1/88

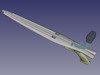

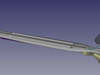

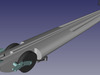

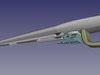

Inverter Vela 95 – Includes Trigger System and Stainless Steel Accessories

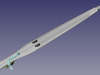

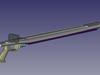

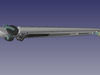

The model presented has been developed to be fast and easy to handle, particularly suitable for quick and instinctive shots.

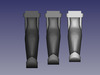

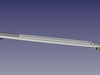

3D Model for Speargun and HandleDesigned for engraving on exotic woods such as teak, iroko, and mahogany.Included files also feature .STEP and .STL formats for the accessories, which can be 3D printed or CNC-machined from plastic materials such as Delrin.

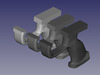

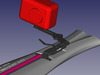

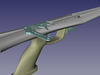

Included DXF ProjectsThe package includes the professional trigger system complete with quick-release cam brackets in DXF format, ideal for stainless steel laser cutting.Among the various DXF files, you will also find:

- Ballast slot covers

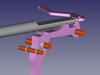

- Rubber tensioners with reel support (see photos)

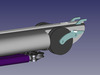

- Muzzle accessories

- Handle plates

- Butt plates

All DXF files come with technical drawings in PDF format, with instructions and dimensions for sheet metal folding and other machining processes.

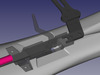

Also included are DXF and PDF files for the pulley carriage, to be manufactured via stainless steel laser cutting or CNC milling in carbon fiber.The DXF files can also be used for CNC cutting on carbon fiber panels if you prefer producing accessories without bends.

Speargun MachiningThe 3D model is designed for engraving on hardwoods. The use of 3- or 4-flute bits specifically for wood is recommended.Using general-purpose bits, or bits intended for metal or plastic, may result in chipping or imperfections.

With a shaft stroke of 95 cm, the speargun is suitable for all types of spearfishing, including ambush-style hunting.

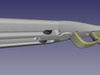

Important Note – Professional Trigger SystemThe trigger system has been designed with extremely tight tolerances—down to hundredths of a millimeter—to ensure maximum safety and reliability.It is highly recommended to have the laser cutting performed by qualified professionals. Inaccurate or poorly executed cuts can compromise the mechanism’s integrity and may lead to accidental misfires.

Likewise, the folding of the trigger housing must be done with great care. Any misalignment of components or axes can negatively affect the proper operation of the system.

Recommended materials for internal mechanical components:

- AISI 316 (not 316L)

- AISI 316Ti (titanium-stabilized)

- AISI 420

- AISI 440C

- AISI 630

The use of AISI 304 stainless steels (both 18/10 and 18/8) is strongly discouraged, due to their relatively low hardness and poor mechanical and wear resistance.

Maximum precision during manufacturing and assembly is essential to avoid malfunctions or accidents.

I disclaim any liability for failures resulting from improper fabrication.The trigger system has been thoroughly tested and validated, withstanding static loads of 280 kg for 48 consecutive hours without failure.

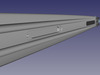

Important Note – Wood PreparationThe speargun structure is particularly slim. A lightweight laminated blank with Okoumé strips is recommended to reduce specific weight and maintain proper buoyancy in the water, avoiding sinking.Use hardwoods like teak, iroko, or mahogany for the central and lateral strips (the width of the central strip should match the distance between the pulley housings on the muzzle).

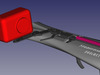

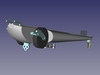

Reduction System and PerformanceThe reduction system ensures greater power, range, and speed due to increased shaft travel and acceleration.The Vela inverter system reduces recoil by up to 100%, making the shot extremely stable and precise.

The pulley system doubles the shaft's exit speed while reducing the load on the rubbers.Recommended setups:

- 2 pairs of large-diameter rubbers (17.5 – 19 mm)

- Or 3 pairs of medium-diameter rubbers (15 – 16 mm)

The rubbers are placed under the barrel, while the Dyneema line runs on top, improving handling and swing speed.To further reduce bulk, we recommend using the Croco block (included in the DXF files) with reel support, along with the “x6” reduction block also included in the files.

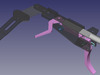

Handle FinishingOnce engraved, the speargun is ready for assembly.The only manual operation required:Sanding and shaping the grip saddle where the parts were glued (highlighted in pink in the photos). This part has not been pre-shaped to allow each user to adapt it to their own anatomy.

Three handle sizes are included (small, medium, large).

The handle can also be engraved on plastic materials such as Delrin or glass-filled nylon. In this case:

- Do not use epoxy resins

- Use D4-class polyurethane adhesives for optimal bonding

- Sand the plastic surfaces before gluing

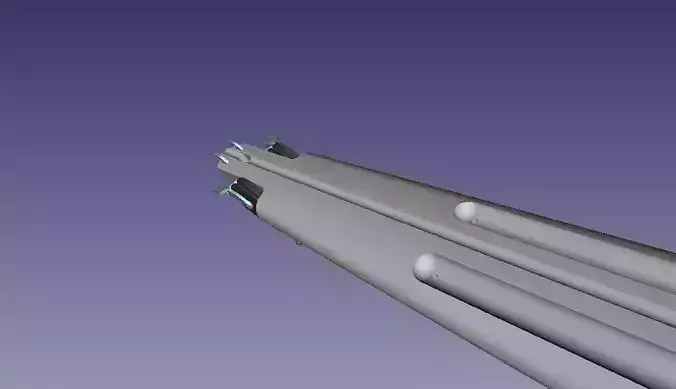

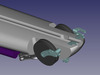

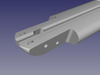

- Muzzle height: 26 mm

- Muzzle width: 55 mm

- Max belly width: 90 mm

- Max belly height: 30 mm

- Speargun

- Handle (3 sizes)

- Handle plate

- Butt plate

- Screw bushings (ballast slots)

- Ballast slot covers

- Line guide with lifter

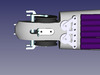

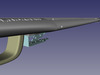

- Inverter pulleys

- Vela pulleys

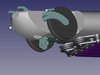

- Pulley carriage

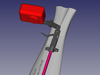

- Professional trigger system

- Cam brackets

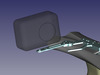

- Muzzle pulley cheeks

- 3x tensioners with reel support

- Muzzle line stopper

- Croco x3 with reel support

- Trigger system

- Muzzle and inverter pulleys

- Muzzle accessories

WARNING:This project is intended for private and recreational use only.It is registered under the domain LDpro3D, owned by Lombardo Davide.Any commercial reproduction is strictly prohibited.Violations will result in legal action.

Technical Note:Specifications and parameters for laser cutting and CNC milling depend on the type of machine and the operator’s preferences.Standardized settings cannot be provided without knowing the equipment used.

REVIEWS & COMMENTS

accuracy, and usability.