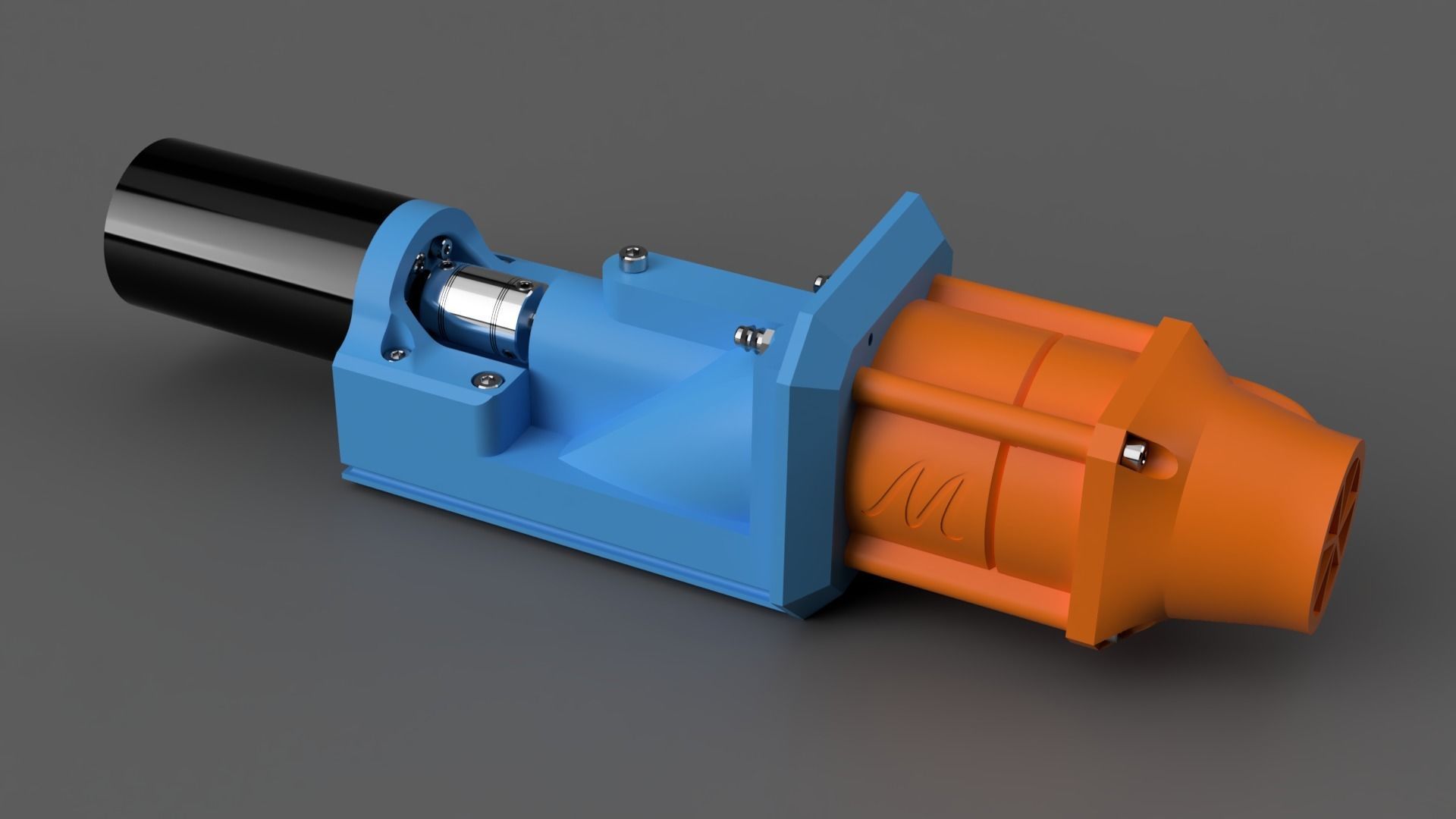

M-Jet 60 - 3D Printable Jet Drive for Electric Surfboards 3D print model

Join the official M-Jet facebook group! https://www.facebook.com/groups/623045356071128

Propulsion system for DIY electric surfboards.

Basic PDF manual: https://drive.google.com/file/d/1WgkuZUZwO3yLBlEEI8PD1eNt4OGTMnqZ/view?usp=sharing

Includes part list, print settings and basic assembly and installation guide.

You get 8 STL files for 8 parts of the jet drive, designed to be FDM 3D printed on any conventional 3D printer. You also get a STEP file of the whole pump, ready to be edited to your needs.You can 3D print it, assemble it with the help of a basic manual. Use two pumps to make your own electric surfboard.

The M-Jet 60 project originally started as a collaboration with the intention to produce the pump physically. The collaboration ended, and therefore I as the designer, decided to sell the design on its own and enable people to build the pump themselves.

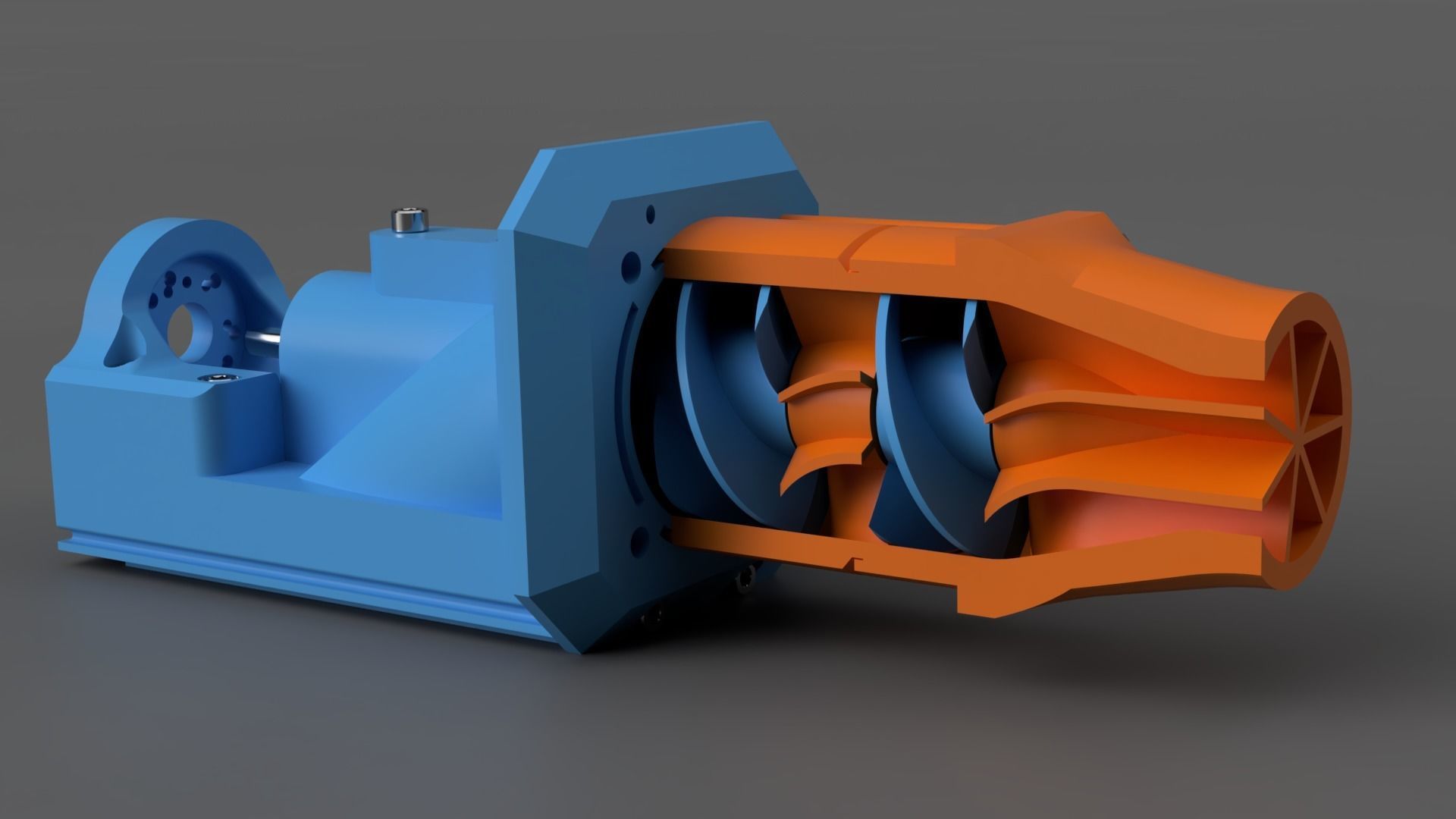

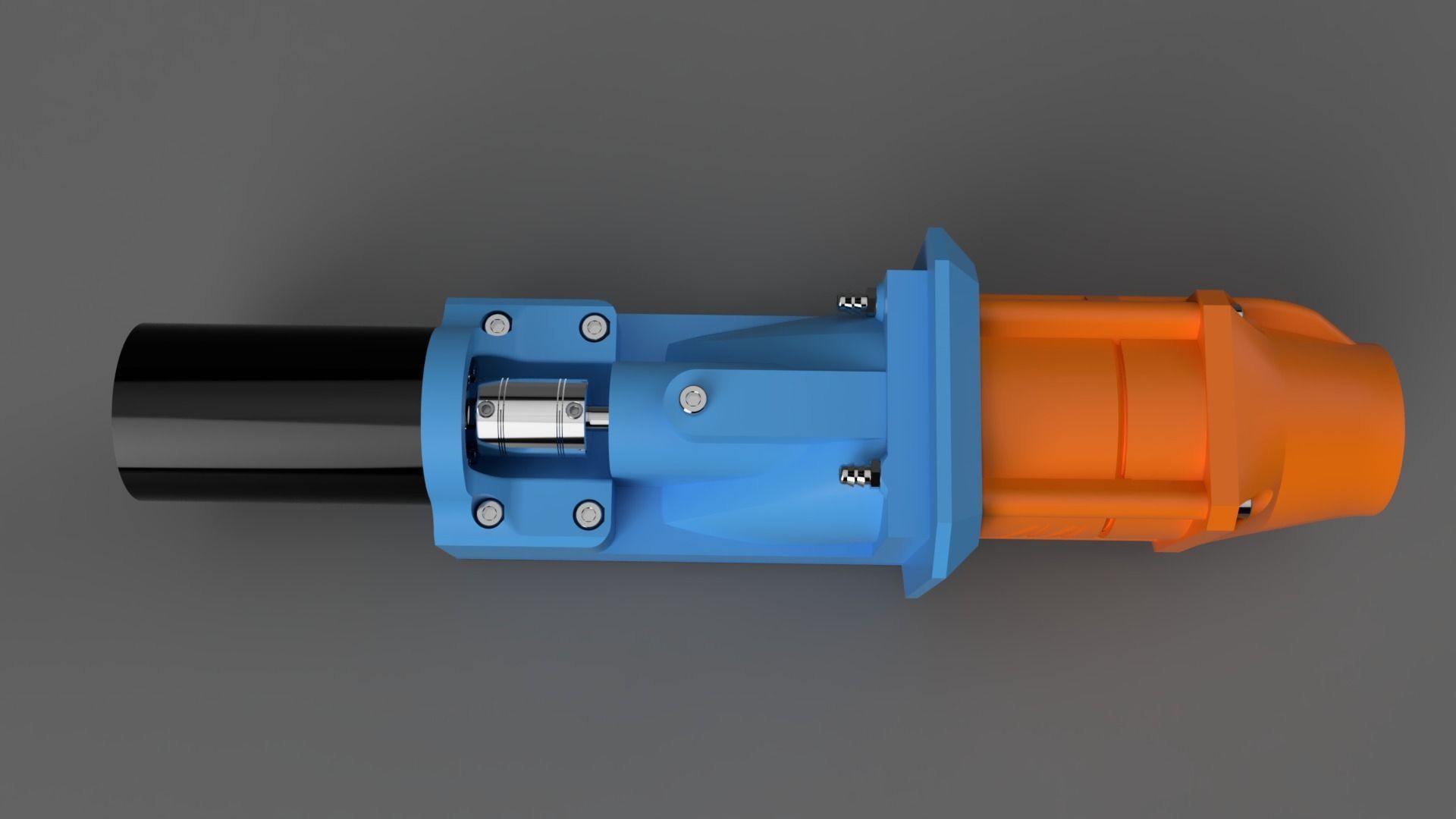

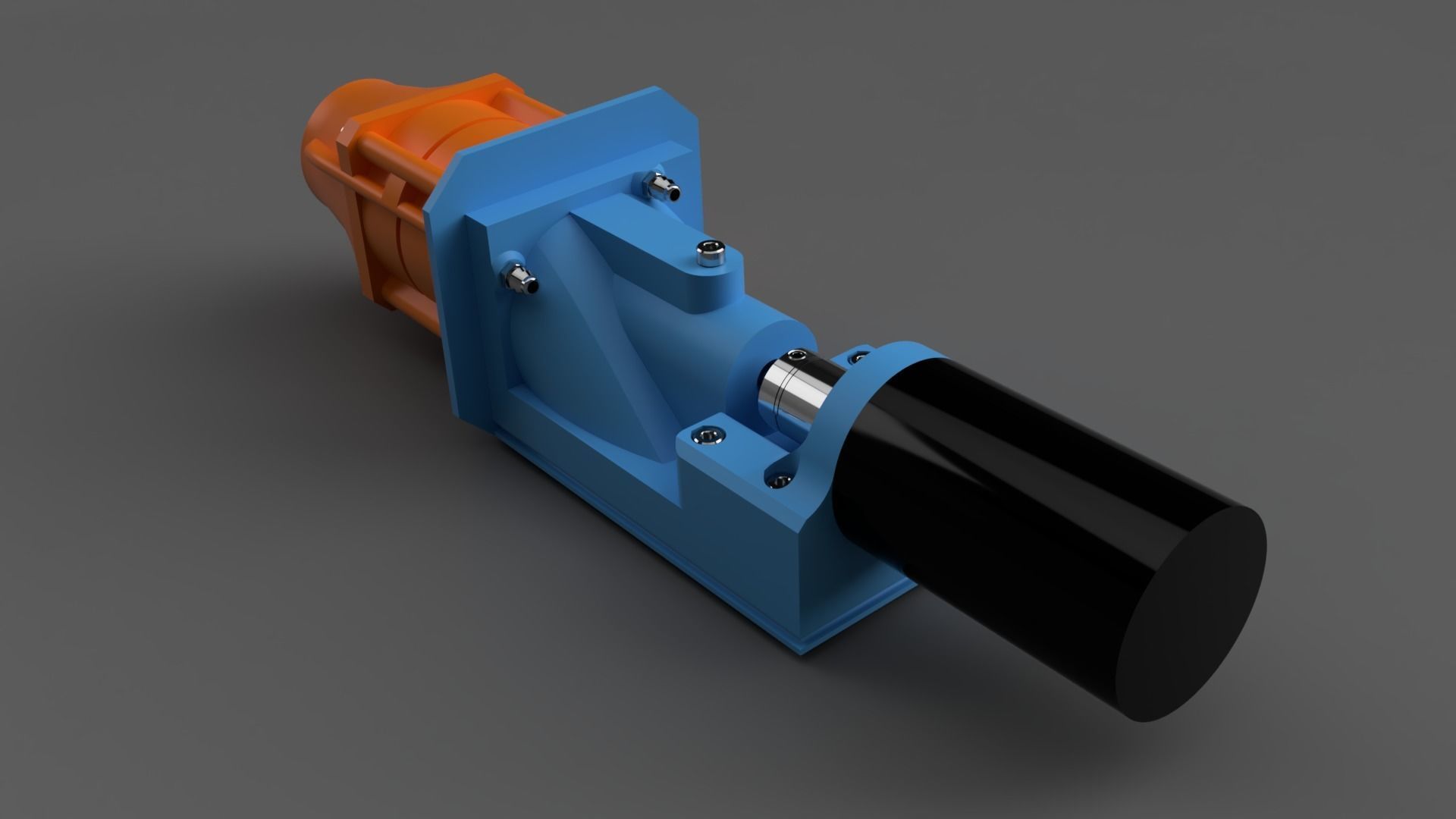

The design is heavily based on my previous M-Jet 30 pump. Main features are 2-stage configuration (2 impellers in a row), integrated motor mount, integrated watercooling, intake grate, thrust bearing, simple impeller mounting system, rear installation. The pump achieves 20kg thrust on 14000 RPM.

Update 24.02.2022: A folder Mods_for_M-Jet_60 with a modified housing with no intake grate was added to the files.

Update 23.05.2022: A single stage mod was added to the Mods_for_M-Jet_60 with modified first impeller and second stage to work in a single stage (single impeller) configuration.

Update 3.6.2023: STEP file of the whole pump was added with the M-Jet_60_STEP_file folder.