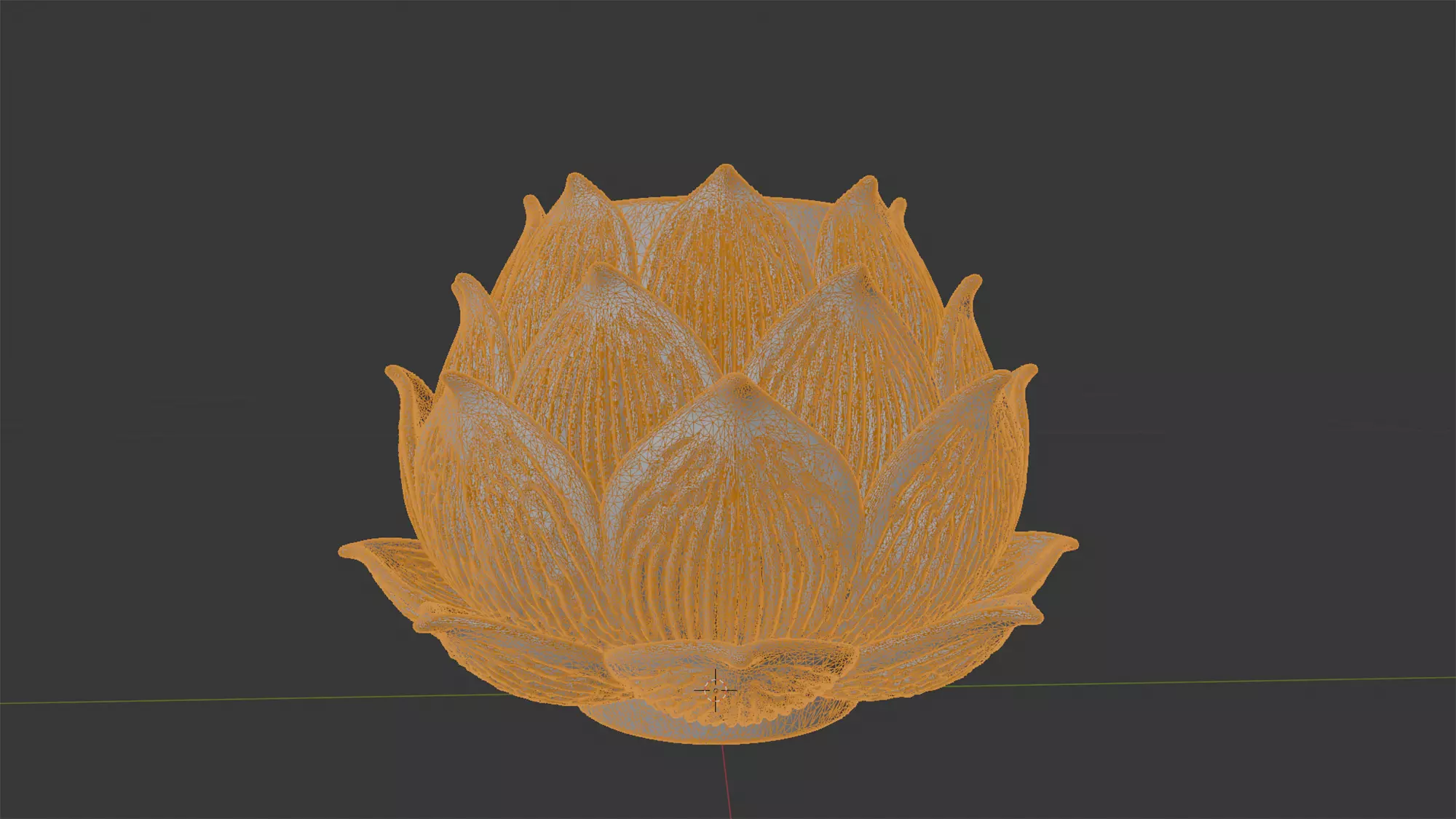

Lotus Flower Lamp Base 3D Print Model 3D print model

The Lotus Flower Lamp Base 3D print model brings elegance and serenity to any interior space, inspired by the timeless symbolism of the lotus blossom. Designed as both a functional lamp base and an artistic decorative piece, this model captures the beauty of unfolding petals while providing a stylish foundation for lighting projects. Ideal for modern homes, meditation spaces, or creative studios, it adds a harmonious and calming atmosphere to any setting.

Optimized for reliable 3D printing, the lamp base features watertight geometry, balanced wall thickness, and support-aware contours for easy production across FDM and resin printers. The design ensures stability and durability, while retaining the fine details of layered petals and smooth organic curves. With proper slicer settings, the Lotus Flower Lamp Base delivers professional-quality results suitable for everyday use or artistic display.

This versatile STL file allows makers to create unique lamp bases that can be customized with various filaments and finishes. Metallic tones offer a premium modern look, translucent materials provide a soft glowing effect, and natural colors emphasize the organic inspiration behind the design. Its adaptable size also makes it suitable for bedside lamps, desk lighting, or ambient decorative accents.

The Lotus Flower Lamp Base is also a thoughtful gift idea for designers, decorators, spiritual practitioners, or anyone who values symbolic art blended with functional design. It combines utility with elegance, making it a meaningful centerpiece for both personal and professional environments.

As a digital STL file, it is available for instant download immediately after purchase, allowing quick preparation and printing. Makers can scale the model to fit different lamp sizes and personalize finishes to match any décor style.

Blending functionality, artistry, and symbolic meaning, the Lotus Flower Lamp Base STL is a refined and versatile addition to any 3D print collection.

Please Note: This STL file may require pre-printing preparation, including support analysis, positioning adjustments, thickness verification, specific settings for your printer and filament, as well as other technical adjustments that may be necessary depending on your equipment and printing method.