1/16

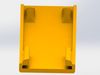

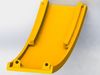

So I decided to design the entire bracket of the Sony MDR 1000X headphones because the plastic is very fragile on them and broke on a regular use.

FOLLOW THE INSTRUCTIONS FOR A GOOD RESULT!

You have to print the parts with rafts and supports. Infill is 100% and I printed at 25-35mm/s speed. PRINT ON A SIDE!Set the parameter Support Z distance (in Cura) which is the distance from the top/bottom of the support structure to the print a little bit lower so it will act like a stabilizer (they will be glued together a little bit)After you finish to clean the supports, sand a little bit the clips that connect the parts to each other. Try to assemble them once before you mount them on the headphones. To lock the screws better in the plastic I used a thread lock paste. Take in consideration that the walls of the parts are a little bit thicker to be stronger than the original !!! Last picture shows how the model should look on the build plate after is sliced.

FOLLOW THE INSTRUCTIONS FOR A GOOD RESULT!

I also added the step, igs files if you want to make some changes to the parts.

Thanks for buying and please don't forget to rate my model, like or leave a comment.

REVIEWS & COMMENTS

accuracy, and usability.