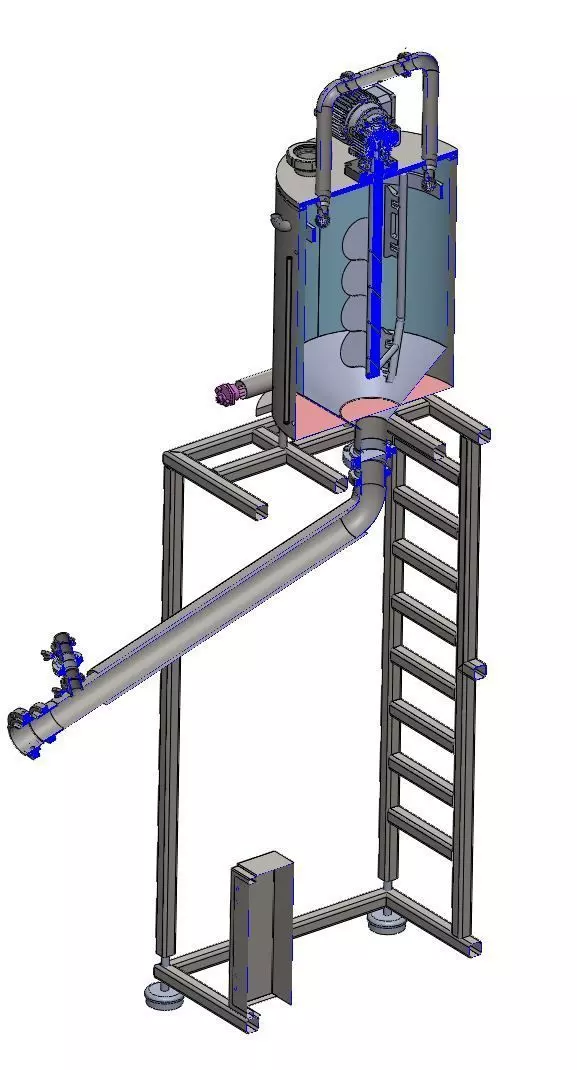

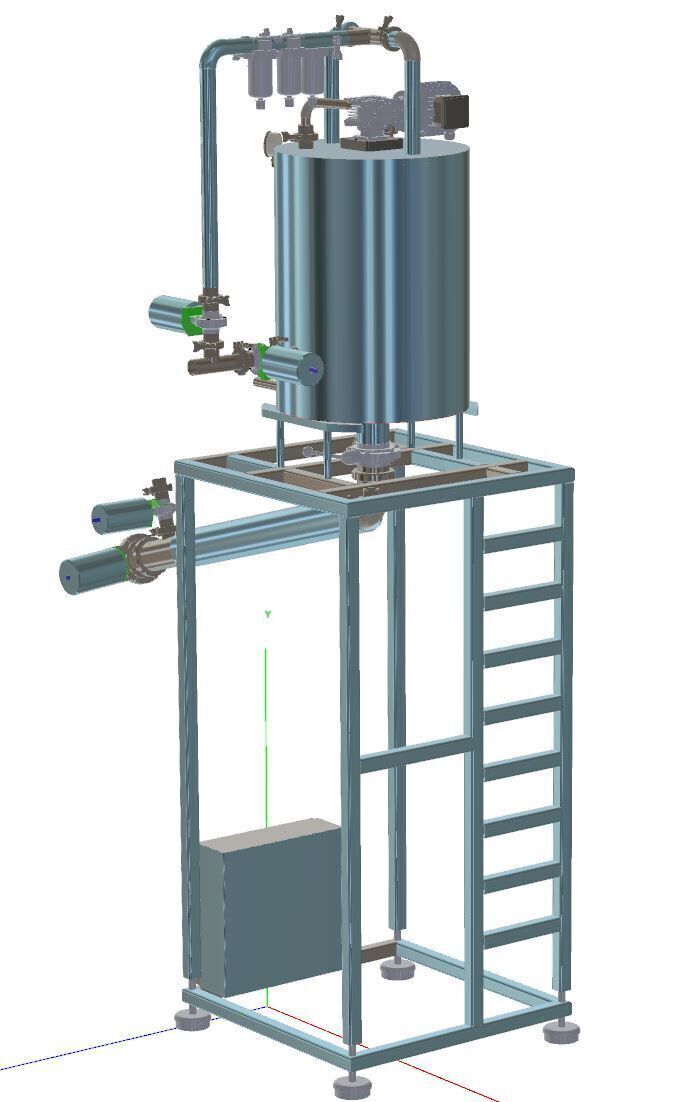

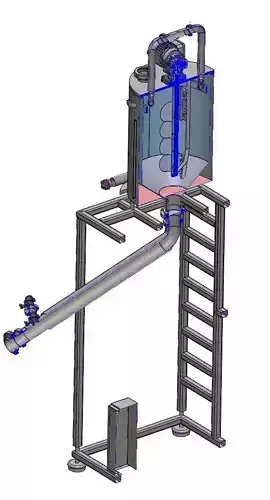

Double-Jacketed Heated Free Flow Filling Tank CIP Compatible 3D model

This custom-designed tank is engineered for heating and homogenizing liquid products prior to filling, using a free-flow discharge system.

With a diameter of 450 mm and length of 652 mm, the tank offers an approximate gross capacity of 103 liters. Its double-jacketed structure allows for precise temperature control by circulating hot water or oil between the inner and outer walls.

An integrated mixer ensures continuous homogenization of the product and prevents sedimentation, making the tank ideal for use in food, cosmetics, and chemical industries.

Additionally, the tank is fully compatible with CIP (Clean-In-Place) systems. It includes dedicated CIP valve lines designed to allow cleaning fluids to pass through all internal surfaces efficiently, ensuring hygienic conditions are maintained without disassembly.