1/4

The factory slide mount that Creality Ender-3 PRO provides is far from ideal. I downloaded and printed several other designs found on the internet but none quite met my expectations. So, I designed my own.

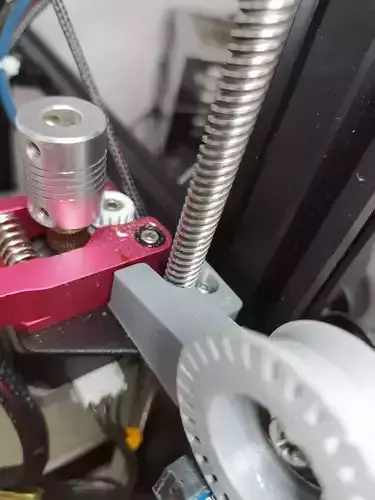

I wanted something that also facilitates the exchange of filaments, because as my printer is closed, the space is quite tight and the thing is very difficult. I also wanted an ideal way for the filament not to touch the Z axis I designed this hinged filament sensor bracket so that it can be attached to one of the Z axis brass lead screws using factory hardware and then the bracket is stabilized on the Z-post roller bracket directly on the hinge.

This end of filament sensor assembly is solid and will not bend during retractions or under filament spool tension.

If you want to enable the Runout functionality, there are several videos on YouTube explaining in detail how to change the software on your Ender3 PROSuggested videos:https://www.youtube.com/watch?v=8aj20G-ZxyUhttps://www.youtube.com/watch?v=5Jt-Qc67FDo&t=18s

Hardware needed:608zz bearingMicroswitch 3 pins for PCB Kw12-31 M4 screw - 20mm with nut2 M6 screws - 20mm with nuts1 PCB - Sensor de Velocidade Encoder1 Arduino Uno boardI added the SolidWorks 2021 file. If you wish, make the changes you deem necessary.

Note: It may be compatible with other similar printers, but I only tested it on my Creality Ender-3 PRO

3D PRINTING SETTINGSPrinter : Ender 3 PROPrint position: Gutter face upRafts : AdvisableSupports: Yes (touching the table)Resolution: 0.20 or lowerFilling: Cubique 99%Filament Material: PETG

REVIEWS & COMMENTS

accuracy, and usability.