1/4

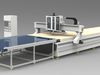

Conveyor Table: It has a storage system that speeds up the automatic loading and unloading of parts. This makes the production process more efficient.

Multi-Directional Cutting: It has a milling motor (spindle) that can process with high precision. It automatically performs different processing steps by changing the various cutting tools shown.

Vacuum Table: A vacuum table is used to fix the parts. This ensures that the part remains stable during processing.

Dust Suction System: There is a dust collection system that keeps the work instructions clean by absorbing the dust generated during the process.

Automatic Tool Change: Automatic tool change feature for different cutting and operations

These features help the machine to increase the efficiency of the range, especially in cutting large wooden panels, engraving, milling and drilling

REVIEWS & COMMENTS

accuracy, and usability.