1/16

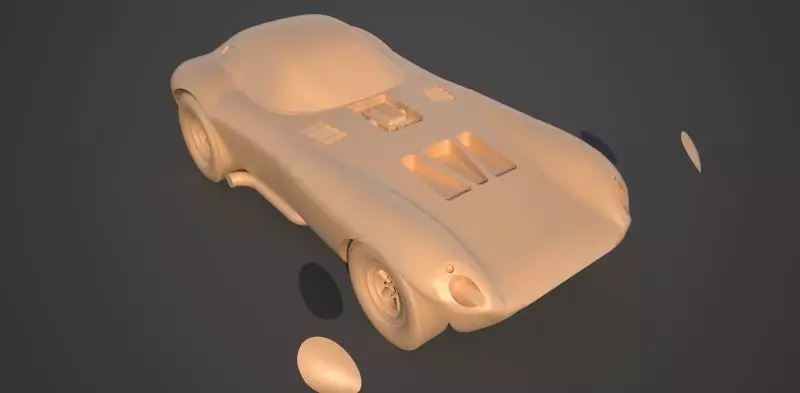

This model was designed in Sketchup and converted to other formats using the buit-in sketchup converter. Rendering program is VRay 5. Materials and Textures in model from Sketchup library and VRay library. Diferent parts of the model (steering wheel, lights, tires and wheels, wing mirrors, seats, etc.) are compiled in components and grouped in one single model.

This model is offered as it is

In 1963 Thomas gained covert support from General Motors Performance Product Group head Vince Piggins to develop the Cheetah as a concept vehicle. It was designed by Thomas and Don Edmunds, his lead fabricator. Edmunds is credited with the bulk of the construction of the car. Financing for the project came from private investors, Thomas, and John Grow, a Rialto California Chevrolet dealer. Grow owned the prototype car. Using his racing connections, Thomas arranged for material assistance from Chevrolet for the major components - the Corvette 327 engine, Muncie transmission, and independent rear-end assemblies. Other components were stocked from the larger GM parts bin, such as Chevrolet passenger car spindles, and NASCAR spec Chevrolet drum brakes.

The production models used fiberglass bodies. The first were produced by two different companies - Contemporary Fiberglass and Fiberglass Trends. Contemporary Fiberglass was selected to produce the bodies following some problems with the Fiberglass Trends molds. Fiberglass Trends went on to produce their own version of the Cheetah under the name GTR, which was used for drag racing.

The Cheetah's chassis was constructed of Drawn Over Mandrel (DOM) cro-moly tubing that was heliarc welded (more commonly referred to as TIG or tungsten inert gas welding) using a P&H Mining DAR-200 welder. The design of the car was unusual in that it was front engined, but with the engine sitting so far back in the chassis that the output yoke of the transmission connected directly to the input yoke on the independent rear suspension's central differential pumpkin housing, basically making the driveshaft only a universal joint linking the transmission with the differential. With the engine positioned in this manner, the driver's legs were beside the engine. The exhaust system headers passed over the top of the driver's and passenger's legs. The tops of the footboxes were curved to make room for Edmunds' handmade headers. This design takes the attributes of what is known as an FRM layout to an extreme. Consequently, this design gave a front/rear weight distribution roughly approximating a mid-engined vehicle without the cost of an expensive transaxle arrangement. This design style resulted in a hot driver's compartment - an issue that would impact the Cheetah's performance on the track.

REVIEWS & COMMENTS

accuracy, and usability.