1/11

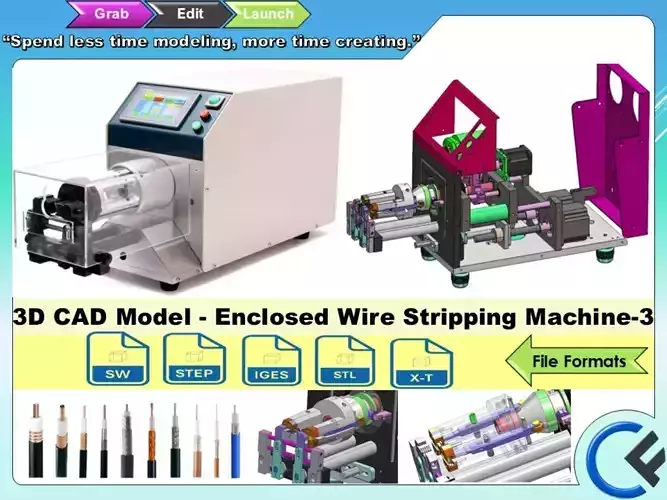

A 3D Design for a Wire Stripping Machine is a detailed digital representation that visualizes the structure, components, and working mechanism of an automated or manual wire stripping device. This design aids in engineering analysis, prototyping, and manufacturing by providing a clear and precise model before production.

Key Features of the 3D Design:High-Precision Modeling: Captures intricate details of cutting blades, rollers, and motor mechanisms.Realistic Rendering: Displays accurate materials, textures, and machine components.Mechanical Simulation: Demonstrates wire feeding, cutting, and stripping actions for performance validation.Customization & Optimization: Allows modification for different wire sizes, stripping techniques, and automation levels.Integration with Automation: Visualizes motorized and sensor-based systems for enhanced efficiency.Components Modeled in 3D:Wire Feed System – Guides the wire into the stripping mechanism.Cutting & Stripping Blades – Precisely remove insulation without damaging the wire core.Rollers & Grippers – Hold and transport the wire during operation.Motor & Drive System – Powers the stripping process (for automatic models).Control Panel – Manages speed, wire size adjustments, and automation settings.Waste Collection Unit – Collects insulation remnants for a cleaner workspace.Safety Cover & Frame – Ensures user safety and structural durability.

REVIEWS & COMMENTS

accuracy, and usability.