1/1

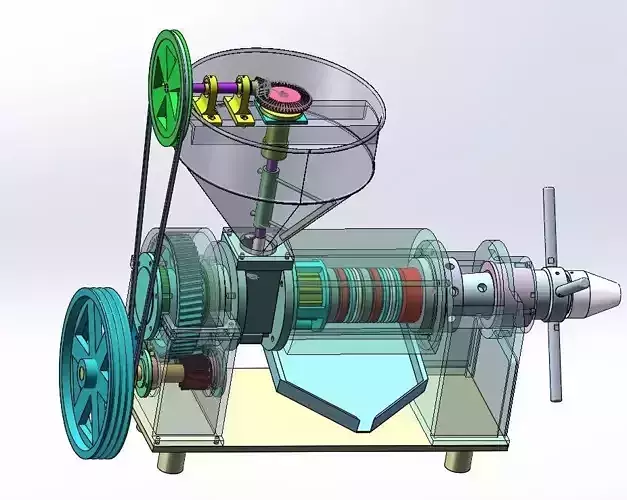

The overall structural design of a small screw oil press covers the oil pressing components, drive system, frame, oil outlet, and feed mechanism. This design includes the selection of motor power and speed, the design of belts and pulleys, and the design of the gears, shafts, bearings, keys, and couplings in the gearbox, along with the associated calculations and verifications. Furthermore, the design of the screw and cage is discussed. These are the main working components of the oil press. The screw consists of a screw shaft, three sections, a discharge adjustment head, a lock nut, and an adjusting bolt. The screw design must ensure a tight fit between the sections and be secured with a lock nut to prevent discharge debris from entering the screw hole and hindering removal. The cage cavity consists of two sections: the front section, which comprises the pressing rod, and the rear section, which comprises the pressing ring. The gearbox design must consider fit, transmission ratio, and torque to meet operational requirements. This machine is suitable for extracting vegetable oils such as rapeseed, peanuts, sesame, cottonseed, soybeans, coconut, tea seeds, and sunflower seeds. (When extracting vegetable oils such as rice bran, the user can replace the screw as needed.)

REVIEWS & COMMENTS

accuracy, and usability.