1/17

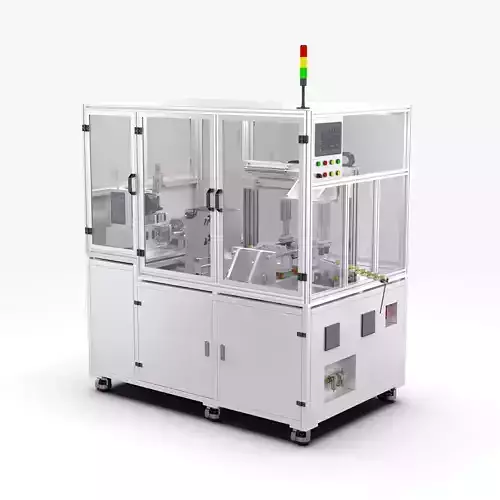

Automatic Micro Motor Rotor Assembly Machine

Introduction

This equipment is used for the assembly and production of rotors in the micro-motor industry. The main products used are squirrel cage rotors with 8042 series rotor specifications. The whole machine mostly adopts the servo mechanism, the equipment features, the chamfering mechanism removes the flash and other foreign matter generated during the die-casting of the squirrel cage rotor, and the power head mechanism is adopted. At the same time, the rotor shaft storage mechanism has a large storage capacity, and at the same time, a horizontal mechanism is used to thread the shaft. The rotor is positioned through the pre-threaded shaft and then the rotor shaft is threaded into the rotor shaft hole. The transfer mechanism part adopts linear synchronous transfer and adopts pneumatic structure. The riveting part uses a 5-ton equivalent servo electric cylinder for riveting. The beat of the whole machine is controlled at 5s, and the riveting depth and riveting pressure are fed back and recorded in real time through the pressure curve.

File Formats

- SolidWorks 2018 | Keyshot 10

- STEP (Standard for the Exchange of Product Data)

- IGES (Initial Graphics Exchange Specification)

- STL (Standard Tessellation Language )

- OBJ (Object Files)

Geometry

- Polygons: 2,092,243

- Vertice: 6,276,729

REVIEWS & COMMENTS

accuracy, and usability.