1/26

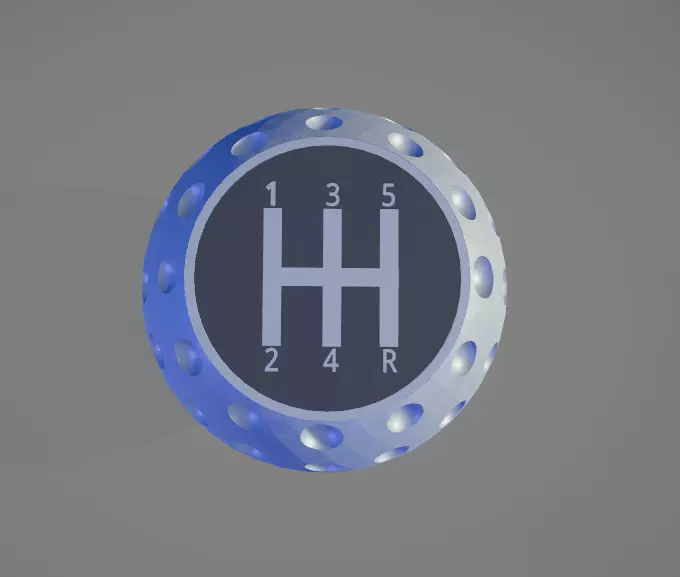

Elevate your vehicle or simulator setup with this upgraded golfball-style shift knob, engineered for 3D printing and digital fabrication in multiple formats (STL, OBJ, GLB, SVG). Building on the original one-piece design, this modular edition separates the main knob body from the gear-pattern insert, enabling multimaterial printing and unique customization. The spherical knob retains its retro golfball-inspired dimpled texture for enhanced grip, while the detachable insert features a symmetrical 5-speed layout with reverse positioned below 5th gear. The insert is press-fit into the knob and secured with adhesive, ensuring a flush, durable bond. Designed for both real cars and sim racing setups, this modular knob offers a realistic tactile feel with the flexibility to personalize finishes and materials.

Technical Specifications:

Knob diameter: 46 mm

Total height: 46 mm (36 mm visible + 10 mm mounting zone)

Gear-pattern insert cavity: Ø29.1 mm × 5.10 mm (press-fit + adhesive)

Gear-pattern insert piece: Ø29.0 mm × 5.10 mm

Variants included:

–M10 edition: Ø12 mm × 25 mm cavity (for M10 × 1.5 thread inserts)

–M12 edition: Ø14 mm × 25 mm cavity (for M12 × 1.75 thread inserts)

Mounting system: Epoxy-glued metal thread insert (not included)

Insert attachment: Press-fit + adhesive for secure bonding

Printer compatibility: FDM printers using PLA, PETG, ABS, Carbon Fiber Composite Filament, etc.

Print orientation: Optimized for minimal or no supports

Assembly Instructions

1:Prepare the partsA: 3D print the shift knob according to the thread size required by your car or simulator setup:

-M10 edition -Ø12 mm × 25 mm cavity (for M10 × 1.5 thread insert)

-M12 edition - Ø14 mm × 25 mm cavity (for M12 × 1.75 thread insert)

B: 3D print the gear‑pattern insert (Ø29 mm).

C: Prepare the metal thread insert (bushing): make sure you have the correct M10 or M12 metal insert, cleaned and ready for assembly.

D: Remove any support material and check tolerances before proceeding.

2: Install the metal thread insert (not included)

A: Apply a thin layer of strong epoxy adhesive around the outer surface of the metal insert.

B: Press-fit the insert into the knob’s cavity until fully seated.

C: Allow adhesive to cure according to manufacturer’s instructions.

3: Attach the gear‑pattern insert

A: Apply a thin layer of cyanoacrylate gel or epoxy inside the Ø29.1 mm cavity.

B: Align and press-fit the Ø29.0 mm insert until flush.

C:Hold light pressure for 30–60 seconds and remove any excess adhesive immediately.

4: Final installation

A: Once cured, screw the knob onto your gear lever (M10 or M12 thread).

B: Verify tightness and alignment before use.

5: Optional Enhancement

The gear‑pattern insert sits slightly below the knob surface, leaving ~0.1 mm clearance. You may apply a transparent epoxy layer (~0.1 mm) over the insert to:Fill the tolerance and achieve a perfectly flush surface.Protect the engraved pattern from wear. Add a glossy, premium finish.

Notes:

-Metal threaded insert not included. Use strong epoxy adhesive for mounting.

-This model represents The 5‑speed layout with reverse below 5th gear (reverse bottom‑right). Do not confuse it with:

The 5‑speed dog‑leg layout (reverse bottom‑left, first gear offset).

The standard 5‑speed layout (reverse positioned at the far left).

Each of these variants is available separately to ensure correct fitment and authenticity.

REVIEWS & COMMENTS

accuracy, and usability.