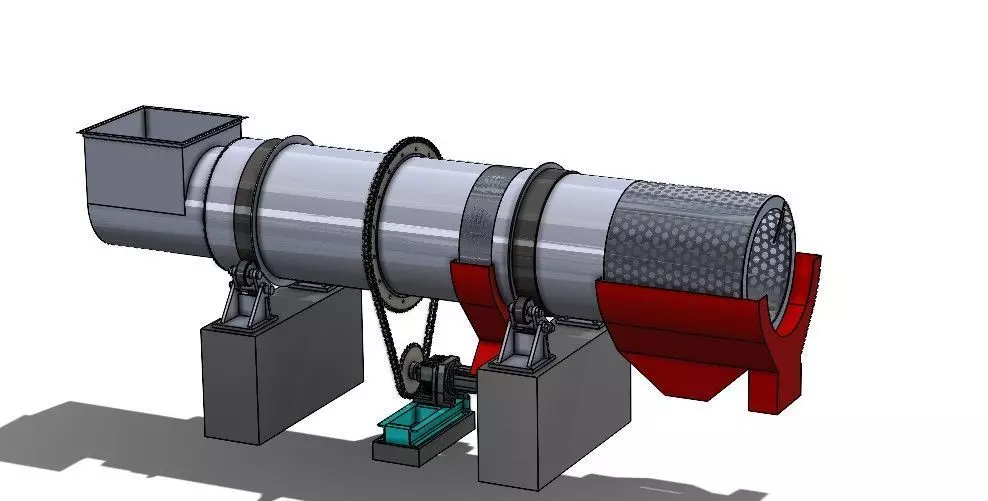

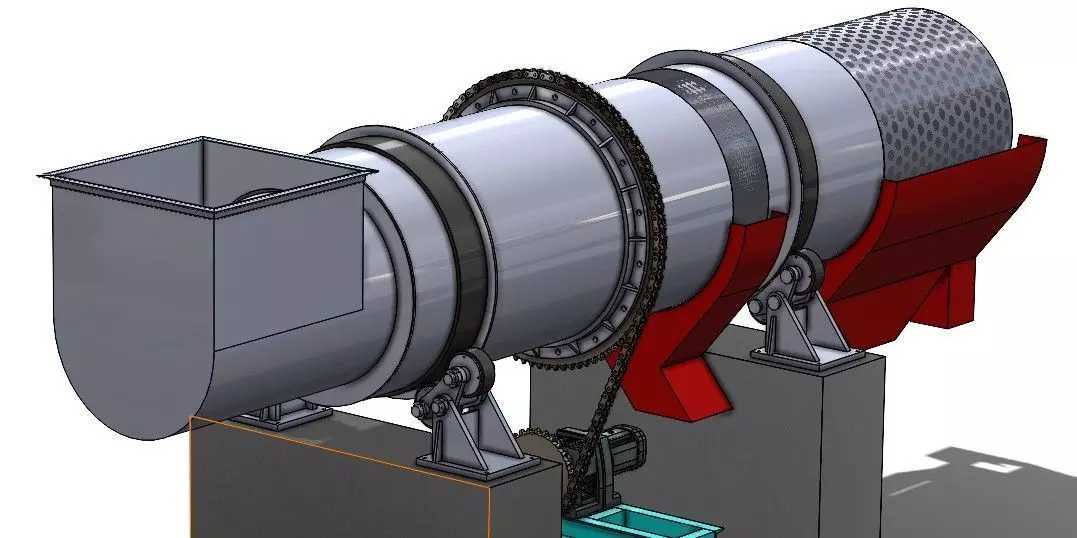

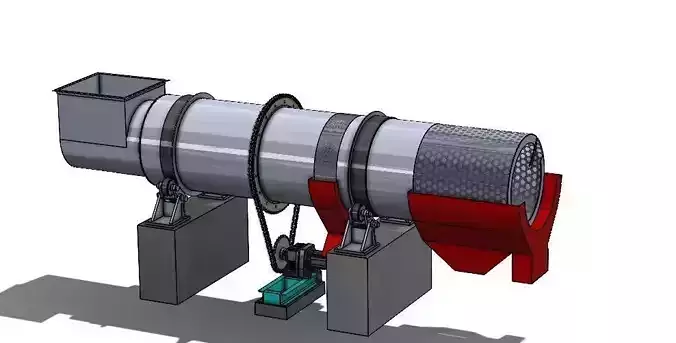

NUT POLISHING DRUM FOR PALM OIL MILL 3D model

A nut polishing drum is a rotary machine used in a palm oil mill to clean and remove residual fibers from the surface of palm nuts before they are sent to the cracking machine. The cleaning process improves the efficiency of the nut cracking stage and helps maintain the cleanliness of the nut silos

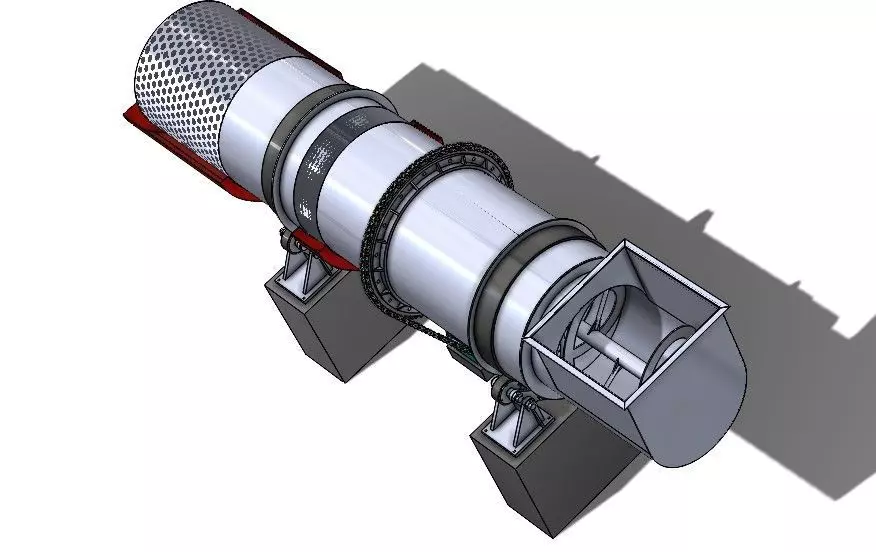

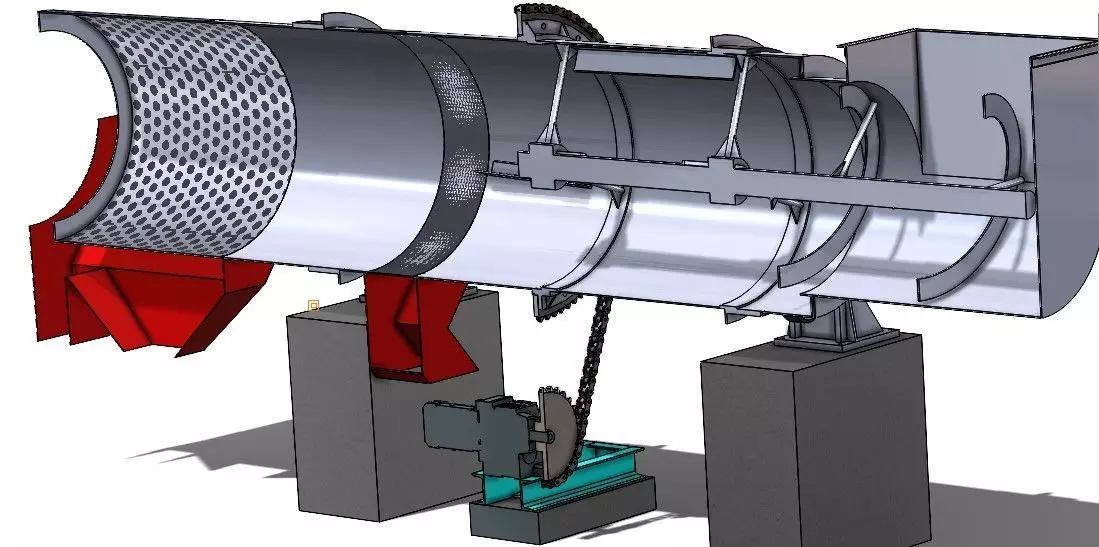

How a nut polishing drum worksPalm nuts are fed into the rotating drum, which is fabricated with internal baffle plates and lifting bars. The working mechanism relies on the nuts tumbling and rubbing against each other and the internal surfaces of the drum.

Cleaning: This tumbling action loosens and separates the remaining fibers from the nuts.

Separation: The drum's outer surface is perforated with holes. The cleaned nuts drop through the perforations into a collection system, while larger impurities like stones and stalk particles are discharged from the end of the drum.

Grading: Modified polishing drums can also grade nuts by size to feed them to different nut crackers, which helps to minimize kernel breakage. Key specifications and components

The design and specifications of a nut polishing drum can vary, but key features include:Capacity: Drums are available in various sizes to match the production needs of the mill, with capacities ranging from 5 to 20 tons of nuts per hour. Some models, such as the one from Zhengzhou Yahua Cereals and Oils Engineering, have a capacity of 10 tons per hour.

Construction: Drums are typically fabricated from thick mild steel (m.s.) plates, often 9mm thick.

Perforations: The perforated plate holes are sized to allow cleaned nuts to pass through. For instance, a commissioning report for a nut polishing drum at Havys Oil Mill lists perforated plate hole sizes between 12mm and 32mm.

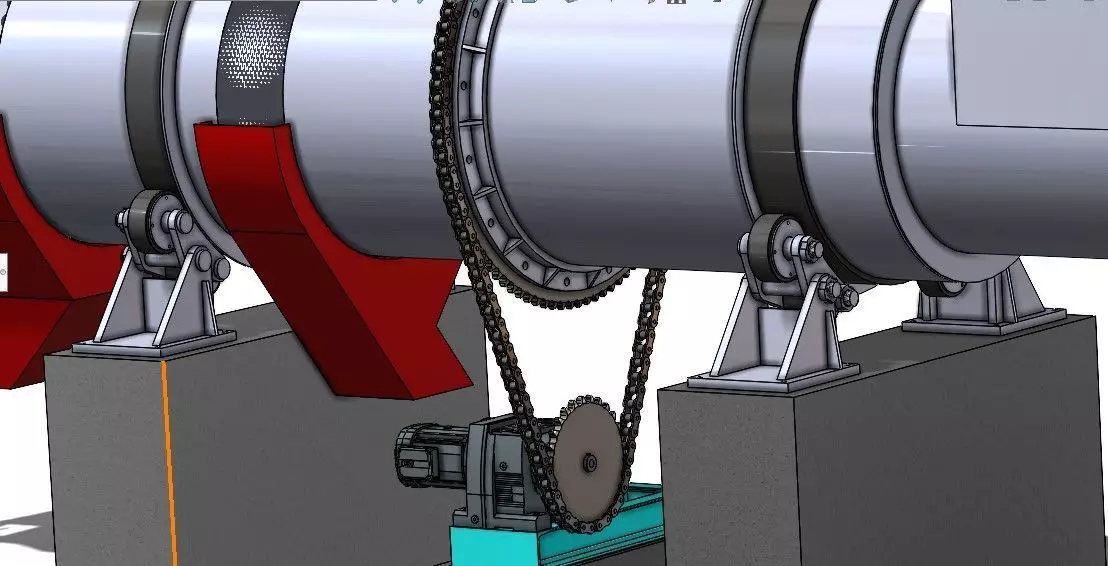

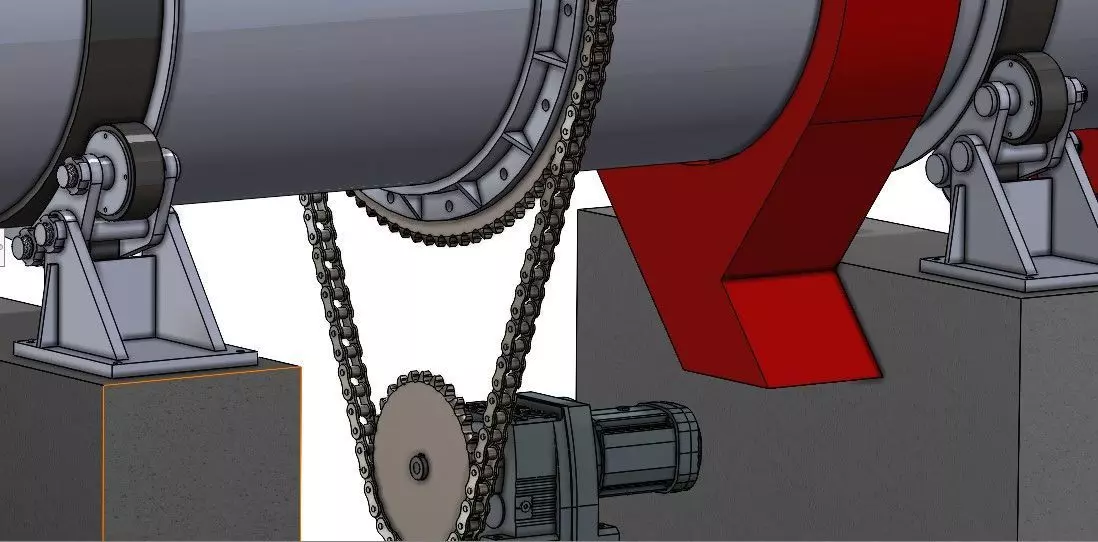

Drive system: An electric motor drives the rotation of the drum, typically via a chain and sprocket system. For example, one unit is specified with a 7.5 kW/10 hp motor and a duplex chain drive.

Accessories: Standard accessories often include a tray to collect any broken kernels and small stones, and a cross conveyor for transporting the cleaned nuts.

Dimensions: Dimensions vary with capacity. A model mentioned in a WordPress post has an approximate diameter of 1,000mm and a length of 5,000mm. A Scribd document details a drum that is 28 feet (8,532 mm) long with a 48.5-inch (1,230mm) diameter.