1/18

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

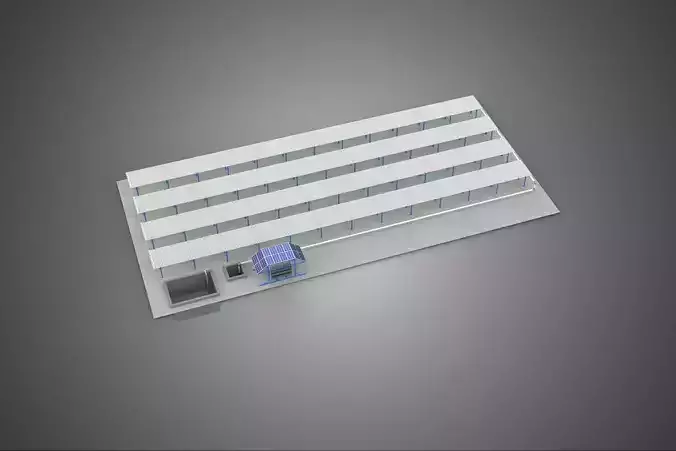

A PLANT CROP FARM CULTIVATION FACTORY LAYOUT IOT SOLAR POWERED NFT system represents an advanced, highly integrated approach to controlled-environment agriculture (CEA). This sophisticated model combines a factory-like spatial design with specialized hydroponic cultivation (Nutrient Film Technique, NFT), intelligent automation via the Internet of Things (IoT), and sustainable energy generation through solar power. Its primary objective is to achieve maximized crop yields and resource efficiency within a precisely controlled, environmentally resilient, and often localized production facility.

Factory Layout and Controlled Environment Agriculture (CEA):

The factory layout denotes a structured, often multi-tiered or vertical farming facility designed for optimal spatial utilization and operational efficiency. This enclosed environment enables year-round cultivation independent of external climatic conditions. Controlled Environment Agriculture (CEA) principles are fundamental, involving the precise management of critical atmospheric parameters such as temperature, humidity, carbon dioxide (CO2) levels, and artificial light intensity and spectrum. This controlled isolation minimizes exposure to pests and diseases, significantly reducing or eliminating the need for pesticides and herbicides, and ensures consistent environmental conditions conducive to plant growth. The architectural design typically incorporates efficient workflows for planting, maintenance, harvesting, and post-harvest processing.

Nutrient Film Technique (NFT):

The Nutrient Film Technique (NFT) is a widely adopted hydroponic method utilized for nutrient and water delivery. In an NFT system, plants are typically positioned in shallow channels or tubes, with their roots exposed to a continuous, thin film of recirculating nutrient-rich water. This shallow film, typically a few millimeters deep, ensures a constant supply of water, dissolved minerals, and essential oxygen to the root zone. NFT is particularly advantageous for crops with shallow root systems, such as leafy greens, herbs, and strawberries, due to its high water efficiency, precise nutrient delivery capabilities, and relatively simple operational mechanism compared to other hydroponic systems.

Internet of Things (IoT) Integration:

The integration of the Internet of Things (IoT) is central to the intelligent operation and automation of the cultivation factory. A network of interconnected sensors continually monitors a comprehensive array of environmental and physiological parameters. These include air temperature, humidity, CO2 concentration, light intensity, nutrient solution pH, electrical conductivity (EC), and dissolved oxygen levels. Real-time data collected by these sensors is transmitted to a central data management system. Actuators, linked to the IoT platform, autonomously regulate and adjust environmental controls (e.g., HVAC systems, ventilation fans, CO2 injectors), control irrigation pumps for the NFT system, manage LED grow light schedules and intensity, and precisely dose nutrient solutions. Advanced analytics, often leveraging machine learning, can identify optimal growth parameters, predict potential issues, and facilitate remote monitoring and control, thereby enhancing operational efficiency, reducing labor costs, and optimizing resource allocation for improved yield and quality.

Solar Power Integration:

The incorporation of solar power underscores the system's commitment to sustainability and energy independence. Photovoltaic (PV) panels, typically installed on the facility's roof or on adjacent land, harness solar energy to generate electricity. This renewable energy powers all critical components of the cultivation factory, including the high-intensity LED grow lights, climate control systems (heating, cooling, ventilation), water pumps for the NFT system, the extensive IoT sensor network, data servers, and various automated machinery. To ensure continuous operation, especially during periods of low solar irradiance or at night, energy storage solutions such as battery banks are often integrated. By primarily relying on solar energy, the system significantly reduces its operational carbon footprint, minimizes reliance on conventional grid electricity, and lowers long-term energy costs, aligning with global initiatives for sustainable and environmentally responsible agriculture.

Synergy and Advantages:

The combined integration of these technologies creates a synergistic system offering numerous advantages. The controlled environment, optimized by IoT, facilitates ideal growth conditions year-round, while NFT ensures efficient nutrient and water delivery. Solar power provides a clean, sustainable energy source, reducing environmental impact and operational expenses. Key benefits include dramatically reduced water consumption (up to 90% less than traditional field farming), minimized land use through vertical cultivation, elimination of pesticides, consistent high-quality yields, localized food production reducing transport emissions, and enhanced food security in diverse geographical and climatic conditions.

Challenges:

Despite its significant advantages, the implementation of such advanced systems presents challenges, including high initial capital investment for infrastructure and technology, the need for specialized technical expertise for design and operation, and the complexity of energy storage and management for consistent solar power supply.

KEYWORDS: Controlled Environment Agriculture, Vertical Farming, Hydroponics, Nutrient Film Technique, NFT, Internet of Things, IoT, Smart Farming, Precision Agriculture, Solar Power, Renewable Energy, Sustainable Agriculture, Urban Farming, Food Security, Automation, Data Analytics, Crop Cultivation, Plant Factory, Energy Efficiency, Resource Management, Environmental Control, Yield Optimization, Automated Irrigation, Sensor Technology, Greenhouse Technology, Multi-tiered Cultivation, Reduced Water Usage, Carbon Footprint Reduction, Agricultural Innovation, Resilient Food Systems

REVIEWS & COMMENTS

accuracy, and usability.