1/20

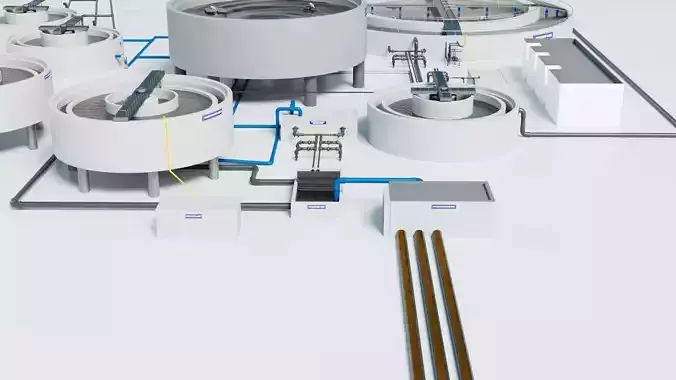

A detailed 3D model of a Common Effluent Treatment Plant (CEPT), created using Autodesk Maya 2024. It visually represents the complete flow and major components involved in the treatment process, typically used for treating a mix of industrial and municipal wastewater before safe discharge or reuse.

Blue and black pipelines clearly indicate separate flow paths for different stages of the treatment process.

A central collection tank is used for gathering effluent from various stages before further treatment or discharge.

Labeled sections highlight specific units, such as Collection Tank, Sludge Handling, and Plant Final Discharge Outlet, facilitating the tracking of wastewater progress through the system.

Major CEPT Plant Processes DepictedCollection and Pre-Treatment: Wastewater from various sources enters the plant and is collected in initial tanks. Screening and grit removal units filter out large debris and sand.

Chemical Enhancement: Coagulant chemicals are added to the wastewater to facilitate the aggregation of fine suspended particles (flocculation).

Primary Treatment (Sedimentation): The water moves into primary clarifiers, where heavy solids settle as sludge, and clearer water proceeds for further treatment.

Biological Treatment: Aeration tanks use microorganisms to degrade dissolved organic matter, efficiently reducing biochemical oxygen demand (BOD) and chemical oxygen demand (COD).

Secondary Clarification: Additional settling occurs to remove excess biomass formed during biological treatment, as seen in the clarifier tanks.

Sludge Handling: Solids settled from clarifiers are pumped to sludge handling and thickening units for further dewatering and safe disposal.

Treated Water Discharge: Fully processed water is sent to the Plant Final Discharge Outlet, meeting environmental standards for safe release or reuse.

Modeling DetailsThe 3D model was constructed and rendered in Maya 2024, which supports accurate geometry, UV mapping, and photorealistic textures to resemble real wastewater treatment infrastructure closely.

Such models are ideal for educational demonstrations, plant planning and design visualization, operator training, and simulation.

This comprehensive digital visualization highlights all key processes of a typical CEPT plant with clear labeling and logical flow, making complex treatment steps easy to understand for engineers

REVIEWS & COMMENTS

accuracy, and usability.