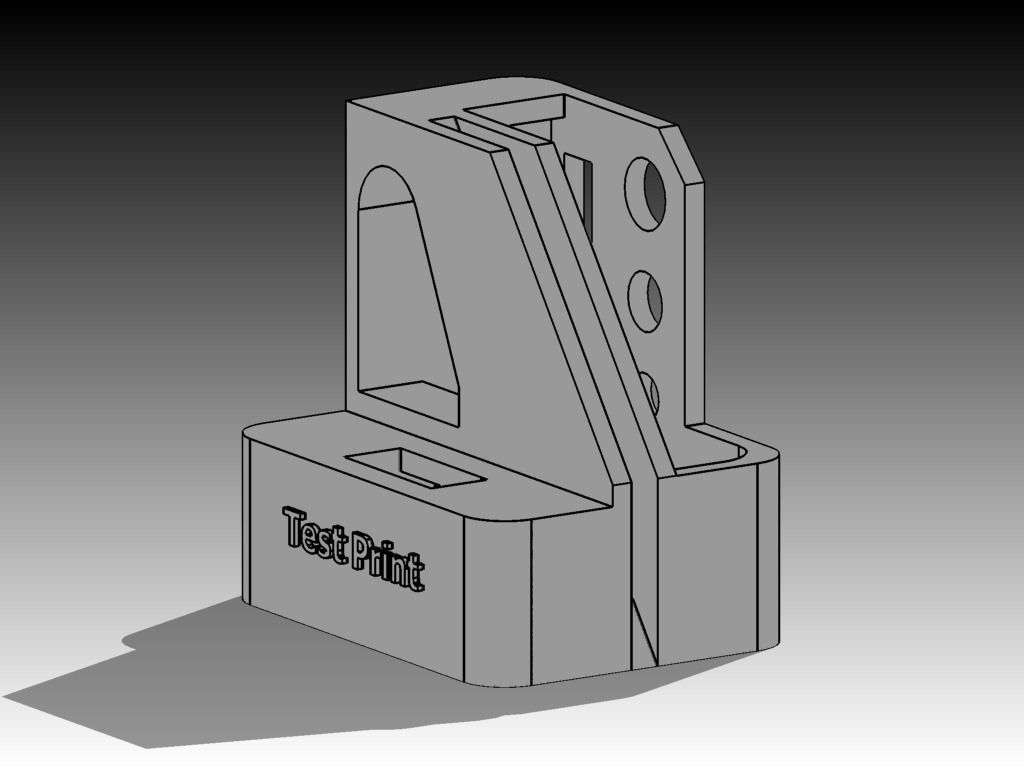

3D Printer Calibration Test Part Free 3D print model

Submission for the "Microsoft 3D Builder Test Model Challenge"

I tried to add as many of the options as I could from the Judging section, while adding in some interesting functionality and trying to keep the build time under 1 hour. This is my result.

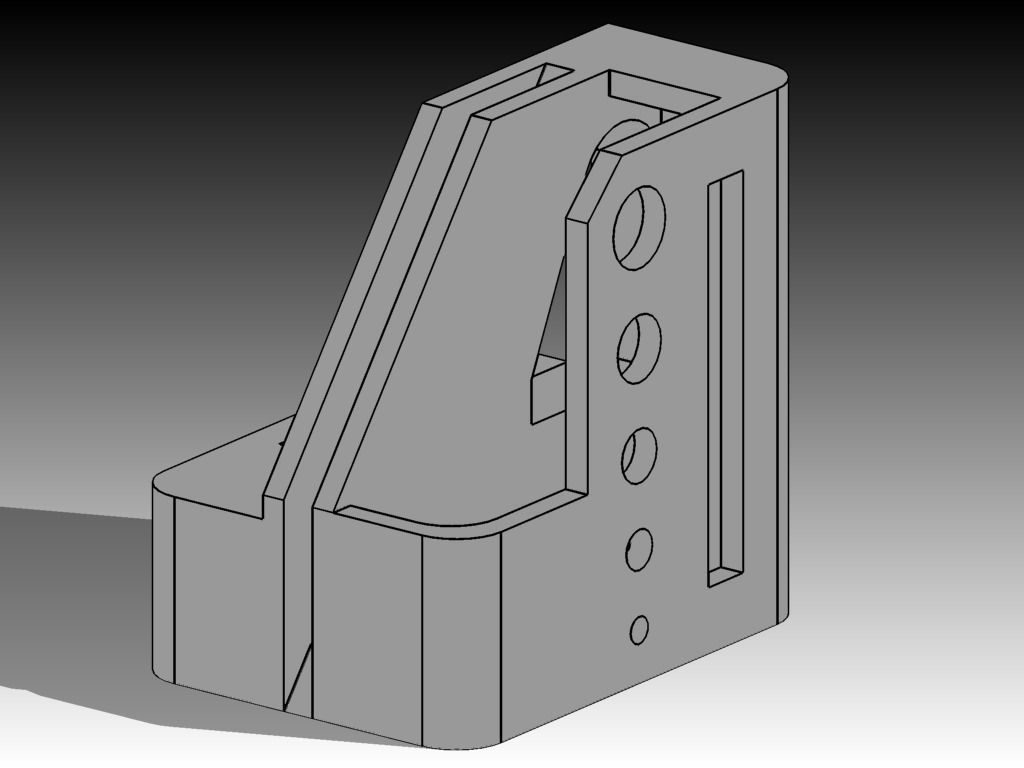

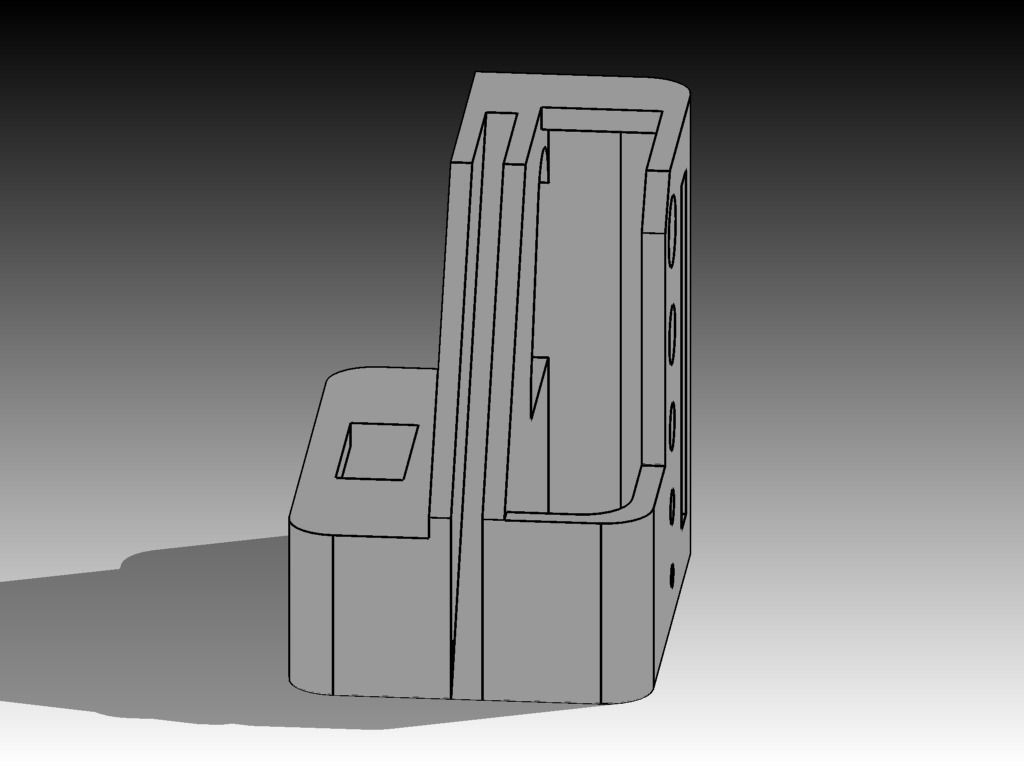

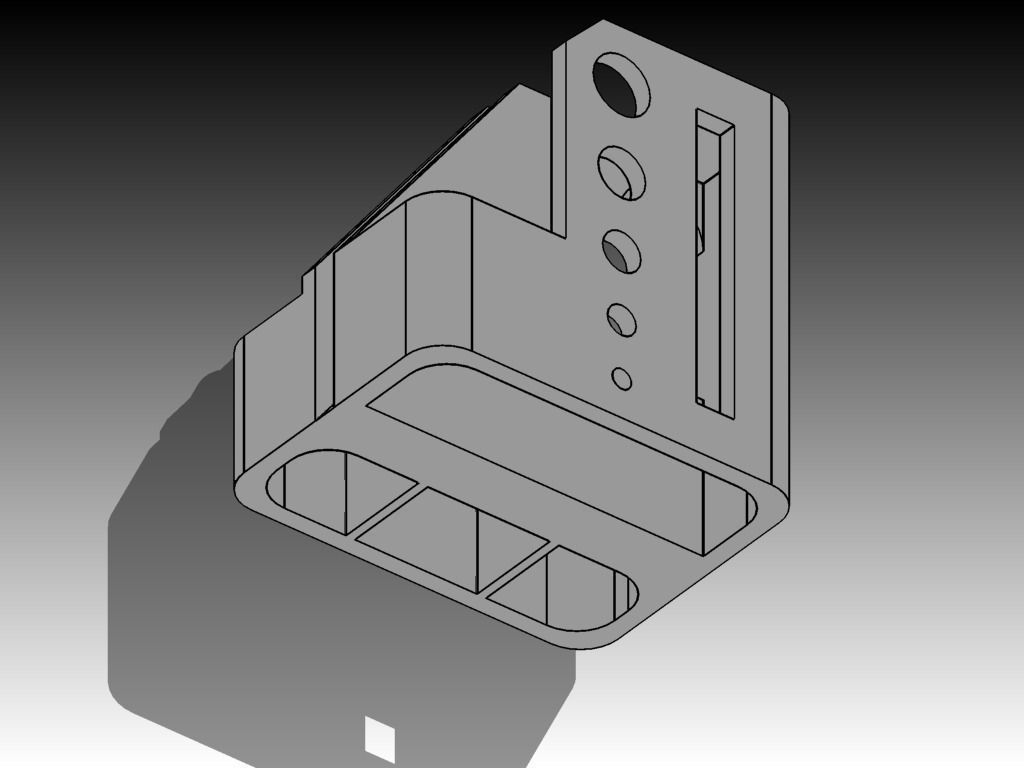

In short, I designed ramps, horizontal holes, flat planar surfases, horizontal/vertical internal/external embossing of text, curves, straight sections, walls, slots and bridging.

Print Volume: ~12.2cm^3Print Settings: 0.2 layer height; 20% Infill; 50mm/s Print SpeedPrint Time: ~1hrWeight ~12g

The added functionality:1) There is a 13mm x 5.5mm slot for storing a USB stick2) There is a ramp with walls, that you can roll a penny down. Most average consumers probably don't have calipers or other measuring equipment, so a good test for quality is to roll a penny down the ramp. The ramp design is 2.5mm, where a penny is around 1.5mm. The walls are 10mm high, about 1/2 the height of a penny. It should be a good way to measure some of the tolerances for general users.

I uploaded the model into CURA to give a general idea of build time, but I won't have access to a printer for showing pictures of the design in action until Monday afternoon, after the submissions closes. But I still intend to print it out and upload the functionality.