1/5

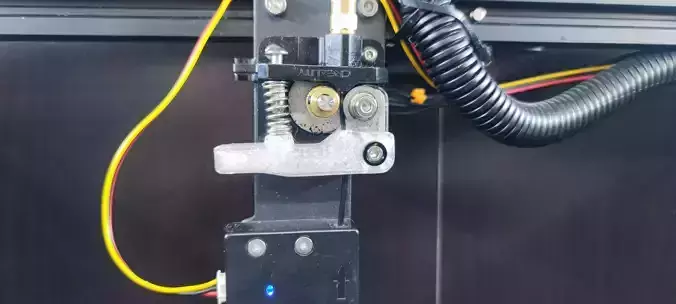

This will work superb, if you take out the billet that is used behind the ballbearing that supports the filament, heat it up and screw it in while holding it in place. Some work is necessary to drill if you dont have the retraction settings correct. My original Creality extruder handle broke off from the bolt that retains the ballbearing. It was sqeeking at first, then it didnt feed the filament, so then i discovered that it was broken after i uninstalled the extruder. Now it extrudes fine, no artifacts etc.

Hole for filament is 2mm, but you might have to drill if your settings isnt correct. Some trial and error, fortunately i didnt have any problems. My settings isnt correct for yours, so with some patiences you will make it!

I highly recommend CPE HG100 filament, as this has proven itself to be the most viable filament to hold both strength wise and when you heat up the billet. However PETG and Carbonfiber can also work but i havent tried the latter.

I have also improved the spring retainer on the bottom part, making it 2mm higher than the original part, so it will be a lot tighter fit. NO slippage!

Only setting i will recommend is using bottom layer as 50, or 100% infill.. I used 50 layers for bottom and worked super!Enjoy!

Ps. I used 1.0 Nozzle, so i didnt have the ridges, and its not that detailed as it could have been if i had used a 0.4 nozzle.

REVIEWS & COMMENTS

accuracy, and usability.