1/20

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

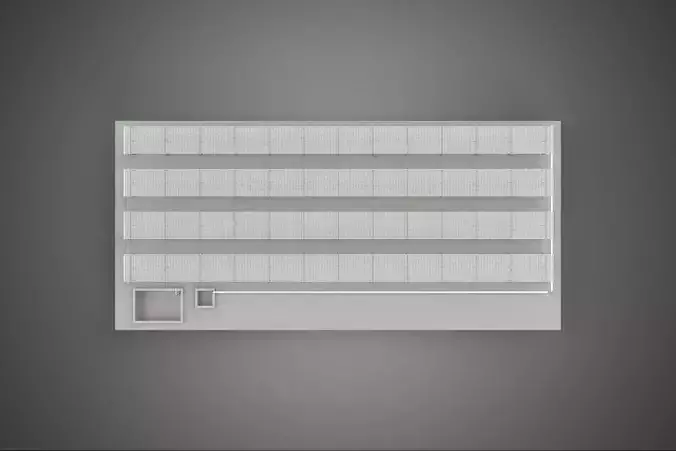

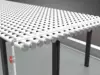

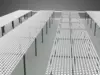

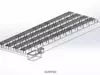

ALIGN AEROPONIC HYDROPONIC LAYOUT ARRAY PARALLEL ROW PLANT FARM

The ALIGN Aeroponic Hydroponic Layout Array Parallel Row Plant Farm designates a highly optimized, high-density Controlled Environment Agriculture (CEA) system characterized by the precise spatial organization of cultivation modules utilizing hybrid nutrient delivery methodologies. This configuration is specifically engineered to maximize resource utilization, standardize crop environments, and facilitate the integration of automated handling and monitoring technologies.

The system integrates both aeroponic and hydroponic techniques to leverage the respective advantages of each method. This dual approach, often referred to as an integrated or hybrid nutrient delivery system (HNDS), is typically tailored to specific crop requirements or stages of growth:

- Aeroponics: Utilized primarily for delivering nutrient-rich mist directly to the plant roots, maximizing oxygenation, accelerating early-stage growth, and improving nutrient absorption efficiency. The precise control afforded by aeroponics minimizes water usage and allows for exact management of root zone temperatures and solute concentration.

- Hydroponics: Generally implemented through methods such as Nutrient Film Technique (NFT), Deep Water Culture (DWC), or substrate-based drip systems. Hydroponics provides environmental stability, nutrient buffering capacity, and structural support, particularly for mature or heavier fruiting crops.

The hybrid nature allows operators to dynamically switch between systems or employ them sequentially, optimizing the stoichiometric ratios and resource flux delivered to the plants throughout their life cycle.

### Geometric Optimization and Layout Array

The core distinguishing feature of this system is its stringent geometric arrangement, defined by the ALIGN ARRAY PARALLEL ROW nomenclature.

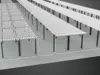

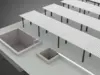

Parallel Row Array: This structure consists of modular growth channels or containers arranged in repetitive, standardized parallel rows. This design establishes uniform access corridors for labor, monitoring equipment, and mechanized harvesting platforms. The modularity of the array facilitates scalability and simplifies maintenance procedures, as individual sections can be isolated without disrupting the entire farm operation.

The ALIGN Principle: The term ‘ALIGN’ refers to the precise spatial orientation and geometric congruence applied across the entire farming footprint. This principle is vital for several operational efficiencies:

- Light Homogeneity: Ensuring that artificial lighting fixtures (e.g., LEDs) or natural light apertures are positioned to deliver uniform Photosynthetically Active Radiation (PAR) levels across all canopy surfaces, minimizing shading variability.

- Airflow Management: Critical for maintaining consistent vapor pressure deficit (VPD) and preventing the buildup of localized high humidity pockets, thereby reducing the incidence of fungal pathogens. The aligned structure dictates predictable air movement patterns.

- Automation Compatibility: Precise alignment ensures that the coordinates and spatial metrics of every plant station, sensor point, and access trajectory are standardized. This consistency is mandatory for the reliable deployment of robotic manipulators, automated seeding machines, and precision sensing technologies.

### Operational Significance and Applications

The ALIGN Aeroponic Hydroponic Layout Array is engineered for high-density planting (HDP), resulting in significantly increased yields per unit area compared to traditional field farming or less structured CEA environments. Key operational advantages include:

- Predictive Yields: Environmental controls and standardized layouts allow for highly accurate modeling of crop growth and resource consumption.

- Resource Efficiency: Significant reduction in water consumption (up to 98% less than conventional agriculture) through closed-loop recycling and minimal evaporation loss inherent in aeroponics.

- Labor Efficiency: The parallel row structure and alignment facilitate the application of automation, reducing manual labor costs associated with monitoring, pruning, and harvesting.

This system is commonly deployed in urban vertical farms, research facilities requiring stringent environmental replication, and large-scale commercial operations cultivating high-value crops such as leafy greens, medicinal herbs, and specialty fruits.

KEYWORDS: Controlled Environment Agriculture, CEA, Hydroponics, Aeroponics, Hybrid System, Nutrient Film Technique, NFT, Deep Water Culture, DWC, Layout Array, Parallel Row, Geometric Optimization, Precision Agriculture, High Density Planting, HDP, Automation, Resource Efficiency, Water Recycling, Vertical Farming, Urban Agriculture, Crop Science, Lighting Uniformity, Airflow Management, Modular Design, Robotics, Plant Factory, Nutrient Delivery System, Solute Concentration, Root Zone, Yield Maximization, Standardized Layout.

REVIEWS & COMMENTS

accuracy, and usability.