3D Printable Chains 3D print model

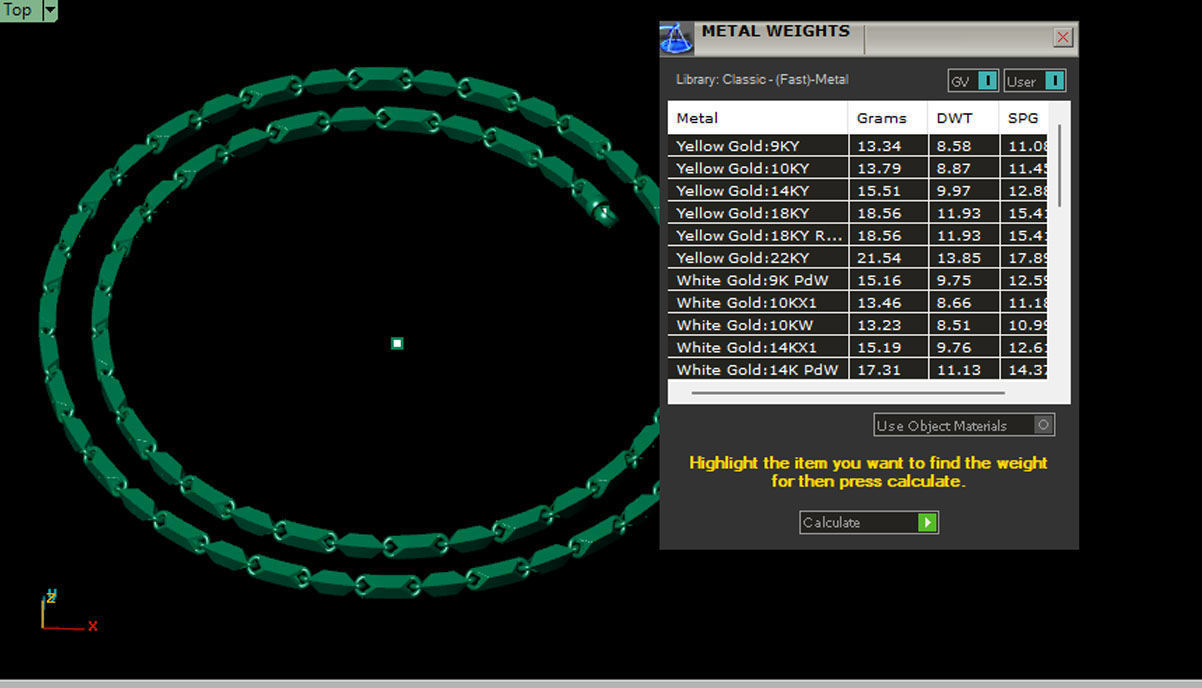

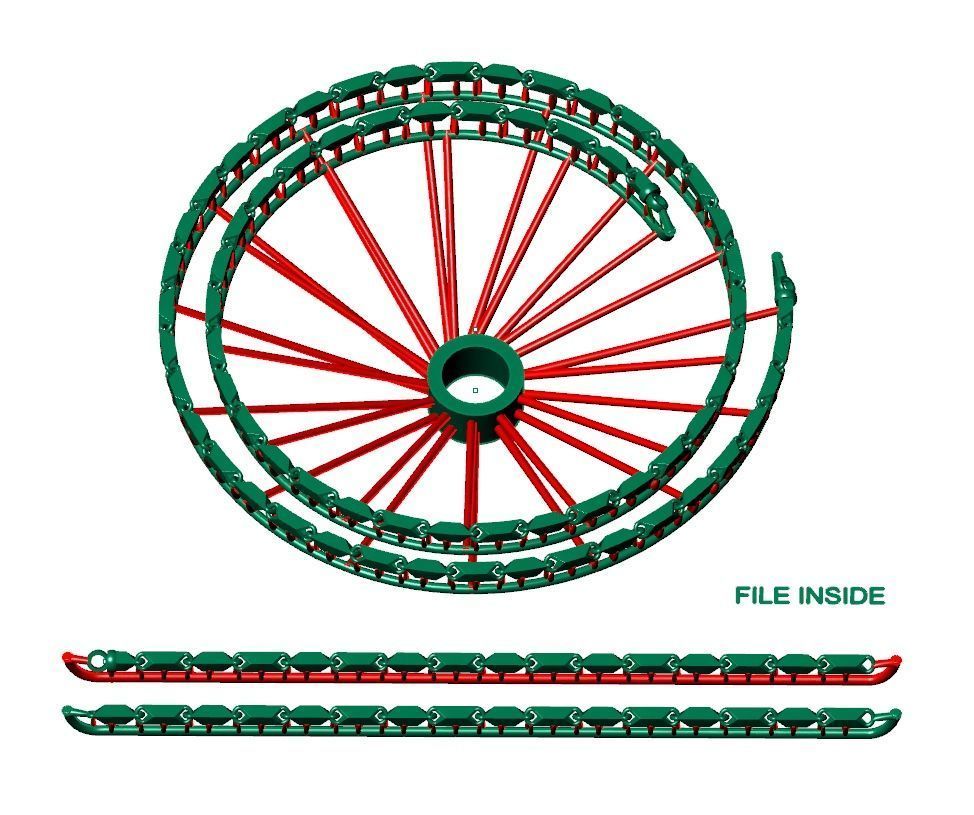

Weighing 22 grams for a 20-inch chain when cast in 22K goldPerfect for creating unique and standout jewelry designs

Strength and precision tested on Phrozen 12K printers for reliable results

Instant download with unlimited access, ensuring seamless design integration

A 3D printable chain consists of a series of interconnected links specifically designed for production through 3D printing technology. These chains find applications in various fields, including jewelry design, machinery, and decorative elements. With advancements in 3D printing, creating and designing a 3D printable chain has become increasingly accessible to designers, hobbyists, and jewelers alike. Whether you're looking to craft an exquisite piece of jewelry or a functional mechanical chain, several key considerations are essential for success.Key Considerations for Designing a 3D Printable Chain

When embarking on the design of a 3D printable chain, it’s important to focus on several critical factors, including the type of links, the flexibility of the chain, and the mechanisms by which the links interlock. These design aspects are vital to ensuring the chain operates effectively after printing. Here are some common types of 3D printable chains:

Curb Chain: Recognized for its flat, interlocking design, the curb chain is particularly well-suited for jewelry applications. Cable Chain: Featuring simple oval links, this chain is versatile and can be used for various purposes. Rolo Chain: A rounded design that is favored in jewelry crafting. Box Chain: Comprising square or rectangular links, this chain delivers a sturdy and geometric aesthetic.

Selecting the Appropriate Material for Your 3D Printable Chain

Choosing the right material is critical when crafting a 3D printable chain. The material you select will influence the chain's strength, flexibility, and overall appearance. Here are some popular materials used in 3D printing chains:

Resin (SLA Printing): Perfect for jewelry applications due to its high-resolution finish and smooth surface. PLA (FDM Printing): A good option for decorative chains that require minimal flexibility. PETG and TPU: These materials provide the flexibility and strength necessary for practical applications, such as mechanical chains.

Designing Links for Your 3D Printable Chain

The links of a 3D printable chain are the most crucial elements. Each link must be designed to interlock smoothly and allow for free movement without the risk of breaking. Consider the following factors when designing your links:

Link Size and Shape: Determine the dimensions and shape of each link based on the intended use of the chain, whether oval, round, or square. Link Tolerance: Ensure there is a small clearance between links to prevent fusion during printing. The necessary tolerance will vary based on your printer's precision. Link Flexibility: Design the links to be flexible enough so that the final 3D printable chain drapes naturally when worn or used.

Creating Your 3D Printable Chain with CAD Software

To develop a 3D printable chain, you’ll need CAD software such as Blender, Tinkercad, or Fusion 360. Here’s a simple guide to follow:

Sketch the Link Shape: Begin by sketching the basic outline of a single link, ensuring the dimensions align with your project specifications. Duplicate the Links: After designing the first link, duplicate it to form a series of interlocking links. Adjust the connections slightly for a smooth interlock. Test Tolerances: Check the clearance between links in your CAD design to ensure flexibility. It's advisable to print a small segment of the 3D printable chain to verify its functionality and strength. Export the Model: Save your final chain model as an STL file, ready for slicing and subsequent 3D printing.

Printing Your 3D Printable Chain

Once your 3D printable chain is designed, the next step is the printing process, which will depend on your chosen material and printer. Here are some tips for successful printing:

Choose the Right Orientation: Print the chain in a flat position to minimize the need for excessive support structures. Test Small Sections First: Before committing to printing the entire chain, produce a small test sample to ensure proper interlocking and movement of the links. Post-Processing: Carefully remove any support structures to avoid damaging the links, and sand rough edges if needed to ensure smooth operation.

Versatile Applications of 3D Printable Chains

The uses for 3D printable chains are extensive across multiple industries. Here are some popular applications:

Jewelry: Create sophisticated chains for necklaces, bracelets, and anklets, with 3D printing allowing for intricate designs that traditional manufacturing cannot easily replicate. Decorative Items: Utilize chains in home décor, such as curtain tiebacks, hanging ornaments, or lamp chains. Mechanical Uses: Design chains for practical applications, including timing chains or conveyor belts, using durable and flexible 3D printing materials.

Benefits of Crafting a 3D Printable Chain

Creating a 3D printable chain offers numerous advantages:

Customization: Tailor designs to reflect your personal style or brand identity. Precision: 3D printing enables high accuracy, facilitating the creation of intricate chain designs with precise link dimensions. Cost-Effectiveness: In comparison to traditional manufacturing, 3D printing can be more economical, particularly for smaller production runs.

Tips for Successful Design of 3D Printable Chains

If you’re aiming to create a 3D printable chain, consider these tips for effective design:

Plan Your Design: Before diving into CAD software, sketch out your chain design, including type, size, and intended application. Select the Right Printer and Material: Choose a 3D printer and material that fit your project's needs. For detailed jewelry chains, resin-based SLA printers provide excellent results. Test and Refine: Always print a small test section of your 3D printable chain to evaluate its flexibility and fit, making necessary adjustments to the design.

Challenges in Creating a 3D Printable Chain

While designing a 3D printable chain can be rewarding, it does come with challenges. One of the main issues is achieving the correct link tolerance. If the tolerance is too tight, links may fuse during printing. Conversely, if it’s too loose, the chain may lack structural integrity. Additionally, intricate chain designs may require support structures, complicating the post-processing stage.Future Trends in 3D Printable Chain Design

The future for 3D printable chains looks bright, with ongoing advancements in 3D printing technologies continually expanding the scope of what's achievable. Expect to see increasingly complex chain designs and innovative materials that enhance flexibility and durability. Furthermore, the combination of 3D scanning and 3D printing could lead to personalized chain designs tailored to individual measurements and preferences.