1/6

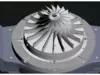

This is one of the core processes in high-end manufacturing, where a five axis machining center is processing precision impellers.The figure shows an integral impeller (commonly found in aviation engines, gas turbines, or turbochargers) being milled using a five axis CNC machine:Equipment: Five axis machining center (with rotating worktable and swing angle spindle), which can flexibly adjust the tool angle through the linkage of X/Y/Z linear axis and 2 rotating axes, solving the problem of blind spots in traditional machine tools.Workpiece: The impeller is a typical complex curved part, with twisted thin-walled structures (thickness often less than 1mm) and narrow spacing between adjacent blades. It requires extremely high machining accuracy (such as surface error<0.01mm) and surface quality (roughness Ra<0.8 μ m).Process: It is usually divided into three stages: rough machining (rapid removal of excess), semi precision machining (uniform excess), and precision machining (high-precision profiling). All surface machining is completed through one clamping to avoid the accumulation of errors in multiple positioning.This type of processing represents the forefront level of the current manufacturing industry, widely used in fields such as aerospace, energy and power, and is a key manufacturing technology for core components of high-end equipment.2: This file has no type of protection. You can reuse scenes, rendering settings, lighting, and materials to evoke the design meaning and imagination of this project, making the future a reality.3: Thank you for your feedback. Please give me more guidance

REVIEWS & COMMENTS

accuracy, and usability.