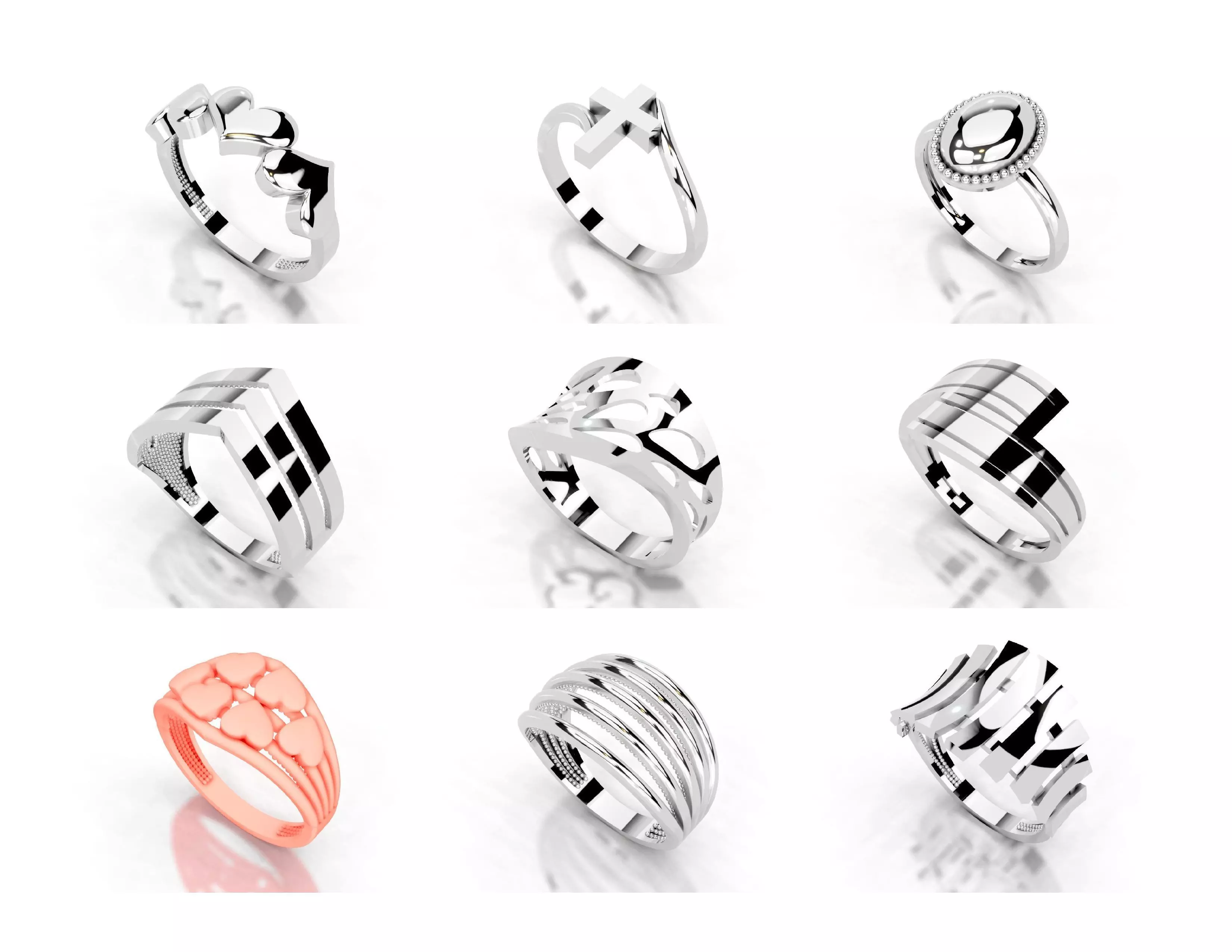

Slim 14K Ring Under 3 Grams US Size 7 Rhino 3DM STL 3D print 3D 3D print model

DescriptionDescriptionCreate sleek, everyday-wear rings with minimal metal usage. This lightweight 14K ring CAD package is engineered to stay under 3 grams in 14K gold for US size 7, helping you save on metal while maintaining strength, comfort, and clean aesthetics. Perfect for rapid production, e-commerce listings, and budget-friendly lines.

Files come in .3DM (Rhino) for full editability and .STL for direct printing—tested, manifold, and oriented for smooth CAM/print workflows. Ideal for independent jewelers, manufacturers, and CAD studios who need reliable, production-ready assets.

What’s Included

Formats:

3DM (Rhino) – fully editable geometry

STL – high-resolution, watertight, ready for printing

Design Focus: lightweight shanks, balanced wall thickness, comfortable inner profiles

Target Spec: ≤ 3.00 g in 14K (at US size 7)

Ring Size: US 7 (base size; can be resized up/down)

Use Cases: direct casting, stone-free plain bands, minimal solitaires/stackables (depending on your selection)

Weight Note: Final casting weight varies with ring size, alloy density (10K/14K/18K/22K), printer/cast tolerance, and finishing. Values are engineered for ≤3g in 14K at US 7 as a design target.

Key Features

Production-Ready: Clean topology, correct normals, closed volumes (manifold).

Lightweight Economy: Metal-efficient designs reduce cost without compromising wearability.

Editable Master Files: Adjust profile, width, comfort fit, or add prongs/channel details in 3DM.

Printer/Caster Friendly: Optimized for lost-wax casting workflows (DLP/MSLA/SLA).

Consistent Sizing: Built at US 7 for accurate scaling across size runs.

Clean Aesthetics: Designed for modern minimal/stackable collections and everyday wear.

Workflow & Compatibility

CAD: Rhino / Matrix / MatrixGold / RhinoGold (via 3DM)

CAM/Print: Any slicer accepting STL (Asiga Composer, B9, Chitubox, PreForm, etc.)

Casting: Standard burnout for castable resins/waxes; recommended sprue at shank’s thickest section

Quality Assurance

All STL files are watertight (no holes, non-manifold edges, or flipped normals).

Shank gauges and wall thicknesses are balanced for light weight + durability (subject to your workflow and finishing).