1/6

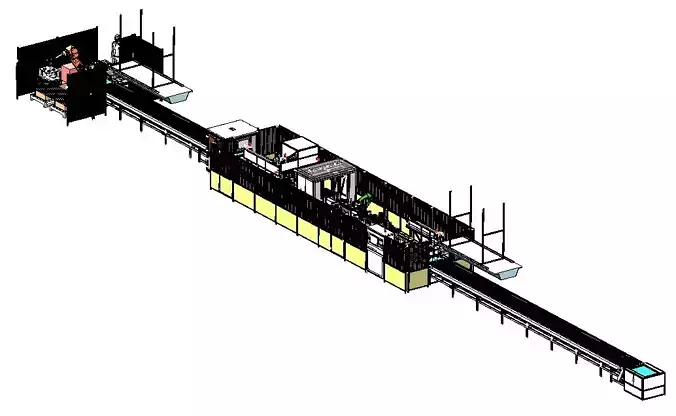

Robot riveting visual inspection line is an automated production system that integrates robot technology, machine vision inspection technology and riveting process. The following describes the work flow in detailWorkpiece conveying: The workpiece to be riveted is transferred to the designated position through the conveying system, waiting for the robot to pull the riveting operation.Image acquisition: The camera in the visual inspection system takes photos of the workpiece, obtains the image information of the workpiece, and provides the data basis for the subsequent analysis and judgment.Image processing and analysis: The image detection software processes the acquired images, including grayscale, filtering, edge detection, feature extraction and other operations to identify the position and number of rivet holes on the workpiece and the situation of rivet.Robot positioning and riveting: According to the rivet hole position information provided by the visual detection system, the control system directs the robot to accurately move to the corresponding position, and controls the rivet gun to carry out the rivet operation to ensure that the rivet is accurately inserted into the hole and firmly riveted.Quality inspection: After the rivet is completed, the visual inspection system takes photos of the rivet part again to check the quality of the rivet, such as whether the rivet is completely pulled in place, whether there is deformation, whether there is leakage and other problems. If the quality is found to be unqualified, an alarm is issued and the corresponding treatment is carried out.Finished product output: After riveting and quality testing qualified workpiece, transported by the conveyor system to the next process or finished product area, complete the entire riveting visual inspection line operat

REVIEWS & COMMENTS

accuracy, and usability.