1/21

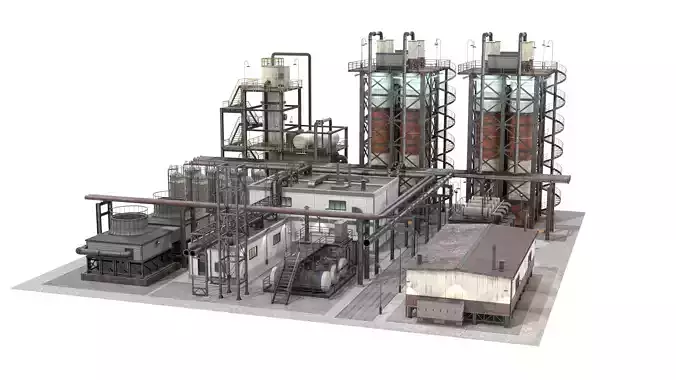

This project is a highly detailed 3D industrial plant facility created with 51 individual objects, modeled with clean quad geometry for maximum efficiency and flexibility. The design maintains professional standards of polygon flow, ensuring the model is optimized for rendering, animation, VR/AR integration, or further texturing and modification.

The model features a complete process plant environment, including piping systems, reactors, distillation columns, cooling towers, storage tanks, auxiliary buildings, and support structures — all carefully placed for realistic industrial presentation.

Unit Breakdown

1. Cooling Towers(Left Section)

- Cylindrical fan-based cooling towers for process heat rejection.

- Detailed external fan blades and piping connections.

- Used for cooling hot process fluids before recirculation.

2. Reactor/Processing Cylinders (Clustered Tanks)

- Vertical cylindrical vessels with access ladders and safety cages.

- Typically used for chemical reactions, filtration, or absorption.

- Includes maintenance platforms for operator access.

3.Main Process Building (Center Block)

- Core control and operation area of the facility.

- Equipped with rooftop ducting, chimneys, and air-handling units.

- Houses process monitoring systems and main equipment indoors.

4.Heat Exchanger / Boiler Units (Horizontal Tanks with Stair Access)

- Cylindrical horizontal tanks connected to piping systems.

- Likely functioning as boilers, feedwater tanks, or fuel reservoirs.

- Integrated staircases for inspection and maintenance.

5.Tall Distillation / Processing Columns (Back Section)

- Large vertical structures with spiral staircases and steel support frames.

- Representative of distillation or separation columns.

- Key units for refining, gas separation, or chemical fractionation.

6.Auxiliary Facility Building (Right Side)

- A smaller rectangular warehouse-type building.

- Functions as a workshop, storage, or maintenance area.

- Detailed with lighting, service boxes, and piping extensions.

7.Pipe Rack & Overhead Piping Network

- Realistic lattice-style pipe bridges connecting all major units.

- Provides structured routing for fluids, gases, and steam.

- Designed with varying diameters and bends for functional realism.

8.Safety Access Systems

- Spiral staircases, steel ladders, and handrails across all towers.

- Elevated platforms for equipment inspection.

- Industrial-standard lighting poles and wall lamps for night operation.

REVIEWS & COMMENTS

accuracy, and usability.