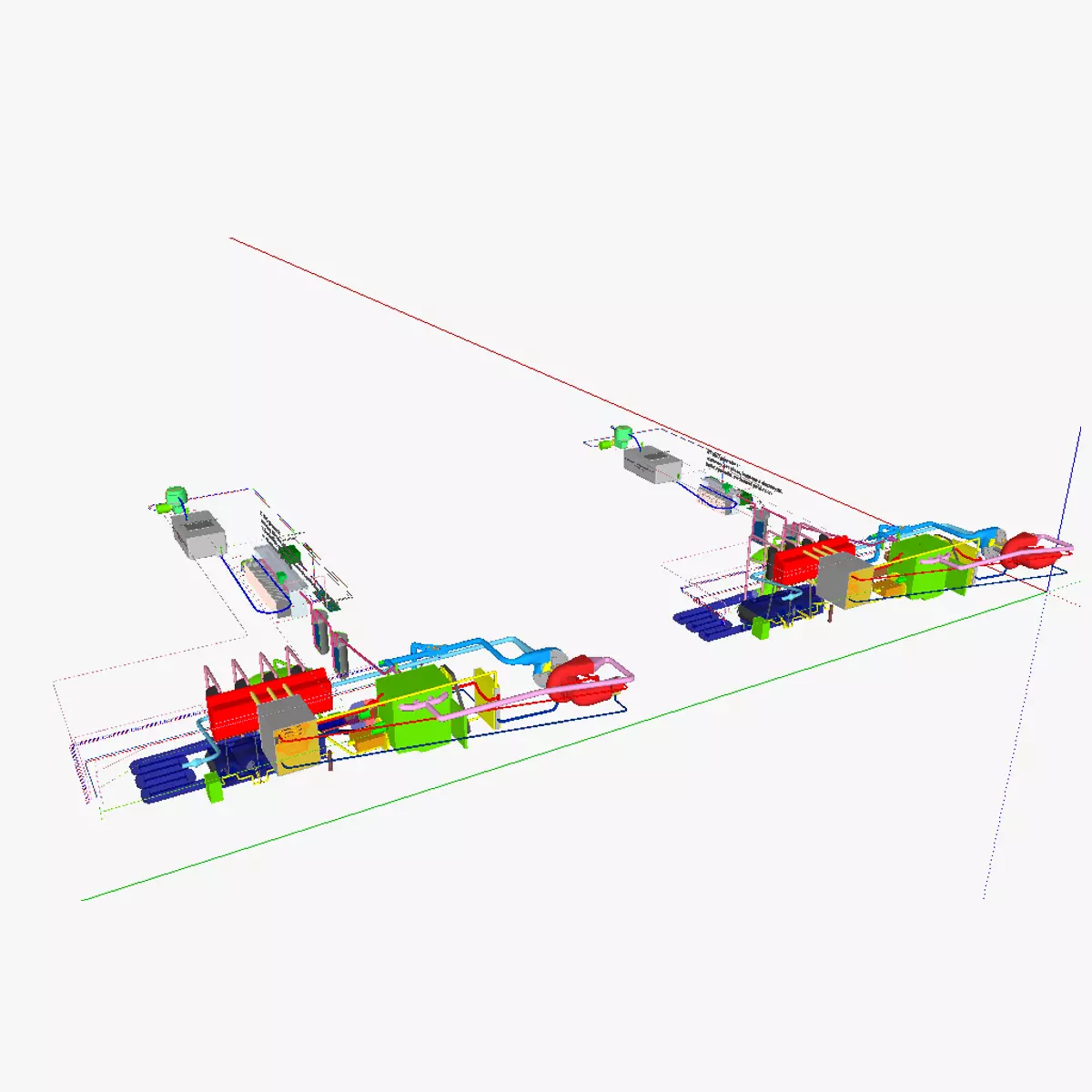

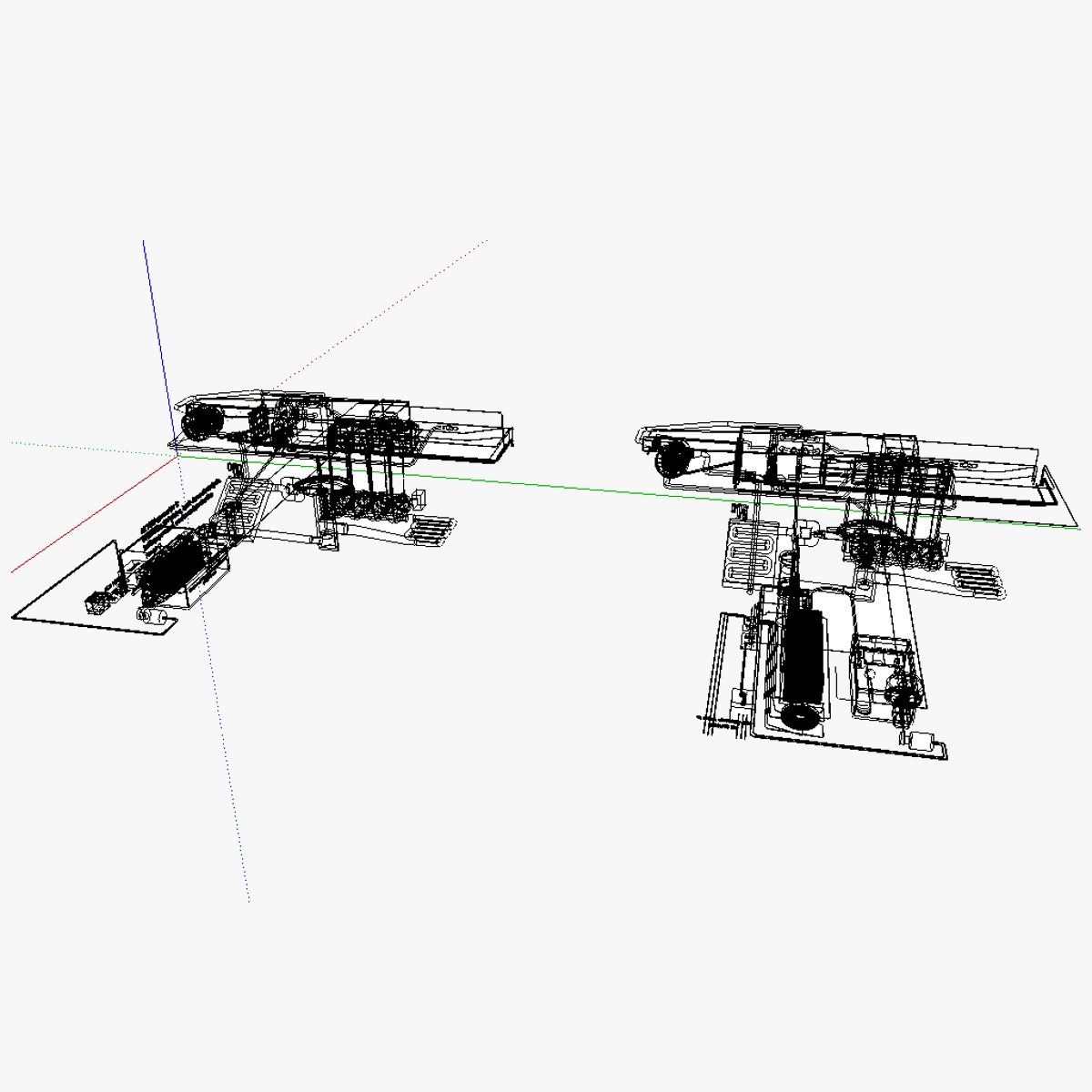

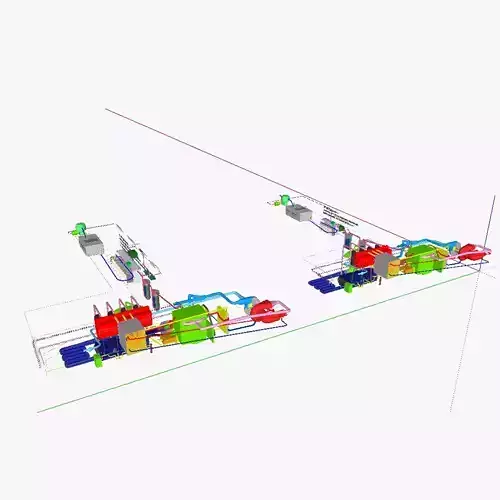

Oxyhydrogen fed AT IC motor 3D model

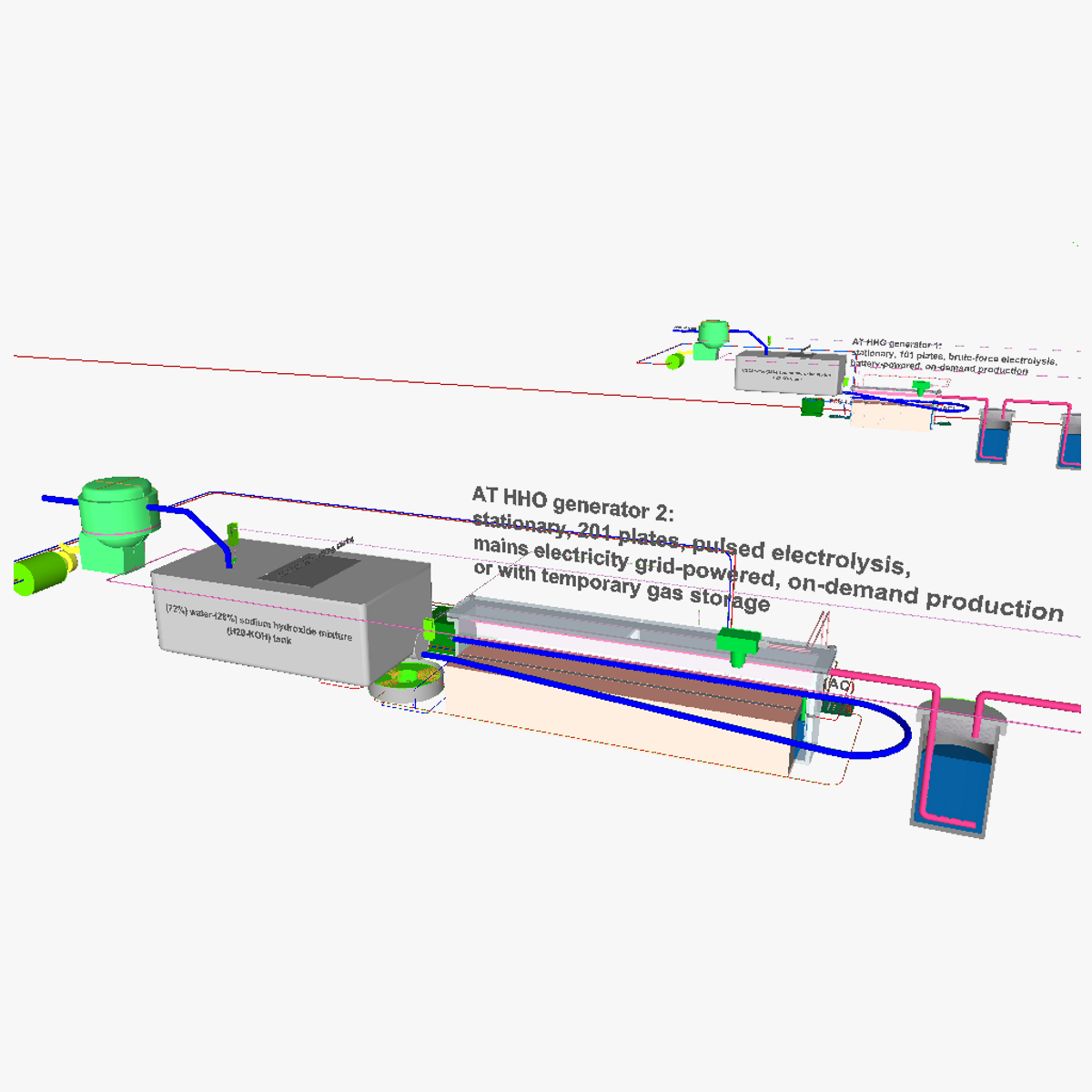

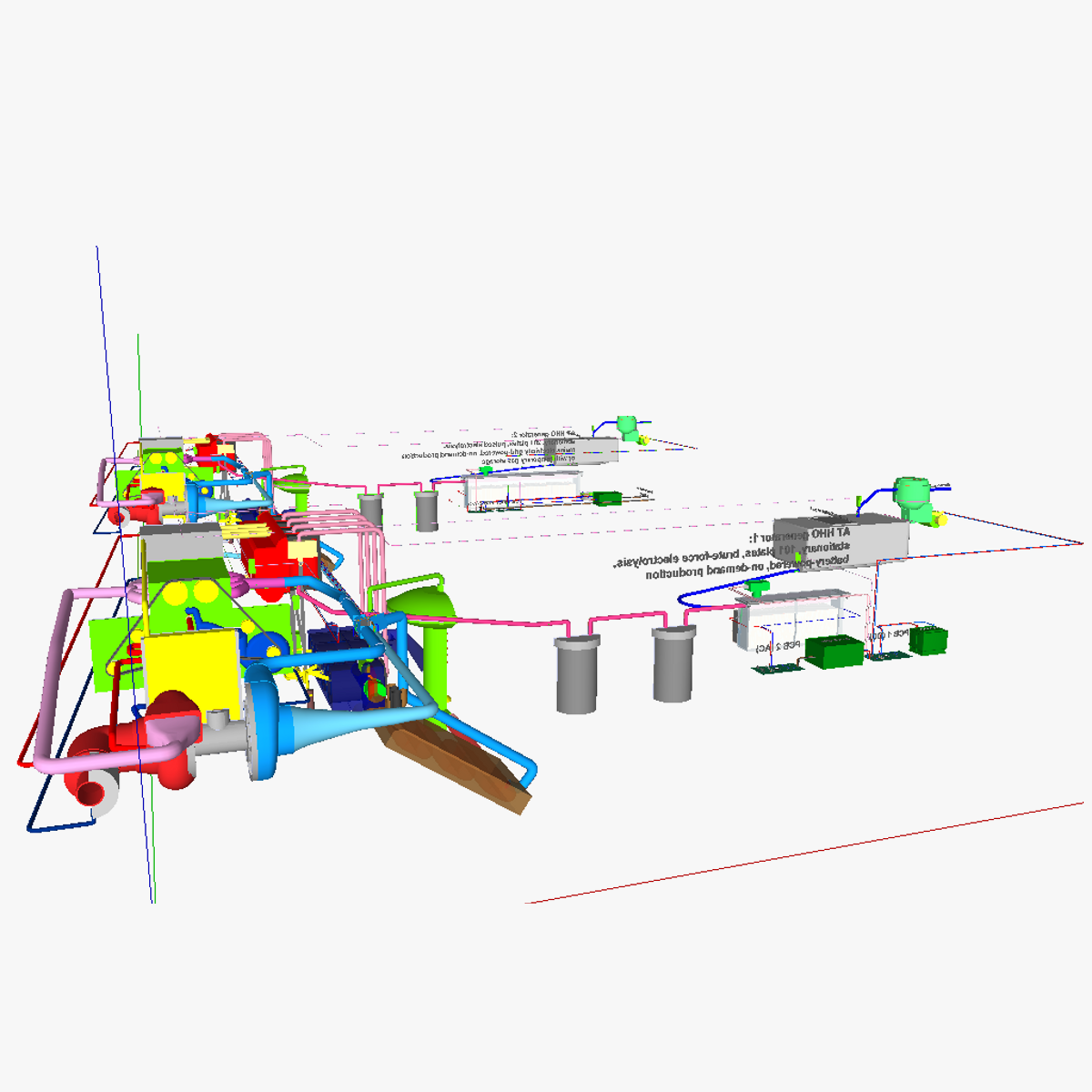

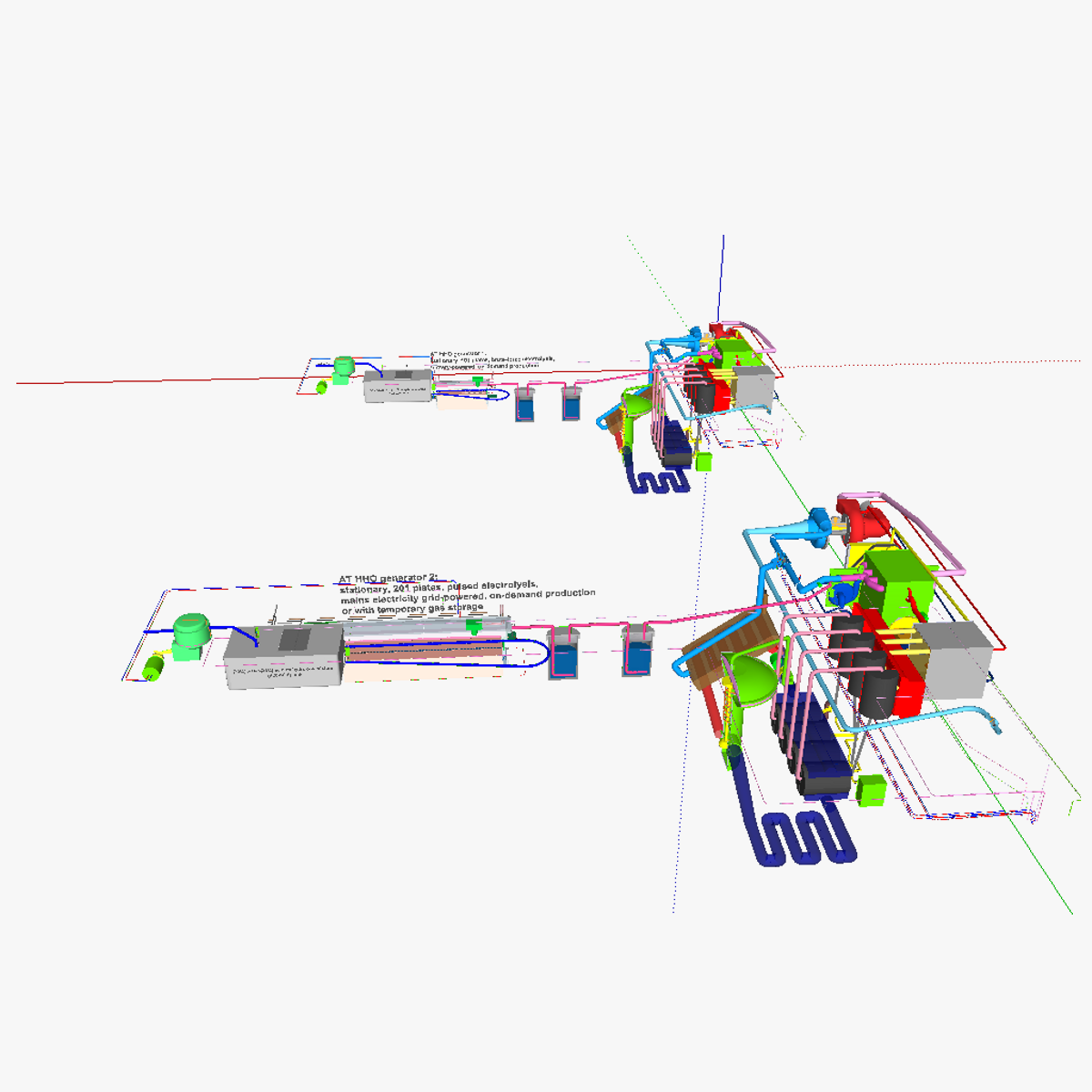

3D model of a oxyhydrogen generation system connected to an IC motor. The oxyhydrogen generation system creates oxyhydrogen gas from water and uses this gas to run an internal combustion engine on. The system was inspired on the system designed by Bob Boyce, but minor simplifications were implemented. This includes: changing the gas pressure switch to a sensor and hooking it up directly to the printed circuit board (PCB) instead of using a relay, another improvement (done in the 3D model) is the use of 2 PCB's, one on DC-power, the other on AC-power. The parts in blue show the electrical parts; the parts drawn in green show the water supply and the red parts show the parts of the gas outlet. According to Patrick J. Kelly, normally, 10% efficiency is attained with electrolysis, yet with the Bob Boyce eletrolyzer, without resonance (brute-force electrolysis) one can attain 600-1000% more efficient energy use. In practice, this means that we attain 6 to 10X more energy output (as gas) than the power introduced to the electrolyzer (electricity). Given that the electrolyzer is 6X less efficient with the brute-force method, we should still have as much energy output (gas) as input (electricity), (6 to 10 divided by 6 is 1 to 1,6) . For mobile applications, that would mean that we actually just convert allready present electricity (ie in the battery). However,if we also calculate in the thermal energy recovery, we attain a number somewhere between 8,4 to 10X more energy output (as gas) with a Bob Boyce-electrolyzer with pulsed electrolysis, and 1,4 and 2,24 with brute-force electrolysis. So, even with brute-force electrolysis, we still double the duration (or power output) we could normally operate using the battery (ie when using the battery immediatelly hooked up to a electrical motor). Another (and perhaps more important advantage than the energy efficiency) is that, as the motor now runs on electricity as the primary energy source, we can also create extra energy at no expense. This is done using energy harvesters (ie wind turbines, PV-panels, ...) To recapitulate, the setup is hence very valuable for IC motor conversions as it allows to make the IC motor emissionless, it allows the use of 'free energy' (energy made on-site using energy harvesters), finally, it increases energy efficiency, as much more gas can be produced than what it requires in electricity ((energy output is larger than input) What it doesn't allow though is efficient storage of power. This, as oxyhydrogen reverts to hydrogen after a while (after 1 to 2 days). This reduces energetic level by 400%. Even after 1-2 hours and compressed in a special-material tank and/or cooled, a good deal of the energy of the gas will have allready dissapated. So, with compression and/or cooling it's possible to store the HHO gas very temporarily, with some reduced energy efficiency. Any longer, and it's little beneficial to perform this operation.

The IC motor itself was improved to a large extent aswell, by replacing the original radiator for cooling with 2 oil tanks circulating the heated/cooled down oil. An Alpha-type stirling motor is added to also immediatelly generate electricity; making it a hybrid system, immediatelly improving efficiency by 40% (making it 70% efficient; IC-engine is 30% efficient). The cold pistons of the stirling motor are cooled by circulating water. The electricity generated can be returned to the net (via net metering). See the 'Purchasing_the_models' link at