1/23

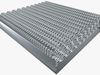

Create your own super light chain mail with 3d printing Turn your 3D printer into a medieval forge with this groundbreaking, multi-layer chainmail model, meticulously designed to maximize space while offering unparalleled fidelity. The result is a life-sized chainmail sheet larger than your printer's build plate. Whit this files you can print large pieces of chainmail and assemble a whole shirt very quickly. Video Tutorials: https://www.instagram.com/propsmaker/reel/C7PDuzHOB1M/ https://www.instagram.com/propsmaker/reel/C59P1-6v6s1/ The files included enable you to print and assemble your own full chainmail shirt, boasting a remarkable level of detail and durability. Package Includes: - Front left chainmail piece - 36 hours - Front right chainmail piece - 36 hours - Back chainmail piece (print twice) - 36 hours per piece - Sleeve chainmail piece (print twice) — 17 hours per piece - Calibration test file for print optimization - Individual ring file for assembly and repair. Total Printing Time: 178 hours Note: All print times are based on the Prusa Core One. Design of the Week on Fabbaloo By Kerry Stevenson on October 24th, 2022 in Design (https://www.fabbaloo.com/news/design-of-the-week-3d-printed-chainmail)

Printing Settings

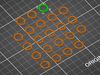

3D printing settingsVERY IMPORTANTIt is imperative that both the general layer height and the first layer height are set to 0.3mm. The model is meticulously designed with this specific layer height in mind to ensure optimal adhesion among the rings and to the platform. Deviating from this set layer height could adversely affect the print's integrity, risking failure.Key Specifications:

- Critical Adhesion: Good adherence to the build plate is crucial for preventing warping and deformations that may ruin ring geometry, leading to assembly or wear issues.

- No Supports Needed: The model includes built-in supports where necessary.

- Adhesion Platform: A specialized platform enhances ring-to-bed adhesion, preventing print failures.

- Leveling Aid: The adhesion platform doubles as a leveling assistant.

- Optimized Layer Heights: Designed for a 0.3mm layer height for optimal adhesion between rings.

- Stringing: Use DRY filament to avoid stringing

- Slice Time: Complex polygonal design requires patience in slicing;Additional InformationEnsure your printer is well-calibrated and the bed is leveled for optimal results. Maintain bed adhesion by keeping the bed clean and free of grease. Use isopropyl alcohol for cleaning and apply adhesive if necessaryTroubleshooting tip:If rings detach mid-print, it could be due to collisions while moving between rings.To prevent this, use a Z lift of 0.5 mm.

REVIEWS & COMMENTS

accuracy, and usability.