1/8

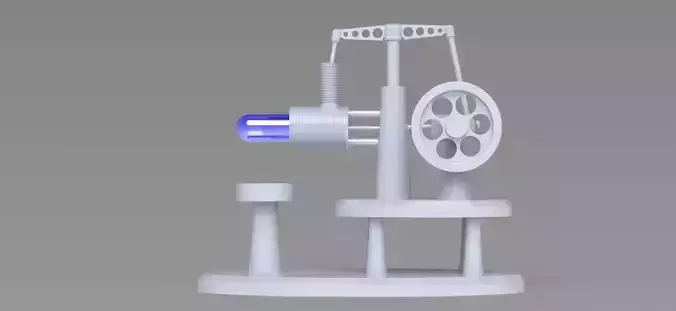

this is a sample model design of tealight candle driven stirling engine part modelling and assembly in solidworks .

A tea light candle-driven Stirling engine is a small heat engine that operates using the heat generated by a tealight candle to produce mechanical work. Stirling engines are known for their ability to convert heat energy into mechanical motion through cyclic compression and expansion of a working fluid (typically air) at different temperature levels. Here's an overview of how a tea light candle-driven Stirling engine works:

Components:

Displacer Cylinder: This is the main chamber where the working fluid (usually air) is alternately compressed and expanded. It contains a displacer piston that moves the working fluid back and forth.Power Cylinder: This cylinder also contains a piston, but it is responsible for converting the working fluid's pressure changes into mechanical work.Flywheel: Attached to the power piston's connecting rod, the flywheel helps smoothen out the engine's motion and store rotational energy.Heating Plate: This is where the tealight candle is placed to provide the heat necessary for the engine's operation.Working:

Heating: The tealight candle is lit under the heating plate. The heat causes the air inside the displacer cylinder to expand and rise, pushing the displacer piston upwards.Cooling: As the air in the displacer cylinder cools down, it contracts and sinks, causing the displacer piston to move downwards. Simultaneously, the power piston moves upward due to the reduced pressure in the power cylinder.Compression: As the displacer piston moves downwards, it compresses the air in the power cylinder, increasing its pressure and temperature.Expansion: The increased pressure of the air in the power cylinder pushes the power piston downwards. This is the power stroke, where mechanical work is generated.Exhaust: The displacer piston rises again, allowing the air in the power cylinder to cool down and the power piston to move upwards.Repeat: The cycle continues as long as the tealight candle continues to provide heat.Advantages:

Educational Value: Tea light candle-driven Stirling engines provide a hands-on way to learn about heat engines, thermodynamics, and energy conversion.Simple Construction: These engines can be constructed using relatively simple materials and basic tools.Disadvantages:

Low Power Output: These engines are typically low-power devices suitable for demonstration and educational purposes, rather than practical applications.Limited Efficiency: Due to their small size and simplicity, their efficiency might not be high compared to larger and more complex engines.Tea light candle-driven Stirling engines are often used as educational tools, providing a visual demonstration of the principles of heat engines and energy conversion. They are a great way to engage with basic engineering concepts and experiment with thermodynamics in a hands-on manner.

REVIEWS & COMMENTS

accuracy, and usability.