1/8

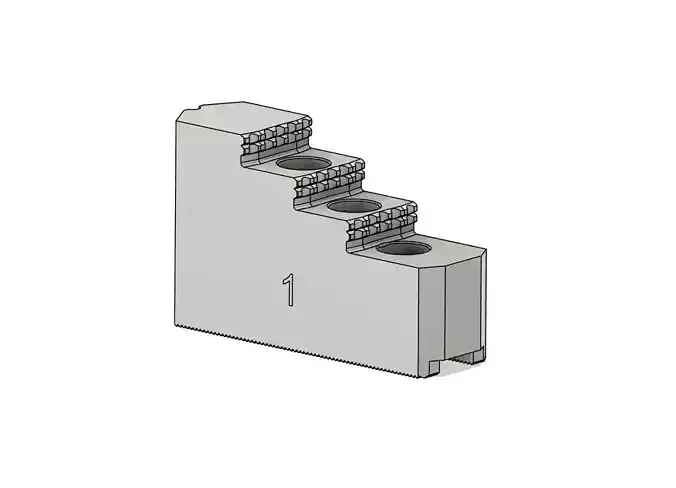

INDUSTRIAL-GRADE CNC LATHE JAWS FOR MORI SEIKI AL-2

Material: Aircraft-Grade Aluminum 6061-T6 (Hardness: 95 HB | Yield Strength: 240 MPa)/Precision-Engineered AISI 4140 Tool Steel (Hardness: 45-50 HRC | Yield Strength: 1,450 MPa | UTS: 1,650 MPa)Design Intent: High-volume manufacturing with tolerance stability (±0.05mm repeatability).

KEY FEATURES

DUAL-FUNCTION DESIGN

- Soft Jaws: Use as-delivered for rapid prototyping

- Hard Jaws: Modify clamping bores (Ø callouts in drawings) for hardened tool steel inserts

MACHINE-SPECIFIC ENGINEERING

- Precision-fit for Mori Seiki AL-2 turret/chuck interface

- Balanced mass distribution (prevents chatter at >2,000 RPM)

MANUFACTURING READY

- 100% parametric CAD (modify bores without remodelling)

- Stress analysis verified (FEA 3x operational load)

- ISO 2768-mK tolerances applied

TECHNICAL SPECIFICATIONS

Base Material = 6061-T6 Aluminum( Soft version)/ 4140 Steel (Hard version)

Critical Tolerances = ±0.05mm (Bore Centers and step in thread)

Surface Finish = Ra 3.2 μm (as-machined Included Formats = STEP

Modularity = 5 Standard Bore Sizes (Ø6-Ø30mm)

REPRODUCTION NOTES

- Material Certification: Requires Mill Test Report (ASTM B209)

- Post-Processing:

- Anodizing recommended for coolant resistance (Type III)

- Hard jaws: Heat-treat bore inserts to 45-50 HRC

- Anodizing recommended for coolant resistance (Type III)

- QC Inspection:

- CMM verification of bore grid pattern

- Runout <0.01mm on mounting face

- CMM verification of bore grid pattern

FILE STRUCTURE:

/MORI_SEIKI_AL2_JIG_REV2_INDUSTRIAL └──README.txt/CAD ├── /MORI_SEIKI_AL2_JIG_REV2_INDUSTRIAL_HARD (Aluminum version) ├── /MORI_SEIKI_AL2_JIG_REV2_INDUSTRIAL_SOFT (Steel version)/Drawings ├── MORI_SEIKI_AL2_JIG_REV2_INDUSTRIAL_SOFT.pdf └── MORI_SEIKI_AL2_JIG_REV2_INDUSTRIAL_HARD.pdf

WARNING: Not validated for aerospace/medical use without additional documentation.

REVIEWS & COMMENTS

accuracy, and usability.