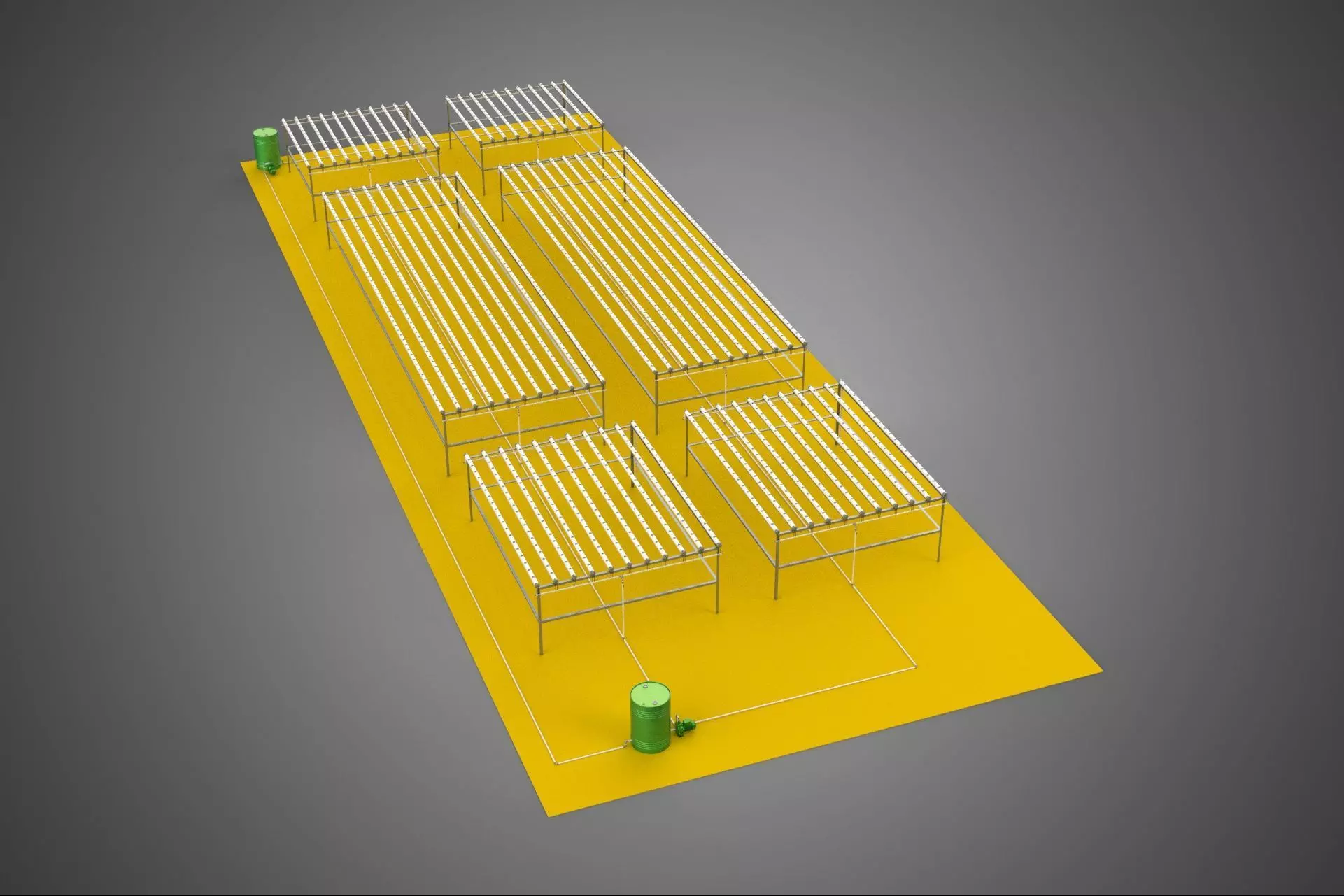

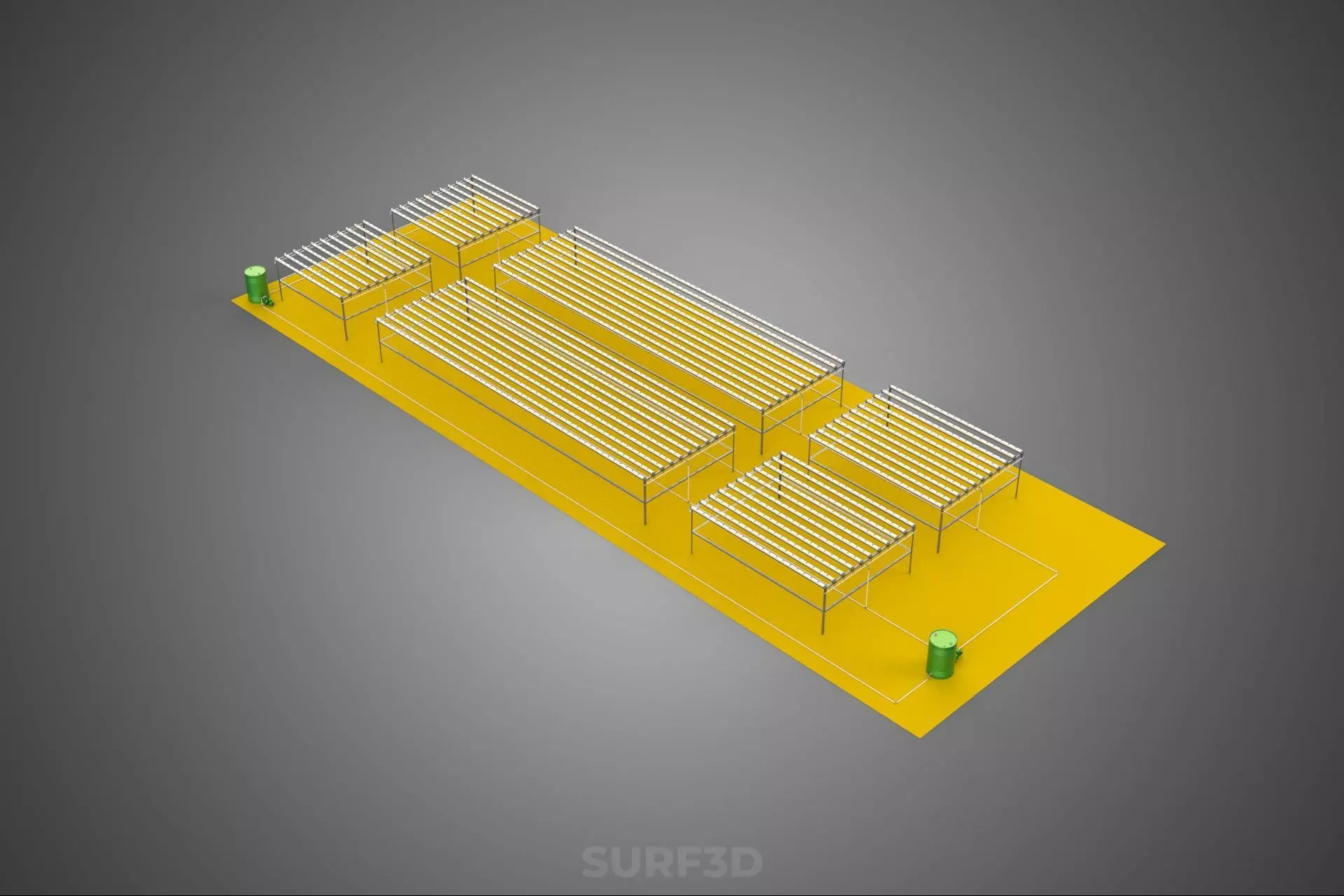

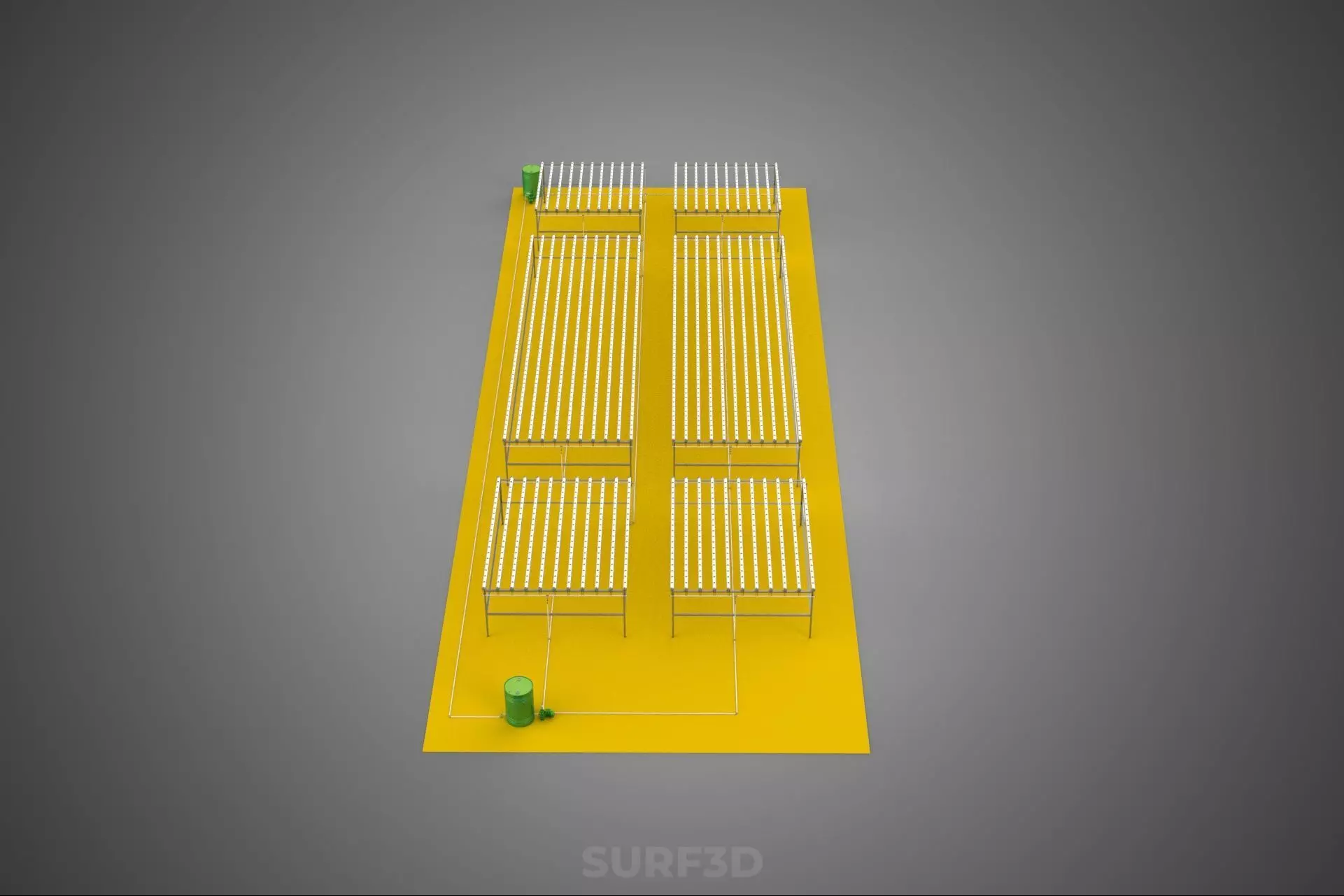

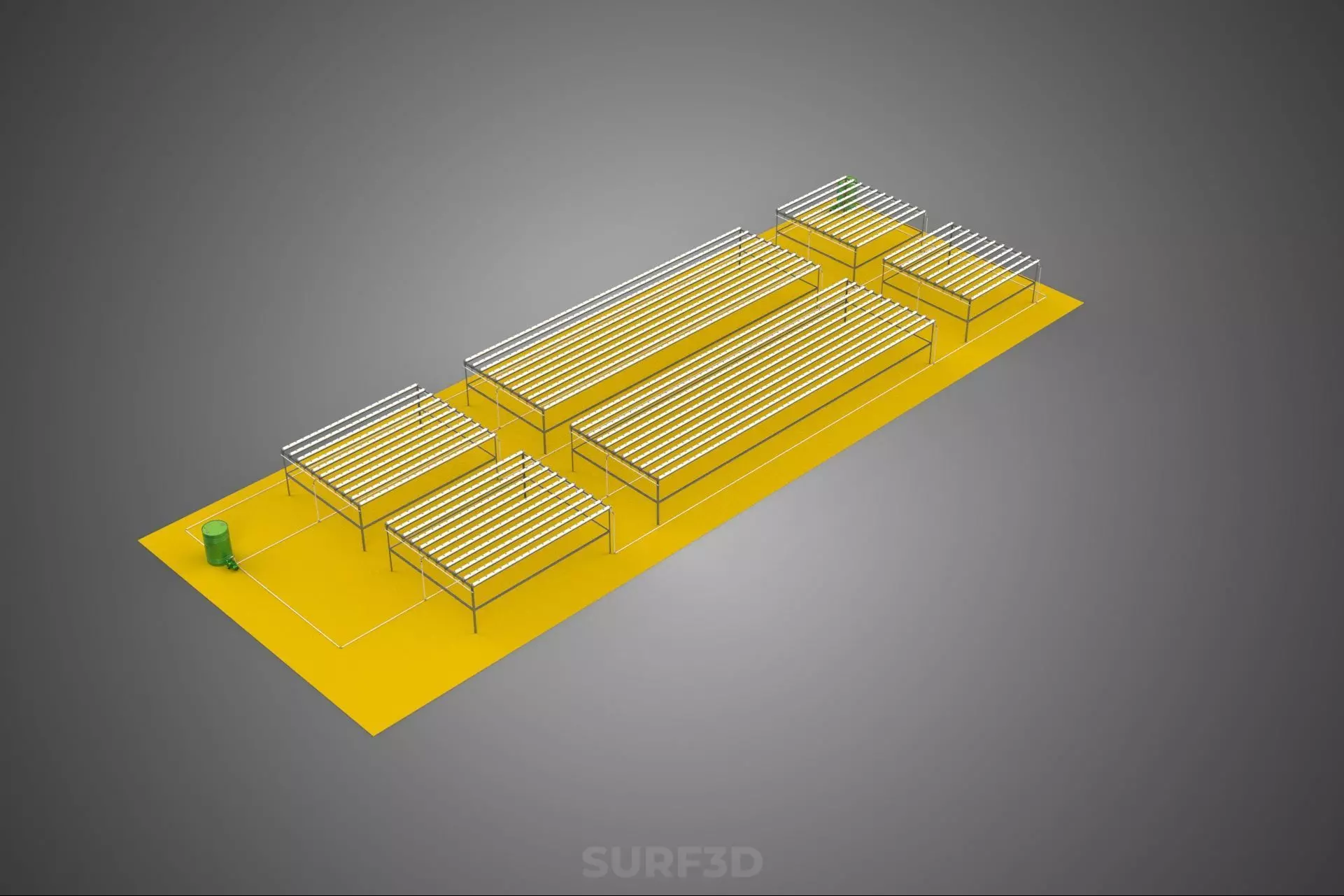

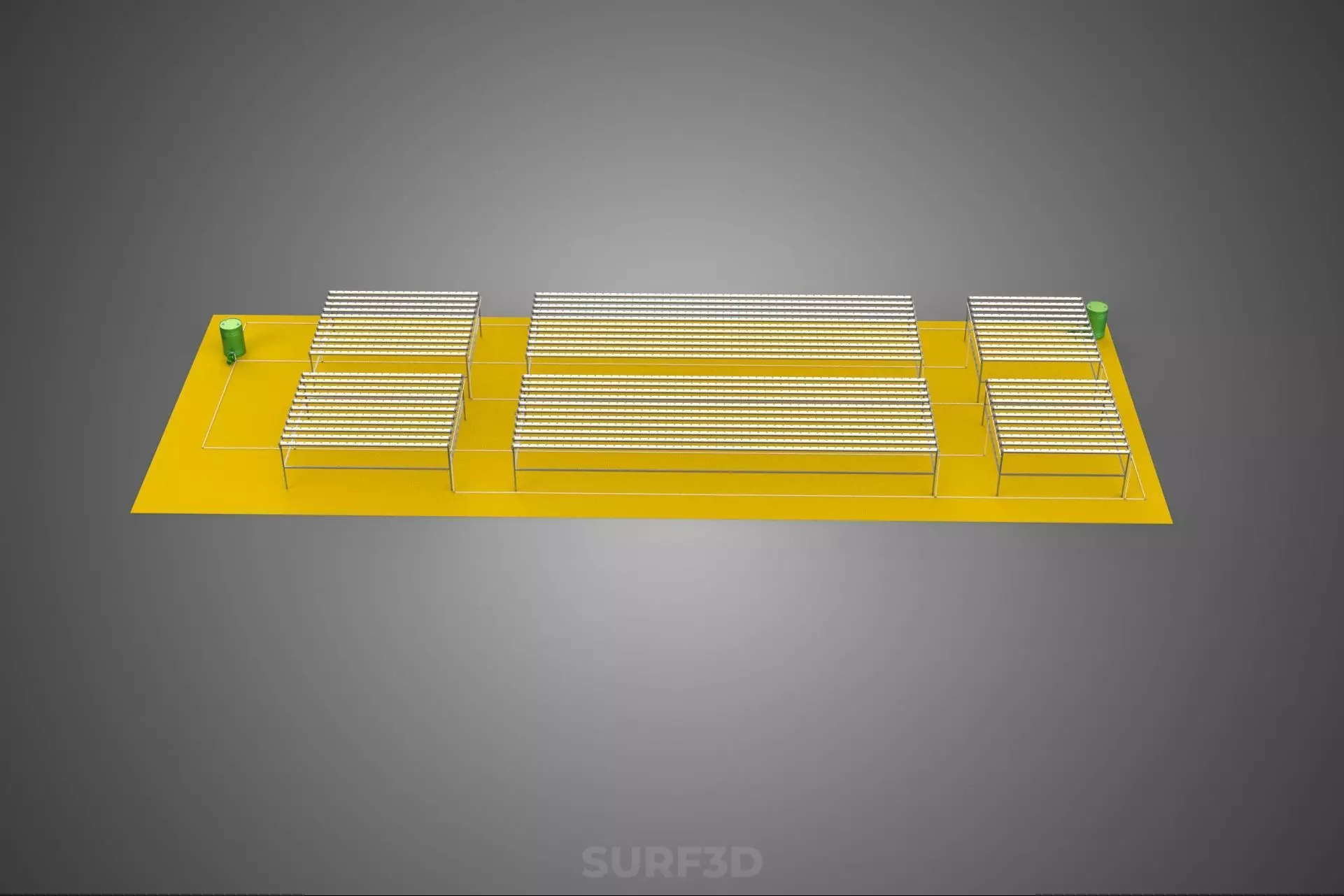

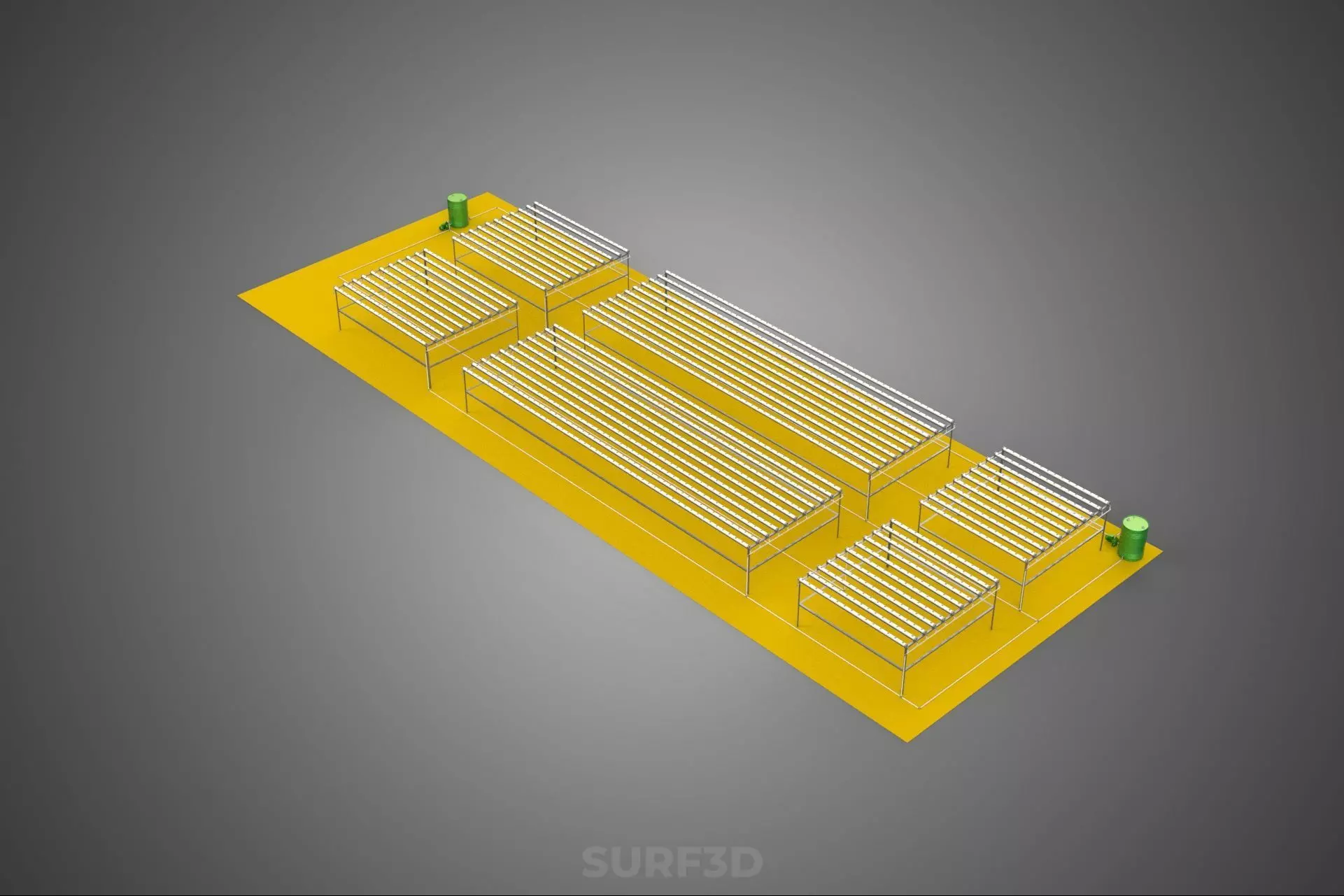

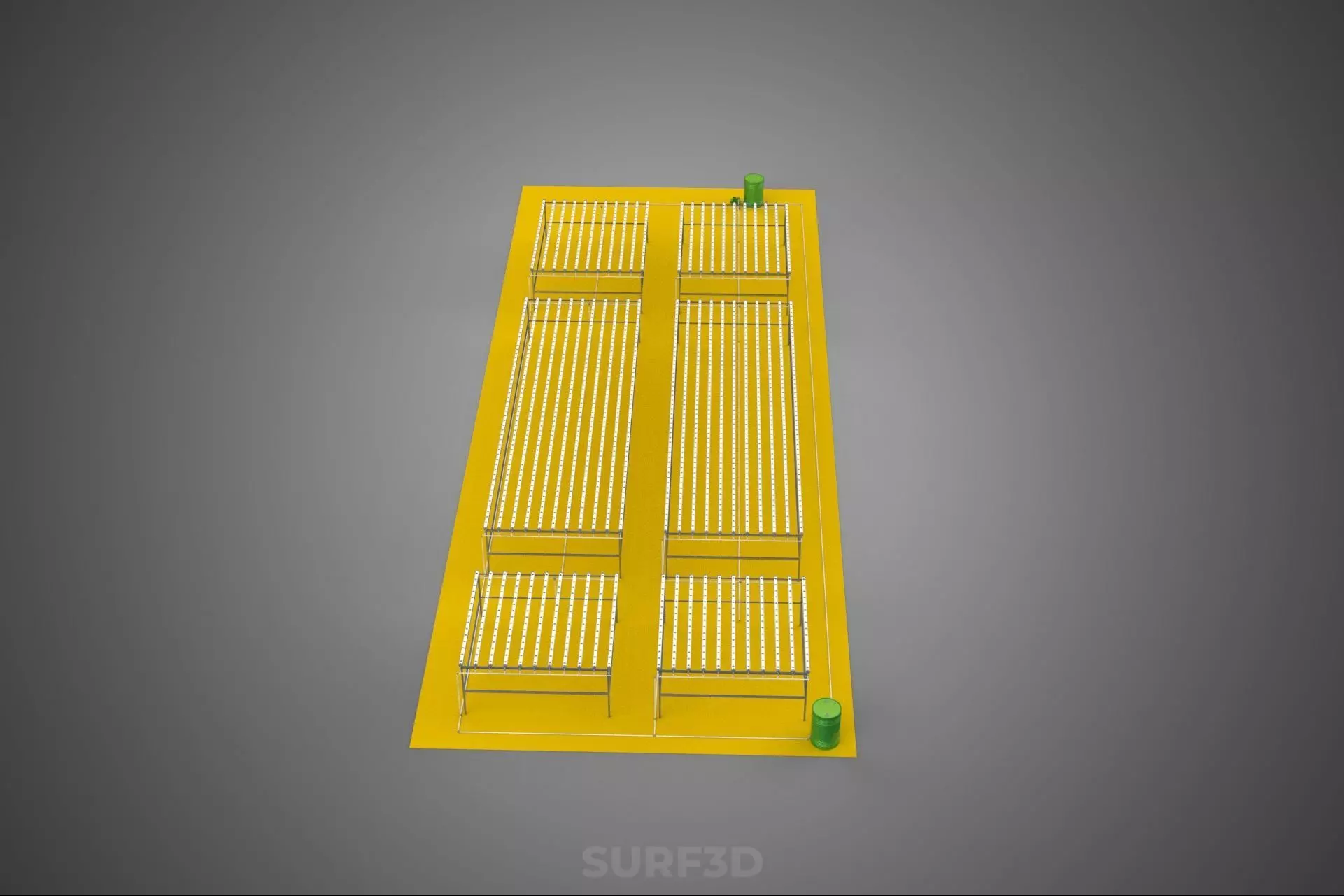

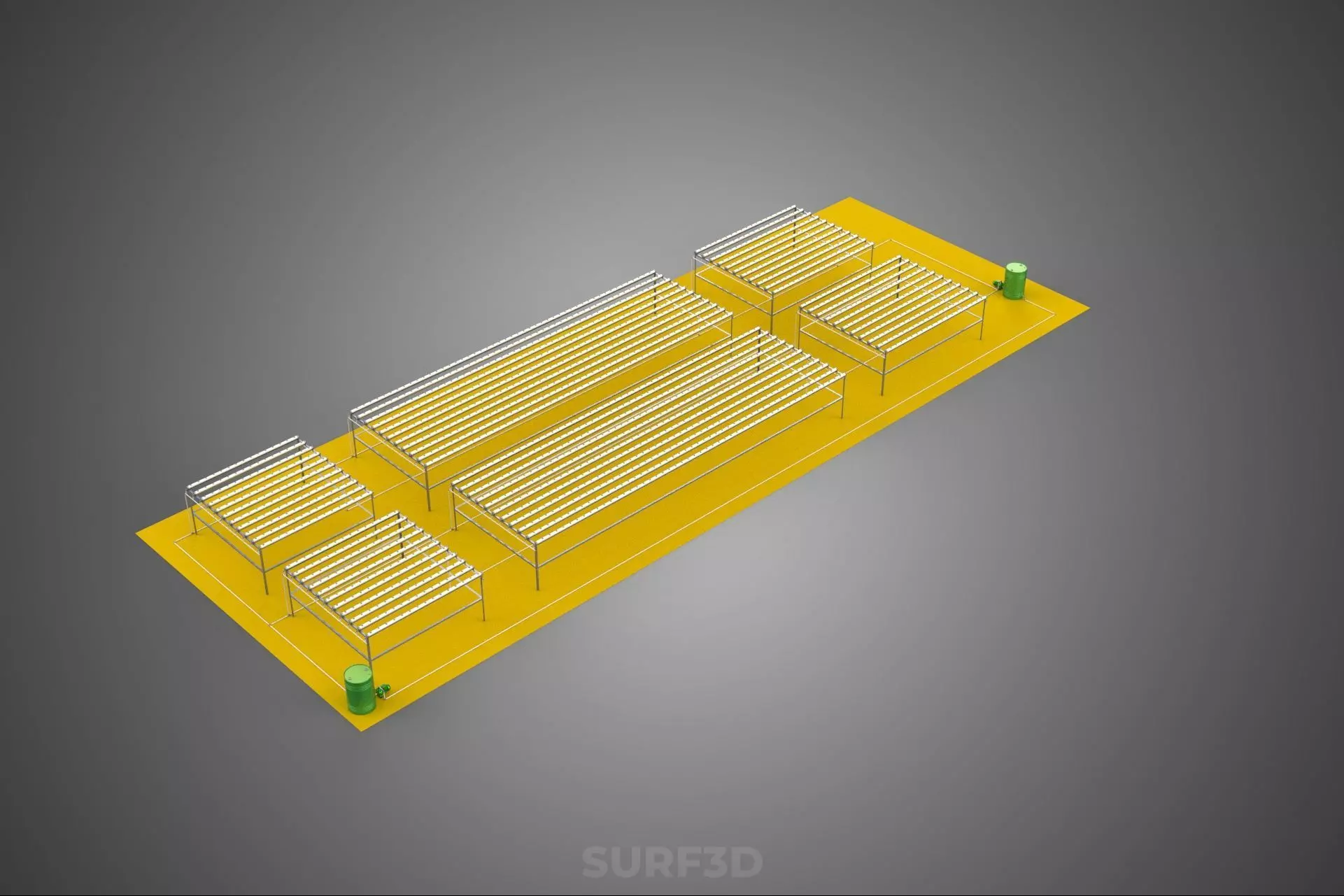

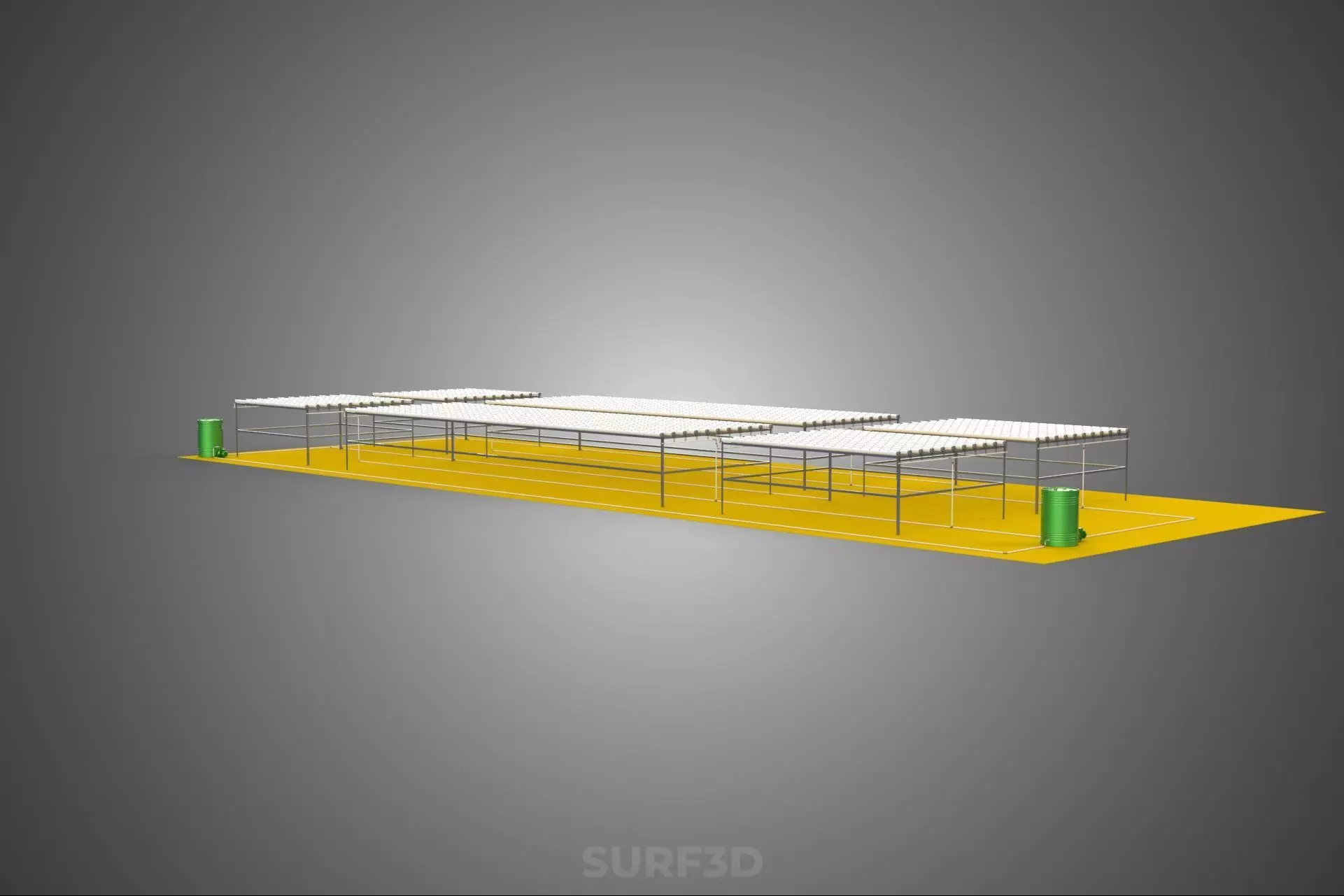

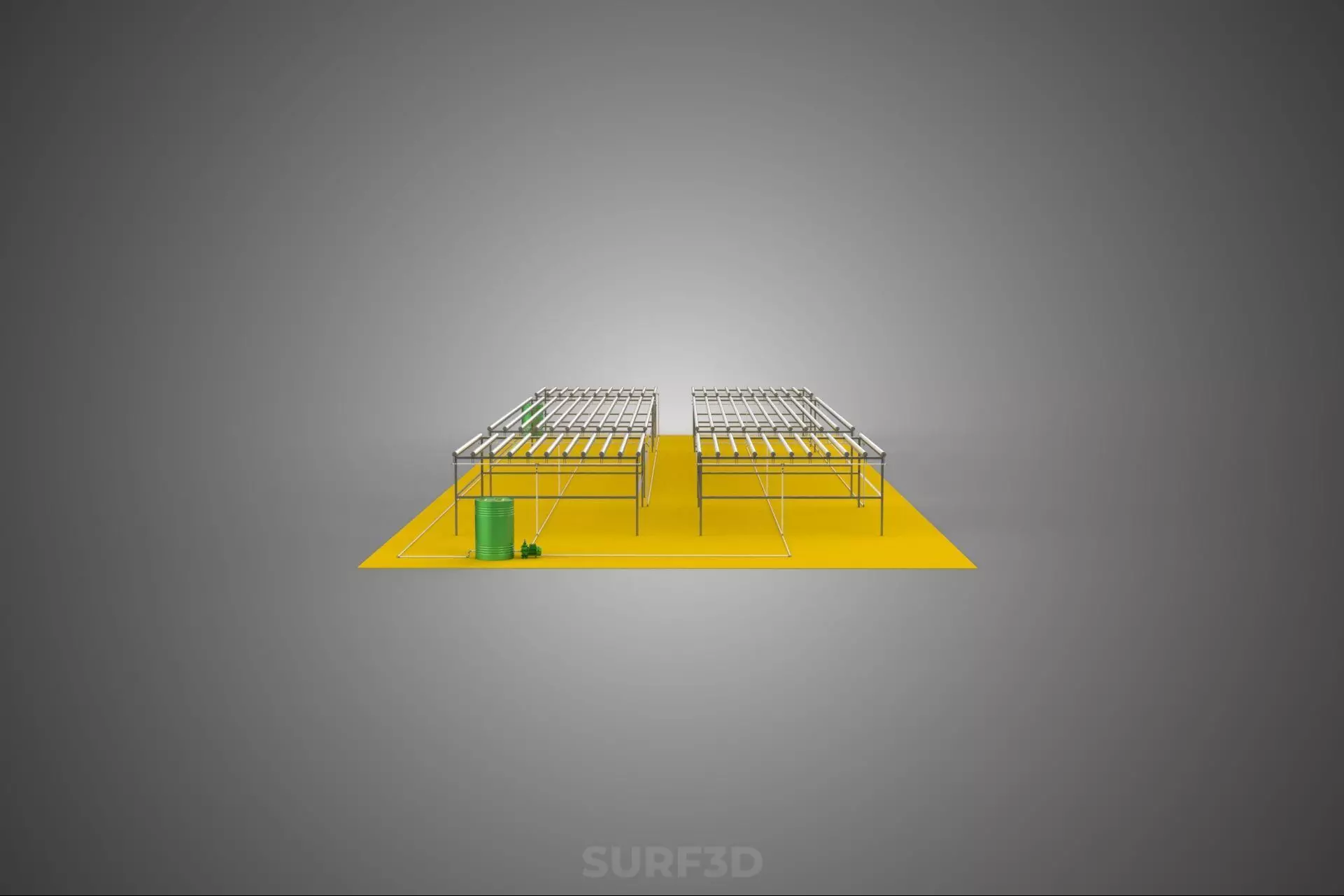

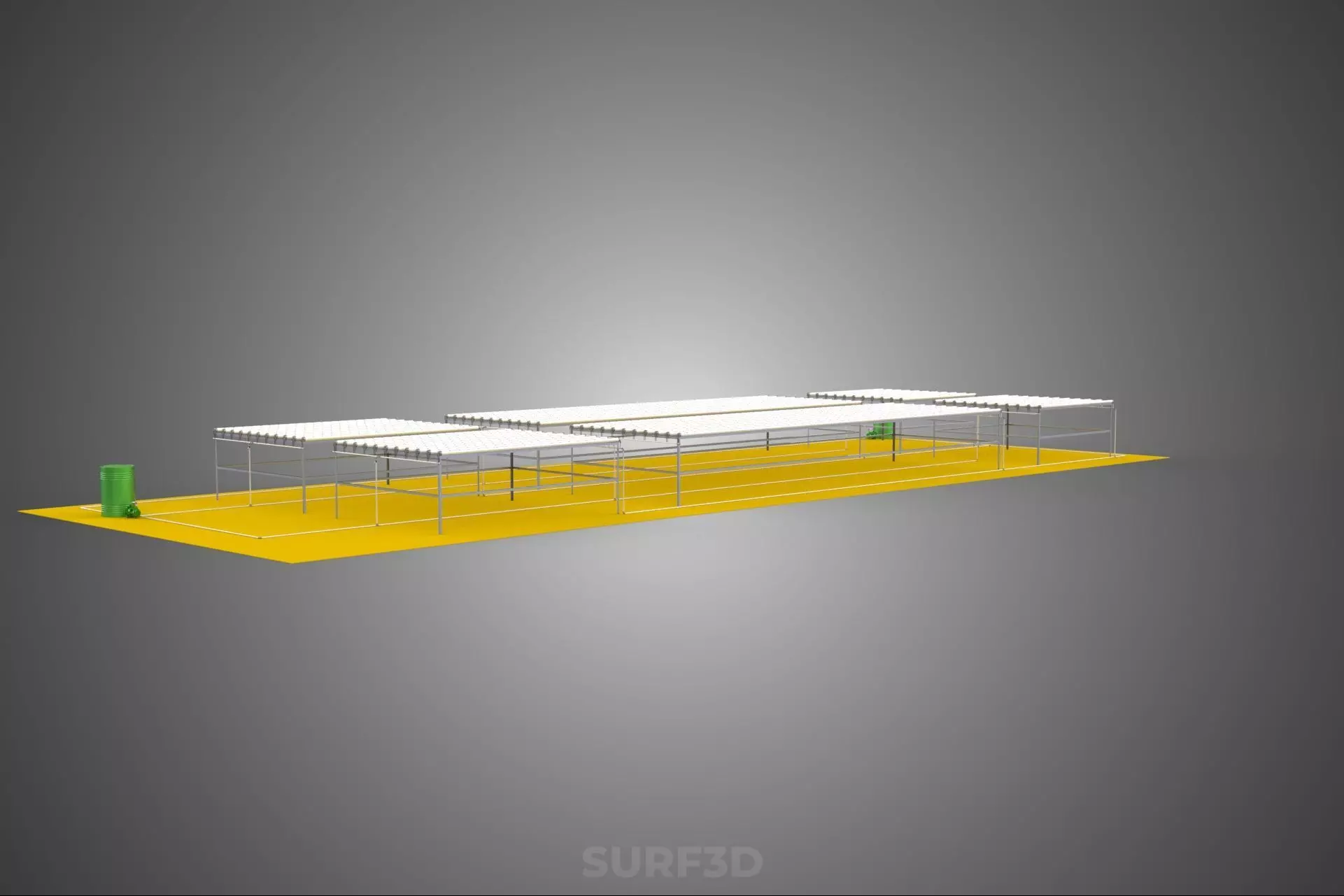

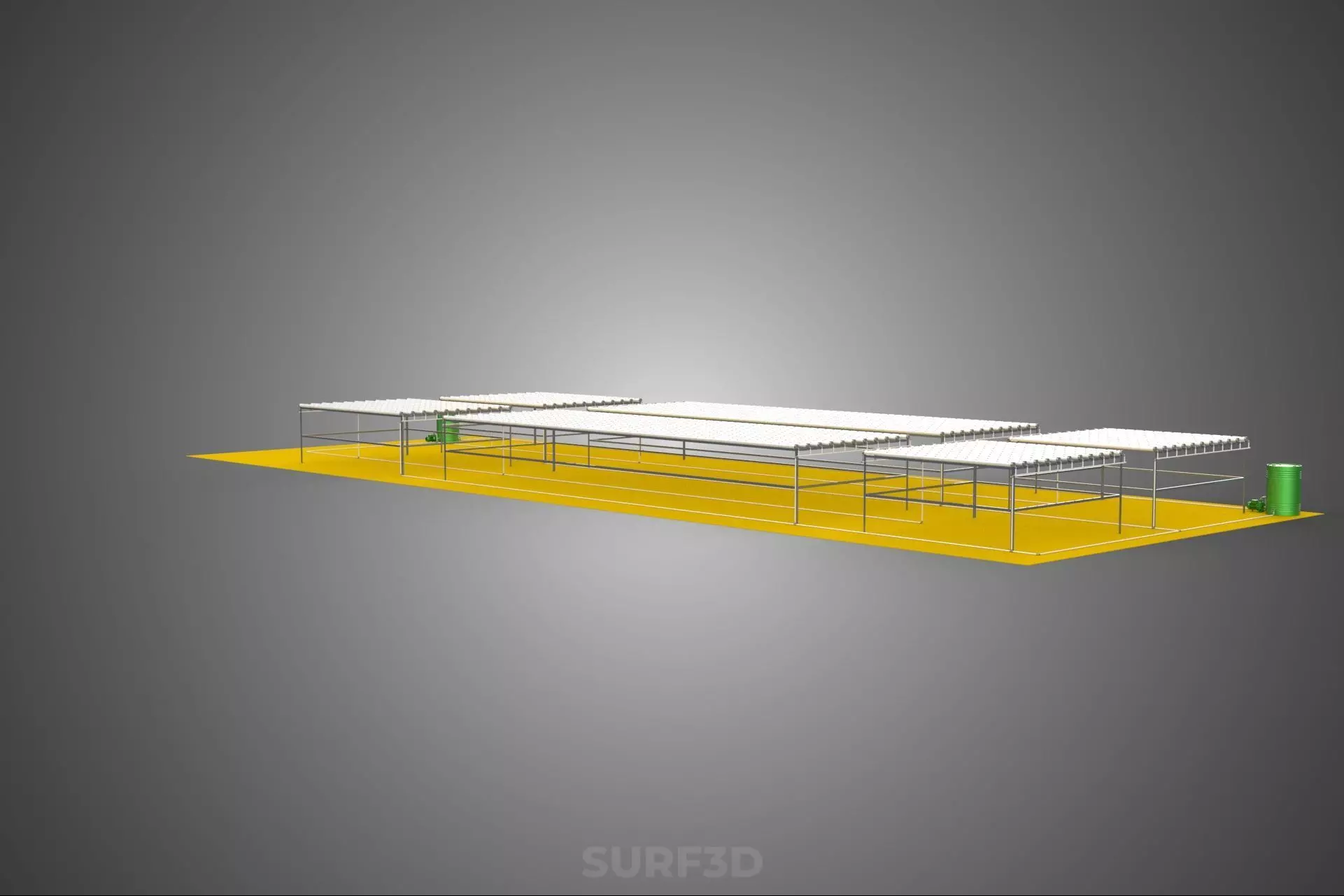

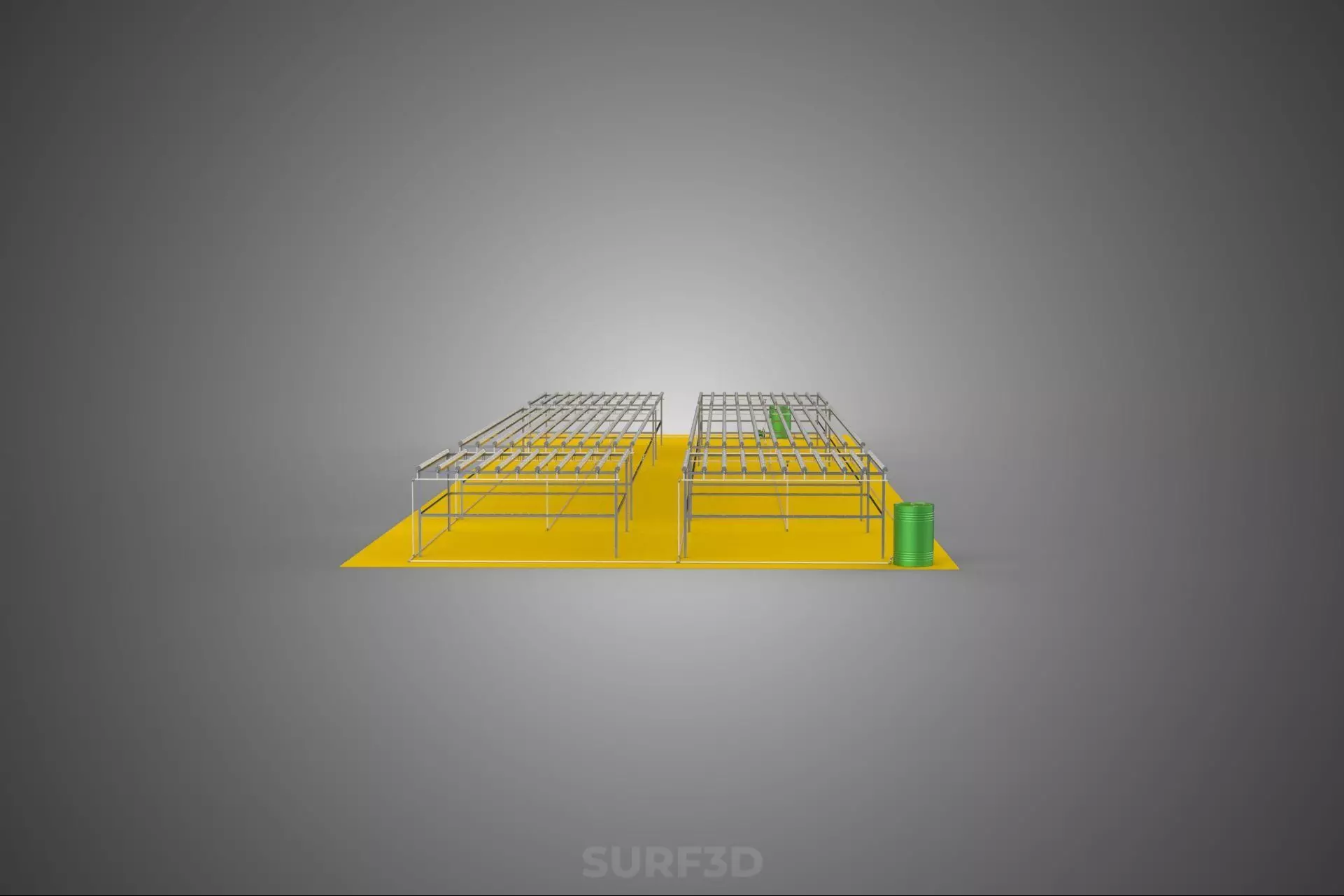

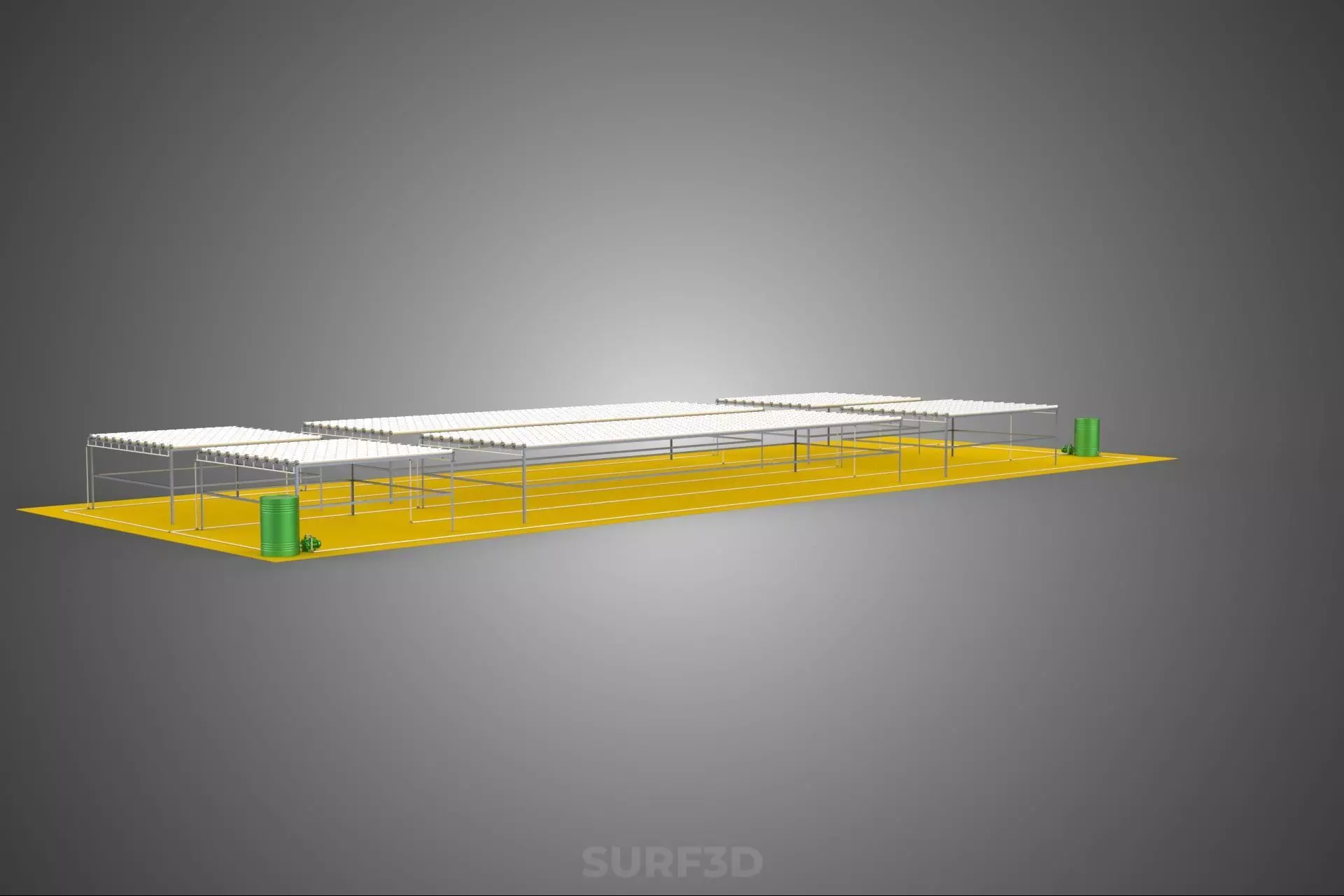

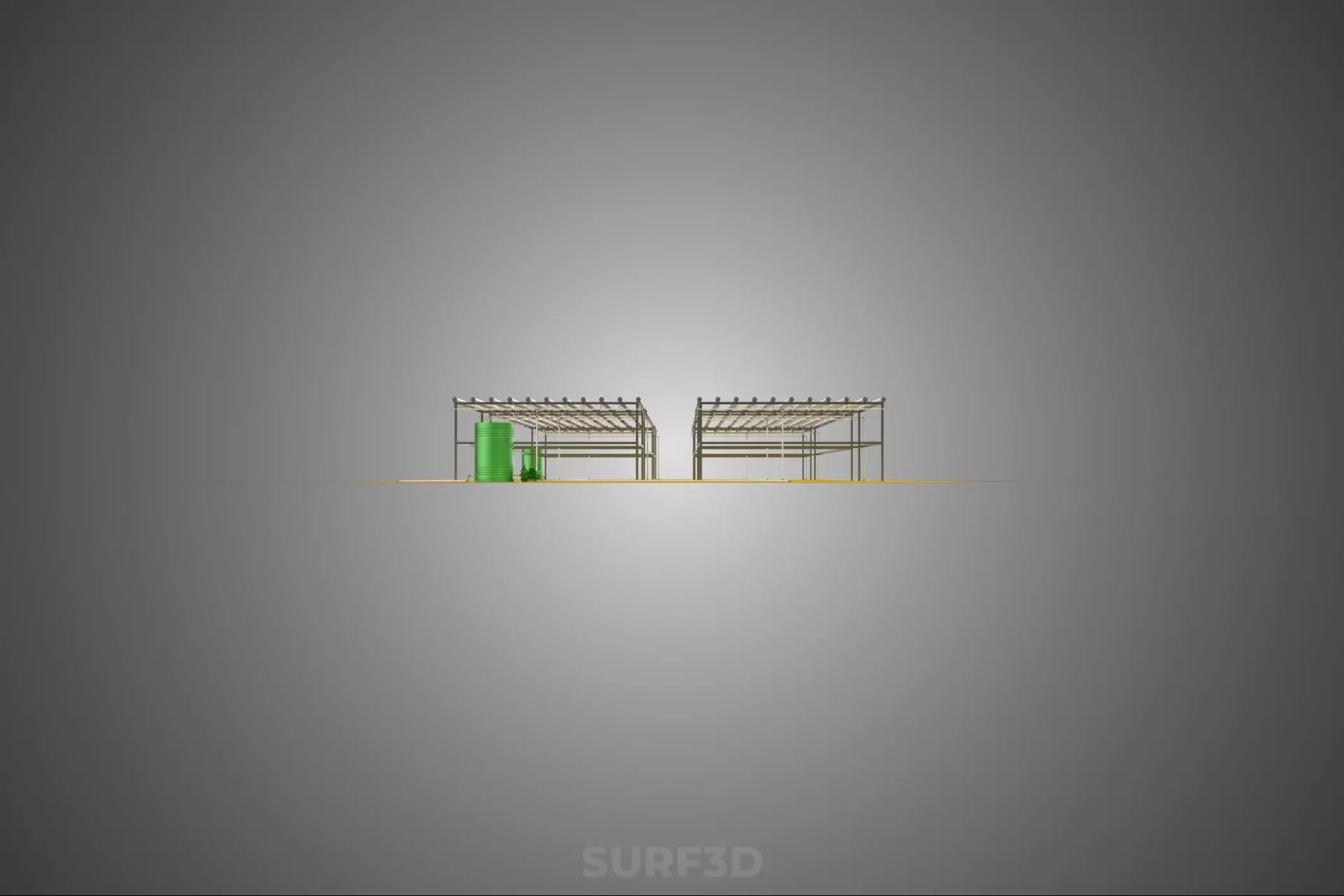

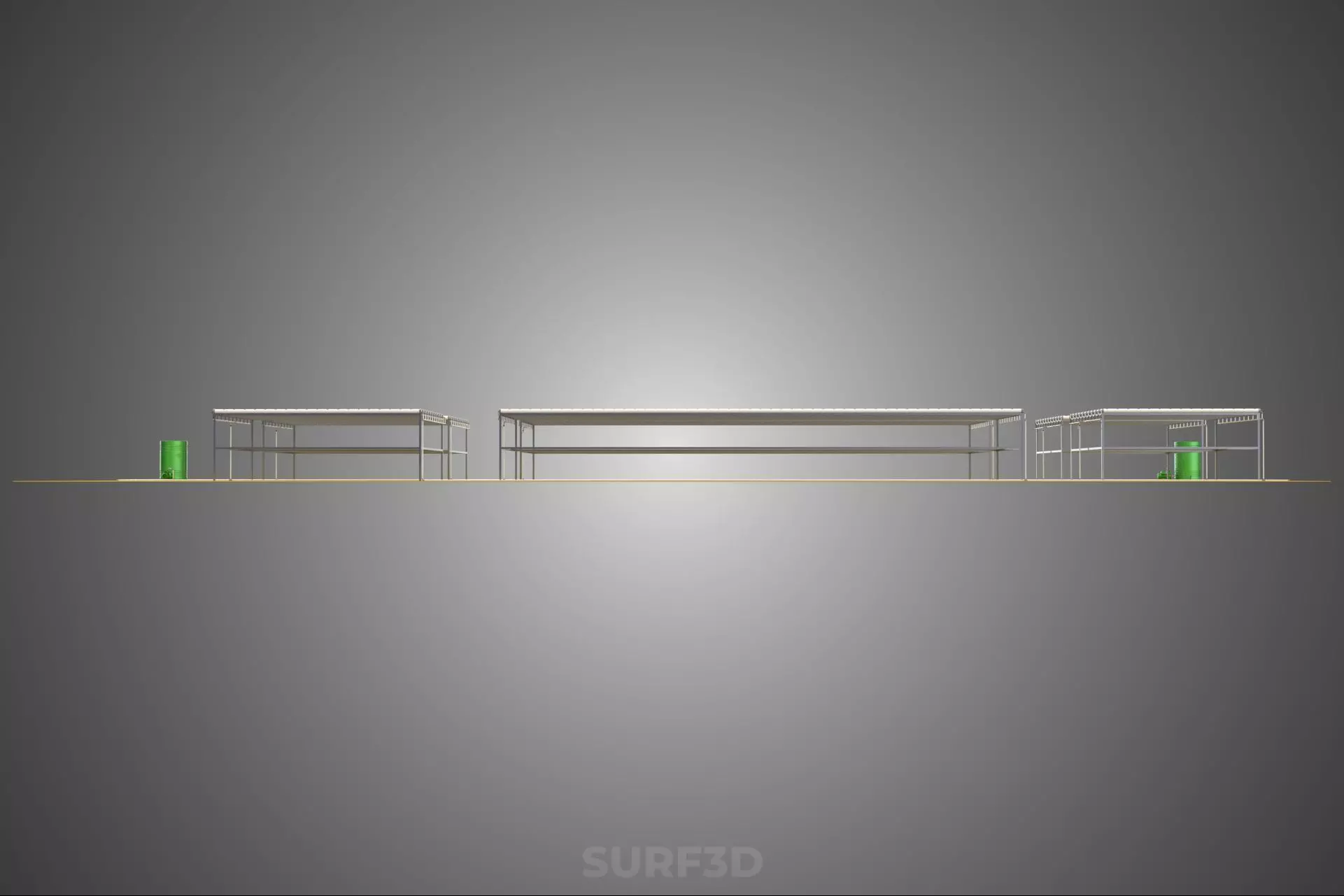

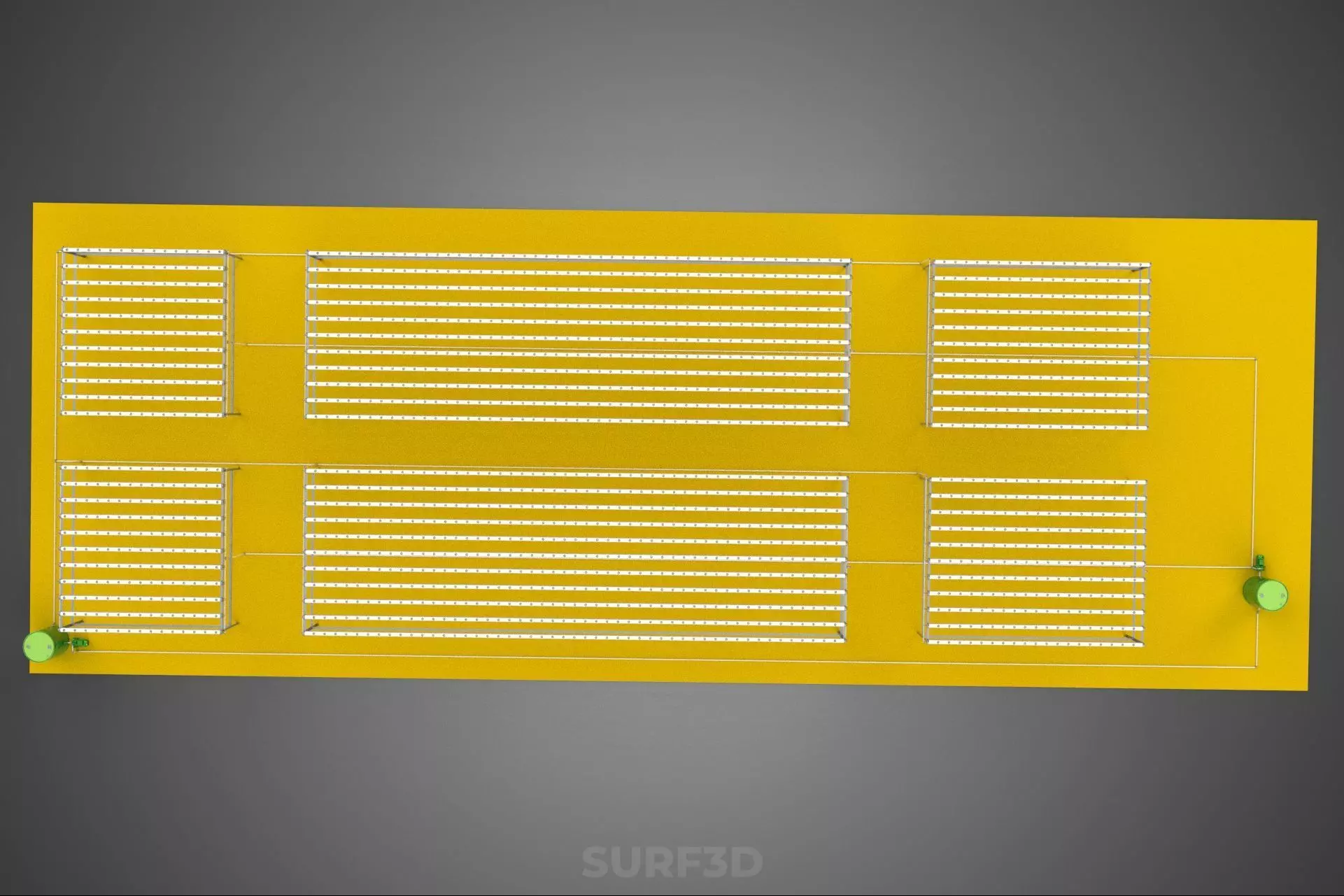

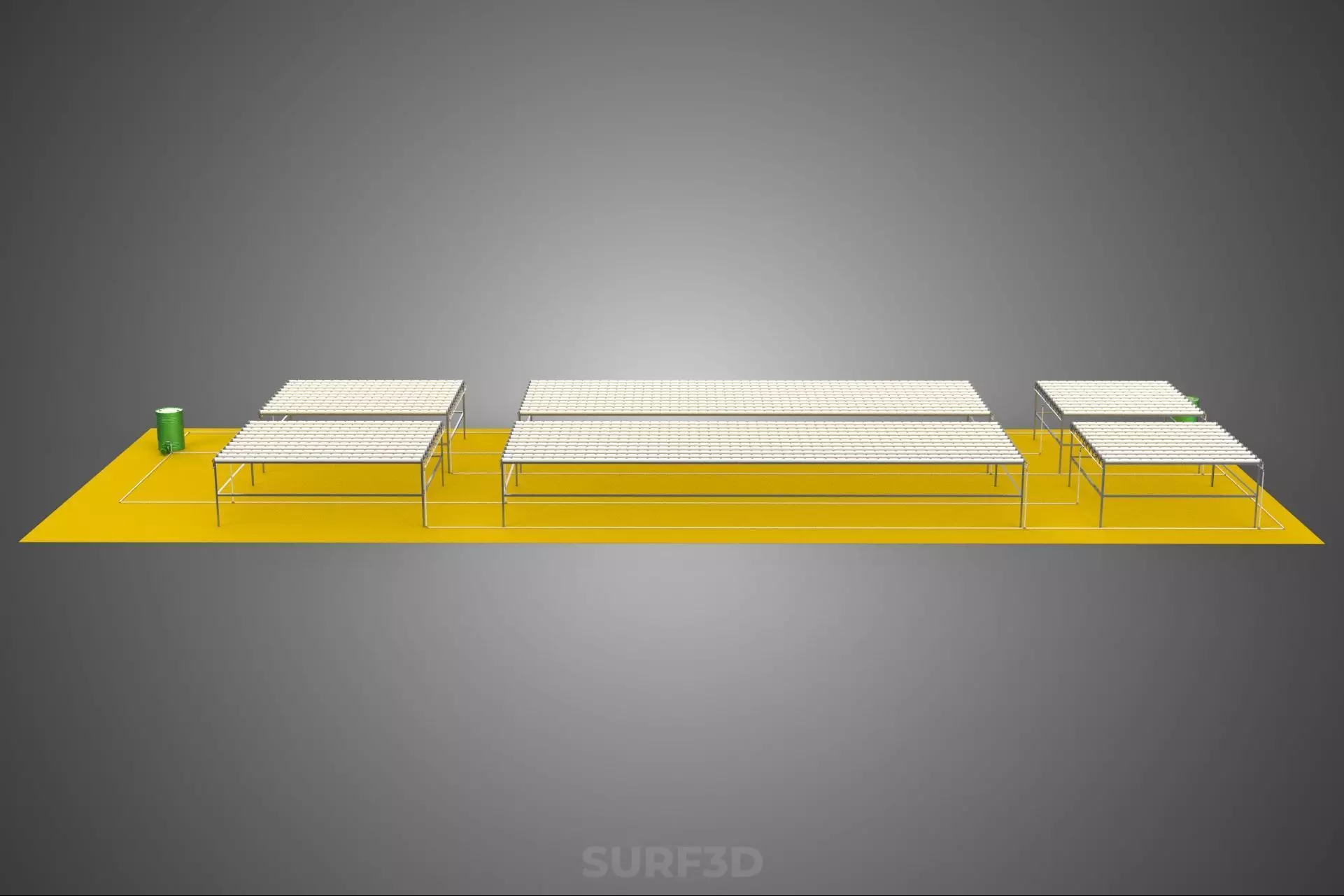

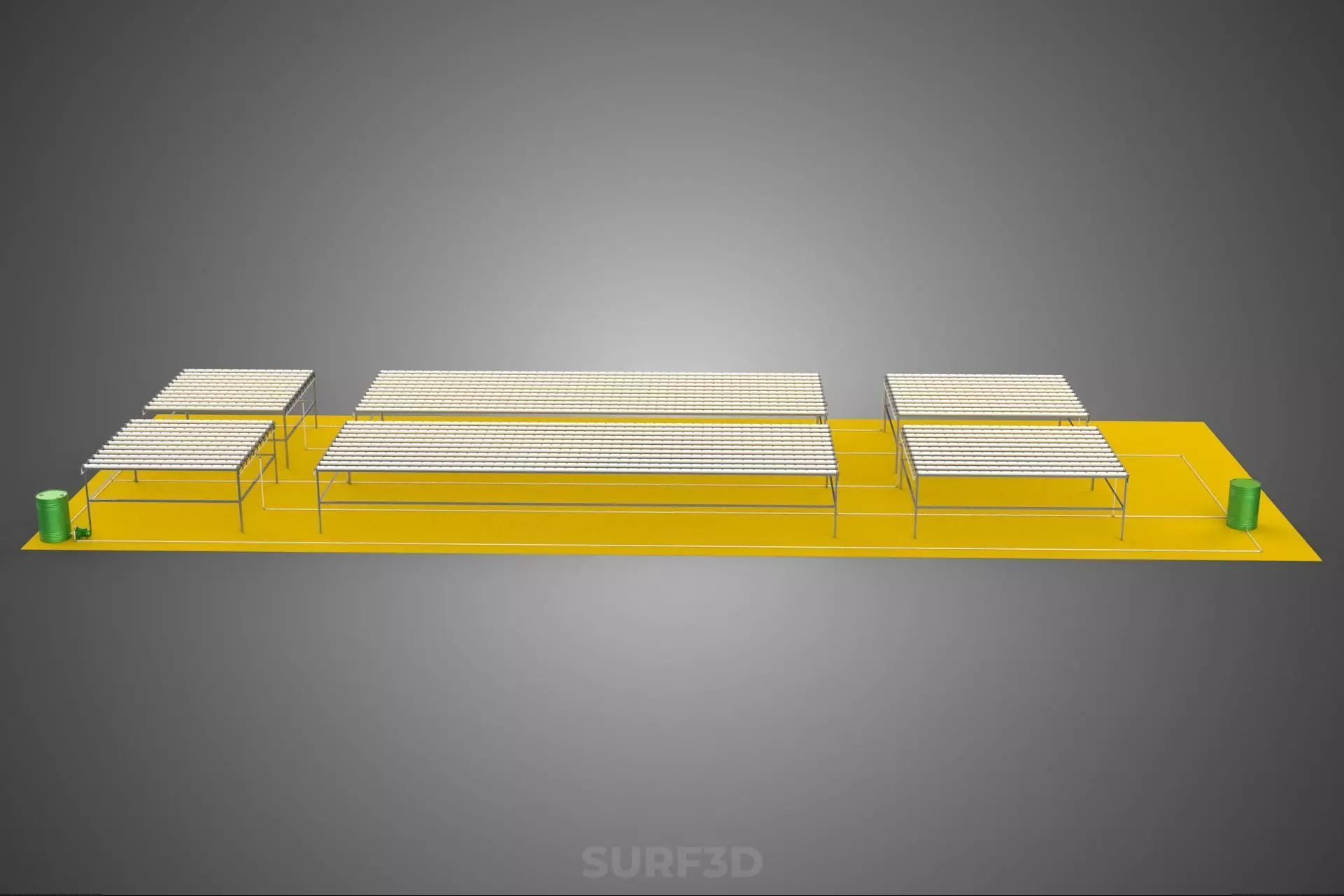

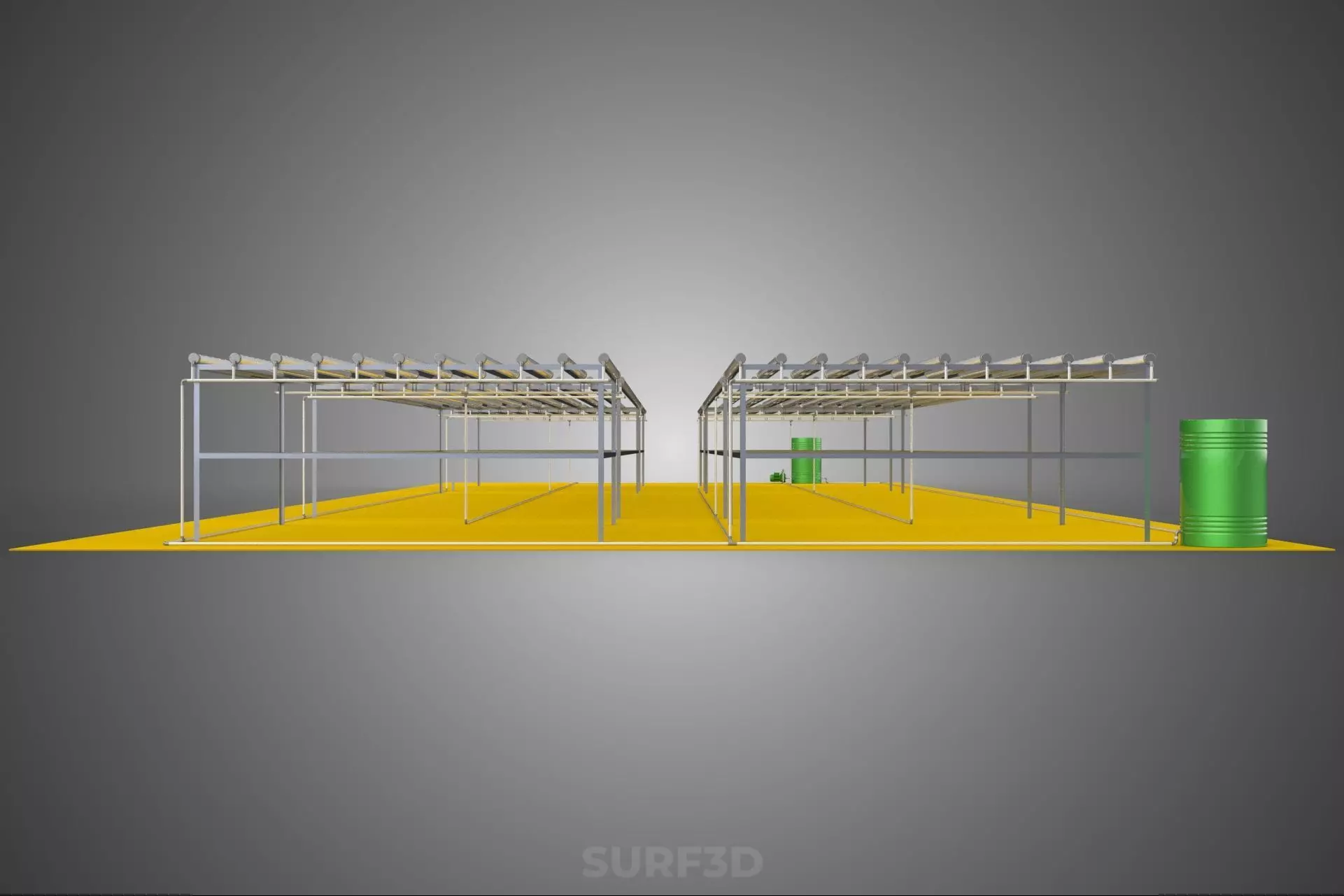

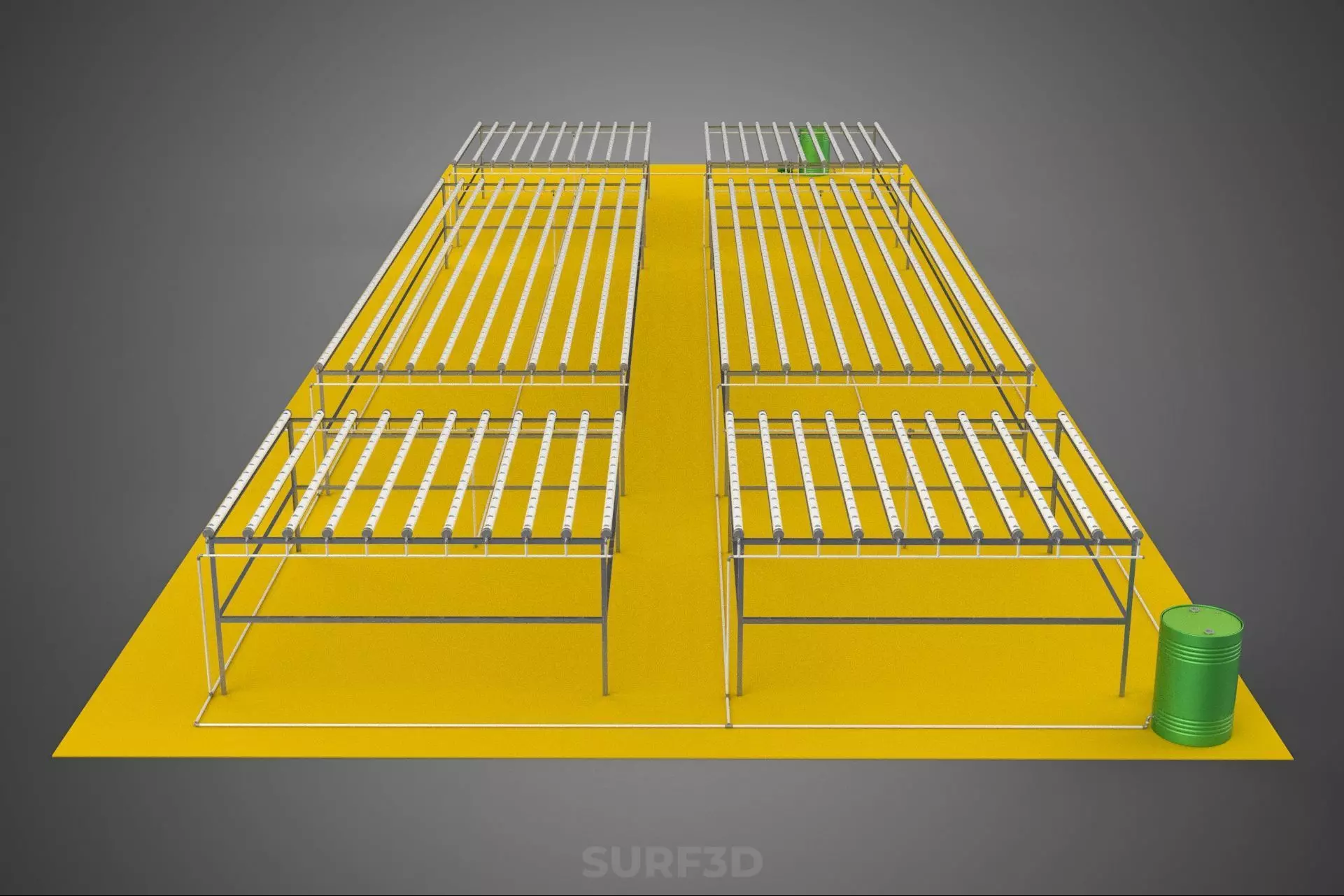

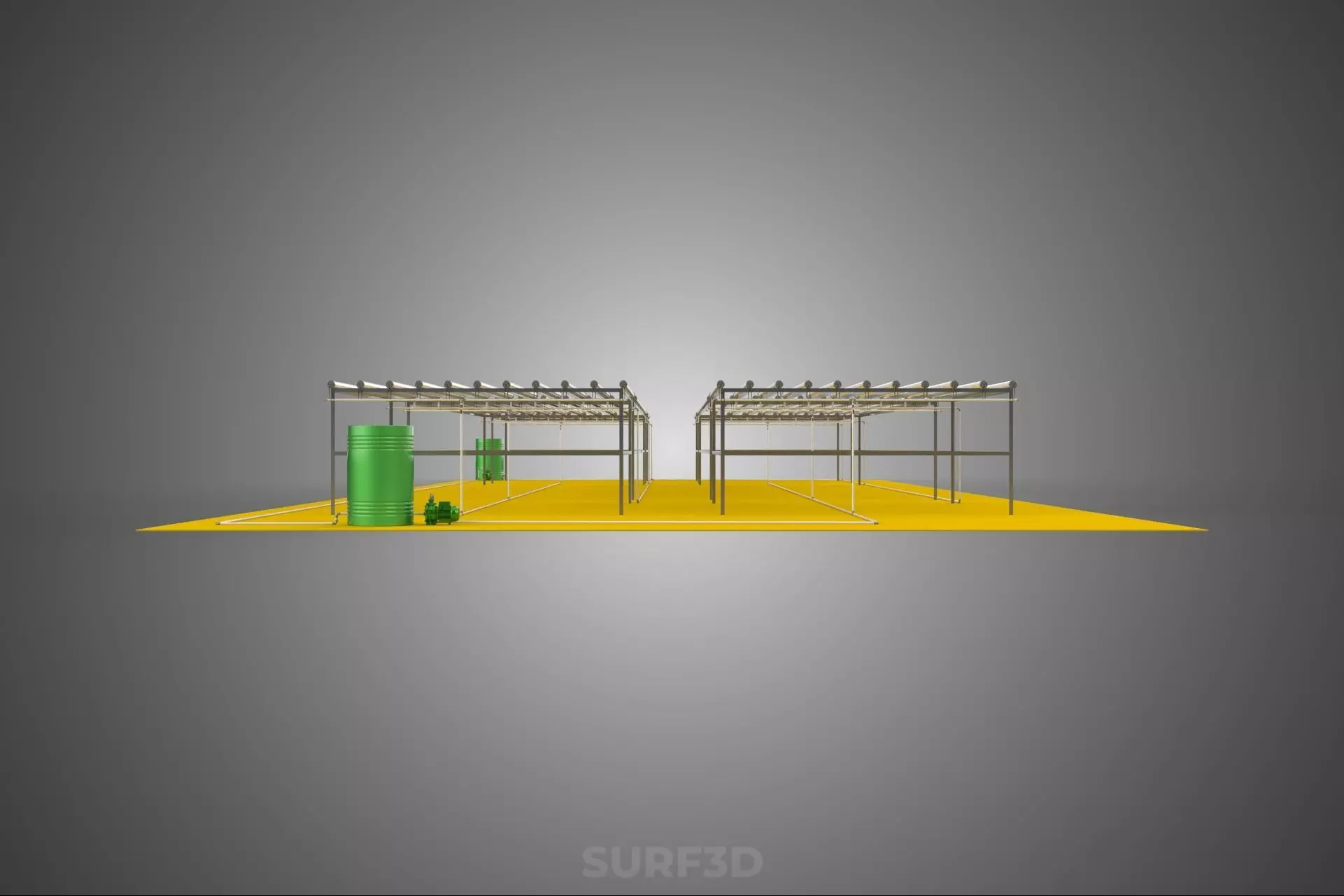

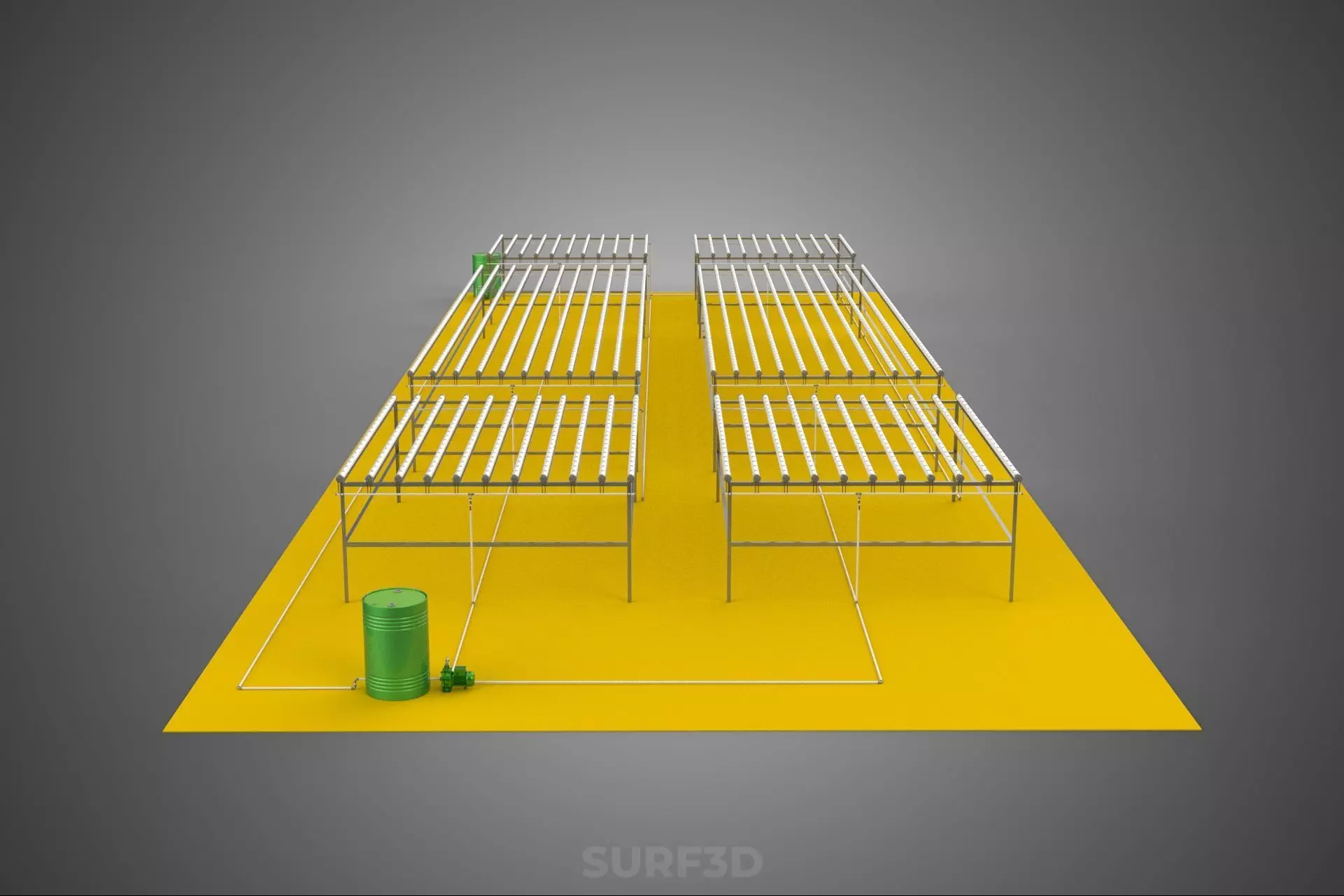

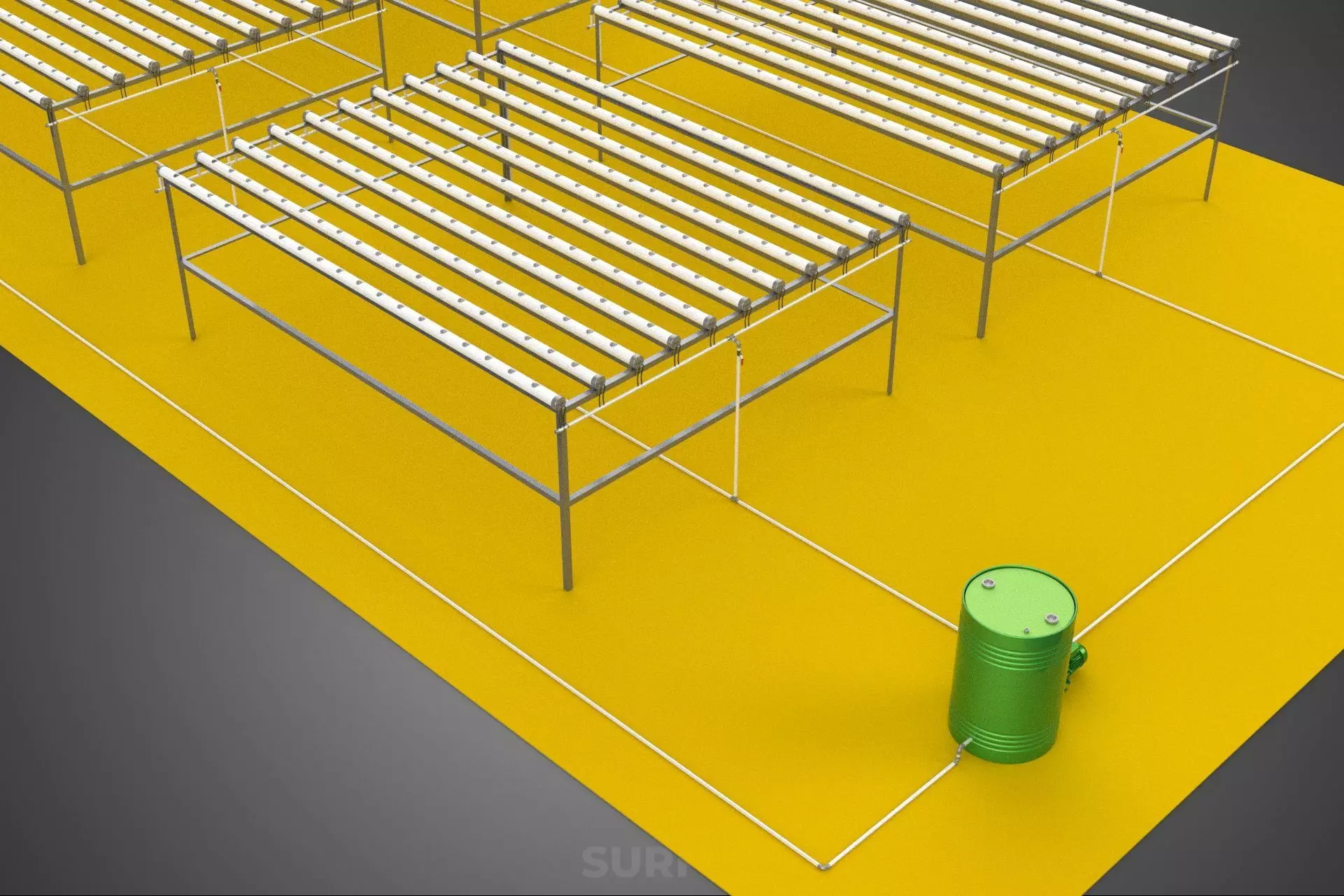

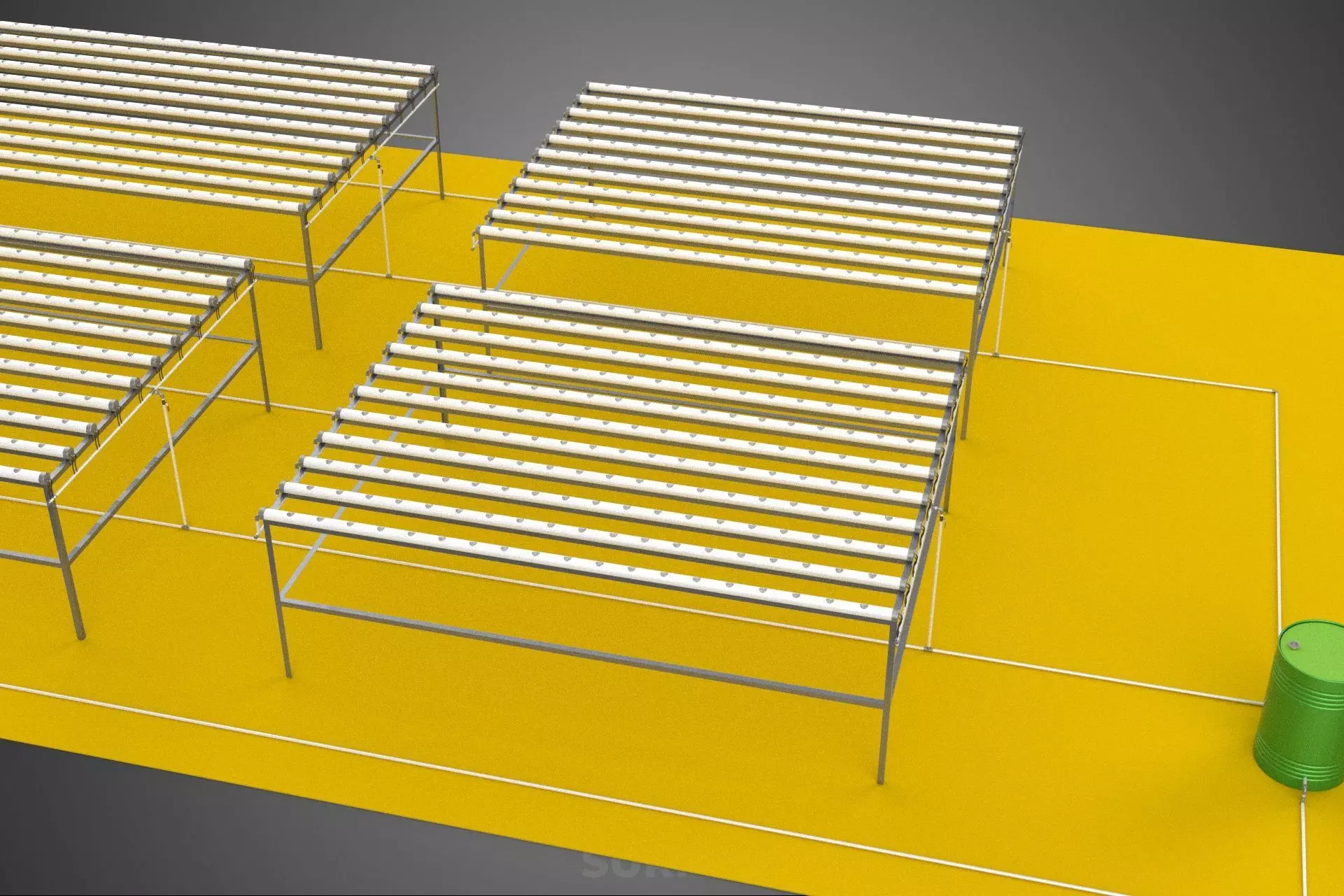

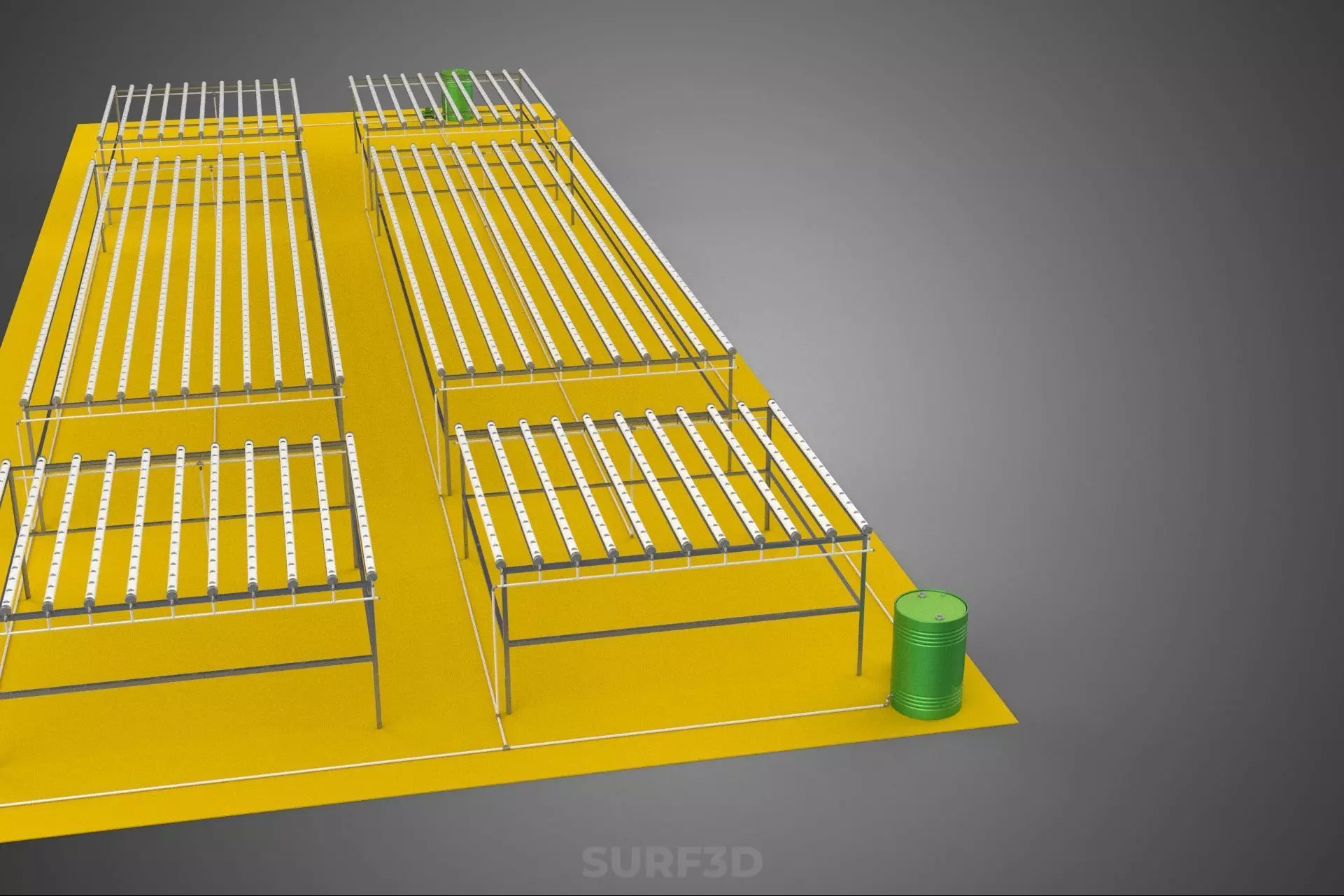

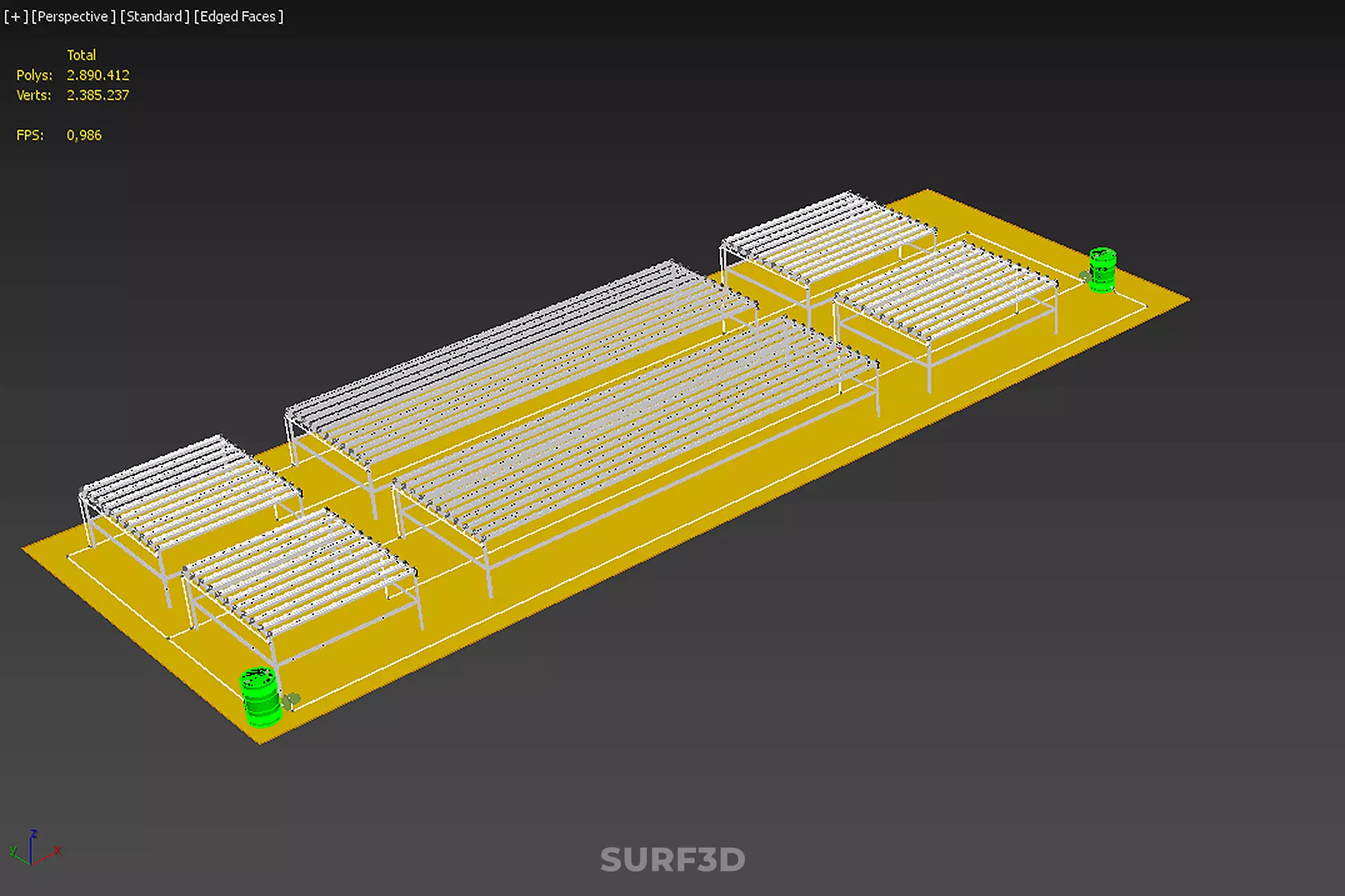

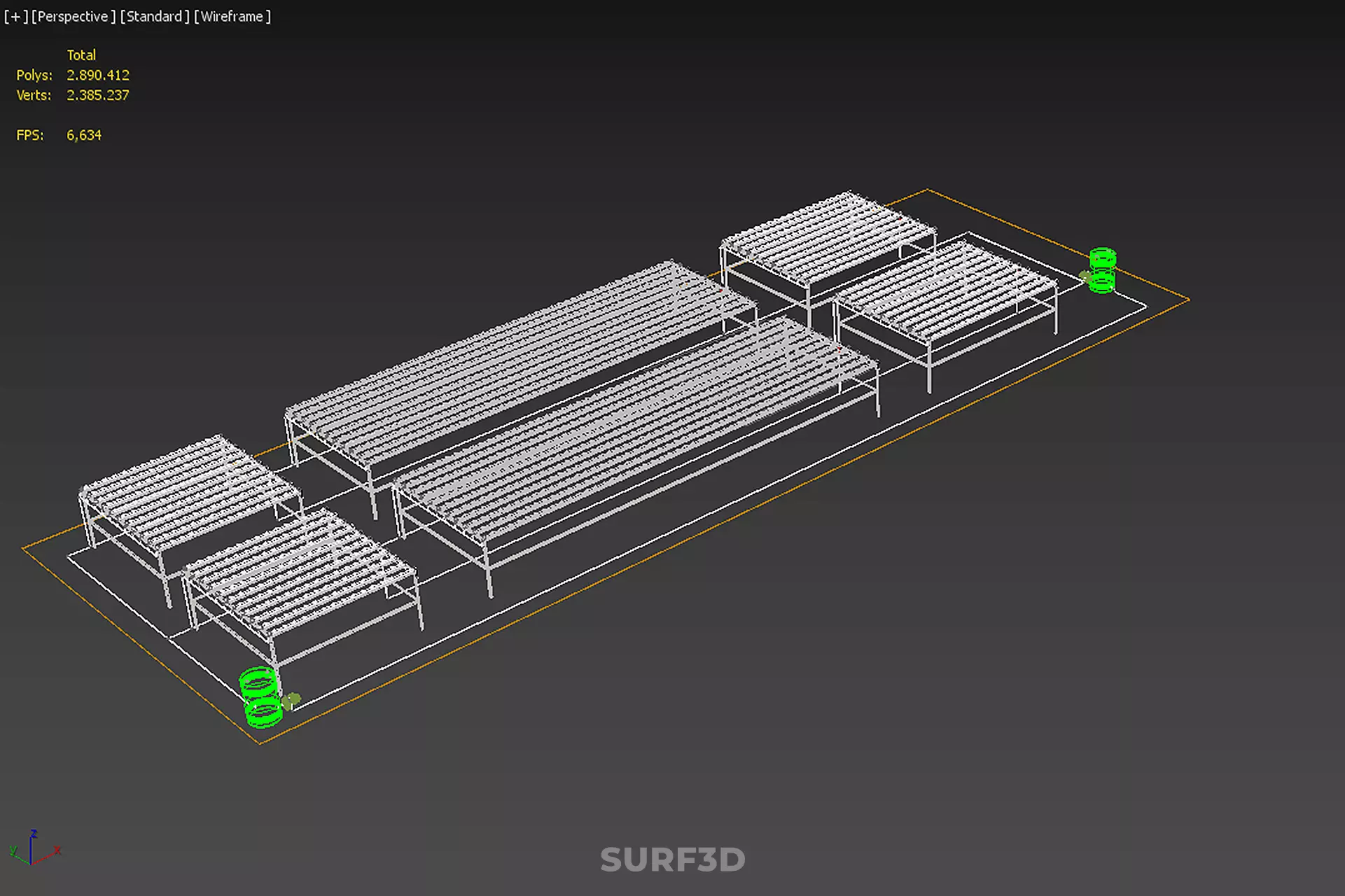

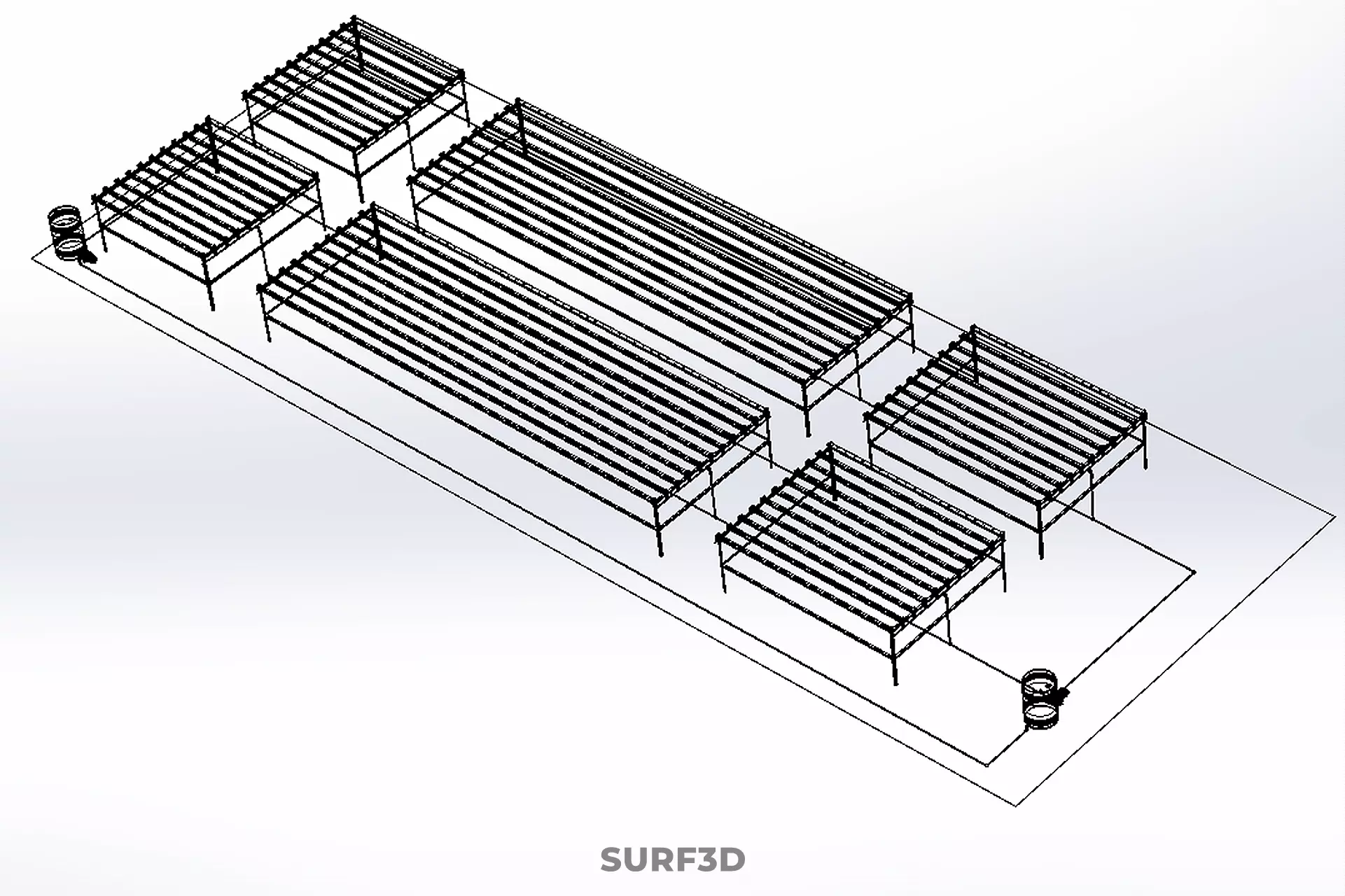

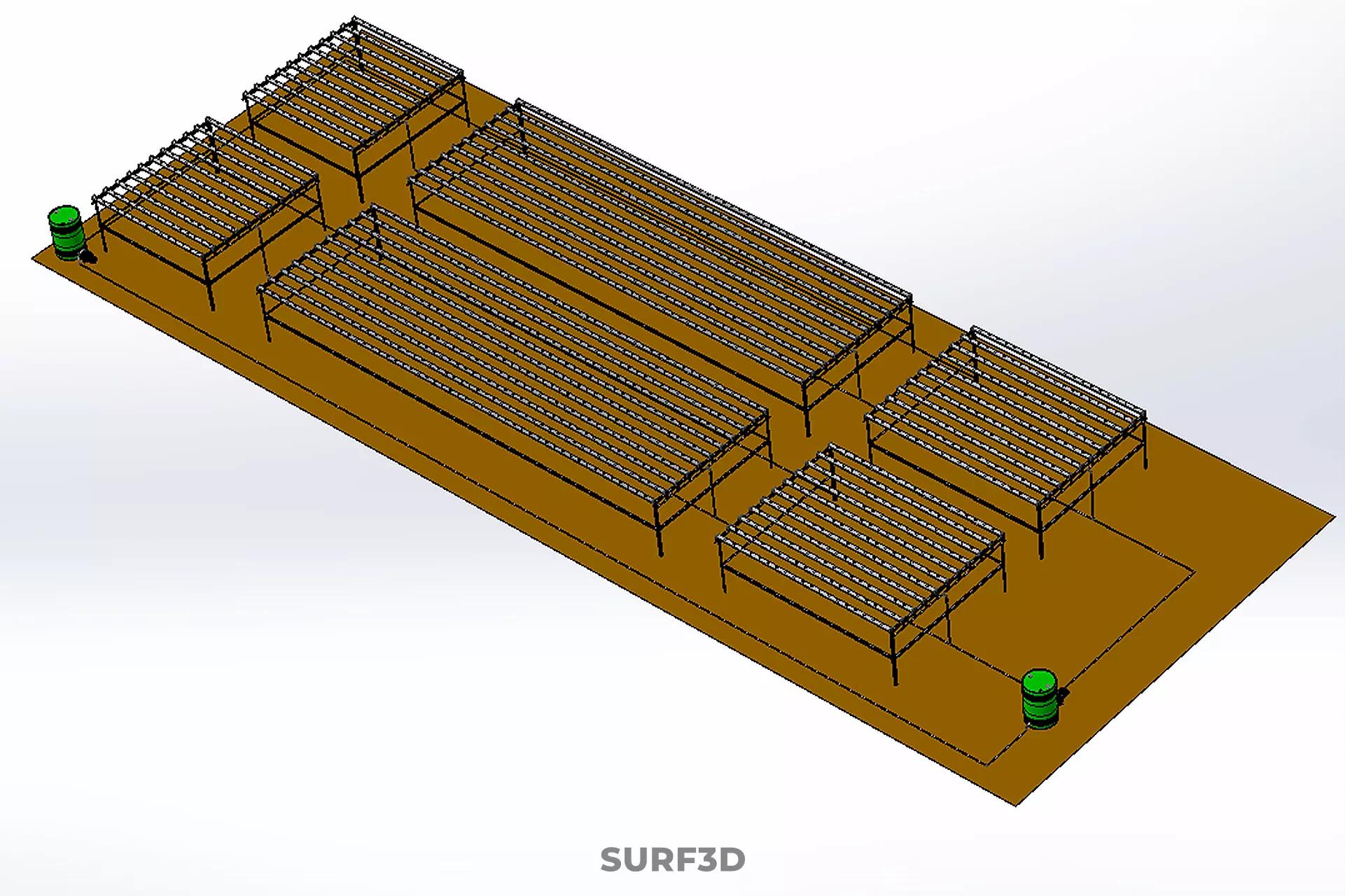

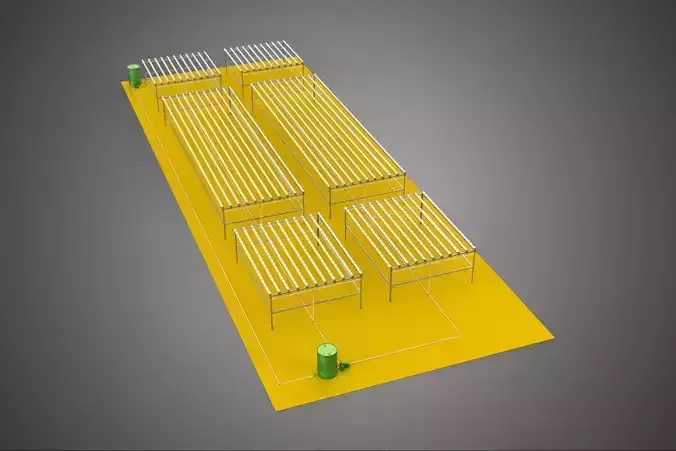

FIELD GARDEN LAYOUT AEROPONIC HYDROPONIC PLANT CROP FARM FACTORY 3D model

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

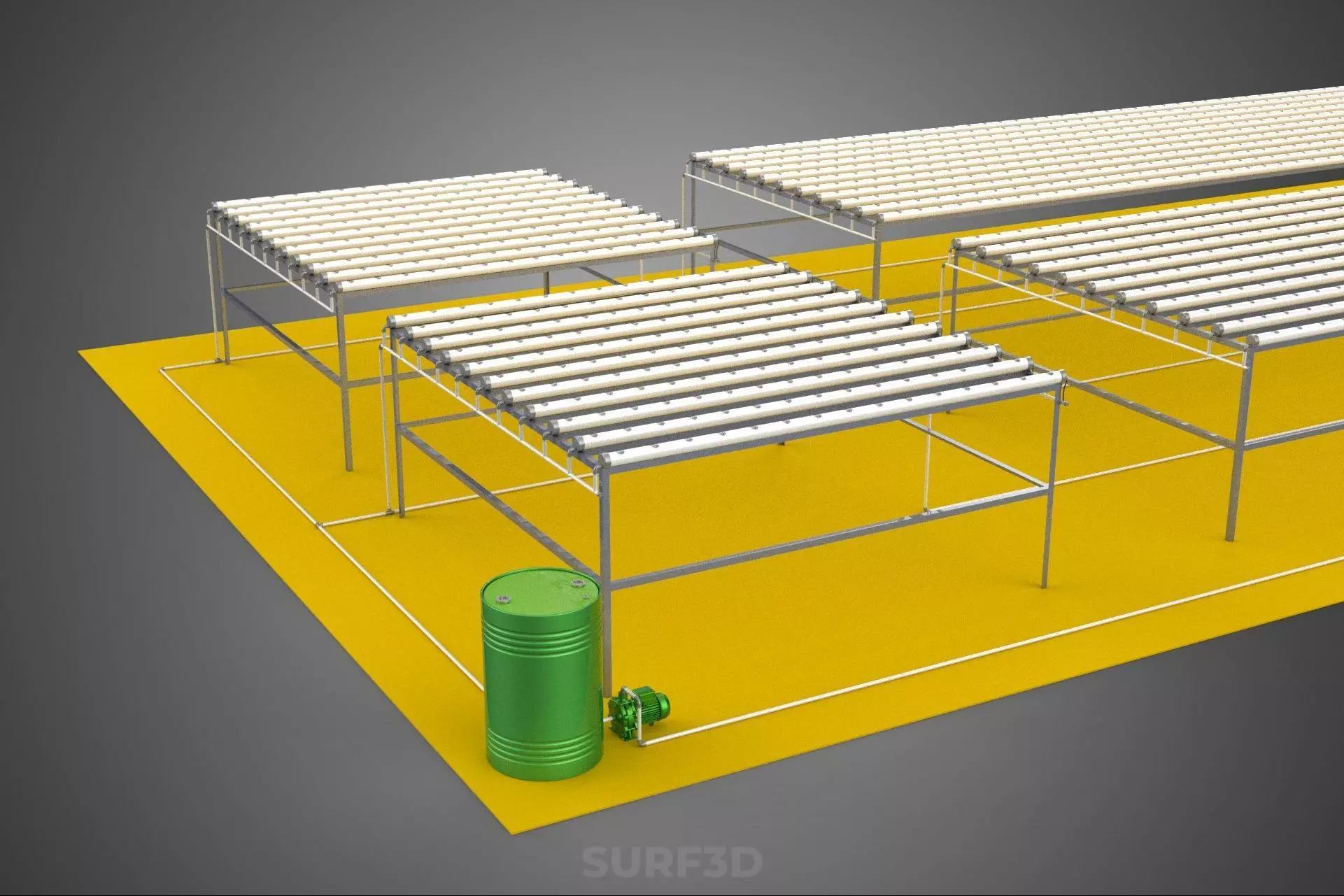

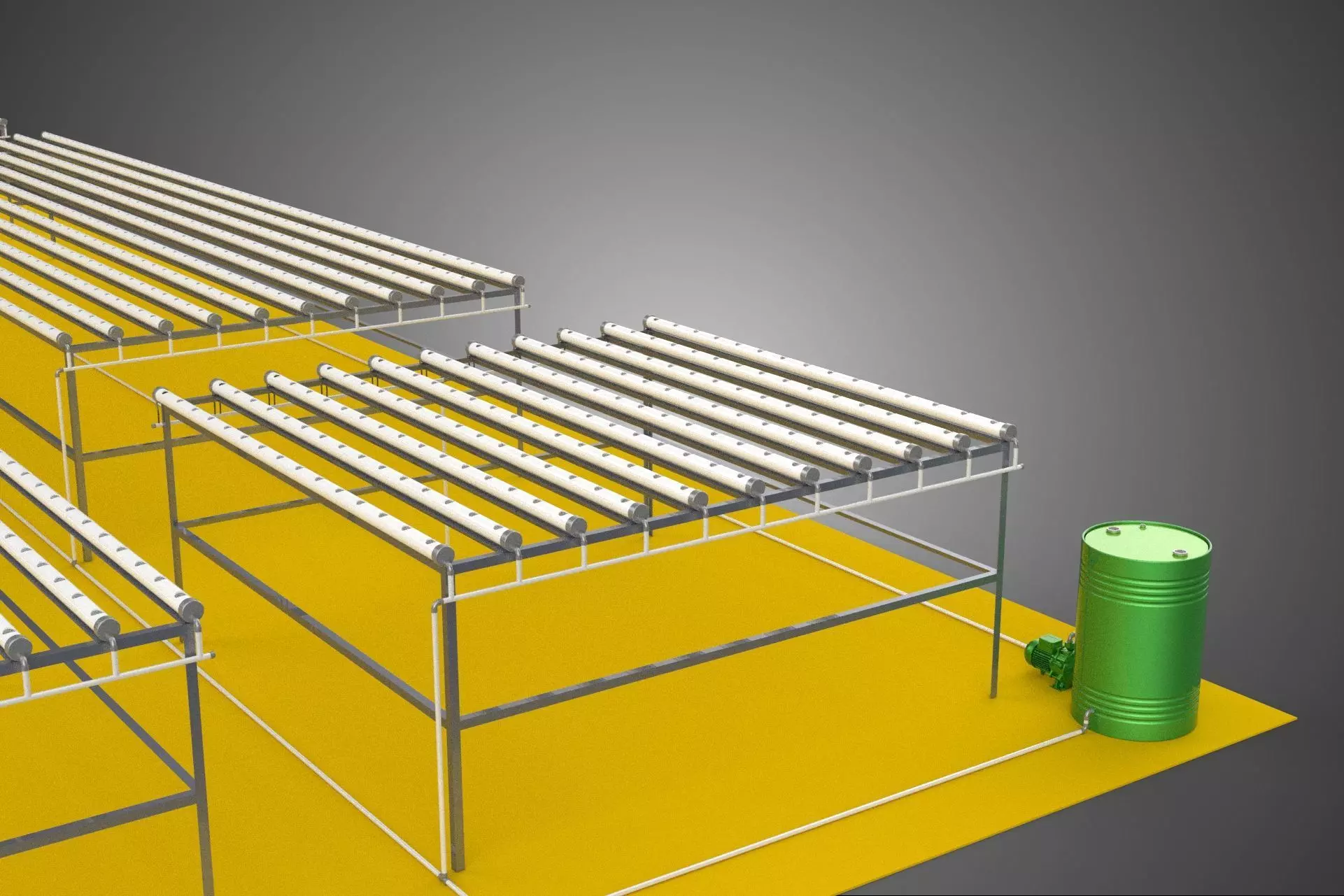

The designation FIELD GARDEN LAYOUT AEROPONIC HYDROPONIC PLANT CROP FARM FACTORY describes an advanced, industrial-scale system within the domain of Controlled Environment Agriculture (CEA), most commonly referred to as a Plant Factory with Artificial Lighting (PFAL) or Vertical Farm. This integrated methodology utilizes soilless cultivation techniques—primarily hydroponics and aeroponics—to achieve high-density, consistent, year-round production of specialized plant crops within an architecturally sealed, climate-controlled facility.

The system integrates elements typically associated with industrial manufacturing (Factory) with intensive horticulture (Farm Garden). The core objective is the decoupling of crop production from geographical limitations and environmental volatility by creating optimized indoor ecosystems.

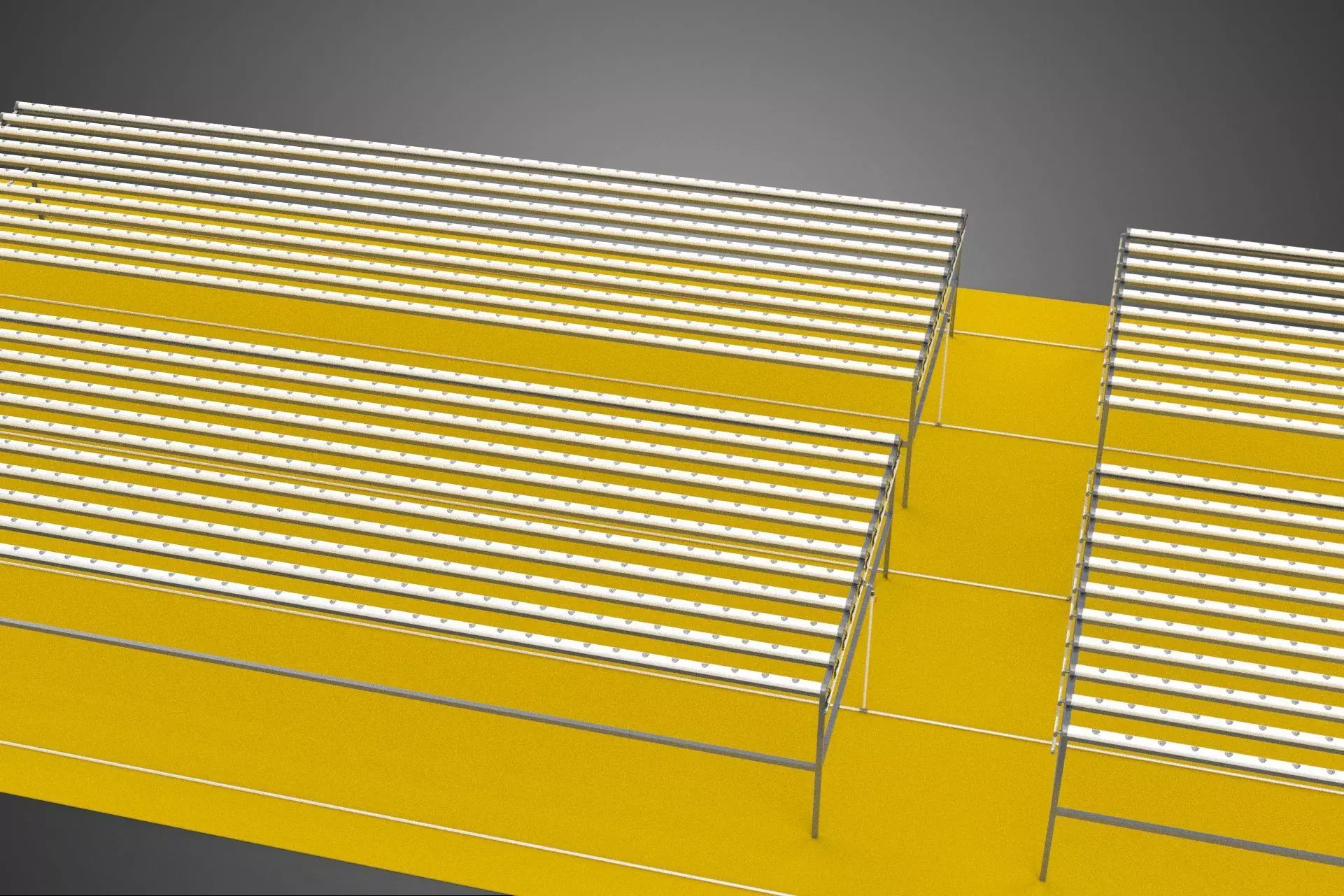

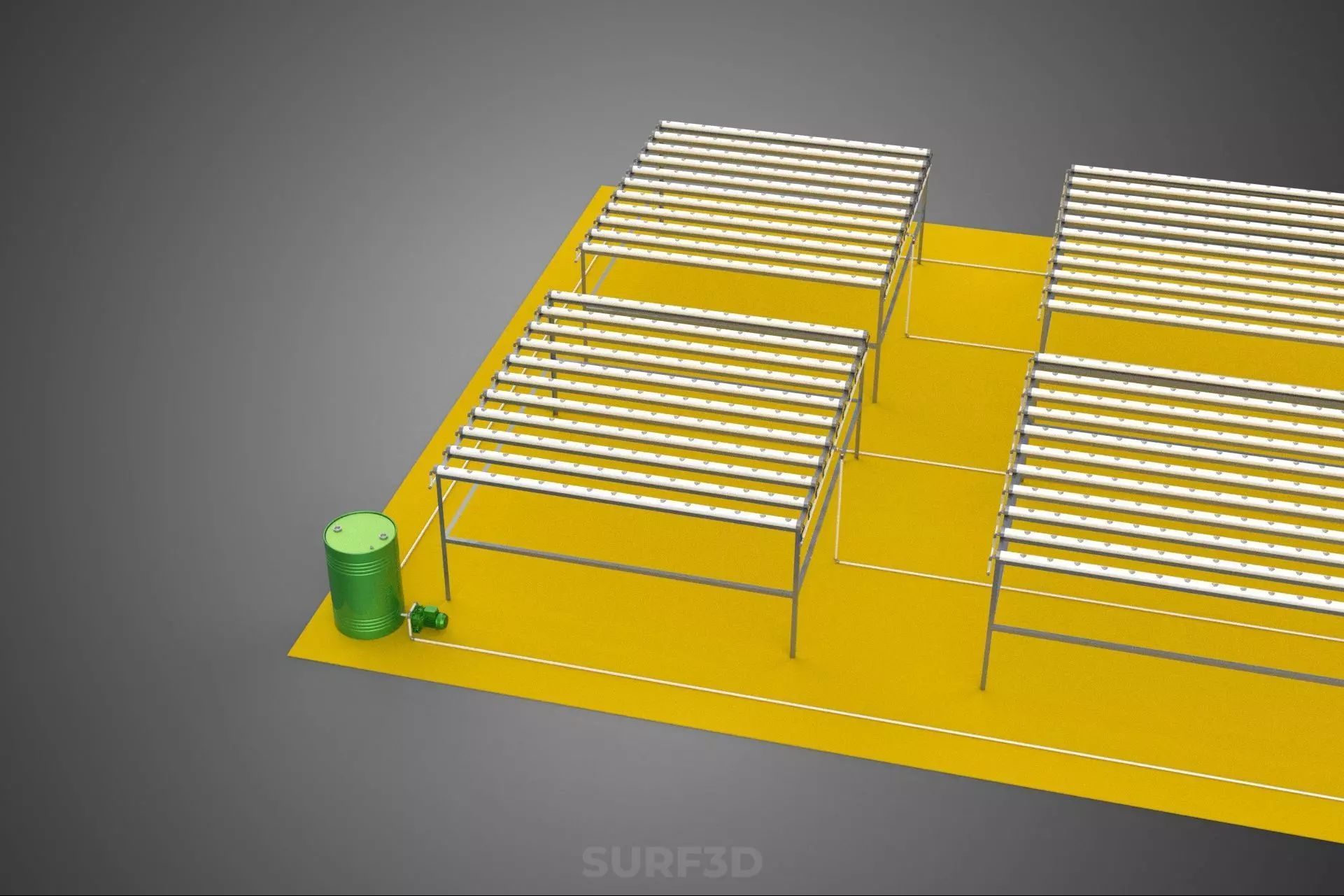

The Field Garden Layout refers specifically to the strategic, often modular, arrangement of cultivation units. These facilities utilize multi-tiered racking systems, maximizing the utilization of three-dimensional volume over a fixed footprint. This layout minimizes spatial requirements compared to traditional open-field agriculture while optimizing operational logistics, such as automated handling and environmental delivery systems. Layout efficiency is critical for managing light distribution and airflow across multiple vertically stacked layers.

The farm factory relies on soilless methods for resource efficiency and precision:

- Hydroponics: This broad category involves growing plants in a nutrient solution (fertigation) rather than soil. Common hydroponic layouts utilized in factory settings include:

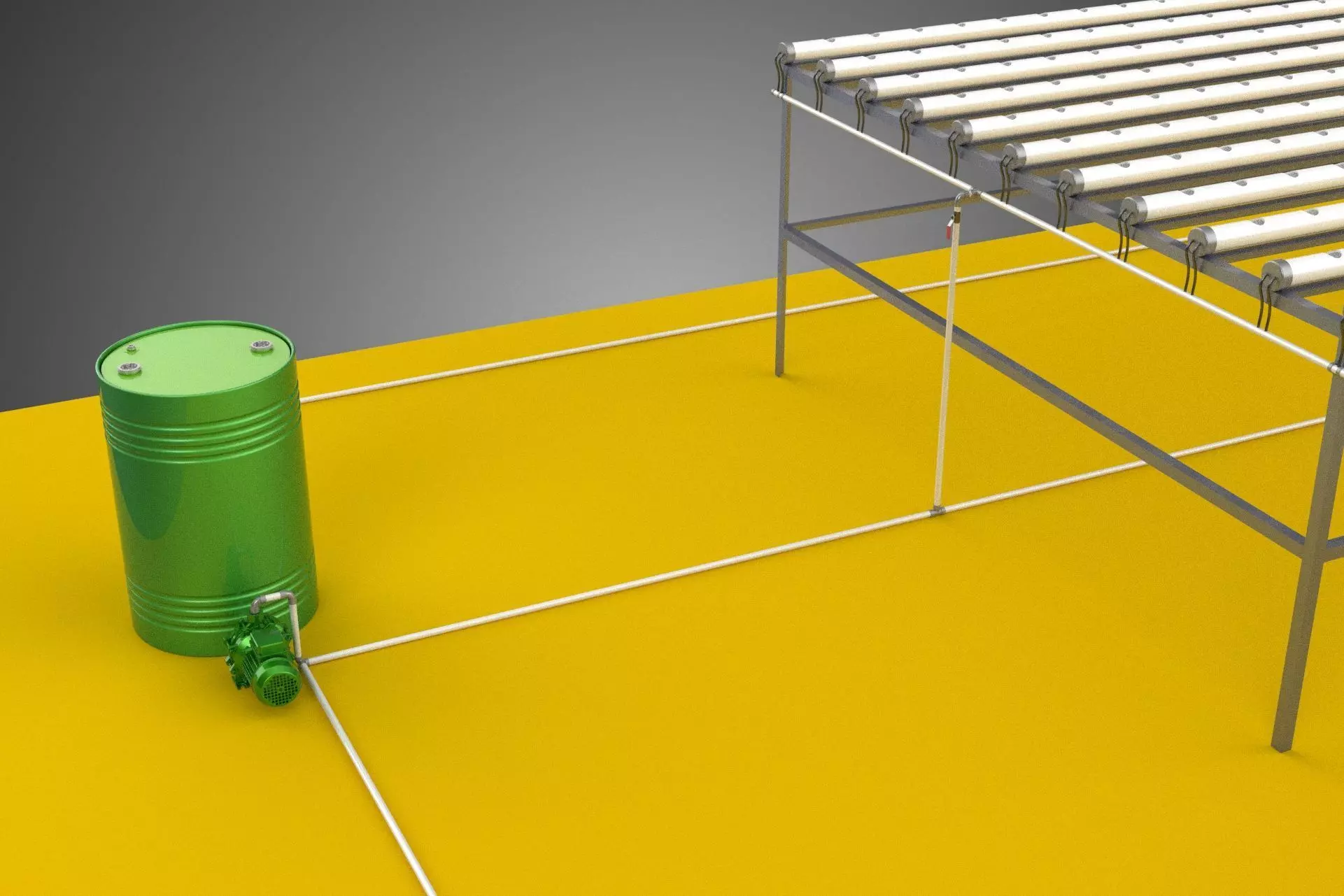

- Nutrient Film Technique (NFT): A shallow stream of nutrient solution flows over the bare roots contained in narrow channels, providing oxygenation and nutrients simultaneously.

- Deep Water Culture (DWC): Plant roots are submerged in a deep reservoir of oxygenated nutrient solution.

- Aeroponics: Considered the most resource-efficient soilless technique, aeroponics involves suspending plant roots in air and periodically misting them with a nutrient solution. This method maximizes oxygen availability to the root zone, often leading to accelerated growth rates and minimizing water usage.

Both technologies operate in closed-loop systems, allowing for the recapture and recycling of nutrient solution runoff. This drastically reduces water consumption, often by 95% or more compared to conventional irrigation.

### Farm Factory Characteristics

The Farm Factory designation emphasizes high technology, precision, and automation:

- Environmental Control Systems (ECS): Sophisticated computer systems manage all atmospheric variables, including temperature, relative humidity, air speed, and carbon dioxide (CO2) supplementation. Maintaining precise CO2 levels enhances photosynthetic efficiency, accelerating growth rates.

- Artificial Illumination: Unlike greenhouses that rely partially on sunlight, factory farms use high-efficiency Solid-State Lighting (SSL), predominantly LED fixtures. These LEDs are tuned to deliver specific spectral recipes—known as light quality—and intensity (measured as Photosynthetically Active Radiation, PAR) tailored precisely to the physiological needs of the target crop throughout its lifecycle. This allows for scheduled, accelerated harvests.

- Automation and Robotics: Industrial facilities incorporate robotics for tasks such as seeding, transplanting, environmental monitoring, precise nutrient dosing, pest scouting, and automated harvesting. This automation minimizes labor costs, reduces the risk of human-borne contamination, and ensures consistent quality control and traceability.

### Applications and Nomenclature

These controlled environment factory layouts are primarily used for producing high-value, fast-cycle crops such as leafy greens (e.g., lettuce, spinach), herbs, microgreens, and specialty fruits (e.g., strawberries). The model is a crucial component of modern urban agriculture strategies, minimizing food miles and enhancing food security by offering reliable local production independent of external climate change or seasonal constraints.

KEYWORDS: Controlled Environment Agriculture (CEA), Vertical Farming, Plant Factory, Hydroponics, Aeroponics, Soilless Cultivation, Nutrient Film Technique (NFT), Deep Water Culture (DWC), Precision Agriculture, Automation, Fertigation, Environmental Control System (ECS), Multi-Tier Racking, Urban Agriculture, Crop Yield Optimization, Resource Efficiency, LED Lighting, Photosynthetically Active Radiation (PAR), Closed-Loop System, HVAC, Industrial Horticulture, High-Density Planting, Food Security, Crop Rotation, Traceability, Modular Layout, Climate Resilience, Water Conservation, Sustainability, Indoor Farming.