Useto navigate. Pressescto quit

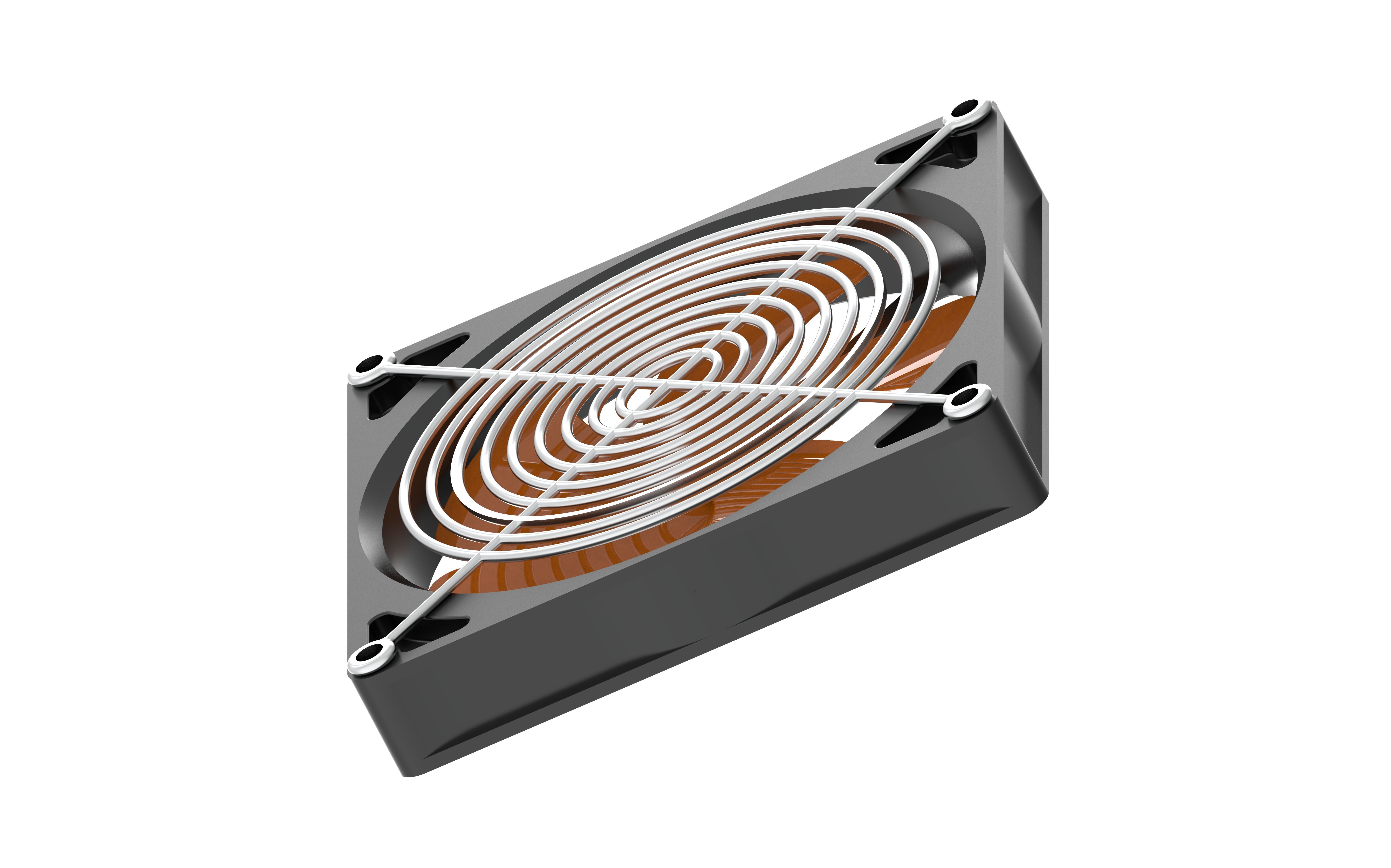

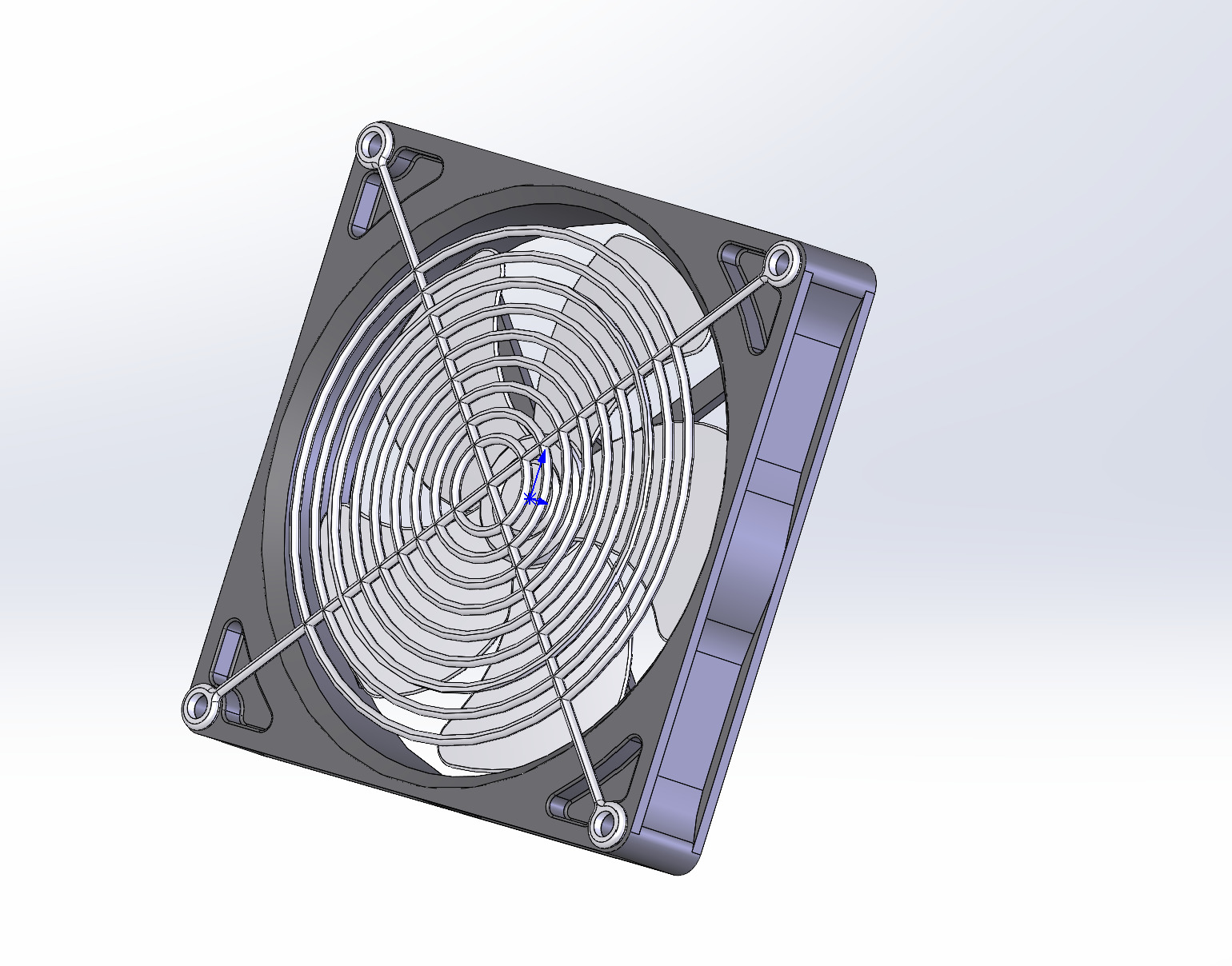

A 3D printed fan 3D print model

Description

3D printed fans are made by stacking materials layer by layer using additive manufacturing technology. Its core advantage lies in high customization: users can freely design unique blade shapes, frame structures, and sizes to optimize airflow, noise, or match specific spaces. Commonly used lightweight PLA or ABS plastic printing is very suitable for making prototypes, small batch production, personalized computer heat sinks, maker projects, or educational models. 3D printing technology greatly reduces the threshold for complex fan designs, enabling rapid iteration and personalized creative expression, while also supporting the use of recycled materials, adding more environmental value.